- What is a “pipe in polyurethane foam”?

- Types of pipe insulation

- Comparison table for types of insulation for external installation

- Types of pipes in polyurethane foam

- How to choose polyurethane foam pipes

- How to determine the quality of a pipe in polyurethane foam

- Acceptance of pipes based on thermal insulation quality

- Why may the delivery length of pipes be slightly shorter than ordered?

- Can I use used pipes?

- How to lay PPU pipes

- Methods for laying pipes in polyurethane foam

- Who produces polyurethane foam pipes

- Condition of heating networks in St. Petersburg

What is a “pipe in polyurethane foam”?

Pipes in polyurethane foam are all pipes for hot water or heating.

They are also called “pre-insulated pipes”, “pipes in polyurethane foam insulation”, “pipes for heating networks”. These are ordinary steel pipes, which are additionally covered with a layer of insulation to reduce heat loss. PPU is an abbreviation that stands for “polyurethane foam”. Pipes without insulation are used only in water supply, gas pipelines or sewerage. The outside of the pipes in polyurethane foam is covered with a black (polyethylene) or gray (galvanized) sheath. And the insulation itself is yellow, with a thickness from 26mm to 90mm depending on the diameter of the steel pipe. Polyurethane foam – yellow. It is very similar to Macroflex foam, but this is not visible in the photographs, because black rubber-bitumen mastic is applied to the end of the insulation so that the foam does not get wet. The ends of the steel pipe stick out from under the insulation to prevent the foam from burning during welding, and they are painted with a primer to protect against corrosion.

At the factory

In the trench

In the context

Application of pipes in polyurethane foam insulation

produces steel pipes in polyurethane foam insulation in accordance with GOST 30732-2006 for heat supply systems, hot and cold water supply.

Steel pipes insulated with polyurethane foam (PPU) are intended for transporting coolants to facilities; they are used in the construction of new and replacement of old heating networks and hot water supply systems. A pipe with polyurethane foam insulation is a reliable way to reduce heat loss from pipelines.

The thermal insulation material of the pipes is polyurethane foam (PPU). Depending on the thickness of the insulation layer, the steel pipe in polyurethane foam insulation is made of two types:

- type 1 - intended for installation in central regions with a temperate climate.

- type 2 - designed to work in low temperature conditions (northern regions).

The thermal insulation layer is covered with a protective shell. According to the type of shell, pipes can be of two types:

- Pipe Art. PPU PE - with a polyethylene (PE) shell - are intended for heating mains, which are laid underground, while the polyethylene (PE) layer protects the steel pipe and polyurethane foam from groundwater.

- Pipe Art. PPU OTs - with a shell made of galvanized steel (OTs) - are intended for heating mains with an above-ground location.

The use of pipes with polyurethane foam insulation reduces the installation time of heating networks, and also reduces maintenance and repair costs:

- A layer of polyurethane foam insulation and a shell made of polyethylene or galvanized steel protects the steel pipe, does not require applying an anti-corrosion coating to the steel and ensures high heat retention. Pipes in PPU insulation have a service life of at least 25 years, which is several times longer than conventional pipes.

- Pipe insulation is carried out in a factory environment, which ensures high quality and reliability of the final product due to compliance with process parameters and hardware quality control methods.

- Due to the presence of the UEC system, pipe integrity monitoring during operation is carried out without excavation work. The UEC system allows you to control the moisture level of the thermal insulation layer and signals its increase if a section of the pipeline is damaged.

Types of pipe insulation

Main types of insulation for external installation:

- Pipes in polyurethane foam – in polyurethane foam insulation. Used for heating networks.

- Pipes in VUS insulation. VUS stands for “very enhanced.” Why "very"? Because those who invented this term have little imagination, and also because according to GOST there is a pipe with reinforced insulation (up to 2.5 mm insulation), and there is one with even more reinforced insulation (up to 3.5 mm). Used for water pipes, gas pipelines, and cases. VUS cases are used to protect underground communications. And even heating network pipes in polyurethane foam are sometimes laid under roads inside steel pipes in VUS insulation. VUS insulation – protects the steel pipe from corrosion and mechanical stress. Some network operating organizations allow the use of used pipes in VUS insulation for cases.

- Pipes in PPM insulation – polymer-mineral foam insulation. A relatively new development, very similar to polyurethane foam, but without a shell. Instead of a shell, it has a hard, thin outer layer of polyurethane foam mixed with sand, and is laid directly into the ground without additional protection. A small range of shaped parts due to the complexity of manufacturing (all products are filled with foam in specially made molds) creates limitations for the designer’s imagination and increases labor costs on site. What can be made in polyurethane foam, at the factory has to be done manually on site.

GOST 30732-2006: standard design PPU PE

PPU products are assembled using the “pipe-in-pipe” principle: liquid thermal insulation is injected into the gap between the steel base and the polyethylene shell. The components harden in the interpipe space, filling all gaps. To improve adhesion, steel pipes are pre-treated with a shot blasting unit and coated with protective compounds. Adhesion of polyurethane foam to the PE shell is ensured by a coronary electrical discharge.

Under the cover layer, signal lines of the UEC system are installed, made of bare copper grade MM (cross-section - 1.5 mm). 2 conductors are built into products with a diameter of up to 426 mm, and 3 conductors are built into pipes with a diameter of 530 mm or more. The indicators are located parallel to the axis of the base. Signal lines allow you to quickly detect and eliminate leaks on the heating main.

Comparison table for types of insulation for external installation

| PPU type | PU INSULATION | VUS ISOLATION | PPM INSULATION | MINVATA |

| Max. pipeline temperature | 140 degrees | 60 degrees | 150 degrees | more than 300 degrees |

| Waterproofing from the environment | Yes | Yes | Yes | No |

| Reducing heat loss | Yes | No | Yes | Yes |

| Minuses | The maximum pipe temperature is not suitable for steam pipe | Does not reduce heat loss, not suitable for hot water | Small range of shaped products due to the peculiarities of the production process | Impossibility to manufacture pipes and elements in a factory; installation is possible only on site |

| pros | Manufacturing features allow us to minimize labor costs during installation, a “turnkey heating main” and a wetting control system are delivered to the site | Low cost of insulation | Absent, compared to polyurethane foam | Suitable for high temperature pipelines, steam pipelines |

| PU INSULATION | |

| Max. pipeline temperature | 140 degrees |

| Waterproofing from the environment | Yes |

| Waterproofing from the environment | Yes |

| Waterproofing from the environment | Yes |

| Waterproofing from the environment | Yes |

| PU INSULATION | |

| Max. pipeline temperature | 140 degrees |

| Waterproofing from the environment | Yes |

| Waterproofing from the environment | Yes |

| Waterproofing from the environment | Yes |

| Waterproofing from the environment | Yes |

| PU INSULATION | |

| Max. pipeline temperature | 140 degrees |

| Waterproofing from the environment | Yes |

| Waterproofing from the environment | Yes |

| Waterproofing from the environment | Yes |

| Waterproofing from the environment | Yes |

| PU INSULATION | |

| Max. pipeline temperature | 140 degrees |

| Waterproofing from the environment | Yes |

| Waterproofing from the environment | Yes |

| Waterproofing from the environment | Yes |

| Waterproofing from the environment | Yes |

Types of pipes in polyurethane foam

In a PPU pipe, the metal pipe itself and the polyurethane foam remain unchanged. The wall thickness of steel pipes in heating networks can be from 3mm to 12mm. Foam thickness from 26 mm to 90 mm. The thickness of the polyethylene shell (black) is from 3 mm to 40 mm, galvanized (gray) from 0.55 mm to 1 mm. It all depends on the diameter of the main steel pipe. PPU pipes differ in the type of protective coating. In addition, there is a separate version with a heating cable, which makes it possible to transport liquid in sub-zero ambient temperatures. Pipes in polyurethane foam have special markings, depending on the features:

- PE - polyethylene casing;

- OTs - casing made of galvanized steel;

- PE-U (or PE-B) - the polyethylene shell is reinforced with overhead bandage rings.

- SODC - (operational remote control system) is added after the designation of the casing, which means that two copper wires pass through the insulation (foam), which allow you to connect special devices (megaohmmeter and reflectometer) to the heating main, and find out whether there is water in the insulation and in which one the place got wet, so as not to dig up or open the entire heating main, but to fix the problem locally.

Types of pipes in polyurethane foam

Where are polyurethane foam pipes used?

They are widely used for the arrangement of heating systems for centralized and local heat supply, as well as cold and hot water supply systems. The demand is due to improved performance characteristics. Compared to other similar products, they have the following advantages:

- High thermal insulation properties. The thermal conductivity of polyurethane foam used as insulation does not exceed 0.030 W/m*K. This is the lowest figure among all materials that can be used for pipeline insulation. Therefore, heat loss is reduced to 1-2%. For comparison, in old pipelines heat loss reaches 25-30%.

NB: In old heating networks, reinforced foam concrete was used as insulation, and roofing felt was used as a gyroprotective coating. A metal mesh was laid on top and plastered.

- Durability. The insulation layer and outer casing eliminate the impact of environmental factors on the metal. That is, they provide anti-corrosion protection and protection against mechanical damage, due to which the service life of the products reaches 30 years or more;

NB: The shell of the pipe in polyurethane foam, when laid externally (on the ground), protects the foam from rain, snow, hail, and when laid underground, from groundwater and stray currents, which, if they reach the body of the steel pipe, will cause electrocorrosion. The thickness of the polyethylene shell is many times thicker than galvanized shell, because it also takes on the pressure of the soil. In addition to all the listed misfortunes, the pipe in the ground does not lie motionless, but constantly moves due to the linear thermal expansion of the metal, and over time it wriggles like a snake. The polyethylene shell protects the thermal insulation layer from all of the above.

- Remote diagnostics. The presence of a UEC system makes it possible to detect defects in a timely manner and, thereby, prevent the occurrence of serious emergency situations;

NB: SODK is a system for operational remote control. It consists of two copper wires that are located in the middle of the heat-insulating layer of the pipe in the polyurethane foam. If water gets into the insulation, the contact between the wire and the body of the steel pipe closes. When you connect a megohmmeter, the device will show a short circuit and it will become clear that there is water insulation in this section of the pipeline. In order to more accurately determine the location of wetting, a pulse reflectometer is used. This device measures the wave resistance of polyurethane foam. Using it, you can create a reflectogram of a heating network with a length of more than a thousand meters and determine the location of the defect with an accuracy of less than one meter.

The future of heating networks is as follows: a stationary reflectometer is connected to each heating network, which, using a GPS modem, transmits a signal online to the operator’s console. As soon as the insulation gets wet in any area, the operator’s control light comes on, and he immediately sends the repair team to the track, telling them the specific area of the wetness.

In Russia in 2021, such systems have already begun to be tested and gradually implemented.

- Quick installation. Channelless installation allows you to reduce the volume of excavation work and do without installing drainage networks. These factors not only reduce installation time, but also reduce the cost of laying the pipeline.

Steel pipes in PPU insulation and fittings in PPU insulation

Steel pipes in polyurethane foam insulation are a structure that consists of several elements:

- steel pipe,

- outer protective shell made of polyethylene or galvanized spiral-lock steel,

- insulating layer made of polyurethane foam,

- copper signal wire,

- centering supports.

The insulation process is as follows: the space between the pipe and the outer protective shell is filled with polyurethane foam. Due to the low adhesive properties of the material, hardened polyurethane foam almost does not absorb moisture, which allows the pipe in PPU insulation to function quite successfully in conditions with high humidity.

Polyurethane foam has another useful property - low flammability.

It does not burn on its own in the absence of an open flame, does not smolder and does not spread flame. The main operating parameters of pre-insulated PPU steel pipes: operating pressure corresponds to the characteristics of a steel pipe of steel grade “steel 20” and should not exceed 1.6 MPa in accordance with the fourth class of pipelines.

Working fluid temperature - no more than +140 °C (short-term up to +150 °C). The service life of pipes in a thermal shell made of polyurethane foam is from 25 to 30 years, which means that the repair of such pipes requires several times less frequent repairs compared to traditional types of pipelines, which leads to improved economic indicators characterizing operating costs.

Deterioration of heating networks. PPU pipe with UEC - “Green technology”

Heat supply is a complex system for providing buildings and structures with heat, consisting of two interrelated, but different in technology processes. The first includes preparing the coolant, bringing it to the required temperature parameters and supplying it to the heating network, and the second involves transporting this coolant through the heating network to the end consumer. The process of coolant production is clear to any layman. It looks quite “transparent”. We take the initial cost of the coolant, add the costs of heating, heating maintenance, and now we have an approximate figure. The transportation process is not so simple. What is counted here and how? How much useful energy will be lost during transportation? Real specialists should understand this. For us, ordinary investors and heat consumers, the only indisputable fact should be clear: the less heat we lose when the coolant moves through the pipe, the warmer the battery will be and the hotter the water that flows from the tap. As the distance of transportation of heated coolant through a pipeline increases, the feasibility of investing in preserving its original thermal parameters increases and, as a bonus, reduces the cost of maintaining the entire heating network. The total length of the heating networks of the Russian Federation, at the beginning of the 2000s, was about 185,000 kilometers, taking into account the direct and reverse laying of the pipeline. No, this does not mean that the coolant is constantly transported over such long distances, but it has to be transported over distances of up to tens of kilometers, from the central heating point to the heat consumption facility, quite regularly. Unfortunately, calling this process “Green” or energy-saving will not work in 80% of all such cases. The pipelines of heating networks were built and launched back in the days of the USSR and their service life has already passed the mark of thirty and sometimes forty years. Steel pipes laid in concrete channels, insulated with mineral wool, which has extremely low thermal insulation properties even when slightly wet, with no anti-corrosion insulation, are worn out by an average of 70-80%, are in some places unsafe and require immediate replacement. At best, these routes effectively heat the air or soil surrounding them, and at worst, they simply flow, cause interruptions in the heat supply to the consumer and require constant local repairs.

How to keep warm? Progress does not stand still and colossal heat losses are being replaced by new, efficient energy-saving technologies. Polyurethane foam pipes and components of heating mains in polyurethane foam insulation are the technical basis of a new comprehensive project to increase the energy efficiency of heating networks of the Russian Federation. Heating networks of almost all Russian cities need total modernization; in some regions, wear reaches 85-90%!!! Unfortunately, at the moment, global reconstruction is financed through tariffs, or rather through utility fees, which prevents the implementation of the necessary capital reforms due to a lack of funds or their untimely receipt. How to save money and keep warm? Eternal question! There has always been, is and will be a careless contractor who is puzzled by the problem: “How to extract additional benefit from our investments?” It is unlikely that he will be able to do this with the length of the pipeline, but with the quality... So how will we defend ourselves? Steel pipe in PPU insulation (insulation made of polyurethane foam) is a modern high-tech product designed to improve the reliability and energy efficiency of heating networks. PPU pipe is a technology that will not allow contractors to save on product quality, since it has mandatory diagnostic elements. Built-in diagnostic tools, combined with a control procedure when accepting products ready for installation at the site, make it possible to eliminate future unforeseen expenses during the warranty period of the route. In accordance with the innovative projects of Russian heat supply organizations with the support of the Russian government, the warranty period for a newly commissioned heating main designed on the basis of a polyurethane foam pipe should be increased to 10 years, the first five of which should be supported by a guarantee from the manufacturer of pre-insulated products. SKTK LLC offers you high-quality polyurethane foam pipes (Moscow), whose parameters and performance characteristics exceed the standards of GOST 30732-2006, which will always allow you to achieve a guaranteed effect from a steel pipeline in polyurethane foam insulation, both in terms of service life and minimizing heat loss. . SKTK always offers high quality polyurethane foam pipes, fair prices and favorable terms of cooperation.

How to choose polyurethane foam pipes

The choice of one or another variety depends on the operating conditions. For example, products in a polyethylene sheath (PE) are intended for the installation of an underground pipeline. Where the pipeline runs under a railway, highway, foundation, or in places of increased soil mobility, it is necessary to use pipes with reinforced insulation (PE-U). Laying of above-ground pipelines is carried out using pipes with a galvanized steel casing (OC). Such a shell not only provides protection from climatic factors and mechanical stress, but also gives the main system additional rigidity.

Equally important is the choice of diameter. In main heating mains and water supply systems, pipes with a diameter of 525 to 1020 mm are used. For urban distribution networks, the diameter should not exceed 525 mm. When constructing an autonomous heating and water supply system in private households, a diameter of 50-100 mm is sufficient.

Note! PU foam pipes can be used in heating networks where the temperature of the working fluid will not be higher than 140 degrees and the pressure will not be 16 bar. A short-term temperature jump of 10 degrees is allowed. At the same time, contrary to common sense and the laws of physics, GOST 30732-2006 for pipes and shaped elements in polyurethane foam does not establish a relationship between diameter and pressure, therefore any pipes in polyurethane foam can be used in the specified pressure range.

Insulation for hot steam pipelines (steam pipelines) up to +220 degrees C

This section provides materials for insulating hot pipelines up to +220 degrees C

A detailed video on how to insulate a steam pipeline can be viewed here:

How to design and calculate the insulation of a hot pipe and steam pipeline with temperatures up to +220 degrees C?

A standard pipe, if it does not relate to the oil and gas sector or the nuclear industry, is subject to design standards according to SP 61.13330.2012 “Thermal insulation of equipment and pipelines”. The calculation of the insulation thickness is based on this regulatory document.

To ensure insulation of a steam pipeline, three conditions must be met:

- The thickness of the thermal insulation of the steam pipeline must be calculated according to the heat loss standards SP 61.13330.2012 (the permissible heat loss standards are given within SP 61.13330.2012)

- The thickness of the steam line insulation must ensure a safe temperature on the insulation surface so that personnel do not receive injuries or burns in case of accidental contact.

- The thickness of the steam line insulation should provide protection from condensation of the transported steam - this will increase protection against water hammer. And in some cases, when, for example, vapors of sulfuric or hydrochloric acid are transported, the appearance of condensation can destroy the equipment and the entire installation.

We can calculate the thicknesses for you and provide a ready-made calculation:

According to SP 61.13330.2012, the design of thermal insulation must include:

- Thermal insulation layer (materials for it are given in this section)

- Covering protective layer.

- Fastening elements (support rings, clamps, support brackets, wire, hangers)

The pipe must be primed to protect against corrosion.

Why is the category of steam pipelines up to +200 degrees C allocated separately? This is the temperature at which simple basalt cylinders made of stone wool can operate without additional supporting elements - Support clamps or support brackets - and will be self-supporting! For a given temperature, it is quite simple to select a solution that can be installed by the customer himself.

installation instructions upon request - There are Video instructions and a paper version.

Payback of steam pipeline insulation: IMPORTANT!

As practice shows, insulating steam pipelines at a temperature of 150-200 degrees has a very quick payback - about 1-2 months, depending on the temperature. At the same time, losses from a poorly insulated steam pipeline are always very large. This happens because conventional heating pipes operate at 95 degrees in the pipe and an average of 5 degrees outside. — temperature difference is 90 degrees.

The steam line operates at 150 degrees or more in the pipe and +5-+20 outside. — temperature difference is 135-120 degrees. Thus, losses will be very large both in winter and summer.

Let's give an example of calculating heat losses from different hot water and steam pipelines (we can provide calculations for your project individually)

- Horizontal - temperature

- vertical - diameter of the steam pipeline

- at the intersection - heat consumption W per 1m.

- Region — Moscow

- Operates during the heating season

- For calculations according to SP 131.13330.2018 Building climatology, we take the street temperature -2 degrees C

- Wind speed: 4 (medium building)

| Coolant temperature, degrees C | ||||||||||||||||||

| losses W/m. | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 |

| d=89mm | 273 | 325 | 378 | 430 | 483 | 535 | 588 | 640 | 693 | 746 | 798 | 851 | 903 | 956 | 1008 | 1061 | 1113 | 1166 |

| d=108mm | 331 | 395 | 459 | 522 | 586 | 650 | 714 | 777 | 841 | 905 | 969 | 1032 | 1096 | 1160 | 1224 | 1287 | 1351 | 1415 |

| d=133mm | 408 | 486 | 565 | 643 | 722 | 800 | 879 | 957 | 1036 | 1114 | 1193 | 1271 | 1350 | 1429 | 1507 | 1586 | 1664 | 1743 |

| d=159mm | 488 | 581 | 675 | 769 | 863 | 957 | 1051 | 1145 | 1238 | 1332 | 1426 | 1520 | 1614 | 1708 | 1802 | 1896 | 1989 | 2083 |

| d=219mm | 672 | 801 | 930 | 1060 | 1189 | 1318 | 1447 | 1577 | 1706 | 1835 | 1965 | 2094 | 2223 | 2352 | 2482 | 2611 | 2740 | 2870 |

And this is from 1 meter! Imagine that every meter of your steam pipeline incurs losses like a home heater of 1.5-2.5 kW - every meter of pipe!

Currently, we have already implemented many investment projects to replace insulation and can provide you with all the necessary calculations to make a decision on replacing insulation

Here's an example of a calculation:

Steam line 150 degrees, D=89mm, works all year round as a process line.

We have already encountered many objects where such a pipe may not be insulated at all.

Let's carry out the calculation: according to the standards of SP 61.13330.2012, the insulation thickness should be 60mm . to ensure a heat loss rate of 54 W/m.

At the same time, a bare pipe under such conditions produces 761 W/m.

If an enterprise has its own gas boiler, the cost of 1 Gcal of thermal energy will be about 1100 rubles per 1 Gcal. (and municipal heating networks give a price tag of about 2200 rubles/1 Gcal.)

The cost of 1 meter of insulation is an average solution with a coating for the street Hotpipe Cylinders Outside - 874 rubles (this is the price)

Installation can be done either by the company’s employees or by hiring a contractor.

The payback period for insulation will be 54 days!

For 100 meters the cost of insulation will be 87,400 rubles.

And the savings in heat losses will be per year: 586,600 rubles! (and this is already minus the cost of purchasing insulation) And we get approximately the same results on ANY steam pipeline!

If you are powered by city heating networks, the effect will be 2 times better because the cost of 1 Gcal is 2 times more expensive!

Below are the calculations:

And here is a graph of the dependence of heat losses on insulation thickness: What is the rate of heat losses according to SP 61.13330.2012. This is the optimal value given in the SP. It is optimal because the dependence of heat losses on insulation thickness is asymptotic in nature. that is, it makes sense to insulate up to a certain thickness. a Above the norm, each next centimeter of insulation no longer gives such an effect (see picture below) - and the return on investment for each next centimeter of insulation is getting worse.

That is why a competent calculation of thickness is done according to SP 61.13330.2012.

For the materials that we supply, we can make calculations for you free of charge - so that you can estimate how much you can save and decide whether it is worth spending money on insulation - call: +7-900-966-07-77

You can watch the review and example of good insulation in our video and also on our YouTube channel:

How to determine the quality of a pipe in polyurethane foam

The quality of the pipe in polyurethane foam is determined according to several GOSTs, GOST 30732-2006 (for insulation) and GOST for the steel pipe itself.

First of all, it is necessary to determine the compliance of the steel pipe with the manufacturer’s certificate. Pipes above diameter 159 must be marked. In the case of pipes of diameter 159 and below, in the absence of markings, a “tag” from the pipe bundle, or “label,” must be attached to the set of documentation. Sample:

Tag sample

It is imperative to check the data from the “tag” and the quality certificate, and also make sure that the length of the pipe whip corresponds to the length stated in the quality certificate.

Since quality acceptance can occur when insulation has already been applied to the pipes in polyurethane foam and the marking can be hidden under it, it is necessary to carry out inspection before applying the insulation, come to inspect the steel pipe, and if this is not possible, for example, when supplied from another region , ask in advance to send a certificate, tag and photographs of the steel pipe with markings.

Also, steel pipes used in heating networks should not be older than a year from the date of manufacture. GOST 30732-2006 does not have this requirement, but this is an unspoken rule in heating networks, since metal warehouses store pipes in the open air, and they cannot lie like that for more than a year - they have time to rust badly.

HDPE pipe with polyurethane foam insulation – what is it?

Pipes in polyurethane foam insulation (PPU insulation) are a structure made according to the “pipe-in-pipe” principle, i.e. consists of two pipes: the inner working (bearing) and the outer protective (shell), the gap between which is filled with polyurethane foam.

In a nutshell, a HDPE pipe in polyurethane foam is a polyethylene HDPE pipe that has additional protection in the form of a heat-insulating layer, the functions of which are performed by polyurethane foam. A protective waterproofing shell made of polyethylene or galvanized steel extends the trouble-free service life and expands the scope of application.

The insulated pipe consists of three layers:

- main (working) pipe . Pipes used: PE 100, PEX-a and PERT.

- thermal insulation material – polyurethane foam insulation . Thermal insulation is provided by spraying polyurethane foam. This innovative material differs from traditional insulators (for example, glass wool) by its low thermal conductivity, hygroscopicity, and durability. Thermal insulation material must comply with GOST 30732-2006. In this case, an important requirement must be met - good adhesion to the material of the working pipe and shell. Permissible displacement (axial shift) – 0.14 MPa (t=23°C);

- PPU insulation shell . As such, black low-pressure polyethylene is used (regulated by GOST 18599-2001) or galvanized (regulated by GOST 52246-2004) - a steel protective shell (made of galvanized strip). The type of shell is noted when marking the product;

Acceptance of pipes based on thermal insulation quality

GOST 30732-2006 contains a huge number of parameters that need to be controlled, including, the manufacturer of polyurethane foam is required to attach an acceptance test report for each batch of products supplied to them, but the main attention should be paid to the following:

Thermal insulation end: The foam must be dense. If you can stick a knife into it more than 40 - 50 mm without effort, you should think about more accurate methods of controlling this batch or demand to provide an acceptance test report.

At the end, where the thermal insulation adjoins the steel pipe and the shell, there should be no gaps or cracks, otherwise water will get there and the insulation will be damaged.

The end must be covered with waterproofing material, and the free end of the pipe must be painted with a primer. The free end of the steel pipe must have a chamfer at an angle of 30 degrees. The waterproof shell should not have deep scratches or cracks.

If, during a visual inspection, the pipe does not perfectly coincide circumferentially with the shell, it is necessary to check the deviation of the axial lines with a tape measure. Usually this problem is not immediately visible, but when cutting the pipe on site.

Any product in PPU must have a marking indicating:

- product designation;

- trademark or name of the manufacturer;

- batch number;

- date of manufacture.

Marking on products in polyurethane foam

If the pipe in polyurethane foam is made with SODK, it is necessary to check the conductors for breaks and short circuits using a megohmmeter. After checking, it is necessary to make an appropriate entry in the work log.

Not all aspects of pipe quality control in polyurethane foam are listed here, but only the main ones; you can fully accept polyurethane foam insulation only after fully familiarizing yourself with GOST 30732-2006.

Pipe length according to GOST 30732-2006

The dimensions of PPU PE pipes are standardized by GOST 30732-2006: with a diameter of up to 219 mm, the length is 8-12 meters, with a diameter of 273 mm, the minimum size increases to 10 m. The maximum length of uninsulated ends is limited to 150 mm for shell diameters up to 315 mm inclusive and 210 mm - for shell diameters from 400 mm. A minus maximum deviation of 20 mm is allowed.

The outer polyethylene pipe must completely cover the thermal insulation, plus a length tolerance of 50 mm. If necessary, a waterproofing coating is applied to the ends of the polyurethane foam.

Why may the delivery length of pipes be slightly shorter or longer than ordered?

When issuing an invoice, the theoretical length of the pipe is taken. At metal warehouses, pipes are stored in bundles, and it is not possible to keep track of which pipe is on top and which is on the bottom. After paying the invoice, at the time of loading the steel pipe at the metal depot, the customer is informed how many strands of pipe and what length were loaded for it and clarifies: should the footage be rounded down or up?

When ordering a seamless pipe, everything is even more complicated; according to GOST 8732-78 and GOST 8734-78 it is unmeasured, that is, each rod has an individual length. GOST allows a difference from 4m to 12m. In reality, the difference in a particular batch is smaller, for example, from 9m to 11m. In some cases, when ordering a standard size, the insulation plant may cut it to size and keep the rest of the pipe, but such cases are always agreed upon in advance (before paying the invoice).

Can I use used pipes?

In laying heating networks, used pipes are practically not used. Only as VUS cases, when new pipes in polyurethane foam are laid inside a used large-diameter pipe. In this case, the used pipe only performs the function of additional protection and the requirements for it are, accordingly, much lower.

The laying of heating networks is strictly regulated by state standards; it is almost impossible to use used pipes without damage. The pipe through which water flowed, even for a relatively short time, is no longer suitable for reuse due to corrosion. The pipes through which oil flowed become so saturated with it that, again, they become unsuitable for heating networks where water flows through the pipes. Only gas pipes after sandblasting look almost like new and are generally similar in their characteristics to new pipes that have been lying in the open air at a metal warehouse for a couple of years. But in any case, it is more profitable for pipe factories to take used pipes for scrap and cast new pipes than to try to sell used products.

The polyurethane foam shell after the cycle “production – delivery – laying – operation – digging – delivery back” becomes unusable. It would never occur to anyone to reuse such pipes in a real heating network, since the insignificant savings pale in comparison to the cost of operation that increases tenfold when the insulation begins to deteriorate and become wet.

How to lay PPU pipes

Laying in a trench is carried out on a flat sand cushion with a thickness of at least 100 mm. Pipes and other pipeline elements are first checked for defects. To eliminate the risk of damage to the containment, the pipes must be lowered smoothly, without hitting the bottom and walls of the trench. At the next stage, the joints are welded and the cables of the UEC system are connected. After checking the quality of the weld with a flaw detector, the joints are sealed using heat-shrinkable sleeves.

Important information! Work on insulating joints should be carried out at an air temperature of at least -15 degrees.

In the case of laying a pipeline through a foundation or wall, seals and wall entry collars are used. The standard length of the oil seal is 450mm, but any length can be manufactured. After their installation, concreting is carried out.

When laying a channel, a drainage pipe must be laid next to the heating main, which drains water from the heating network, and collects it in a reinforced concrete well, and a flap valve according to the A-397-80 series is installed at the outlet of the drainage pipe.

If underground installation is not possible (for example, in a wetland), the above-ground method is used. It involves installing pipes on special supports. The technology for connecting joints remains the same.

Pipes are delivered by scow. A scow is a machine 12m or 13.6m long. The machine must be capable of top loading; the pipes are loaded with a crane.

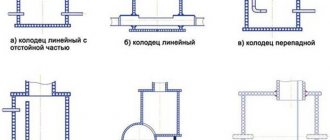

Methods for laying pipes in polyurethane foam

Ductless pipe laying

Channel pipe laying

Initially, all heating networks were laid without ducts, but then wise people came up with the idea of additionally insulating the pipe in polyurethane foam with reinforced concrete channels (trays). The channels perform the function of additional waterproofing, and also take on the load of the soil in places where heating networks pass under roads, where, in addition to the soil, passing traffic puts pressure on the pipe. For channelless installation in such places, VUS insulated cases are used.

The main problem lies in the method of compensating for the linear expansion of the steel pipe. As mentioned above, the pipe in the ground does not lie motionless, but is constantly moving and bending. When laying without channels, compensation for pipeline expansions is carried out naturally; the route is not laid in a straight line, but makes many turning angles, and it, like an “accordion,” compensates for itself. Soft mats are placed under the turning angles so that the bends have somewhere to “play”. In the case of channelless installation, pipes are laid almost in a straight line, which is definitely a plus, because it is not always possible to design many turns, for example, neighboring underground communications may interfere.

To compensate for linear temperature expansion during channel installation, SKU - bellows compensators are used

Inside the SKU in the PPU there is a KSO - an axial bellows compensator, which is an “accordion” made of stainless steel, which has the ability to compensate for compression and decompression. This device is placed between two fixed supports, and the pipes are mounted on sliding supports (they are called SPOk - Sliding Channel Supports), on concrete pads installed on the bottom of the channel. The bottom of the channel in the places where the pillows are installed is coated with technical petroleum jelly.

Bellows compensator

What do we end up with? Hot water is supplied to the heating main, the pipe expands, “rides” on lubricated cushions along the line of the route, the “accordion” contracts and compensates for the expansion, the pipe does not bend. As the temperature drops, the pipe contracts, the “accordion” expands, and the pipe on the cushions “rides” back along the axis of the route.

Pipe design in polyurethane foam insulation

|

The three-layer system is based on a high-quality steel pipe through which the coolant moves. The material for the production of internal steel pipes can be steel pipes made of steel grades that comply with GOST standards 550, 8731, 8733, 10705, 10704, 20295.

Steel pipe diameters, mm: 57, 76, 89, 108, 159, 219, 273, 325, 426, 530, 630, 720, 820, 920, 1020. The standard length of manufactured pipes is 10-12 m.

Condition of heating networks in St. Petersburg

The heating network system of St. Petersburg is one of the most extensive in Russia. The total length of the pipelines exceeds 4770 km, and the diameter of the pipes varies from 50 to 1400 mm. Heating mains are mostly laid underground. Unfortunately, a significant part of them are in emergency or pre-emergency condition, since these are still Soviet pipes 30 years old. Therefore, the installation of new energy-efficient heating networks is more important than ever for the city.

The information in the article is current as of 06/01/2021.