The drainage system on the site is a very important link in draining the site and preventing the destruction of the foundation by excess moisture.

This type of sewage system can be equipped independently, that is, with your own hands.

The main thing is to familiarize yourself with the basic principle of operation of the system and select the appropriate material.

To install the device, drainage pipes of the appropriate diameter are used.

Drainage system on site

How a drainage pipe works and what its purpose is is the main question for most summer residents and people living in the private sector.

First of all, you need to understand that thanks to drainage pipes, the territory is drained by collecting and draining ground and atmospheric waters into the collector.

Of course, before starting installation, it is necessary to select materials, draw a diagram of the future highway and calculate all the parameters.

Drainage pipes are classified as follows:

- perforated pipes;

Perforated pipes

- pipes with filter wrap;

Pipes with filter wrap

- corrugated pipes.

Drainage corrugated pipes

What is a drain pipe?

An extensive network of interconnected pipes, called drains, performs a very important function. It receives and discharges water, thereby draining the area. It is installed around the site or house to absorb moisture and remove it far beyond the boundaries of the home. In areas where groundwater lies close to the surface of the earth, this is a prerequisite. Even at the stage of drawing up the project, it is planned to lay a drainage pipe in accordance with the individual characteristics of the area.

This allows you to prevent subsidence and destruction of the foundation, flooding of the cellar and basement, icing and accumulation of water on paths in the garden, the formation of mold and mildew - the causes of allergic reactions and respiratory diseases. To carry out all these activities, a variety of drainage pipes with their own characteristics and properties are used.

Installation of drainage pipes

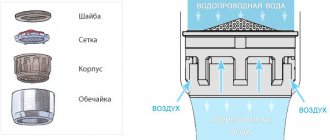

A drainage system is a network of branched pipes connected to each other by fittings and other elements. It includes trenches, wells, storm drainage, which all work together to achieve results. The drainage pipe is equipped with holes. In this case, perforation can be either complete or partial. In the first case, the entire surface of the product is covered with holes located at a certain distance from each other. In the second, the cavities are made in three rows on top of the pipe. To increase the throughput of the system, several pipes of different diameters are often laid in a trench.

How does a drain pipe work?

To understand how drains function, you need to understand the features of their installation:

- To ensure unhindered absorption of moisture, it is necessary to dig a trench and fill it with a layer of crushed stone. This is important for increasing network throughput.

- The principle of operation of the drainage pipe is to collect excess water, and for this it needs to be sloped towards the well. Then moisture from the soil will get inside and flow to a designated place.

- In this way, the area where the house is built is drained.

Features of the drainage system of the foundation and site

Any country resident sooner or later is puzzled by the question: how to drain water from the house?

FORUMHOUSE users are well aware that excess moisture has a negative impact on the foundation, causes flooding of basements and significantly complicates landscaping work. Therefore, drainage and groundwater drainage systems are the key to long and trouble-free operation of the cottage and site. We have already talked about what to do if the basement floods, and how to build a cellar when the groundwater level is high. It’s time to talk in detail about the features of the drainage system.

From our material you will learn:

- What is a drainage system and why is it needed?

- Why do you need to do geological surveys on the site?

- What types of drainage systems are there?

- How to protect the basement from flooding?

- How is the drainage system installed on the site?

- What mistakes are most often made when installing a drainage system?

What is a drainage system and why is it needed?

The drainage system protects the foundation from the negative effects of hydrostatic pressure of groundwater, which reduces the risk of its entry into the base. The drainage system also protects the area from flooding, waterlogging or waterlogging. If you neglect the design of the drainage system, this can lead to a decrease in the service life of the foundation due to its excessive waterlogging and the occurrence of the destructive forces of frost heaving.

Hydraulic engineer "EC Ekopochva - LD" Evgeniy Muravyov:

– The task of the drainage system is to drain groundwater, high water and lower the groundwater level to the design values necessary for the normal operation of the foundation, basement rooms and site.

Developers often have a question: is it possible to do without installing a drainage system, and if so, in what cases?

TechnoNIKOL Corporation expert

– Each case must be considered separately. I advise you to use the recommendations of MosKomArchitecture “Guide to the design and installation of drainages, 2000.”

The installation of a drainage system is mandatory in cases of location:

- Operated buried premises below the calculated groundwater level or when the level of the finished floor of the basement exceeds the calculated groundwater level by less than 500 mm.

- Operated buried premises in clay and loamy soils, regardless of the presence of groundwater.

- Technical undergrounds in clayey and loamy soils when they are buried more than 1.5 m from the surface of the earth, regardless of the presence of groundwater.

- Any structures located in the capillary humidification zone, when their operating conditions are associated with strict temperature and humidity conditions.

Construction engineer at Fundamentalno.rf Andrey Pashukhin:

– The drainage arrangement depends on the groundwater level at the site.

From here:

It is necessary to install a drainage system if the groundwater level approaches the critical level for the foundation or is so high that the entire area looks swampy and nothing grows on it.

There is no need to install the system if the area is dry. The groundwater level does not reach critical levels during floods and heavy rainfall.

To make a preliminary assessment of the groundwater level at a site, you can use the following method.

Head of Design Bureau Alexey Korovin:

– If there is a well on the property or in the neighbors, then the water level can be determined by the water level in the well rings. It is best to do this in late July-early August. The closer the water is to the surface of the earth, the higher the groundwater level.

You can also estimate groundwater level by the level of the water edge in a lake or river (if they are located near the site). It should be remembered that a waterlogged area significantly complicates or makes it impossible to carry out landscaping and landscaping work.

Alexey Korovin:

– Many plants cannot grow in waterlogged soil. For example, apple trees do not tolerate excess water. In trees and shrubs, due to lack of oxygen, the root system may begin to rot.

Thus, in the case of high groundwater level and in the absence of drainage, the number of species of plants, shrubs and trees that can grow and bear fruit on a personal plot is significantly reduced.

In addition, if you start installing a drainage system after the house has been built, the garden paths have been laid and the lawn has been planted, you will have to carry out the entire complex of excavation work on an already developed area, which will lead to damage to the landscape and additional monetary costs.

Evgeny Muravyov:

– Although swampy and obviously waterlogged areas are visible to the naked eye, you should not choose drainage and drainage methods based on indirect signs. Only a hydrogeological study of the soil on the site can give a complete picture.

Why is a hydrogeological study of the site done?

Different types of soil have different characteristics, which can significantly affect the choice of drainage system and its route. It should also be taken into account that the soil and groundwater level in a neighboring area may differ from the soil in the area where the foundation and drainage system are planned to be installed. Therefore, it is better to solve this issue not “by eye”, but by resorting to hydrogeological research.

General Director Andrey Nikitin:

– This event will determine:

- Geological structure of the site.

- Physical and mechanical characteristics of soils.

- Groundwater recharge sources.

- Markings of groundwater levels, their chemical analysis. This will make it possible to understand at what levels the groundwater is relative to the surface of the earth and the designed foundation.

- What type of water: is it pressurized or not, its chemical composition and corrosiveness.

- Availability of aquifers. It happens that the water is quite high, but is blocked by an upper aquifer. Without breaking it, i.e. Without deepening the foundation, you can avoid the impact of groundwater on the foundation of the house.

- Filtration properties of soils and the granulometric composition of sands, which are the main conductor of groundwater - to understand how the drainage device will affect the composition of the sands, whether there will be suffusion removal of particles, which can lead to foundation settlements.

Andrey Nikitin:

– The composition of engineering-geological surveys includes:

1. Execution of drilling operations.

2. Measurements of groundwater levels.

3. Sampling of soil and water.

4. Laboratory determination of the physical characteristics of soils, which also includes determination of the filtration properties of soils.

Analysis of the survey results will allow you to select the optimal foundation design and type of drainage system.

Types of drainage systems

Errors in the design and construction of a drainage system may appear several years after the start of its operation. Therefore, the design of a drainage system begins with its design, and first you need to understand the main types of drainage.

Drainages are divided into local and general. Local drainages are used to protect foundations and basements from flooding with groundwater, general drainages are used to protect the site.

Evgeny Muravyov:

– The following types of drainage can be distinguished:

- Wall-mounted – protects against high water.

- Ring - protects basements and basements from flooding with groundwater.

- Layered - protects basements and basements from flooding with groundwater in conditions of the layered structure of the aquifer and groundwater pressure.

- Systematic. Used for draining large areas.

- Ray. Used when draining existing park areas. A characteristic feature of this drainage is its sensitivity to the root system of plants.

Andrey Zubtsov:

– Reservoir drainage is installed at the base of the protected structure directly onto the aquifer. Moreover, it is hydraulically connected to a tubular drain located on the outside of the foundation, at some distance from the plane of the building wall.

The reservoir drainage system protects the structure both from flooding by groundwater and from wetting by capillary moisture. Reservoir drainage is widely used in the construction of underground structures erected on low-permeability soils, as well as in the presence of a powerful aquifer under the foundation. To protect basements and structures in which, due to operating conditions, the appearance of dampness is not allowed, formation drainage should be installed when these premises are located in the zone of capillary soil moisture.

Ring drainage (most often these are tubular drains) is located along the contour of the protected building or its area. The action of ring drainage is based on lowering the groundwater level inside the protected circuit, which provides protection against flooding of underground structures and buried parts of buildings. The depth of this depression depends on the depth of the pipes, galleries or filter part of the wells relative to the groundwater level, as well as on the size of the protected circuit. Ring drains are located at some distance from the structure, thanks to which they can be installed after its construction. In this regard, ring drainage compares favorably with reservoir drainage, which can only be installed simultaneously with the construction of the structure.

Andrey Zubtsov:

– Wall drainage consists of drainage wall structures (pourable, glued, installed) and tubular drains laid on the outside of the structure and serving simultaneously as a pipeline collecting and discharging drainage water.

Wall drainage is used both independently and in conjunction with other types of drainage.

How to protect the basement from flooding?

If there is a high groundwater level on the site, then even at the stage of digging a pit for the foundation it will be flooded with water. This can seriously affect the quality and speed of work. Therefore, it is necessary to provide measures for water drainage in advance.

Evgeny Muravyov:

– It is necessary to clearly understand that there is regular foundation drainage, for example MZLF. In this case, we protect the foundation from the harmful effects of groundwater and reduce the risk of frost heaving forces. And there is a set of measures to protect basements and basements from flooding.

The risk of flooding exists when constructing basements in clayey and loamy soils and when the difference between the groundwater level and the basement (basement) floor elevations is less than 0.5 meters. In these cases, drainage is required.

Andrey Pashukhin:

– The foundation drainage device allows:

- increase the stability of the structure;

- remove the unfavorable factors of heaving in winter;

- improve the performance of hydraulic protection of foundation structures.

Groundwater is removed from the basement floor by installing a ring drainage system. The purpose of its work is to collect groundwater at the required elevation and discharge this water into a receiving collector well.

If flooding of the basement floor has already begun, then the following measures must be taken:

1. First you need to understand and assess the scale of flooding. The future work plan depends on this. If a leak appears somewhere locally, then you can use special hydrophobic compounds with an injectable implementation system.

2. If flooding begins over the entire area of the basement floor, then drainage, installation of pits and additional measures to waterproof the basement cannot be avoided.

How is the site drained?

One of the technologies for constructing a drainage system is as follows:

1. A trench is dug along the perimeter of the building around which drainage needs to be arranged and the required slope necessary for the natural flow of water is maintained.

According to the standards, it is necessary to maintain a slope of 1 cm per 1 p/meter.

2. The bottom of the trench is compacted and covered with river sand in a layer of 10 cm, maintaining the specified slope.

3. The trench is lined with geotextiles. This is necessary to separate the layers and prevent silting of the crushed stone.

4. Granite crushed stone is poured in a layer of 5-10 cm, maintaining the specified slope.

5. Drainage pipes are laid. The pipe or drain (usually pipes with a diameter of 110 mm are used) has slotted perforations or holes with a diameter of 1.5-5 mm.

They are located around the entire circumference of the pipe. Some drainage pipes are equipped with shells made of filtering materials - a geotextile “shirt” that protects the pipe from rapid silting.

A pipe wrapped in geotextile is used only in clean medium- and coarse-grained sands. In other conditions, it quickly, within 2-4 years of operation, becomes clogged (silted), so on other soils a pipe without a geotextile wrap is used.

6. After laying the drain, it is sprinkled with crushed granite stone of fraction 5-20. It turns out that the pipe is surrounded on all sides by a crushed stone “jacket”, which is separated from the layer of sand and soil by geotextile fabric.

7. The edges of the geotextile are overlapped and laid on top of each other, and then the trench is filled with the excavated soil.

To monitor the operation of the drainage and periodically clean the pipes (for which a fire hydrant is used), inspection wells are installed. According to the requirements of SNiP, they are installed at least every 50 meters on straight sections of drainage, as well as in places of turns, intersections and changes in pipe slopes. The water collected by the drains enters the water intake well. It is dug at the lowest point of the site.

Evgeny Muravyov:

– The question often arises – where to divert this water. It can be given:

- to the village stormwater network;

- into a ditch;

- into a ravine;

- into the stream;

- into absorbent containers.

If the terrain of the site allows, then water flows into the drainage well by gravity. If this is not possible, then you will have to use pumping equipment.

Andrey Pashukhin:

– In this regard, using a pump gives greater freedom in deciding where and how to discharge water. At the same time, the work is simplified, because there is no need to ensure that the slope of the drainage pipe is maintained.

It also allows you to reduce the amount of excavation work due to the absence of the need to dig deep under the slope. Installation of the pump requires competent selection and configuration of engineering equipment, as well as connecting the power supply line.

The main mistakes made when installing a drainage system

The most common errors include:

- the use of wall drainage (pipe at the marks of the base of the foundation) to drain groundwater;

- the use of a pipe in a geotextile filter in loamy soils and sandy loams, which inevitably leads to clogging of the filter;

- using levels when laying pipes instead of a level and theodolite;

- installation of stormwater wells instead of drainage wells.

Alexey Korovin:

– One of the most common mistakes developers make is installing only a drainage system around the foundation. Practice shows that this is not enough. It is also necessary to install a drainage system that will drain precipitation from the roof into the storm drain.

Moreover, it is impossible to combine stormwater and drainage in one pipe, because this will lead to the opposite effect - during the rainy season, the drainage system will not cope with excess water. The soil near the foundation will become waterlogged, frost will strike, and this will cause heaving of the soil, which can lead to deformation of the blind area, movement of the foundation, or its destruction.

Storm drainage is made from ordinary orange sewer pipes, which are designed to be laid in the ground, and water intake trays, where water is discharged through the drainage system. Water from the storm drain is also discharged into the intake well. The water collected in the receiving well can be used for irrigation or technical needs.

How is a drainage system installed correctly? All methods are here. FORUMHOUSE users can find out what kind of water interferes with living on the site in this topic. A detailed photo report on the drainage arrangement is here and here. If you follow this link, you can see how to drain the area.

This video explains how to waterproof a basement. And from this video you can learn about all the nuances of the drainage system.

Application of drainage pipes

Such devices have found application in a variety of areas:

- Foundation protection in construction and groundwater drainage.

- Removal of atmospheric precipitation. Drainage channels or trenches are used here.

- Sewage discharge. For this, a drainage pipe without perforation is used.

- Arrangement of the site with a pool or pond. This is required in a place where the soil is rich in clay or black soil. The drainage pipe in the pool prevents the destruction of its walls and finishes.

At what depth should drains be laid?

Before starting work, it is important to determine the depth of laying the drainage pipes. It will depend on several factors. One of the important conditions for determining the installation depth is the soil freezing line.

This condition must be met to ensure that the pipe does not freeze and is in working order during a flood. The depth of freezing depends on the type of soil, as well as climatic conditions. For example, clay soils freeze slightly less than sandy soils because they have greater porosity.

As for climatic conditions, the average annual temperature determines the depth of freezing: the lower it is, the greater the depth. Thus, the laying of drainage corrugated pipes in Arkhangelsk must be carried out taking into account the standard freezing depth of 160 cm for loamy and clayey soils. As for sandy loam and sand, in such soils the standard freezing depth is 176 cm.

In Kazan, the first value is 160 cm, while the second is 176 cm, respectively. For Orenburg, the depth of soil freezing for the soils mentioned above is 160 cm and 176 cm, respectively. In St. Petersburg, clay freezes at 120 cm, while sand and sandy loam freeze at 132 cm.

Types of drainage pipes

Drains vary in material of manufacture and installation method. As for the last option, the drainage system can be:

- Open

. It is represented by a drainage ditch. - Closed

. In this case, a corrugated drainage pipe is used. - Backfill

. For this, gravel, brick or rubble are used.

Asbestos cement drainage pipes

Cement drains reinforced with asbestos are used less and less in drainage systems. Pipes for water drainage have a diameter in the range of 10-50 cm and a length of 3.95-5 m. As a rule, their perforation is partial and is located in the upper part in a checkerboard pattern with a pitch of 100-200 mm. The weight of such a product can reach 500 kg, which creates difficulties during installation. It is easy to maintain, but that's where all the advantages end. Due to their short service life - about 20 years, they have practically ceased to be used for drainage.

Plastic drainage pipes

Synthetic materials are increasingly used in industry and construction, and drainage pipes for draining groundwater are increasingly made of plastic. For this, polyethylene, polypropylene or polyvinyl chloride is used. They have a lot of advantages, including high corrosion resistance, increased flexibility, load resistance and excellent strength.

The drainage pipe with perforation made of plastic is lightweight, which greatly facilitates the installation process. Its service life is 40 years or more, and the price is affordable for most owners of their own plot. The components for the pipes have the same low cost. The plastic drainage system is the most popular today.

Ceramic drainage pipes

We are talking about products made from clay with the possible inclusion of various additives. The perforated drainage pipe is particularly durable, and all thanks to thermal hardening, carried out at a temperature of 1300°C. On sale you can find options with perforations, slotted holes and a corrugated outer surface, which increases the absorption capacity of the entire system. However, such a drainage pipe turns out to be thick-walled and heavy.

One of the advantages is the extremely low coefficient of friction, that is, the contents of the system will circulate freely inside, but this same feature creates difficulties with attaching the filter material. The price for such products is also significantly higher than for options made of plastic, so they can rarely be found in the ground as drainage.

Concrete drainage pipes

Reinforced concrete products are widely used in construction as sewer settling wells. They can have a wide variety of diameters, heights, weights, and be equipped with a bottom and a lid. A drainage pipe for sewerage with perforation has found its way into various filtration systems, for example, in the installation of a two-chamber overflow septic tank. The first chamber is designed to purify wastewater, and the second to disperse it into the ground.

Metal drainage pipes

At first glance, such drains are not suitable for drainage. They are heavy and easily corroded. However, such products, unlike lightweight plastic, can withstand significant loads, where analogs made from other materials quickly fail. They are laid under a bridge, highway or railroad bed. A drainage pipe without perforation finds itself in related and other areas - for organizing water supply systems, ventilation, in the automotive industry, and so on.

photo9

Types of products

There are several types of drainage pipes: ceramic, asbestos-cement, polymer. Nowadays, products made of polymer materials are mainly used. This is due to the fact that such pipes are lighter, cheaper and easier to install. They are divided into several types:

- Drains in geotextiles are pipes with a winding to protect the holes from clogging. The braid additionally acts as reinforcement and filters out impurities. Drains work well on loamy and sandy soils. Typically, geotextiles with a density of 100-200 g/m² are used. Sometimes a denser material is available, but it is a little more expensive.

- HDPE pipes are the most popular products for modern drainage systems. This is explained by good flexibility, high strength, and long service life (50 years). In addition, they have high throughput, so they are successfully used in both private and industrial construction.

- Polypropylene products have a number of positive properties, which include a long service life, the ability to withstand high loads, ease of transportation and installation, and lack of clogging. Their assembly requires electrothermal welding, which solders the pipes into a monolithic structure.

- Due to their high cost, drains with coconut winding are rarely found in construction, but they have a number of advantages: resistance to loads, do not rot, and do not become clogged. In addition, the coconut wrap is 100% natural material.

- Polyvinyl chloride (PVC) pipes are mainly used for deep drainage, as they have high strength. The maximum depth for their laying is 10 m. In severe frosts, polyvinyl chloride becomes brittle, so transportation in winter should be carried out very carefully.

There are also drains made of white asbestos, which are considered environmentally friendly without harmful impurities. They differ in that water enters them not through holes in the walls, but through pores.

How to choose drainage pipes?

The criteria for selecting products for groundwater drainage are as follows:

- Material of manufacture

. Modern homeowners do not use expensive and difficult to install asbestos-cement and ceramic pipes. Plastic analogues are more preferable. More often than others, polyethylene drains are chosen, but polypropylene and polyvinyl chloride are also in demand. - Type of hole arrangement

. The manufacturer can apply the slots evenly throughout the entire product or make them only on one side. In the latter case, it is necessary to ensure that when laying the perforation is on top. - Product diameter

. In rare cases, the developer has information about the level of groundwater and data on the amount of precipitation. They rely on average statistical standards and choose the diameter of the main drainage system in the range of 160-200 mm, and the diameter of the secondary branches of the system is at least 110 mm. - Layering

. The two-layer drainage pipe has special strength and is used where there are increased loads on the surface layer. In addition, such products can be immersed deep underground. - Presence of corrugated surface

. It significantly simplifies the requirements for the geometry of the drainage scheme, makes installation easier and cheaper, including due to savings on additional connection elements - bends, elbows, etc. - Availability of geotextiles

. This is a special fabric made from polypropylene or polyester threads. Equipping the pipes with it helps to avoid clogging of the holes.

Stages of network installation work

Before installation work begins, the site is marked out, indicating the location of drainage channels. Taking into account differences in heights, recesses for the trench are prepared.

Preparation of trenches is the first and very important stage of work on installing a drainage system

The main task of the ditch network is the unhindered and rapid outflow of water.

Note! To check, you can run a certain volume of water and make sure that it does not accumulate in certain areas.

Before installing the drainage pipe, the bottom of the trench must be thoroughly compacted. Next, filter material is laid, the ends of which should extend beyond the ditch, as well as river sand and crushed stone to a maximum thickness of 20 cm.

Drainage pipes are cut with a jigsaw or pipe cutter and connected with fittings. When they are wrapped with geotextile, the joints are secured with thin wire or rope. In addition to throughput, the function of the filter material is to protect the perforation holes from clogging.

When laying pipes, a slope is maintained, and their ends are connected to inspection wells. Wells are divided into 2 types:

- sealed - allow the collected water to be used for technical purposes;

- absorbent - to drain water back into the soil.

The surface of the pipe is covered with an absorbent layer of sand or crushed stone. At the final stage, the structure must be wrapped in a sheet of filter material and covered with soil.

How to wrap drainage pipes?

If the drainage pipe is laid in a trench in its natural form, over time grains of soil, sand, and other particles will penetrate into the trench, depositing in layers and clogging the holes. That is, the system will become silted, and this cannot be allowed. The drainage pipe in geotextile is reliably protected from external influences. This material does not rot, does not tear, and does not corrode, which is why it is used in drainage systems. You can wrap it yourself or purchase products already covered with geotextiles.

Famous brands

Nowadays, the domestic construction market offers a large selection of drainage pipes. In our country, they are produced by the companies Ruvinil, Nashorn, Politek and others. Popular brands of pipes include:

- Perfokor - drains with a double wall, so they are very durable. Products are produced both in coils and in sections with a stiffness class from SN4 to SN8. Pipes with a diameter of 110 to 160 mm are connected with ECOPAL couplings without O-rings.

- Korsis are double-wall corrugated pipes produced by Poliplastik. Enterprises of this brand operate not only in Russia, but also in the CIS countries. In addition to drains, this brand produces shaped parts for connecting them.

- Pragma - products are used in the construction of storm, municipal and industrial drainage. They are made from polypropylene, which can withstand extreme temperature changes and is shock-resistant. In addition, drains made of this material are easy to cut and connect to each other. It is possible to install them with HDPE and PVC pipes. Installation of Pragma products is carried out manually, which provides clear savings during construction work.

- Softrock - products are manufactured using the technology of the company of the same name. Perforated pipes are made with polystyrene foam filler. The products are laid without the use of crushed stone, which reduces construction time and increases the efficiency of drainage.

Among foreign manufacturers, Polieco, Uponor, Wavin and Rehau are especially famous.

Installation of drainage pipes

The organization of the drainage system is carried out in several stages:

- Dig a trench approximately 40 cm wide greater than the diameter of the pipes used. Many people are interested in what depth to bury the drainage pipe, so it is worth answering that it should lie 300-500 mm below the foundation of the building.

- Trenches are dug at an angle of 1-2% towards the well. If it is not possible to achieve the desired goal, the slope is made using available materials, for example, crushed stone.

- Lay out a filter layer of sand 20 cm deep. Compact thoroughly.

- Pour a layer of crushed stone of the same height.

- Carry out installation by connecting pipes with fittings and other connecting elements.

- Install inspection wells at turns.

- At this stage, the work is performed in reverse order. The top of the pipe should be covered with a layer of crushed stone, then sand, and finally the previously excavated soil should be laid.

How to determine the slope of drainage pipes?

This parameter is calculated depending on the diameter of the drains. The slope of a drainage pipe with a cross-section of 150 mm is 8 mm per meter of length. If the diameter reaches 200 mm, then this parameter is reduced by 1 mm. A drainage pipe of a smaller cross-section, for example, 40-50 mm, can be laid at a slope of 30 mm per meter of length. With a diameter varying between 85-100 mm, this figure is 20 mm.

Laying a drainage pipe

All work on organizing drainage on the site must be accompanied by the development of a drainage project, taking into account the quality of the soil, the type of terrain and the level of groundwater. Those who want to know how to properly lay a drainage pipe on a site should remember that in the most simplified version it is done like this:

- The first horizontal surface drain is laid at the top level of the site.

- The second part of the system is created on the opposite lower side.

- Both are connected to each other by perpendicular trenches.

- A horizontal drainage pipe with lower level perforation is used to drain water into a drainage well.

Design Features

The presence of partial or complete perforation is considered the main design difference of drainage pipes. In drains with full perforation, the holes are located in a circle, with partial perforations - only at the top. Pipes are single-layer and double-layer. Depending on this characteristic, they have different classes of rigidity.

Perforated single-layer drains are used at a depth of no more than 3 m. Their strength is taken into account, which is used to determine the filling depth. Pipes with stiffness class SN2 are installed no more than 2 m, SN4 - 3 m.

Typically, two-layer turfs have a hardness class of SN6. Their inner surface is smooth, and the outer surface is made in the form of corrugation. When laying drainage pipelines, sections no longer than 4 m are used. Flexible corrugated turf with holes belongs to the SN8 stiffness class and is installed at a depth of up to 10 m.

Flat drainage pipes are often used to drain water from building foundations, roads and supports. They are made from low-density polyethylene (HDPE), which allows them to deform during loading, but not collapse.

Pipes for storm drainage

Storm drain pipes will help drain melt and rainwater away from the building. They, together with gutters, trays and storm inlets, form above-ground or underground storm drainage systems and ensure the safety and durability of the structure. Requirements for materials: strength, resistance to solar and mechanical influences, sedimentary reagents, temperature changes.

For the construction of drains, cast iron, polymer or reinforced concrete pipes are used (laying under roads). It is important to choose the correct diameter so that the storm drains do not overflow. For private houses, sewer pipes Ø 100 mm are used.

Rules of operation and maintenance

Drainage pipes should be regularly checked for dirt accumulation inside and cleaned if necessary. For this purpose, inspection wells are installed in the system. The inspection is carried out:

- Scheduled – once every 12 months;

- Unscheduled - after heavy rains, floods, floods.

The need to clean the drainage pipeline is usually signaled by stagnation of water in the inspection well. Scheduled cleaning is carried out every three years. It is necessary because even despite the filter elements in the system, sedimentation of sand, silt, and dirt still occurs over time. You will have to clean it more often if there are no filter elements in the system.

Cleaning of drains is carried out mechanically or hydrodynamically. The first option involves crushing solid elements in the system and then extracting them using a pneumatic gun. The hydraulic method involves flushing the line with a stream of water, which is supplied by a pump and compressor under pressure. The latter option is usually more expensive, but also more reliable than mechanical cleaning.

With the right choice of drainage pipes, the system can last almost half a century. But before purchasing drains, it is always necessary to first work out the design of the entire system. It is not worth saving on such products, as this can significantly reduce the service life of the drainage system, as well as increase the number of necessary cleanings of the line.

How and why does drainage work?

An artificially constructed watercourse is a system of underground pipelines and surface channels for collecting water. The moisture enters special containers and is then removed outside the site. Discharge can be carried out both into natural reservoirs and city sewers.

You can determine whether an area needs drainage based on indirect signs. High soil moisture is indicated by:

- the presence of moisture-loving plants (for example, nettle);

- flooding of cellars and basements;

- long drying of the area after rain (large puddles remain, from which water does not drain well).

But even in the absence of such warning signs, buildings are not immune to water damage. For example, during heavy rains or during active snow melting. For this reason, experts recommend in any case installing drainage around the foundation and installing storm drains.

The main advantage of drainage systems of this type is the elimination of expensive treatment facilities and other technical components.

The complete system consists of:

- from drainage pipes;

- storm drains (gutters and storm water inlets);

- sand traps - special mechanical filters at the entrance to the system collector;

- common drainage wells;

- a collector with a check valve (from here the water is discharged into the ground or reservoir).