CONTROL METHODS

4.1. Testing of drills must be carried out on drilling machines with mechanical feed, the accuracy standards of which comply with the requirements of GOST 7353-90.

Coniferous wood blanks are processed in accordance with GOST 9685-61 with a moisture content of no more than 12% at the cutting conditions specified in Table 2.

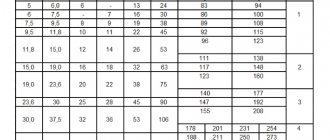

table 2

| Drill diameter, mm | Feed, mm/rev | Spindle speed, min |

| 10,0 | 0,2 | 10000 |

| 25,0 | 0,8 | 4100 |

(Changed edition, Amendment No. 2, 3).

4.2. Drilled holes should not have burns or chips at the entrance.

4.3, 4.4. (Excluded, Amendment No. 2).

4.5. The hardness of drills must be checked in accordance with GOST 9013-59 using a TR type hardness tester in accordance with GOST 23677-79.

4.6. Control of the appearance of drills is carried out visually using a magnifying glass LP-1-5 in accordance with GOST 25706-83.

4.5, 4.6. (Changed edition, Amendment No. 2).

4.7. The surface roughness of drills (clause 2.3) is checked by comparison with roughness samples in accordance with GOST 9378-75* or with standard tools that have limiting surface roughness values. _______________ * GOST 9378-93 is valid. — Note.

4.8. Errors in measuring the dimensional and geometric parameters of drills should not be more than:

values specified in GOST 8.051-81 - for linear dimensions;

35% tolerance on the angle being checked - for angular dimensions;

25% tolerance for the tested parameter of deviation of the shape and location of surfaces.

4.6-4.8. (Introduced additionally. Amendment No. 1).

4.9. Acceptance values of the average and established durability periods should not be less than those indicated in Table 3.

Table 3

| Drill diameter, mm | Processed material | Acceptance value of durability periods, min | |

| average | established | ||

| 10 | Coniferous wood according to GOST 9685-61 | 47 | 24 |

| 25 | 29 | 15 | |

(Introduced additionally, Amendment No. 2).

Varieties of drills by types of shanks

The shank, the so-called “drive” of the drill, is a mandatory fastening element of the drill, which is clamped in the chuck of a hammer drill, drill or spindle head of the machine. All types of drills are produced with shanks of the following shapes:

- conical (cone-shaped);

- cylindrical (cylindrical);

- faceted;

- SDS type.

Conical (Morse taper)

This drill shank is shaped like a cone and is intended for drills used on machine tools. The cone-shaped head allows for quick tool changes in automatic mode. The variety of designs of tapered shanks is due to the methods of fixing drills for machine tools. They are:

- with claws - fasteners in the spindle head are carried out by wedging. Thanks to this fixation, light materials are prevented from turning during drilling.

- with thread - fastened by means of a rod. This type of fixation is the most reliable. It prevents the tool from falling out.

- without threads and paws - designed for working with light materials.

Types of tapered shanks

There are several modifications of tapered shanks:

- Instrumental. The product parameters are regulated by GOST. The most common type, since they are specially designed for quickly replacing drills on machine tools.

- Shortened. Used to form shallow holes. The tail part is reduced due to thickening.

- Elongated. Necessary for deep drilling.

- Metric. The ratio of the length of the shank to the working area of the drill is one to twenty.

The main advantage of the tapered shank is the ease of centering without the use of additional tools.

Cylindrical

Drills with a drive of this shape are the most popular among home craftsmen, since the cylindrical shank is suitable for a regular drill. As a rule, the diameters of the cutting part of the drill and the shank are identical, but it happens that for more reliable fixation in the chuck, a shank of a larger diameter is used. But if you need to clamp a thick drill in a standard drill chuck, select shanks with a smaller diameter. The main disadvantage of working with a cylindrical drive of drills is their slippage during rotation.

Faceted

Such shanks are rods with three, four or six edges.

tetrahedral

The use of these shanks has been practiced since the mid-19th century. Initially, they were simply inserted into the spindle or secured with a screw. Over time, clamping chucks appeared, but most modern drills are not equipped with devices that can securely hold drills with a square shank. In addition, the centering of the drill is not ensured. The advantages of the design include ease of manufacture and resistance to rotation. Drills with similar shanks are used for working with a brace.

Hexagonal (hexagonal, hex)

The six sides of the shank provide excellent resistance to twisting of the drill and transmit high torque to it. Therefore, for thin drills that require high torque, a shank of this configuration is made. With this type of drive, there are various types of drills: pen drills, twist drills, Forstner drills.

Triangular

The convenience of using these shanks lies in the possibility of clamping in standard three-jaw chucks, transmitting high torques, and also being resistant to rotation.

Type SDS

This design was developed and patented by Bosch for the rapid replacement of used drill bits in rotary hammers. A design feature is the presence of grooves on the tail rod of the drill, due to which the drill is fixed in the chuck. There are several types of SDS shanks used in different models of rotary hammers or jackhammers.

Classification of drills by purpose

It is recommended to use a specific type of drill for each material. Illiterate use of cutting tools often leads to damage to equipment, fittings and, of course, the source material. To avoid such mistakes, you need to know which type of drill will do the best job for a particular job.

Drills for working with metal

Drilling in metal is usually carried out with a milling, twist or step drill. The material used to make such drills is usually high-speed steel. This should be indicated by appropriate markings. If it is missing, the product should be treated with caution - there are many low-quality fakes on the construction market. The table below contains information about which grade of drill bit is suitable for a specific type of metal.

| Markings on Russian products | Marking on foreign products | Characteristics, scope |

| M1 | HSS-R, HSS | Basic metal drills with average wear resistance, not very resistant to overheating and impact, but are inexpensive. You can drill shallow holes. |

| R6M5, M2 | HSS-G | They have a wide range of applications. High levels of wear resistance, strength, and impact resistance. Suitable for forming holes of any depth in sheets of carbon and alloy steel, in alloys of cast iron and non-ferrous metals. |

| R6M5K5, M35 | HSS Co, HSS-E | Recommended for processing stainless steels. |

| – | HSS-G TiAlN, HSS-G TiN | Metal drills of maximum hardness and heat resistance. The cost of the tool is high, but you can drill particularly strong metals and titanium alloys. Sharpening of drills of this type is not allowed. |

In addition to the marking, the sharpening angle may indicate the purpose of the tool. The sharper it is, the softer the alloy should be. For such cases, the optimal angle is 80-90º, for drilling cast iron and steel alloys - 100-120º, for harder metals - 130-140º.

Wood drills

The following types of drills are used for working with wood:

- spiral;

- feathers;

- Lewis spiral;

- Forstner;

- milling, etc.

A twist drill for wood is visually not much different from a drill for metal, but it requires special sharpening with a centering spike. Therefore, to make holes with increased accuracy and a smooth, clean surface, you need to use a wood drill with an appropriate working surface, made of carbon or tool steel.

Drill bits for concrete/brick

To work with brick, concrete, stone and similar materials, you need a special concrete drill tipped with a high-hardness alloy, for example, Pobedit, on the tip of the working surface. The operation of drilling concrete itself is somewhat different: the drill or drill, together with rotational movements, must perform shock-translational movements. In this case, the stone will not be cut, but crushed. It will be difficult to make a hole in concrete more than 6 mm deep with a drill, even an impact drill. Therefore, to work on concrete, brick or stone, you need a hammer drill and high-strength drills.

To make large-diameter holes in concrete, brick or stone, a core drill with diamond coating or carbide teeth will help.

Drill bit for tiles/glass

Working with tiles/glass requires special care and, accordingly, special tools. For these purposes, tubular diamond drills (crown), as well as feather (spear-shaped) drills soldered with tungsten carbide or Pobedit, are used. The effectiveness of tools of these configurations is the same, however, for drilling large holes in tiles, it is better to use a crown, and for glass - a feather. To make large holes in the tiles, use a “ballerina” device. At minimum speed, drilling is performed from the back of the tile.

Universal drills

In addition to drills for narrow purposes, there are universal ones. They can be sold individually or as a set. Thanks to the special sharpening, such drills can process almost any material from wood to steel and ceramics. Most often this is a pobedite soldered tool. The packaging with a set of drills usually indicates what materials they are suitable for.

Types of coating

Additional processing of the external surface of the drill performs several important functions: it protects the tool from corrosion, strengthens the surface, improves heat transfer, and reduces friction. Let's look at the most well-known drill coating operations.

- Oxidation is the application of a black oxide film to the drill, protecting it from extreme heat and corrosion. This type of coating is the most common and inexpensive.

- TiN – drill treatment with titanium nitride. This technology increases the service life of the drill by more than 3 times, allows you to work with fairly hard materials, and reduces friction. But a drill coated with titanium nitrite cannot be sharpened, so as not to remove this hardening layer from the working surface.

- TiCN – titanium carbonitride coating. In terms of performance characteristics, it is close to TiN treatment.

- TiAlN – titanium-aluminum nitride coating. Increases the service life of the tool by five times or more.

- Diamond coating is the most durable coating available today. It makes it possible to drill holes in particularly hard materials.

Drill color

By the color of the drill, with some degree of probability, you can determine what kind of processing the tool was subjected to and what characteristics it has. Approximate correspondence between drill color and coating method is given in the table:

| Color | Image | Coating |

| Steel | No additional processing | |

| Black | Oxidation (treatment with superheated steam) | |

| Light gilding | After the vacation procedure | |

| Bright gilding | TiN, TiCN |

When purchasing drills, you need to pay attention to the uniformity of the tool’s coating and the absence of cracks, chips, or burrs.