How is it different from a file?

A needle file is often called a mini file or file. With the “adult” file, they are closest relatives, but there are differences. The rasp also belongs to the processing tools, although it has its own specifics. What is the difference between a needle file, file and rasp:

| Characteristic | Needle file | File | Rasp |

| Working blade size | From 80 to 160 mm | From 100 to 400 mm | From 140 to 350 mm |

| Notch size | Small | Average | Large |

| What is it needed for | Jewelry, engraving, glass work, cleaning of small and hard-to-reach parts in other areas | Metalworking work, turning large hard elements | Carpentry, plumbing, leveling of rubber, soft metals, wood, leather |

In fact, all of these tools are files. They are designed to remove the top layer from materials by scraping and grinding. However, a needle file gives the smoothest result and is designed for finer processing, cutting out clear shapes; this is its main difference from a simple file.

What types of files are there?

There are several dozen types of files, differing in their performance characteristics.

The purpose of this tool is to remove a layer of material, which could be, for example, wood, metal or plastic. Each file consists of a working part and a handle. A special notch is applied to the body of the tool, due to which it is possible to remove layers of material from the surface of the product. The type of a particular file and its name are determined precisely by the size of the notch. Files are a general name for a whole line of tools, which includes rasps and needle files. Such a tool can have different sizes and profiles. Most often, craftsmen have to work with files with a flat or square section. There is a tool whose working part has a round, oval, diamond-shaped or triangular profile. Having an arsenal of files of different types and sections, a mechanic can process parts of a very complex configuration.

Shapes of needle files and their application

The shapes of needle files differ from each other according to their purpose.

Craftsmen often use a whole set of mini-files in a certain sequence.

Multi-stage processing of the part allows you to achieve optimal condition and correct all flaws without much difficulty.

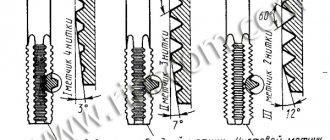

According to the profile, the tool is divided into the following types:

- triangular pointed-nosed (triangular). They have three equal faces, respectively, three working edges. This form is suitable for processing corners, placing corner notches, turning small grooves inside and outside;

- trihedral obtuse. They resemble a triangle with equal sides and an obtuse angle. May have 1 or 3 edges of different textures. Used for processing corners, medium and large holes;

- wedge-shaped. They have one edge and two working edges with a sharp end. Suitable for processing valves, small corners, casts, sawing notches;

- rhombic. Convenient for products with different angles in shape. The working surfaces fold into a diamond shape with sharp edges. The tip is blunt;

- semicircular. One side is flat, the other is oval. Notches all over the instrument. In cross-section - a segment. A universal type, since both round and flat surfaces can be processed. An essential tool for a jeweler when making rings;

- flat, blunt-nosed. Rectangular, with four elongated sides. Two wide and narrow working edges. You can process a variety of grooves and even elements;

- flat pointed noses. Rectangles with a sharp end. Application is similar to blunt-nosed, but more possibilities for hard-to-reach places;

- square. They have a cross-section in the shape of a square. All surfaces are working. Used for filing backlashes, notches, grooves with right angles;

- oval. Used for rounded parts and creating smooth lines. In cross section they look like an oval. The tip is often pointed;

- round. Round working part, blunt or sharp tip. Notches all around. Ideal for correcting embossed, rounded surfaces;

- grooved Very similar to the flat type of needle files. The main difference is the rounded ends. The nose can be sharp or blunt. Widely used for processing holes of various formats;

- differently convex. Similar to a biconvex lens. There is a notch on both working sides, the nose is pointed. Perfectly aligns the shape of the rings from the inside;

- knife-shaped. They look similar to a household kitchen knife. Most often they are used to clean parts from dirt, rust, plaque, fine sharpening, and adjustment;

- needle-shaped. A distinctive feature is the short working part. A file without a handle is only 25 - 55 mm long. Square shank, sharp tip. Used by jewelers to polish surfaces. In other areas it is occasionally used for hard-to-reach places. Also called a gold file;

- velvet. Needles of this type are used for the most delicate processing. In one stroke they remove 0.05 mm without visible marks. This effect is possible thanks to 25 - 80 cloves per centimeter of working surface;

- riffles. Needles for special purposes. Mainly used by jewelers. The shape is curved like a sickle or hook, an alloy with a magnetic additive. They process chain links and gold rings. The magnetic component allows you to shake off metal crumbs so that debris does not interfere with extremely delicate work;

- Needle files for sharpening saw chains, such as chainsaws. Manual versions have a guide plane and a working rod with notches. The shape and size are selected in accordance with the chain pitch. It can be quite difficult to maintain calibration with such a file. The electric or pneumatic version greatly simplifies working with a chainsaw. They look like belt sanders. The movement is carried out by a belt and a motor; the kits come with several attachments. Such devices are also actively used in the automotive industry, glass and aluminum turning;

- double-ended. The handle of such instruments is located in the center of the length. Working surfaces are located on both the right and left edges. Often used by engravers and jewelers for small details.

Types by material

Based on the source material, needle files are divided into diamond and fog-shaped.

IMPORTANT . An error in choosing the file material can result in a damaged product. Unsuitable friction force can destroy the coating.

Diamond

Diamond mini files have a huge range of applications.

The most obvious example is ordinary nail files.

Glass, ceramics, metals, alloys, plaster and painting compounds readily lend themselves to adjustment with such a tool. During the process, the material is not cut, but partially removed from above.

The working area of the file is cast from carbon steel and coated with diamond chips. However, sputtering has nothing to do with jewelry. In fact, particles of durable artificial stone are used.

Spraying is done in different hardnesses (50 - 60 units). The higher the indicator, the larger the grain. A small size fits more tightly, which means the sanding result will be as smooth as possible. Hardness must be indicated on the handle of the tool in the form of a mark or a colored stripe (red - 160/125–100/80 grains; blue - 80/63–63/55; without a mark - 50/40–40/28).

Diamond needle files according to GOST have a standard length of 100 - 200 mm. however, there are specimens from 50 to 160 mm.

Fogoltsevye

Fogol files are made from alloy steel.

This steel is characterized by wear resistance, strength, hardness, heat resistance, and high corrosion resistance.

All of the listed characteristics are ensured by adding chromium, nickel, molybdenum, manganese and other elements of the chemical table to the iron-carbon alloy.

Fogol'tsevy file is found mainly in jewelry workshops. The material interacts well with ductile metals and gives the desired shape without damage.

As a rule, a fogol needle file is cast in a semicircular shape with a tapered end. Other options are less common.

What is a needle file?

An elongated block with single or double notches is a needle file. This tool is manufactured in strict accordance with GOST quality standards, which have been approved for both the mold and the metal alloy. Certain steel compositions are used for needle files; they must be durable. Jewelry workshops use tools made of magnetic compounds; this is necessary so that the shavings do not mix with each other during work. The number of notches on the working blade of the tool determines its number, which is stamped on the handle for ease of use.

What does a needle file look like?

It is easy to distinguish a needle file from other tools that perform similar functions. When you see a small file with a long handle equal to the working part, you can be sure that it is a needle file. It differs from its “brothers” in size and notch located at different angles. Some tools come with replaceable handles.

What are needle files for?

A professional craftsman has various tools designed to perform a specific type of work. When filing small areas located in hard-to-reach places or cleaning internal cavities, you cannot do without a file for fine work - a small needle file. The finest filing of various materials, smooth grinding of surfaces is possible with a metal assistant with notches of different sizes.

Types by notches

According to GOST number 1513-77, there are five types of needle files based on notches. Options 1 and 2 include mini files with 28 - 56 notches for every 10 mm of working surface. In classes 3,4,5, the indicator increases to 40 - 112 units per 10 mm. The exact number and corresponding type are easy to determine and are indicated on the handle.

A rougher cut will be obtained when working with a needle file of types 1-2. They are used to create relief and carve out risks. The third number gives an average result. It is used for fine finishing grinding. The fourth and fifth files are used to interact with jewelry, precious and semi-precious stones, frames, glass, small elements, and make small notches with them.

Reference. At different stages of working with one product, files with different notches may be needed. It is recommended to study the nuances before starting the process.

Types of files

There are many types of this tool, and choosing a single universal file for the job is very difficult. An electric needle file is a modern “must-have” that any advanced craftsman should have; it is also called a “grinder”. It works with different surfaces, has many attachments and a variety of programs. Small hand files are indispensable for work that requires a jewelry approach. Needle files differ in several ways:

- by type of material

: diamond, fogol, metal; - by size

: there are needle files of 80, 120 and 160 mm; - by number of faces

: wedge-shaped, needle-shaped and multifaceted; - according to the number of notches

: bastard, personal and velvet.

What types of pens are there?

The file handle greatly simplifies the work process.

Without this device, the master will easily rub the skin of his hands, lose precision of movement, and drop the slippery metal.

The comfortable handle has no nicks or burrs, it is smooth and easily fits into the curve of the palm. Markings are visible on the surface. The most convenient proportions are equal to the length of the file and the holder.

Some mini files already come with handles made of plastic, wood or rubber. But there are single copies and sets without this. Manufacturers offer to purchase amenities separately. In such cases, it is recommended to pay attention to the quick-release handle for the file. The most common option is a wooden block with a hole for the tool. A special bushing protects the device from splitting and increases service life. You can put the handle on by lightly hitting the workbench or gently tapping it with a hammer.

A more modern and optimal option for a removable holder is a handle with a collet clamp. The spring eliminates the need for shock when putting on and taking off. The movable sleeve securely fixes the file with one turn, then releases it in the reverse order. These handles are made from stainless steel or durable wood. The case often has a cavity for storing the files themselves.

How to choose a tool?

Choosing a needle file is a responsible process that in the future will influence the result of the master’s work. The file must be of high quality and match the type of specific work or material.

The quality of the grinding surface is checked by a simple operation. You need to take two files and run the blades over each other. A good notch will not be damaged, will not fade or be scratched, the grain will remain in place without baldness.

A conscientious manufacturer must ensure that there are no external defects. Curvature of the shape is allowed only to a slight degree. A slight slope may occur during the hardening production stage. Strong curvature will complicate the operation of the tool. The notches should be evenly spaced. Plaque, rust, and traces of other corrosion are unacceptable on metal.

You can check the strength by simply tapping on a hard surface. A solid gun will give a clear, clear sound. A characteristic rattling sound will indicate the presence of cavities or cracks in the housing. Such defects significantly reduce the life of the tool and increase the risk of its breakage during active use.

As for the configuration, for household needs it is better to opt for sets of 5 - 10 needle files of different shapes, sections and sizes. The most popular, universal types are usually placed in such boxes. Notches, lengths, types can be seen on the packaging. For highly specialized purposes, it is worth purchasing profile needle files. Such specimens often indicate a specific purpose (engraving, jewelry, soft alloys, leather, glass, etc.).

If in doubt, it is better to consult the seller. A specialist can easily select the required needle file upon request.