Required Tools

Professional metal drills (for example, Bosch, Makita, Metabo or Hawera) are made exclusively from high-speed steel HSS. Some are coated with a protective layer, which increases their wear resistance when drilling.

Hand tools - drills and drill bits should be selected carefully. If you have no experience in this area, you should seek advice from a store employee. Purchasing an expensive, high-end drill does not always guarantee its long service life.

Compliance with the technology for making holes in metal and a correctly selected drill significantly increases its service life and protects against premature wear. Basic rules for operating cutting tools:

- Selecting the appropriate type of gimlet for drilling metal of a certain hardness. Many manufacturers have developed entire programs using which you can select the appropriate tool.

- Selecting cutting modes, setting the correct rotation speed.

- Correctly selected feed, application of appropriate pressure on the cutting tool.

- Application of cooling. An oil-based emulsion is recommended.

- Proper fastening of the material (for example, in a vice).

- Attaching the drill to the stand is precise and perpendicular.

- Use of an expanded set of gaskets when drilling through holes.

Technological process

Drilling is the process of removing small parts of the material being processed, chips, using a drill. During drilling, the temperature of the workpiece increases. The cutting force leads to damage, the friction force causes a change in the geometry of the cutting edge, plus high temperature, as a result the tool gradually becomes dull.

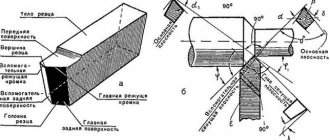

Most drills are made from high-speed steel with varying cobalt content. It is very important that it is sharpened correctly: the cutting edges are of equal length, the jumper between them is located along the axis of the cutting tool.

This ensures that both edges will perform identical work during the drilling process. The drill will not have runout, the hole diameter will correspond to the size, and heating of the part and the tool will be minimized.

A drill-drill with chamfer correction has a smaller jumper, due to this the cutting edges are lengthened. With such drills you can drill a hole without preliminary marking with a core.

The choice of drills depends on the type of work being performed . NWKa HSS Baildon drills are optimal for drilling:

- structural steel;

- cast iron;

- brass;

- bronze;

- aluminum;

- plastics;

- tree.

How to make a tapered hole in solid metal?

Most often, to obtain a cone in a product without a previously prepared hole, it must first be drilled. Moreover, the diameter of the drill chosen for this purpose must be less than the minimum diameter of the cone by at least a couple of millimeters. If the cone has a large slope, the hole will have to be drilled with ledges.

Preliminary machining of large cones on equipment is carried out as follows: first, take a drill of the largest diameter, which makes a shallow hole, then you should move to a drill with a smaller diameter and make the next ledge with it, and so on, until it reaches the smallest diameter.

When boring a hole, it is recommended to choose a cutter whose clearance angle should take into account the minimum diameter of the hole. It often happens that at the beginning of processing the selected tool copes with its functions perfectly, but at the end of the work the selected cutter angle may not be large enough. This results in friction between the hole surface and the tool, which is unacceptable.

Drilling metal

A special feature of the drills is the presence of a sharp edge, which allows for mechanical processing of the material. They have an equal diameter along the entire length, and the blade is sharpened at an angle of 118°. The sharpening angle varies depending on the hardness of the material, for example, for alloy steel, it is 135°. This type of drill is made of HSS steel with 5% cobalt. During operation, they require cooling with special drilling oil .

In order to drill a nozzle in metal evenly and accurately, it is necessary to use a guide device - a jig.

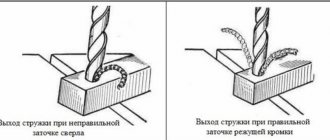

When drilling, it is best to use as little force as possible. When drilling a through hole, when the moment of exit of the cutting tool approaches, it is necessary to reduce the feed so that the part does not tear out, the drill does not break, or burrs do not form.

A conical drill is used to produce a conical hole in metal. It is used as an independent tool. They can drill a cylindrical hole, turning it into a conical one. A conical hole in the metal is made on a lathe in order to drill and bore the resulting nozzle with a cutter.

Cutting modes

The most common mistake is using too high a drilling speed . The more difficult the material to process, the lower the drilling speed should be used. For example, in the case of drilling an 8 mm hole in brass, the drilling speed should be 2500 rpm, for harder alloy steel - 800 rpm. The best sign that the drilling speed is correct is nice, long chips.

Depending on which tool to choose, cutting parameters are important. It is necessary to select the correct rotation speed and feed. Bench-top drilling machines provide the best parameters, but they cannot be used everywhere. It is necessary to follow the principle: the lower the speed and the lower the feed, the longer the tool will last.

For example, take stainless steel, 8mm hole, 4mm thickness, cooling lotion or oil, HSS drill bit, drill or drilling machine: The revolutions should not exceed 400 rpm, and the feed should not be more than 0.10 mm/ turnover In other words, you can drill at a speed no higher than 400 rpm. But this speed is not optimal. Therefore, it would be optimal, for example: 170 rpm, and the feed for every 30 revolutions is 1 mm (three times less than recommended).

Cooling the drill during the drilling process is very important. Use emulsions, oils, drilling sprays. Water should be avoided, as it does not have the properties of lubricating fluids, but only cools.

Large diameter holes

To the question of how to drill a large diameter hole in metal, there is only one answer: in the technological process of drilling necks . For example, you need to increase the neck and get a size of thirty millimeters in diameter. First, it is drilled with a tool of a smaller diameter, for example, four millimeters, then to a size of 8 millimeters, then 12 millimeters, and so each size is expanded to the result.

A large diameter neck in a product can be made on a lathe. The operation is as follows: drilling a hole, boring the neck of the desired size. As pre-drilling is required, the process can be divided into stages: small-diameter drilling, reaming with a gradual increase in drill diameter.

Drilling thin sheet metal

The peculiarity of obtaining an armhole in a thin sheet of metal is its reliable fastening . After the drill comes out to the other side, there is a danger that the sheet may suddenly jam and tear out if it was held in your hands. The best way to securely fasten a sheet is a clamp. In this case, the risk that the tin will be torn out is much less. The number of burrs formed is reduced, which will greatly facilitate the finishing of the element.

Read also: Circuit breaker cut-off current is

If the metal is 0.1 millimeter thick, you can make a hole without a drill by using a metal punching tool. Its design is very simple, like pliers. A punch is attached to one lever, and a matrix to the other. The principle is the same as cold stitching using a stamp.

To cut a through groove in sheet steel, you need to drill a successive row of holes according to size, connecting them into a single slot using a chisel and hammer. To do this, it is necessary to cut off the bridges between the holes and smooth out the unevenness with a file.

Metal pipes

When drilling a metal pipe, make sure that the workpiece is securely secured in the vise. It is advisable to mount the drill on a vertical stand. Insert a piece of wood of the same shape and size inside the pipe, which will protect the pipe from deformation. In this case, use low feed.

Getting narrow nozzles

Drilling deep holes of small diameter can only be done on a special machine or lathe using a device. The part is clamped into a 3-jaw chuck and checked for runout with an indicator. The device is mounted on a tool holder. A drill chuck with a drill is installed in the fixture. First, the hole is centered, then the nozzle is drilled to a given depth. Using a tailstock is problematic, since it needs to be constantly removed to remove chips and lubricant.

To obtain vertical holes, a right angle drilling device is used. For an electric drill, this is a vertical stand at an angle of 90 degrees to the base. The easiest way is to use a vertical drilling machine.

The working area of a cone drill (also known as a “step drill”) is a spiral-shaped recess with several annular transitions of different radii. This device, due to such design features, makes it possible to determine at any stage of processing what size the hole is.

At first it seems that the use of conical step drills, which are characterized by an increased price, is inappropriate, since it is always possible to take a drilling tool of a specific radius and use it to make the desired hole. However, they have some advantages that make their use worthwhile in a variety of situations.

Varieties

Different criteria are used to subdivide developments into types.

- Method of use: machine or manual.

- The shape of the hole being processed and its own configuration are conical or cylindrical.

- Fastening method: mounted or tail mounted.

- The arrangement of the cutting edges around the circumference is uneven or with a certain pitch, that is, uniform. The roughness of the machined surface directly depends on the design used.

Machine reamers (installed on machines) and manual reamers are structurally different. In particular, the second type of tool has elongated cutting edges located on the working part. And the shank has a square cross-section, which allows you to securely fix the manual reamer in the existing driver. Using a machine tool, you can deploy nests that are characterized by a sufficiently large depth. This is ensured by the following features:

- the working part is noticeably shorter;

- the neck, on the contrary, is longer.

You need to choose a suitable scan taking into account:

- diameter of the hole planned for processing;

- types of tools: machine or hand type; for what processing is it suitable - finishing-finishing or preliminary-roughing. In the latter case, when choosing, you need to be guided by the following numbers of the required allowance: finishing reaming - min 0.05 mm; max 0.10 mm; roughing operation – min 0.1 mm; max 0.15 mm.

More complete information on this issue is shown in the table. Numerical values are given in millimeters.

| Allowance for surgery | Hole diameters and corresponding allowances | ||||

| 100,0 | 50,0-75,0 | 30,0-50,0 | 18,0-30,0 | 12,0-18,0 | |

| Clean deployment | 0,1 | 0,08-0,1 | 0,07 | 0,06 | 0,04-0,05 |

| Rough deployment | 0,3 | 0,2-0,22 | 0,18 | 0,14 | 0,1-0,11 |

| Common value for both types of processing | 0,4 | 0,3 | 0,25 | 0,2 | 0,15 |

Scope of use, design

Conical drills have a long service life. This is due to high-strength cutting edges. The stepped tool makes it possible to carry out processing for which it would be necessary to use several ordinary drills. The high price of instruments in this group is mainly due to their versatility.

Twist drills with a conical shank make it possible to process parts at high speed. At the same time, the quality of the edge does not decrease at all. The product consists of the following elements:

- tip for preparatory drilling;

- transition with a bevel to eliminate burrs;

- cutting edge that widens the holes.

With a cone drill it is possible to make holes not only in metal, but also in plasterboard, wood, plastic, and other parts. The pointed end of the tool makes it possible not to use a centering device and can easily enter even dense material. The resulting hole does not need to be further processed using a needle file or grinding device.

The progressive recesses of the device, which are arranged in a spiral, are made in various sizes with a smooth transition. This design increases the efficiency of processing thin-sheet material with a twist drill with a conical shank by approximately fifty percent. Conical tools can be used both manually and when mounted on special equipment.

An abrasive consisting of diamond/titanium particles can be applied to the working area of a two-stage drill. There is no contradiction with the rules of GOST (state standard). This coating makes the cutting edges much stronger. Thanks to this, the conical drill does not need to be sharpened often. Of course, it is necessary to follow operating rules and not subject the tool to excessive loads.

A step drill for metal is often used to correct inaccuracies made when processing a part with another device (for example, torn edges). A product with a conical shank is indispensable if you need to drill holes in thin sheet material or fiberglass parts. The versatility of step devices allows us to say with complete confidence that they will definitely come in handy both in production and in your workshop.

Exploitation

Step drills are optimally suited for drilling holes in tubular products, sheets of steel and non-ferrous metal, and plastic workpieces. Their use allows you to perform several procedures in 1 pass. When making a pass, the burrs are cleared, holes of various sizes are centered and drilled. Cone tools have a special tip, thanks to which they do not slip/slip even on significantly protruding areas.

Experts say that using step drills is very convenient. When using them, various auxiliary items are not required. There is also no need for additional alignment. An ordinary drilling device can go sideways when processing a part. Because of this, the hole will be made unevenly, and additional alignment will have to be done. The conical shank does not deviate anywhere when drilling, the hole is made evenly and smoothly.

How to choose?

It is necessary to choose a drill with a conical shank only after you know its basic parameters. You can learn a lot about an instrument by paying attention to its shade.

- A gray tint indicates that the tool has not been heat treated and is therefore of low quality.

- The dark shade indicates that the drill was processed with hot steam and is quite durable.

- The golden color indicates that there are no internal stresses in the drill material. This ensures improved performance.

- The bright gold color means that the tool is very wear-resistant. This is due to titanium nitride, which is contained in steel. The rather high price of such drills is explained by the long operational period.

To make a drill with a conical shank, different types of metal are used. The material is indicated in the labeling. If a drill is marked with HSS, it means it is capable of processing a part at high speed without deforming. Also, its strength does not decrease with strong heating.

When choosing a step drill for metal, you need to take into account the following characteristics:

- radius. The determining factor here is the size of the holes you plan to create;

- manufacturer. The performance indicators of the product and its price depend on it; compliance of the purchased tool with GOST;

- the ability to sharpen the product many times. Here you need to rely only on your preferences and skills.

Read also: Acid for soldering at home

Recommendations when choosing a product

Cone drills are expensive, so when choosing them, you need to study all the characteristics. According to state standards, high-quality products are made from high-strength alloy steel in the range of the following parameters:

- with diameters from 5 to 80 mm;

- working cone length – from 58 to 85 mm;

- tail diameter - from 6 to 12 mm.

The color of the metal as an indicator of its strength

An important characteristic of a product is the color of the material from which it is made. The color of a step drill indicates its quality

The color of a step drill indicates its quality

The gray color of the cone drill with a steel tint indicates that the steel has not been hardened. Consequently, the product is not of high quality and will not last long.

Hot steam treatment makes the steel more durable; products made from such steel have a significant service life and are distinguished by a black color.

Conical products of golden color are made of higher quality metal, in which residual stresses are eliminated. They are more durable and comfortable to use.

Elements of a brighter golden color have high wear resistance. They are coated with titanium or diamond coating, which significantly increases their service life. The long working life explains the high cost of the products.

How to sharpen it yourself

Cone drills provide the ability to drill holes with a radius from 0.2 to 1.6 cm. They are manufactured in 2 versions. One of them can be sharpened, the other cannot. The increased price of tools that belong to the second type is due to their high strength.

The cutting edge of such drills (if you follow all operating rules) does not deform for a long time. It is worth noting that an attempt to sharpen such drills for metal will most likely lead to them becoming unsuitable for subsequent use. First, you should study the technology of sharpening a conventional drill, and then take on a similar tool.

To properly sharpen a drilling tool, you need to watch a special video and listen to the advice of professionals. To sharpen a step drill, you do not need a drawing. You can simply restore the original geometry of the drill.

It is possible to sharpen a step drill using a special machine device that is equipped with an abrasive wheel. The working area of the circle should be covered with ordinary sandpaper. In addition, you can use diamond stones of small thickness, which are often used for sharpening knives, scissors, and other objects.

Restoring the geometry of conical tools, the guide recesses of which are located rectilinearly, can be done manually. If they are arranged spirally, it is necessary to use a sharpening machine device. Remember that the better the quality of the drilling tool, the easier it is to sharpen it.

Instrument care

Industrial plants use various types of cone drills. The consumer can choose the necessary tool for working with different materials:

- when processing materials with high strength;

- drilling of alloys of different metals;

- processing of plywood, wood and plastic products.

After finishing using the tool, it must be cleaned of dirt and residues of the material being processed, and then lubricated with a special product.

Self-sharpening

When sharpening the drill used, you must follow the instructions and also have initial skills. To restore the cutting surface of straight grooves, it is recommended to use diamond grinding stones. Spiral edges are sharpened using high spindle speed machines.

Restoration occurs faster for products with high quality workmanship; it is recommended to use machines with a wheel made of abrasive material and sandpaper.

The use of such a tool will facilitate the work and also satisfy the consumer with a high-quality hole.

Where to buy normal metal drills. Chinese drill test

Watch this video on YouTube

Price, selection tips

If there are no difficulties with the acquisition of ordinary spiral tools, the landing area of which is made in the shape of a Morse cone, then with a conical product the situation is somewhat different. Its price depends on 2 key characteristics: working size and the metal from which it is made.

A buyer who intends to buy two-stage drills may be confused by the widely varying prices. To clarify this issue, we need to consider price examples. Drills designed to create holes with a radius of 0.2 to 1 centimeter have a fairly low cost (400-500 rubles). Russian conical tools, which allow you to create holes with a radius of 0.2 to 1.5 centimeters, cost almost 2 times more (one thousand one hundred rubles).

The price of a product greatly increases if it belongs to a popular brand. For example, the cost of conical drills from, the radius of which is from 0.2 to 1 centimeter, is equal to two thousand nine hundred rubles. A device that makes it possible to create holes with a radius of 0.3 to 1.9 centimeters costs about five thousand rubles. You can also purchase a set of Bosch drilling tools, which allows you to drill holes with a radius from two to fifteen millimeters. It will cost approximately ten thousand rubles.

Many companies that sell conical devices provide them at a fairly high cost, without in any way confirming their high quality. When buying a drill from such companies, as well as from those that provide tools at a low price, you need to prepare for the fact that the product parameters will be far from ideal. In view of this, you need to purchase tools only from those organizations that have all the required certificates. In addition, it is worth considering how the tool is marked. Products that have indicators that meet the requirements of GOST and have the necessary certificates must be marked accordingly. So, if you want not to make a mistake when choosing a drilling tool, carefully study the markings of the drills. This will allow you to buy a product that best suits your needs.

We also recommend reading:

A good craftsman should know what smooth conical and stepped metal drills are intended for. If this is the first time you’ve heard about this type of cutting equipment, then it’s time to understand the purpose, types and design features. Step cone drills replace a series of cutting attachments, so having the equipment is always useful.

Selecting a cone drill

The ability to read markings is a key skill for all craftsmen, and conical drills are no exception. The marking indicates the diameters of the holes that the nozzle can make, the step pitch and the length of the product. It also provides information about the metal from which the device is made. For example, the marking Ø4−12/2 HRC 61±2 should be interpreted as follows:

- Ø4 - initial diameter;

- Ø12 - final diameter;

- 2 — pitch of step drill diameters (with the given parameters, it is possible to make holes Ø4, Ø6, Ø8, Ø10, Ø12);

- HRC - steel grade (in the example this is high-quality high-speed steel);

- 61±2 - Rockwell hardness.

Pay attention to the length of individual steps and/or the total length of the working surface. The type of shank plays an important role - the compatibility of the cutter with drilling equipment depends on it. Shanks can be cylindrical, conical or hexagonal.

Cone drills are made from more than forty different grades of steel. The average consumer does not need to understand all the differences between them; it is easier to remember the abbreviation HSS. Its presence means that the drill can be used in high-speed processing, and during intense heating it will not deform or lose its strength characteristics.

Having decided on the geometric parameters and material of the nozzle, they look at its color. And this is not a matter of aesthetics, since the color determines what additional processing the product has undergone at the factory:

- The surface of a bright golden color indicates the presence of an abrasive coating, usually titanium nitride (TiN, AlTiN). Spraying significantly extends the service life of the drill (by 25 and 50 percent, respectively), but you will have to pay for increased wear resistance.

- Golden color means that the metal is free from internal stress.

- The black tool is treated with steam, its strength is increased.

- Gray-steel cutters are not subjected to additional processing; other things being equal, their service life and performance characteristics are inferior to the first three types.

What is a cone drill and what are they for?

A cone drill is an attachment for a power tool, consisting of two parts - a cone-shaped tip and a cylindrical or hexagonal shank. Devices are classified into two types - smooth and stepped. A smooth conical drill has a wall shape corresponding to the design, and a stepped drill has the shape of steps.

Cone-shaped elements are used for drilling round holes in different materials - metal, wood, plastic. For such purposes, cylindrical drills are used, you say. So why are cone devices needed? They are used for drilling holes in sheet steel, as well as similar structures made of non-ferrous metals - aluminum, copper and brass. The presence of one conical drill replaces a whole set of cylindrical cutting devices - this is the main difference.

Differences between a smooth conical and a stepped drill

Before we find out the scope and advantages of cone devices, let’s look at their varieties. Smoothing elements in the form of a cone drill thin sheet steel, gradually increasing the size of the hole. To drill a hole of the required diameter with such a drill, you need to periodically stop and take measurements. Some manufacturers of smooth-bore cone drills eliminate this drawback by applying digital markings.

Stepped elements allow you to drill a hole with greater accuracy due to the presence of degrees. When drilling, there is a smooth transition through the steps, and as a result, the operator can easily track what diameter the hole has. It should be noted that cone drills are quite expensive. Their price ranges from 2 thousand rubles or more. It all depends on the material of manufacture, as well as the size of the holes being drilled. Many people may think that cone devices are completely useless equipment from China until they test the cutting tool in action. Craftsmen openly declare that if frequent drilling of thin-sheet materials is necessary, it is recommended to use conical cutting attachments.

Where are cone drills used?

Cone drills are used for drilling holes of different diameters in thin sheet materials. Moreover, the resulting holes are distinguished by such advantages as evenness and accuracy without scoring, chips or burrs. You can drill through thin-sheet material with a regular cylindrical drill, but the quality of the work will suffer and the task will also become more complicated. For example, the slightest deviation of the drill from the surface will result in a triangular or oval hole rather than a round one. In addition, burrs, scuffs and chips are formed, which ultimately negatively affects the quality of the work performed.

Read also: Wearing machine price video

The use of conical drills can significantly simplify the work, eliminating all the disadvantages of cylindrical devices. Due to its advantages, the equipment has found its application in various fields:

- Automotive and repair

- Landscape design

- Construction

- Installation of plumbing equipment

- Installation of electrical installations

The device is not effective in situations where you have to drill holes in materials whose thickness is more than 10 mm.

What are the advantages of cone drills?

Like all types of cutting tools, cone drills have their own characteristic advantages. The advantages of using the devices in question include:

- Possibility of drilling holes of different diameters using just one nozzle

- Wear resistance - unlike cylindrical elements, conical elements have a long service life. The cutting edges of the nozzles have high strength values, so the device wears out very slowly

- Speed - the nozzle allows you to quickly drill holes, which has a positive effect on its service life. The cutting edges do not have time to heat up, so their quality does not decrease

- There is no need to pre-punch the material, since the tip of the cone drill easily cuts into any metal, even with a dense structure

- At the same time, it plays the role not only of a tool for drilling holes, but also as a grinding material

- Improves the quality and efficiency of drilling thin sheet material

- Eliminates the possibility of deformation of the drilled sheet, which is associated with a smooth transition with increasing diameter

- Possibility of using the attachment not only on stationary drilling equipment, but also on drills

- The presence of abrasive coating increases the strength and efficiency of the equipment. Cone drills can be coated with titanium or diamond

- Does not require frequent sharpening

Cone drills make it possible to drill large-diameter holes, thereby eliminating the need to use metal crowns. This type of cutting attachment is suitable not only for drilling holes in sheet materials, but also corners, pipes, profiles, etc. The main condition is that the thickness of the steel should not be more than 7 mm, and ideally no more than 4 mm.

Stepped types of nozzles are classified according to the type of edge into spiral and straight. The straight edge design has the advantage of being easier to sharpen than the spiral edge design. Spiral types of edges are characterized by softness and smooth movement of the drilling device.

Self-sharpening

Only the cutting edge (groove) is sharpened. It is prohibited to sharpen the transitions of step drills, as this leads to a change in the geometry of the working surface and the formation of burrs during operation. Improper sharpening leads to a decrease in the quality of the tool, often to complete unusability.

The long service life of conical drills requires periodic re-sharpening. At home, drills with a straight translational groove are the easiest to use. This is done manually using abrasive rods, diamond stones for knives or sandpaper.

Any home craftsman needs to know how to sharpen a step drill for metal with a spiral flute. The process requires the use of sharpening machines, on which the drill is directed so that the abrasive wheel passes exclusively in a spiral. For simultaneous smooth rotation, special devices are used; feeding the drill manually is highly not recommended.

What you need to know to choose a cone drill

In shape and design, conical drills differ significantly from cylindrical ones. Like cylindrical devices, conical devices are similarly fragile and require careful handling. To select cone devices for the appropriate work, you must consider the following recommendations:

- Attachment color - if you are choosing a core drill, then you are probably presented with models that differ in color.

If the seller says that there is no difference between the devices, then he does not understand this. The black part indicates that the nozzle has undergone additional heat treatment. Such devices have a long service life. The golden color means that the nozzle is coated with titanium nitride, which increases its strength properties. Steel-colored products do not have any coating, and they are not subjected to heat treatment, therefore, compared to previous options, they last the least - Marking - indicated directly on the outside of the equipment (on the shank).

By the marking you can understand what the nozzle is made of, as well as its diameter and accuracy class. Often the marking begins with a letter designation, and begins with the letter “P”. This letter indicates that high-speed, high-strength alloy steel is used to produce the cone drill. After the first letter, the second letter with a numerical value is indicated. The number indicates the percentage of the alloy, for example, M - molybdenum, F - vanadium, K - cobalt, A - nitrogen. The marking also contains the designation of the minimum and maximum diameter, as well as the accuracy class. Equipment with a diameter of up to 2 mm is not marked. The drill may be marked HSS type, which means high-speed steel

The marking after the HSS designation may also indicate additional information:

- HSS-E is a high-speed steel, which is an analogue of the domestic material P6M5. Designed to work with low carbon steels and cast iron, as well as hard alloy and stainless steel devices

- HSS-Co - 5% cobalt is added to the alloy

- HSS-G TiN - sustainable materials for processing titanium products

To work with conical drills, stationary drilling machines or two-handed drills are used. How to properly drill holes with cone drills is described in detail in the material.

Taper drill set for 3-30mm holes: better than step drills

Recently, step drills have become popular, allowing large diameter holes to be made in one go. Their main advantage is drilling diameters up to 20...30 mm, without replacing the drill and without preliminary preparation (without drilling with a smaller diameter). There are large step drills with diameters up to 50 mm (!). True, there are also disadvantages to similar ones - they are difficult to sharpen, you need to be able to work with them correctly. But today I will tell you about another model of similar equipment - these are stepless conical drills.

Set of cone drills (3 pcs, 3-30 mm)

Set of step drills (5 pcs, 5-35 mm)

Characteristics: Lot: set of drills Type: cone drills Purpose: drilling large holes in metal without preparation Material: high-speed tool steel HSS 4241 Dimensions: 16-30 mm / 8-20 mm / 3-14 mm Shank: 10/8/6 mm

Cone drills are much more convenient than step drills, primarily due to the smooth transition of diameter. The edges of the hole are smooth, without burrs. The review will include a set with diameters for holes of 3-30 mm. By the way, such equipment is suitable not only for processing products made of wood, plastic and aluminum, but also for various types of steel.

We recently talked about accessories for Dremel, and today we will talk about a set of drills for metalworking. I won’t go into detail about specific application cases, I’ll just note that drilling several 1/2″ holes in an electrical distribution cabinet for input seals with similar drills is just a fairy tale. Depending on the required diameter, we select a specific drill. There are three pieces in the lot with diameters of 16-30 mm, 8-20 mm, 3-14 mm. The declared high-speed steel is HSS 4241, approximately equivalent to our high-carbon tool steel R2AM3.

The photo shows a small cone drill with an initial diameter of 3 mm and a final diameter of 14 mm.

Pay attention to the cutting edge. This is a sharp, smooth edge that you can sharpen yourself or remove burrs if you wish.

The drill shank is truncated, for jaw chucks, diameter 6 mm. The shank is marked with cone diameters: 3-14 mm.

The next largest drill is the average 8-20 mm.

At the tip of the cone, a pronounced “approach” is clearly visible - a sharpened part for drilling into the material.

The shank of this model is already larger, 8 mm, also truncated for cams. Marking 8-20 mm.

The largest drill from the set is a large cone of 16-30 mm

There is also a sharp approach, the cutting edges are wide.

The shank is already larger here, by 10 mm. Marking 16-30 mm.

The length of the shank varies, depending on the size of the cone.

Approximately 2.5 cm. This is enough to securely clamp into the drill chuck.

Shank diameter measurements: 6 mm for the small one, 8 mm for the medium one and 10 mm for the largest one.

The measured maximum cone diameter practically coincides with the declared one. This means that you should not try to drill a 14mm hole with the smallest drill bit.

It is better to take a larger drill (medium), which will give the desired result. The situation is similar with the medium and large cones. True, for specific application purposes such diameters are sufficient - these are inputs of 1/2″, 3/4″, or 1″. There's plenty to spare.

For comparison, I am using a small step drill from the kit. The yellow coating is titanium nitride, which is supposed to increase the durability and strength of the drill. A selection of other sets of equipment and tools.

Step drills were convenient until I discovered similar cone drills. Cone drills give high-quality results, smooth, not ragged, edges of the hole.

If necessary, conical drills can be sharpened independently - the cutting edge is available for processing. For those who love step drills, try sharpening them. Every step. On one's own))))

Getting ready for a little test with a Milwaukee cordless drill (Review). By the way, this drill recently appeared in a comparison review with Makita.

I immediately sweep wood, aluminum and other plastics aside - only hardcore, only corrugated pipe 40x40x4 mm.

A corrugated pipe is a serious test for equipment, especially if it is not a pair of holes, but an array that finishes off the drills immediately.

In the photo, the drill enters with virtually no pressure, simply under the tool’s own weight.

The result is excellent - smooth holes are obtained without burrs, without torn edges. There is one caveat - the hole for the thread will need to be turned out, since the profile of the resulting hole is conical. This is the specificity of this equipment. It is not necessary to deploy for other types of connections.

The cutting edge was not damaged after several holes.

Similar cone drills work with any drills and screwdrivers, but if you are drilling serious workpieces, then you need to take care of the power of the tool.

The photo shows a Metabo BE 850-2 drill with a power of 850 W and brush reverse.

In general, these cone drills “plowed” the work shift without any comments. If we compare it with conventional ones, then to drill a grid of holes in a corrugated pipe, it was necessary to go through all the holes with several diameters in 2-3 permutations, and this is about plus a couple of hours. You can, of course, have 2-3 screwdrivers with different equipment numbers installed, but this option is extremely rare. A step drill does not produce the required hole quality. But the conical one is just what was needed.

Of course, there are also disadvantages to such equipment: firstly, it is difficult to catch exactly the required diameter, unless you mark the depth directly on the drill, or “teach your hand”. Secondly, these are the walls of the resulting holes on a cone, which does not make it possible to immediately cut a thread and requires additional expansion of the hole. Otherwise, this version of the equipment turned out to be of high quality for the money (three pieces for $9 in total), durable and suitable for heavy work. As for durability, it is enough to periodically sharpen the edge, and such drills will last a long time.

As for this lot, it’s common among many, the delivery is fast (if in the current situation we can talk about speed), the packaging is symbolic. Good price for a lot of three.

The Chinese continue to amaze with their new equipment; I will try to show more reviews of useful tools in the near future.

How to properly drill holes with a cone drill instructions

To learn how to drill correctly with cone drills, you must first prepare the necessary tools and materials. For work you will need the following materials and tools:

- Blank for drilling. These are sheet steel, plastic, glass, wood, etc. The workpiece must be securely secured in the jaws of a vice or a clamp.

- Drill - any power tool that can develop a rotation speed of 3-5 thousand revolutions per minute is suitable. In this case, it is recommended to attach an additional handle to the drill, which will avoid distortion. Drilling is performed in non-impact mode

- Cone drill of suitable diameter. Depends on the hole that needs to be drilled in the workpiece

After this, we proceed to the actual work. The drilling instructions are as follows:

- The nozzle is fixed in the tool chuck

- Select the location where you want to drill a hole

- The tool is applied to the surface being processed strictly in a perpendicular direction

- The tool motor starts. The first seconds of drilling into metal help center and cut a small hole. As soon as the drill begins to go deeper into the hole, the diameter increases with each subsequent revolution. At the same time, the speed of work execution increases

- The end result is a neat hole without chips, burrs or other defects.

It is enough to try the attachment in action once and then stop using cylindrical drills when processing sheet materials. How a conical drill shows itself in action when drilling plastic, plexiglass, metal and other materials is shown in the video clip.