Before starting construction of your house, it is important to take into account that the minimum distance from the sewerage system to the foundation of the building must comply with SP (SNiP) standards. Only in this case will the parameters of the plumbing system be optimal. The distance from the foundation to the sewer largely depends on the type of the latter. But more about everything.

We comply with SNiP standards

Why is it important to keep this distance

Sewerage located too close to the foundation is unacceptable. This applies to both large apartment complexes and private houses. Failure to comply with established standards can lead to critical consequences.

Building foundation slab

Here's what sometimes happens when you get too close:

- The sewer breaks through (for some reason, not because of the distance between the sewer and the foundation of a residential building).

- The soil does not have time to absorb water, and it rises to the base of the building.

- Even ordinary water in such a situation will erode the foundation. And sewer water often contains aggressive substances that aggravate the process.

We should not forget that this poses a sanitary threat. That is why too small a distance between the building’s sewer system and its foundation is unacceptable not only according to SNiP, but also according to SanPiN.

With such a problem, the consequences will not be immediately visible.

The foundation will begin to sink, but gradually. And the deterioration of the sanitary situation will not make itself felt sharply. The first signs will appear only with time.

Laying under the foundation on a summer cottage

This is both an unpleasant smell and the position of the house in space. But then you will have to take measures that would not be necessary if the sewerage system was laid correctly.

Repair of communications in this case involves the dismantling of surface structures, including tiles. Such work is labor-intensive, expensive and also risky. There is a risk of damaging serviceable communications, as well as the supporting structures of the house. That's why it's better not to let things get to that point.

Rules for installing plastic sewerage

The standard materials for the construction of a sewer system are considered to be cast iron or asbestos concrete, which is explained by their strength. Despite a number of advantages, working with such materials is quite difficult. A modern solution is plastic sewerage, the basic installation rules of which are simple and clear. In addition, it must be said that plastic sewerage is a durable and practical structure.

The complete set of such a sewer system includes such basic elements as pipes, storage tanks and wells made of polymer materials. To produce these elements, the following are most often used:

laying a plastic sewer system in a private house

Is it possible otherwise?

The SNiP standards presented above are justified if we are talking about a more or less ordinary building. If this is some kind of unique house, for example with a bunker, the distance to the foundation may be different. But it is important to take into account that the minimum distance in any case must always comply with the standards of SP and SanPiN.

Horizontal spacing standards

In the design of a room, half the work can be done by a person who is illiterate in architecture. However, when designing communications, you should immediately contact an engineer if there is no understanding of the issue. After all, in order to correct the mistakes made at the beginning, you will have to redo the entire drawing.

5 mistakes related to the arrangement of in-house sewage systems

Very often, mistakes during sewerage installations are associated with incorrect calculations of the parameters of the pipes used. To ensure uninterrupted operation of the sewage system, the installation of sewerage pipelines must take into account the following nuances:

Tilt angle

The selected angle of inclination of horizontal pipes will depend on the size of their internal section. According to regulatory data, the fifty pipe should fall three centimeters per meter. A pipe with a diameter of 100 to 110 tilts two centimeters. A part from 160 millimeters can have a slope not exceeding 0.8 cm per meter of product.

You may also like: Slope of sewer pipes according to SNiP

Height difference

Do-it-yourself installation of sewerage from plastic pipes implies compliance with such an indicator as height difference. Its value should be equal to one meter. For the rest of the plumbing it is three meters. If it is necessary to exceed the standard value, then you will have to think about arranging ventilation at each end of the line.

Angle selection

Another common mistake lies in choosing the wrong angle. If it is straight (90 degrees), then when it rebounds, a clog will begin to form. The problem can be avoided by creating a smooth transition in a corner location using shaped parts with an angle of 135 degrees.

Fan pipe outlet

An error is considered to be the discharge of the waste pipe into the general ventilation system of the premises. This option will allow the sewer aroma to instantly fill all rooms. It is important to remember that the flow of water creates a lot of noise. To rid yourself of uncomfortable sound, you should consider sound insulation. You can use mineral wool to wrap the pipes. Additionally, you can build special boxes using drywall.

Not equipped with a check valve

The pipe that connects the septic tank to the waste system is not equipped with a check valve. In this situation, if the outdoor tank overflows, the wastewater will return to the house and flood the basement.

Read more in the article: Non-return valve for sewerage - what, where, when?

Sewer installation procedure

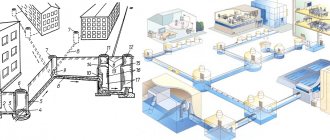

The distance is determined at the stage of the engineering highway design. The distance between nearby highways and water-bearing sources is taken into account. It is important to maintain the distance from the sewer well. The distance to the highway, street, neighboring buildings and houses is also taken into account. Of course, they take into account the cross-section of the sewer pipe.

Laying the pipe to the foundation of the building

They operate in this order:

- They draw up an accurate plan taking into account SNiP standards. It takes into account all the distances described above, including from the foundations of houses. And also others, if any are present in the area.

- Check whether the data in the project corresponds to all graphic drawings and diagrams. If there are discrepancies, correct and check again.

- They check whether there are remains of old communications in the place where pipes will be laid. And any kind, even if it’s just wires. If any are found, plan the work so as not to damage anything. To do this, leave a margin of distance to already laid communications. As a result, the risk of damaging them is minimized.

Then it will be possible to lay the sewerage system in accordance with the joint venture. If other communications are present, they will not be damaged while remaining at the required distance from new ones. With this approach, the distance from the foundation of the building to the sewer pipes will also be maintained.

Layout of the septic tank from the foundation and walls of a residential building in accordance with SanPiN and SNiP standards

Thanks to this, many problems will not arise, including troubles with health, with your home and legal risks. It is important to remember that there are neighbors around and they can also get hurt.

Rules for installing sewer pipes

Plastic sewer pipes, which are installed using fittings, provide the highest quality connection. If butt welding is used, it is recommended to use it when constructing a hidden pipeline.

The principles of installing a sewer system can be divided into:

- installation of sewer pipes in the house (internal);

- external installation of sewerage.

Rules for installing the internal system

- When creating a sewer installation, it is advisable to use as few joints and turns as possible;

- it is necessary to use pipes with a diameter of 50-100 mm;

- the angle of inclination of the pipes can vary from 1-2 cm/m;

- when equipping pipes made of plastic, it is recommended to use additional lubricant;

- revisions should be provided at every turn;

- when fixing the material with plumbing fixtures, adapter cuffs made of rubber and sleeves should be used;

- risers must be fixed from bottom to top using clamps;

- PP pipes are cut with a special hacksaw or grinder;

- when installing sewer pipes in an apartment from leftover material, the latter are connected using repair shaped couplings;

- joining PP pipes using sockets does not require additional sealing.

Rules for installing external sewerage

- such sewerage is installed in trenches equipped below the ground freezing level;

- if necessary, as well as when the sewerage system is laid at a depth of up to 0.5 m, it is recommended to insulate it with fiberglass;

- the bottom of the trench is lined with a sand cushion with a layer of 10-15 cm;

- the laid sewer pipe is covered with sand from the sides and compacted;

- inspection wells are installed at turns, as well as every 25 m;

- the finished system is discharged into a cesspool or connected to a septic tank.

Installation of sleeves in walls and ceilings for utility networks

The sleeve should protrude beyond the wall. However, some features should be taken into account: • The standard requirement is a 50 mm output, but this is not always justified. • In rooms where the possible water level is higher than the clean floor (bathtub), a hermetically sealed sleeve near the pipeline is required. • Sometimes the case can protrude only 5-7 mm, since it is not economically feasible to make it large. • The sleeve should not be an obstacle to the finishing of the walls - protrude beyond the plaster or wallpaper. The size of the gap should ensure high-quality sealing with material. The inner diameter must allow free movement of the pipe. Practice has shown that sleeves are made from sections of polymer or metal pipes. In some cases, it is possible to use a rolled waterproofing material - roofing felt. But it is worth remembering that they contain petroleum components. This is undesirable for wooden building structures. Non-metallic sleeves have an advantage. No burrs or sharp ends that often scratch polymer pipeline components. To solve the problem, the edges of the steel sleeves are processed and flared outward. Plastic, in turn, does not have good adhesion to cement mortar. The thickness of the walls is determined by the type and objectives of the structure.

How to ensure maximum service life of building structures and pipelines?

There are a number of recommendations: • According to SNiP standards, non-insulated units should not have direct contact with building structures; • Before the horizontal outlet, protection is provided with a cement layer of several centimeters; • Use sleeves (cases) in places where pipelines cross; • To increase sound insulation properties, an elastic material is used, which is placed in the gap between the outer diameter of the pipe and the inner diameter of the case; • Sleeve waterproofing can only be used for slabs; • During installation, uneven shrinkage of the foundation is taken into account: gaps are sealed with mastic or sealants. Moreover, the internal diameter of the case must exceed the diameter of the pipe by 2 cm; • Copper components are also placed in cases, and the border with the building structure is treated with cement, in wooden houses - with asbestos; • Changes due to temperature changes are compensated by means of sliding supports, which must be taken into account during the creation of the project. At the exit, install a fitting (tee, elbow) to prevent it from being removed from the wall.

General information

It is necessary to install the pipeline so that when materials of different strengths come into contact, the structures will last for many years.

There are general rules for arranging sewer risers through structural slabs.

If metal-plastic pipes pass through the ceiling structures, they are placed in special tubular plastic cases of a suitable size.

1. Sound insulation of the sewer riser in the apartment is ensured using sleeves.

2. Polymer pipes are subject to changes due to temperature changes depending on different seasons and time of day. Sleeves protect pipelines when moving inside ceilings.

3.The use of sleeves allows you to dismantle the damaged section of the pipe without destroying the entire sewer system. It is not necessary to always place all the elements in the sleeve; this is due to the presence of emergency circumstances. For example, a cold water pipeline made of polymer will have to be completely replaced only after fifty years, when its service life expires.

4. If you properly seal the cracks formed by the sleeve with pipes that are laid through the walls of buildings, as well as their ceilings, then you can completely get rid of the smell and insects from neighboring rooms.