If you buy good pipes, the sewer system will last for decades. In the article we will tell you how and which pipes to choose.

Three factors play a role in pipe selection: material, pipe location, and fittings. The material of the pipes determines their reliability and durability.

Depending on the location: for external and internal sewerage, the requirements differ. External sewerage - underground on the street. The inner half goes underground and half comes from toilets, sinks and showers throughout the house.

The availability and range of fittings have a lesser influence on the choice of pipes, but they determine the ease of installation of the sewer system. Let's first consider two types of sewerage: internal and external.

External sewerage

The external sewer system runs underground on the street and carries wastewater to the septic tank. Pipes for external sewerage can withstand static and dynamic loads:

- soil pressure,

- movement of people

- traffic,

- groundwater movement,

- temperature changes,

- humid environment,

- aggressive environments.

Dynamic loads. These are all variable loads: movement of cars and people, movement of groundwater. Pipes with high ring stiffness can withstand dynamic loads well.

Static loads. These are loads that constantly put pressure on the pipeline: soil pressure. Products with high ring rigidity also resist pressure well. Static loads also include others; we will consider them separately.

Temperature changes. The most dangerous are cold snaps, since many pipes can withstand 30-degree heat, but cannot cope with 30-degree frost.

Therefore, sewerage pipes are placed below the freezing level of the soil and are made frost-resistant. The freezing level is different for each region. For the Leningrad region, for example, 1.16−1.71 meters - depending on the type of soil.

Wet environments. High humidity in spring and autumn destroys ferrous metals without anti-corrosion coating and some other materials. Groundwater movement can dislodge the pipeline if it is not installed correctly.

Aggressive environments. These are acids, salts and alkalis that are found in soil and wastewater. Therefore, pipes inside and outside must be resistant to various substances.

Internal sewerage

Internal sewerage runs in the house itself and is connected to the external one under or through the foundation. For the internal pipeline, rigidity is not so important; the load on it is several times less. But other general requirements remain:

- Durability. Nobody wants to change the pipeline every two or three years. Especially when there are materials with a service life of 50 years or more.

- Easy replacement. To replace old sewers, major repairs are carried out. It is better if the pipeline can be easily replaced in case of breakdown.

- Soundproofing. Pipes for internal sewerage must isolate the sounds of sewage movement from the inhabitants of the house.

- Ease of installation. Some plastic pipes can be easily installed by a non-professional. The easier the installation, the faster the sewer construction takes place.

- Non-toxic. Pipes must be non-toxic and not release toxic substances upon contact with wastewater.

- Smooth inner surface. The sewer will silt and become clogged if the inner walls of the pipes are rough.

In addition, the internal and external water pipes must be easily connected to each other. If they do not connect well, the joint between them will become clogged or leak. This is especially important when partially replacing the pipeline.

Go ahead. Let's consider which pipes are most suitable for sewer systems:

- PVC pipes,

- PE pipes,

- PP pipes,

- asbestos-cement,

- concrete,

- cast iron,

- ceramic.

Dimensions and applications

What are the dimensions of sewer plastic pipes?

For PVC, the standard provides for a range of diameters from 10 to 630 mm. However, as we remember, the standard applies to all uPVC pipes; It is for sewerage that sections of 32 mm and above are used.

Polypropylene is limited by the capacity requirements of internal waste systems and is produced with a cross-section of no more than 110 mm; in any case, the author has never come across polypropylene pipes with a cross-section of 150 millimeters or higher.

Polypropylene sewerage is produced with a diameter of 40 - 110 mm.

Sewage pipes made of polyethylene have plastic dimensions, as we remember, according to GOST 22689; but not only for him. On sale you can find sections up to 1200 millimeters inclusive.

It’s interesting: the thickness of the walls of these pipes allows them to be connected not only with couplings with rubber seals, but also by butt welding.

Where and what sections are usually used?

- 32 and 40 millimeters are outlets from sinks, bidets and washbasins. Considering the tendency of sewers to become overgrown with grease, it is undesirable to use such sections for sinks; In fact, you can’t find the corresponding products on sale everywhere.

- 50 millimeters is the diameter with which internal sewerage is most often laid to all plumbing fixtures, except toilets. The list includes: bidets, bathtubs, shower cabins, washbasins, sinks, etc.

Since several plumbing fixtures are extremely rarely used at the same time, the use of large diameters is rarely justified even where, for example, there is a shower stall, bathtub and washbasin on the same branch of the drainage system.

In some projects of old houses, 50 mm pipes were even used for sewer risers connecting kitchens.

- 110 mm is the most common size for outlets from toilets and risers. He also performs discharge to a well or septic tank in private homes.

- 150 mm is the typical size for drainage pipes (horizontal branches that combine several risers in apartment buildings) and sections of the drainage system between wells within the same house.

- 200 - 300 millimeters is the typical diameter for areas between individual houses and the collector. Large diameters are used for the collectors themselves.

Manifold gasket with polyethylene pipe.

PVC pipes

PVC or uPVC - polyvinyl chloride, a new polymer material. PVC pipes are lightweight, environmentally neutral and easy to install.

Advantages:

- long service life,

- no overgrowth,

- resistance to acids,

- wear resistance,

- ease.

Flaws:

- inoperability at temperatures below −10°C,

- deform (elongate) at temperatures above 60°C.

Gray PVC pipes are excellent for indoor sewerage, where they are used. Red PVC pipes for sewerage with hardness SN-4 and higher can be used for external pipelines.

To connect, the pipes are inserted into each other: at one end of the pipe there is a socket with a rubber ring, and at the other there is a chamfer that is tightly inserted into this socket. The inner surface of PVC pipes is perfectly smooth, so they rarely become clogged or overgrown.

Such pipes should be buried deeply, otherwise they will freeze. Also, you should not drain liquids with a temperature above 60°C through them for more than a minute. For a short time they can withstand temperatures exceeding 95°C.

Cast iron pipes

Cast iron pipes for sewerage

When listing the types of metal pipes used for installation of sewerage systems, one cannot fail to mention products made of cast iron. Since cast iron pipes have been the main material for assembling sewer networks for decades. The main advantages of this material are:

- Durability and long service life;

- Corrosion resistance.

The disadvantages of the material include:

- Heavy weight, which makes it difficult to transport the material and install it.

- Relatively high fragility. Cast iron pipes do not withstand shock loads well.

- It is impossible to use for laying an external pipeline in saline soils, since soil brine quickly destroys the material.

- Rough inner surface, which causes pipes to clog faster.

Advice! Today, manufacturers produce improved pipes made of cast iron with a polymer coating. As a result, the pipes acquire ideal smoothness of the inner surface and increased resistance to corrosion.

Asbestos cement pipes

Asbestos-cement pipes

For the production of such pipes, a mixture of asbestos fiber and Portland cement is used. Advantages of these products:

- Resistance to corrosion processes.

- Simplicity of machining, which greatly facilitates installation.

- Long service life.

- Smoothness of the inner surface.

- Asbestos cement is a dielectric, so this material is not subject to electrochemical corrosion.

Asbestos-cement pipes have disadvantages, these are, first of all:

- Fragility of the material. When working with pipes made from asbestos cement, you have to be extremely careful and careful.

- Under the influence of soil, the outer surface of the pipes quickly collapses, so protective measures must be taken.

Ceramic pipes

Ceramic pipes for sewerage

Ceramic pipes are similar in properties to cast iron pipes, however, they are lighter and one hundred percent resistant to corrosion. The undoubted advantage of ceramic pipes is their resistance to high temperatures and aggressive environments - acids and alkalis.

However, the material is quite fragile, so you need to handle the pipes carefully during loading, transportation and installation. In addition, mechanical processing of pipes (cutting) is difficult; if you try to cut the pipe, it may simply split.

Pipes made of polymer materials

PVC sewer pipes

Today, various types of plastic pipes for sewerage are widely used. For the manufacture of such products, three types of polymers are used:

- Polyvinyl chloride.

- Polypropylene.

- Polyethylene.

PVC pipes are designed for gravity sewer systems. The material is quite durable and can withstand high loads. PVC pipes are widely used for the installation of external systems, as they are inexpensive, can withstand aggressive environments, and are resistant to ultraviolet radiation. But pipes cannot withstand exposure to temperatures above 70 degrees; at very low temperatures, PVC becomes brittle, so it is recommended to insulate them.

Advice! It is not recommended to use PVC pipes for internal pipelines. The fact is that when ignited, this material releases extremely poisonous phosgene gas.

Various types of polypropylene pipes are widely used for assembling sewerage systems. These pipes have a long service life and can be used for both gravity and pressure systems.

It is necessary to distinguish between the types of propylene pipes intended for internal and external pipelines. The first type of pipes was created for use at home; they are quite durable, but are not able to withstand the effects of low temperatures and loads exerted by the soil.

Plastic internal sewer pipes

For external pipelines, special types of pipes are produced - two-layer ones. Their inner layer is perfectly smooth, and the outer layer is corrugated, so the pipes are characterized by increased strength.

When assembling sewerage systems, different types of polyethylene pipes are increasingly used. This material is mainly used for the installation of non-pressure systems. The great advantage of this material is its high elasticity; when the liquid in the pipe freezes, the polyethylene does not collapse, but only deforms.

Metal-plastic pipes

For the assembly of various systems, including sewerage systems, different types of metal-plastic pipes are widely used. These pipes are coated with plastic, so they are one hundred percent corrosion resistant, chemically neutral and fairly easy to process.

At the same time, the presence of a metal core gives these products increased mechanical strength. The disadvantages of the material include their rather high cost.

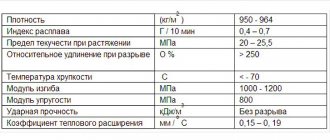

PE pipes KORSIS and KORSIS Eco

Polyethylene is another polymer. KORSIS and KORSIS Eco pipes are made of high-density polyethylene (HDP) and an external corrugated layer is added. It increases ring rigidity, so the products are suitable for external sewerage.

Advantages:

- durability,

- ease,

- elasticity,

- frost resistance down to −60°C,

- resistance to acids and alkalis,

- soundproofing,

- polished inner surface.

Flaws:

- sensitivity to sunlight,

- maximum temperature of the transported substance: 80°C.

Pipes made of high-density polyethylene, unlike PVC, tolerate low temperatures. At the same time, they are also lightweight, elastic and more reliable for external pipelines.

sells polymer pipes made of PVC and high-density polyethylene. SIS is the official distributor of the Poliplastik Group, a manufacturer of plastic pipes for sewerage, water supply, and heating. SIS sells products from the Polyplastic Group at prices from the manufacturer, and also helps you choose material for pipelines.

Materials for piping elements

To organize sewerage systems, structures made of different materials are used:

They are durable and resistant to corrosion, but they are difficult to install and carry out logistics.

Ceramic products- Cast iron pipes have remained popular for many years. The material is suitable in all respects for installing a sewerage pipeline. Cast iron is durable and not subject to corrosive changes. The tightness of the joints is ensured by casting. To increase the quality of connections during installation, caulking is used.

- Plastic pipes are increasingly replacing products made from other materials. Lightness of products, strength, reliability, durability, ease of installation - all this distinguishes plastic pipes. The main method for installing the structure is the socket method.

Dimensions of sockets for sewerage inside the house:

- pipes serving as outlets must have a cross-section of fifty millimeters.

- the socket for the fan pipe or riser must have a size of one hundred or one hundred and ten millimeters.

- the socket leaving the house towards the septic tank is equal to one hundred, one hundred ten or one hundred fifty millimeters.

PP pipes

Polypropylene or PP pipes are also a new plastic building material with high strength values.

Advantages:

- resistance to high and low temperatures,

- durability,

- ease,

- resistance to acids and alkalis,

- strength,

- ease of installation.

Flaws:

- instability to temperatures above 80°C.

The disadvantages of PP pipes relate to temperatures above 95°C and work with fire-hazardous objects. High temperatures have a bad effect on polypropylene, as well as on other polymer materials.

In general, this material is excellent for any sewer systems. PP pipes are used for storm drainage, in private houses and apartment buildings due to their strength and wear resistance.

Diameter selection

When deciding what and how to install a sewer system in a private house, special attention should be paid to the correct choice of pipe diameter for it. For the riser and street area, it is recommended to take products with a cross-section of 100–110 mm, and for bends to plumbing fixtures, 40–55 mm is enough. But here a lot depends on the volume of wastewater, the length of the pipelines and the number of connected plumbing fixtures. Ideally, it is necessary to prepare a project with a full calculation of the amount of wastewater. However, for small cottages the above figures are quite sufficient.

You should not use pipes that are too wide for the installation of internal sewerage, as they will clutter the space of bathrooms and kitchens. At the same time, there is zero benefit from such “breadth”. And narrower options than the recommended ones are dangerous due to constant blockages. This is definitely something no one needs.

Recommended pipe diameters for the home sewer system

The same electrical wiring in an apartment or house also does not tolerate wires that are too thick or too thin. Each electrical appliance must have its own cable with a rated cross-section; sewerage in a private house at this point is no different from the electrical network.

Asbestos cement pipes

Asbestos-cement pipes are durable, which is why sewer pipelines are made from them. Cement and asbestos fiber are not destroyed by rot, acids or corrosion.

Advantages:

- cheapness,

- durability,

- resistance to acids, alkalis, aggressive environments,

- strength,

- ease of installation,

- resistance to clogging.

Flaws:

- fragility, instability to mechanical stress,

- harm to people and the environment.

Given their low cost and durability, asbestos-cement pipes are not the best option. They are more difficult to transport and install than polyplastic - the weight is higher than that of polymers.

Also, asbestos cement crumbles at the edges, which is why the tightness is compromised if the connections are incorrect or of poor quality. The most dangerous, especially for internal connections: the environmental damage of asbestos concrete. Asbestos releases carcinogens; it is dangerous to work with and live near it.

Concrete and reinforced concrete pipes

This is heavy artillery. This sewage material is used in industrial buildings: factories or wastewater treatment plants.

Advantages:

- resistance to mechanical loads,

- durability,

- resistance to corrosion,

- cheapness.

Flaws:

- heavy weight,

- complexity of installation,

- rough inner surface.

Concrete is a cheap, durable and sustainable material. But using it for the construction of a private home sewer system is unjustified: it is unlikely that there will be such high loads there, except perhaps for organizing a septic tank.

But transportation and installation of pipes will be expensive and take a long time. For example, the installation site is prepared: the soil is additionally compacted. Concrete and reinforced concrete are suitable for the construction of septic tanks. Concrete rings are strong and durable, so the septic tank most likely will not have to be replaced for several decades.

Cast iron pipes

Cast iron pipes are divided into gray cast iron and ductile iron materials. Gray cast iron does not resist dynamic loads well: for example, cars passing over a sewer line. Malleable cast iron perfectly withstands any load and, unlike other ferrous metals, does not rust.

Advantages:

- high strength,

- durability,

- resistance to low and high temperatures,

- simple installation,

- corrosion resistance.

Flaws:

- heavy weight,

- roughness of internal surfaces,

- instability to salts and saline solutions,

- high price.

To bring and install cast iron pipes you will need special equipment. The costs of the material itself add up to the costs of building a sewer system. However, after installation, the sewerage system does not guarantee a long period of flawless operation due to the possibility of silting.

Rules for installing sewerage systems made of plastic pipes

There are several rules, the application of which in practice will make it possible to create a strong and reliable sewer system. When installing sewerage from plastic pipes, you should adhere to the following recommendations:

- Make a slope in the place where the pipe leaves the plumbing fixture. The slope angle depends on the purpose of the device and is on average 30 0.

- Avoid perpendicular joints. If the system turns by 90 0, it is better to make two turns of 45 0. A perpendicular joint is a potential source of clogging;

- Place the toilet as close to the riser as possible so that sewage immediately goes into the sewer;

- At branch points, install inspection fittings designed to clean the system in case of contamination;

- Do not leave pipes open. Plastic ones are a source of noise. This especially causes a lot of inconvenience to residents of apartment buildings. Such pipes should be placed in polystyrene foam, and then special boxes with windows in the places of inspection fittings should be built over them;

- Before installing connected pipes to the system, they should be checked for leaks, paying attention to the joints.

We recommend that you read: What is LDPE in pipe production and how is it deciphered?

Ceramic pipes

This is the most ancient material of all, which is gradually being used less and less.

Advantages:

- neutrality to chemicals,

- smooth inner surface,

- resistance to temperature changes,

- easy installation.

Flaws:

- fragility,

- short length of one pipe.

Ceramic products used to be excellent for sewerage. But now many other materials that are lighter or stronger have similar properties.

Fitting

Fittings also influence the choice of pipes for sewerage, although to a lesser extent. Fittings are pipeline connecting parts that allow you to branch, close, or direct pipes in another direction.

The most common fittings are for plastic pipes. They are made from the same polymers: PVC, PP, PE - they have different diameters and sizes and are easy to install. The range of metal fittings is more modest.

They are just as easy to install, but the parts themselves and their sizes are smaller. The same goes for ceramic fittings. For other types of pipes, fittings are not sold at all; they are connected differently. In terms of fittings, polymer pipes are better for sewerage.

Materials for sewer construction have many similar characteristics: immunity to aggressive environments, relative smoothness inside, strength.

But at the same time, plastic pipes are always light and, in addition, elastic. Installation and docking are simplified. At the same time, pipes made of different plastics are easily connected to each other.

Therefore, internal and external sewerage can be made from different, most suitable polymers. It is obvious that plastic pipelines are the future for both internal and external sewage systems.

Source: remstd.ru/archives/kak-vyibrat-trubu-dlya-kanalizatsii/

Metal pipes

These are ferrous metal products that are the best from an economic point of view:

- they are highly durable;

- can be operated in a wide temperature range;

- easy to process.

But all these advantages are negated by their susceptibility to corrosion and significant weight. At the moment, metal types of pipes for sewerage are practically not used in everyday life. They are used only in industry for the removal of waste chemical liquids.

Cast iron pipes

Modern cast iron pipe

Cast iron is more expensive than steel sewer pipes due to its significantly greater mass, but it is less susceptible to corrosion. Cast iron products are sometimes used in everyday life for sewer risers and external outlets to the collector.

In addition to the advantages and disadvantages inherent in all ferrous metal products, cast iron sewer pipes:

- They have a rough surface, which promotes the accumulation of dirt, which leads to a noticeable decrease in drainage capacity.

- Inconvenient for installation - to ensure the tightness of the joints, special materials and certain experience of workers are required.

A modern version of cast iron is ductile iron pipes for sewerage, obtained by modifying plain cast iron with magnesium. As a result, the material became more durable and ductile, eliminating the risk of cracks and their propagation.

Ductile iron pipes combine:

- Mechanical characteristics of steel: impact resistance, tensile strength, ductility, high elongation.

- Corrosion resistance of cast iron.

No. 1. Material of internal sewer pipes

Internal sewerage can be done using the following pipes:

- cast iron. Previously they were installed everywhere, but today they are practically not used;

- polyvinyl chloride (PVC);

- polypropylene. Looking ahead, we note that this is the most optimal option;

- polyethylene. Infrequently used;

- steel and copper. Expensive pipes that are not used, but are sometimes still used due to their appearance.

Despite the fact that polypropylene and PVC pipes are most widespread, when choosing, do not rush to immediately discard the other options, since in some cases cast iron and even copper pipes may be useful.

Plastic and fiberglass pipes

- Polyvinyl chloride pipes (PVC). The products are easy to install, transport without problems, and withstand the effects of chemicals contained in sewage. In addition, the surface of all types of plastic pipes is absolutely smooth, which indicates their maximum throughput. The disadvantage of PVC pipes is the inability to operate at temperatures above 40 degrees Celsius. The marking of PVC sewer pipes is as follows: pipes for internal sewerage are marked in gray, and for external sewerage - orange.

- Polypropylene pipes (PP). They have all the advantages described above, but can operate at high temperatures - up to 80 degrees, so they are often used to connect washing machines and dishwashers. Marked in grey. In addition to ordinary pipes, corrugated two-layer products are made from polypropylene, used in the construction of external sewer networks.

- Polyethylene pipes (PVP). Made from polyethylene. Advantages: high strength, low weight, good flexibility, easy installation. In terms of their ability to work at high temperatures, they are between PP and PVC pipes. To equip external systems, two-layer and corrugated products are manufactured.

- Fiberglass pipes. The main material for manufacturing is glass fiber reinforced polyester resin. Positive qualities of fiberglass pipes: high mechanical strength, easy installation, ability to withstand temperature changes, resistance to chemicals, ease of transportation. The disadvantages of these products include very high cost and considerable weight.

When selecting pipes for the sewer system, you must immediately pay attention to thermal insulation materials: internal sewer pipes sometimes require insulation, not to mention external ones, which are always recommended to be insulated. The installation process will largely depend on experience, but if you really want to, you can install sewer pipes yourself (you can find out more in the article on installing sewer pipes).

Conclusion

From this article you could find out what sewer pipes are made of. It is impossible to give a clear answer to the question of which sewer pipes are better, since each situation requires a completely different type of material. Only one thing can be said for sure: the characteristics of products are mainly influenced by the material of sewer pipes.

No. 2. Cast iron pipes for internal sewerage

Several decades ago there was no particular alternative to cast iron pipes, so they are widely found in old houses. Today, cast iron is being replaced by plastic, but is still used.

Such pipes are made from gray cast iron by centrifugal casting. To protect the material from corrosion and make the internal surface smooth, the pipes outside and inside are coated with a bitumen compound. The diameter of cast iron pipes ranges from 5-15 cm, the wall thickness is 10-12 mm.

Advantages of cast iron pipes:

- durability. The service life reaches 50 years and often exceeds this mark. Some data suggests a longevity of 90-100 years;

- high strength and resistance to deformation. On the other hand, the material does not tolerate shock loads well;

- the ability to withstand long-term exposure to hot waste (from a washing machine or dishwasher, for example);

- resistance to temperature changes;

- fire resistance;

- environmental Safety;

- good sound insulation.

Surely, cast iron pipes would have remained among the leaders if not for significant shortcomings:

- the walls become overgrown with sediment over time. This is all due to the roughness of the material, which even with a bitumen coating cannot be completely eliminated. The process of overgrowing leads to a narrowing of the pipe lumen and a decrease in its throughput. Anyone who has seen what a pipe looks like after many years of use will never forget this terrible sight;

- heavy weight of pipes, which complicates transportation;

- complex installation, which is explained not only by the large weight, but also by the peculiarities of connecting pipe sections. In order for the sewer system to be airtight, it is necessary to correctly connect the elements. Usually they use the method of caulking or caulking using a heel; susceptibility to corrosion processes;

- high price.

Cast iron pipes are not used today to build a new sewer system, but they may be needed when existing systems are being reconstructed.

At the moment, the use of cast iron pipes is also justified when arranging external sections of private sewers and intra-house risers.

When choosing, it doesn’t hurt to carefully examine the products and tap each of them. This way, it is easy to detect cracks and other defects that form when the manufacturing process is disrupted.

A defective pipe does not have a long service life. Various types of fittings, plugs and sockets are produced for connecting cast iron pipes.

Cast iron

The traditional material for making sewers; in old houses, the drainage system is made of cast iron. Its advantages include high strength, heat resistance, and less corrosion than steel pipes.

The main disadvantages of sewer pipes made of cast iron are heavy weight, difficult installation, and high price. The inner surface is rough and eventually becomes overgrown and clogged.

Cast iron pipes are further divided into:

- Bell-shaped cast iron pipes ChK;

- Cast iron pipes SML - socketless, connected with clamps;

- VChShG cast iron pipes (high-strength cast iron with nodular graphite).

The latter are distinguished by greater strength, comparable to steel; in addition, to protect against corrosion, the pipes are coated on the outside with varnish or zinc, and on the inside with a cement-sand coating. In addition to corrosion resistance, CPP increases the smoothness of the walls, reducing fouling and increasing throughput.

The price of ductile iron pipes is correspondingly higher than that of conventional cast iron pipes. In turn, they are divided into:

Tyton type - socket connection with a special Tyton O-ring.

Type RJS - with socket-lock connection for Tyton O-ring;

Type RJ - with a socket-lock connection, additionally fixed with a locking wire.

No. 3. Polyvinyl chloride (PVC) sewer pipes

For arranging internal sewerage, PVC pipes are considered almost the most suitable option. During the production process, some other substances are added to polyvinyl chloride, which include stabilizers and polymers. Elements of the required shape are formed from the heated mass.

PVC pipes can be of two types:

- pipes made of plasticized PVC (PVC) have good elasticity and low strength;

- pipes made from unplasticized PVC (PVC-U) are more rigid and resistant to aggressive influences.

Of course, it is better to use unplasticized PVC, but in practice both types of pipes are used. The diameter of the products ranges from 2 to 20 cm.

Main advantages:

- affordable price;

- light weight;

- ease of installation. Separate sections of pipes are connected by couplings and connecting rings - everything is done without welding;

- low temperature coefficient of expansion. With a short-term or constant increase in the temperature of the drains, the pipes will not sag;

- sufficient strength and durability up to 50 years;

- sufficient resistance to ultraviolet rays, so that some sections of pipes can not be afraid to run on an open surface;

- resistance to corrosion and some aggressive substances;

- Thanks to the smooth inner surface, the walls do not silt over time

Minuses:

- limited operating temperature range. With constant exposure to negative temperatures, pipes become fragile and lose their tightness, and with constant exposure to temperatures above +60...+700C, the material can deform and also lose integrity;

- insufficient fire resistance;

- The inner walls of PVC pipes are smoother than those of cast iron, but over time they will still develop plaque. In addition, the internal diameter changes over the years. As a result of exposure to high temperatures, the circular cross-section is transformed into an ellipsoidal one, and this impairs the throughput and contributes to the occurrence of leaks;

- some aggressive substances contained in drains can still lead to the gradual destruction of pipes.

To install internal sewerage from PVC pipes, appropriate connecting elements are used. These include an elbow designed to rotate the pipeline at an angle from 20 to 87 degrees, a tee for arranging branches, a cross for connecting four pipes, and a reduction for connecting sections of pipes of different diameters.

Requirements for pipes used as part of the sewer network

By its design, the sewerage system is represented by a pipeline that ensures the spontaneous removal of household wastewater, the movement of which is ensured by the action of gravity. In the engineering pipeline system there are 2 jointly functioning components: the external and internal parts. Accordingly, the selection of pipes for each part is subject to a different list of requirements based on building regulations.

In order for the assembled system to function safely for a long period of time, the pipes used must have all the qualities listed below:

- High levels of strength and rigidity;

- Resistance to strong temperature fluctuations. Neither frost nor heat should in any way affect the performance of structural elements. Moreover, increased frost resistance is the most important criterion;

- Wear resistance;

- Resistance to the unwanted effects of various aggressive chemical environments.

Please note that the question regarding the standards governing the selection of pipes for different sections of the water supply system is quite rightly considered to be quite specific, and therefore it is worth asking it to the sales consultants of a company specializing in the sale of the relevant products. It will be very difficult for a person who is far from all these matters to independently compare the product and the existing standards. Companies, on the contrary, care about their clients, and therefore strive to provide top-class service and provide all possible assistance in selection.

So, regarding the characteristics of pipes for internal and external engineering systems, consult with professionals - this will be better for everyone.

No. 4. Polypropylene sewer pipes

Polypropylene pipes today are actively used in the arrangement of heating systems, cold and hot water supply. The properties of a material strongly depend on its structure.

Pipes made from a copolymer of propylene and ethylene (PPR) are suitable for internal sewerage; they can withstand temperatures up to +700C. PPs type pipes behave even better, they can easily withstand temperatures up to +950C and short-term exposure to even higher temperatures.

Reinforced pipes will be more durable, and fiberglass reinforcement is considered optimal. The product labeling also indicates the operating pressure: for internal sewerage, PN10 pipes will be sufficient (withstand 1MPa), but more often they take PN20.

Advantages:

- durability up to 50 years;

- resistance to corrosion and almost all aggressive substances (acids, alkalis and salts will not damage the material);

- high strength of pipes and connections. Polypropylene is stronger than polyethylene and PVC, it is more resistant to cracks, and joints are less likely to depressurize;

- light weight;

- an absolutely smooth inner surface, so there will be no problems with pipe overgrowing;

- resistance to high and low temperatures, which allows the pipes to be used in almost any conditions. The pipes are not deformed;

- relative ease of installation. The connection of individual sections is made with a special welding machine, which almost anyone can learn to work with;

- relatively low price, but polypropylene pipes will cost more than polyvinyl chloride pipes;

- polypropylene type PPs belongs to the group of flame-resistant materials.

Among the disadvantages of polypropylene pipes, one can note only temperature deformation, so they will either have to be insulated or equipped with compensators.

Technical and operational characteristics of various pipes and connections

There are various types of sewer pipes on sale. The materials from which sanitary products are made differ in a number of properties from each other.

The choice of material depends on the purpose of the utility network.

Polyvinyl chloride

Polyvinyl chloride sewer systems are made on the basis of polyvinyl chloride thermoplastic - a material that, as a result of high-temperature processing and extrusion procedures, retains its shape well. There are products made from plasticized and unplasticized PVC, but their characteristics are almost the same.

Polyvinyl chloride sewer pipes.

Polyvinyl chloride has many advantages. With a sufficiently high level of strength, its weight is light, which makes assembly and installation of the sewer convenient.

Due to the low temperature coefficient of expansion, polyvinyl chloride products hold their shape, do not sag, do not melt, and do not increase in length when placed in a warm room or during short-term heating.

PVC pipes are tested for impact strength even at the production stage. In addition, they are tested for changes in length as a result of heating. These tests are regulated by the relevant GOST.

The internal surface of PVC pipeline elements is almost smooth, so the likelihood of sediment accumulation and blockages is extremely low.

Polyvinyl chloride is not subject to corrosion and is resistant to chemically aggressive environments (acids, alkalis, etc.). Bacteria do not linger or multiply on the surface of polyvinyl chloride products, which indicates the high hygienic qualities of the material. Polyvinyl chloride is quite resistant to temperature fluctuations; the operating temperature range is from -15°C to +66°C.

Assembling a sewer system made of polyvinyl chloride is not very difficult and does not require the use of special equipment. A large selection of utility network elements facilitates the design of a sewer system. On sale you can find polyvinyl chloride pipes of various sizes for any purpose. It simplifies installation and eliminates the need to ground the pipeline (PVC does not conduct electricity). The service life of polyvinyl chloride products is about 50 years.

The disadvantages of polyvinyl chloride systems include instability to elevated temperatures: with prolonged exposure to temperatures of +70°C and above, the material becomes brittle and loses elasticity. Polyvinyl chloride is highly flammable, releasing phosgene when burned. Another disadvantage of PVC is its instability to concentrated organic solvents, which change the structure of the material.

Made from polypropylene

The main advantage of polypropylene is the low weight of products. This simplifies the installation of sewerage. At the same time, polypropylene systems are characterized by strength and wear resistance. Polypropylene is elastic, as a result of which, under mechanical stress, it is slightly deformed, maintaining integrity, and is restored to its original state.

Sewage pipes made of polypropylene.

Polypropylene is not subject to corrosion. It can be used to remove aggressive substances (acids, alkalis, etc.). Products made of polypropylene can withstand exposure to open fire and do not emit harmful substances. The service life of polypropylene products reaches 100 years.

Polypropylene, unlike polyvinyl chloride, has a wider range of operating temperatures - up to +70°C with short-term increases to +95°C. In this regard, the installation of polypropylene systems is more applicable in a house or apartment where there are household appliances that discharge waste hot water into the sewer.

However, the material is poorly resistant to low temperatures: cracks may appear even at -15°C, so polypropylene sewers must be additionally insulated.

Polyethylene

Polyethylene products are made from two types of polyethylene: high-density polyethylene and low-density polyethylene.

Products made from polyethylene have a number of advantages. This material is not subject to corrosion and does not react with chemically aggressive substances, so it can be used to remove acids, alkalis and other compounds. Polyethylene is lightweight, which simplifies pipeline assembly. The service life of polyethylene products reaches several decades.

Sewage pipes made of polyethylene.

Polyethylene pipes have a smooth inner surface. Thanks to this quality, there are no deposits on them that lead to blockages. Polyethylene products are characterized by flexibility and impact resistance.

Another property of polyethylene is low thermal conductivity. Thanks to this, condensate forms on the elements of the utility network in a minimum amount.

Polyethylene is resistant to low temperatures (up to -70°C), but is prone to softening when exposed to temperatures above +80°C, so it is not recommended for use in systems where hot water is drained.

Polyethylene is less wear-resistant than polyvinyl chloride and polypropylene.

With regular abrasive exposure to waste rich in solid particles, the surface of polyethylene quickly loses its smoothness and becomes rough, which leads to the accumulation of sediments and sewer blockages.

Metal pipes

The main advantage of metal products is temperature resistance. Metal provides strength and a high level of sound insulation. Metal sewer pipes are made of steel and cast iron.

Metal sewer pipes.

Steel structures

Steel structures guarantee strength and provide rigidity to the sewer system. The material maintains the slope angles of the system and withstands high temperature loads.

Steel sewer pipes.

However, steel sewer systems have many disadvantages. Thus, steel in its pure form is susceptible to corrosion, so products are coated with paint or treated with bitumen, and when a waterproofing layer is applied, the resistance of the material to temperature influences decreases from +700°C to +60°C.

The joining of sewerage elements is carried out by threaded connections or welding, which increases the vulnerability of steel to corrosion. Due to rust deposits on the inner walls of the steel pipeline, its clearance narrows, which causes blockages. In addition, the cost of steel pipes is higher than plastic ones.

Cast iron pipes

Cast iron sewers are more wear-resistant than steel ones. Its other advantages include high strength, environmental safety, good level of sound insulation, fire resistance, resistance to chemicals and mechanical factors, and a wide range of operating temperatures. The service life of cast iron products reaches 100 years.

Cast iron sewer pipes.

However, cast iron products have many disadvantages. Cast iron, like steel, is susceptible to corrosion, so the inside of a cast iron pipeline is coated with enamel or treated with bitumen. This measure also makes it possible to partially smooth out the roughness of the internal surface of the sewer.

However, despite this, accumulations of rust and other deposits often cause blockages in cast iron sewer networks. In addition, cast iron products are susceptible to pinpoint impacts.

Other disadvantages of cast iron sewers include the high cost and labor-intensive installation work - a consequence of the large weight, which makes it difficult to manipulate the products.

Alternative materials - asbestos cement and ceramics

Ceramic sewer pipes.

The basis of asbestos-cement pipes is Portland cement and asbestos fibers. The service life of products made from this material reaches 25 years. They are characterized by lightness, resistance to chemicals and are not subject to corrosion.

Asbestos cement pipes can withstand prolonged exposure to temperatures up to +160°C, but have low strength. They often become clogged due to the roughness of the internal walls, are difficult to install and are available in a limited range of standard sizes.

Ceramic sewerage is characterized by resistance to corrosion (100%), immunity to aggressive environments (acids, alkalis, etc.), heat resistance (withstands temperatures of +1000°C and above). Its inner walls are smooth, which prevents the formation of deposits on them.

The service life of ceramic pipes reaches 150 years. However, ceramics are rarely used in sewerage installations. Ceramic products are fragile and heavy, which complicates the installation of the sewer network.

No. 5. Polyethylene sewer pipes

Polyethylene pipes are rarely used in the construction of internal sewage systems. Typically, either low-density polyethylene or cross-linked polyethylene is used.

The first option can withstand a maximum of +400C, so it makes sense to use it only in places with cold drains. Cross-linked polyethylene is designed to operate at temperatures of 0...+950C; for a short time it can withstand temperatures from -50 to +1200C, so it is usually used.

The material has the following advantages:

- high strength, wear resistance and flexibility;

- corrosion resistance;

- smoothness of the walls and almost complete resistance to the formation of growths;

- light weight;

- resistance to pressure changes;

- durability;

- flexibility and easy installation;

- relative availability in terms of price.

Minuses:

- fear of ultraviolet rays;

- Oxygen can pass through the material, which will damage the metal elements in the system. The manufacturer applies a special coating, but it is quite delicate, so during installation you must be extremely careful so as not to damage it;

- low abrasion resistance

Types of plastics

Let's start by considering the physicochemical properties of all types of plastic used.

Plastic sewer pipes can be made from:

- Polyvinyl chloride (aka PVC, or vinyl).

- Polypropylene.

- Polyethylene.

We will begin to study the materials in this order.

PVC

Polyvinyl chloride is known to the reader as the plastic from which profiles for plastic windows are made. In the recent past, gramophone records were also made from it. As is easy to see, plastic has sufficient rigidity with limited ability to deform.

Curious: the so-called plasticized polyvinyl chloride is used for the production of linoleum and artificial leather.

Here is a complete list of material properties.

- Its ignition temperature is 500 degrees, which makes PVC practically safe in terms of fires. However, when heated above 150 degrees, its thermal decomposition begins with the release of hydrogen chloride, the presence of which in the atmosphere is not so harmless to people and animals. In addition, the stability of the geometric shape and dimensions is maintained only up to 70 C; the maximum long-term operating temperature does not exceed 60 degrees.

Polyvinyl chloride is not resistant to high temperatures.

- PVC density is 1.34 - 1.43 g/cm3.

- Plastic has high electrical resistance. From a practical point of view, it can well be considered a dielectric: PVC is used as insulation for wires and cables.

- Resistance to acid and alkali solutions is quite high; A plastic sewer pipe made of PVC is afraid of contact only with dichloroethane and, partly, with acetone.

The raw materials for production are chlorine, obtained by electrolysis of an aqueous solution of table salt, and ethylene, a product of cracking oil. The availability of raw materials and the relative simplicity of production technology make PVC one of the cheapest plastics.

Polypropylene

The main raw material in this case is the hydrocarbon obtained by cracking oil; polymerization takes place in the presence of metal catalysts.

What else is useful for us to know about polypropylene?

- This is the only plastic with a density lower than that of water - 0.93 g/cm3.

- It is hard and extremely abrasion resistant. A sewer plastic pipe made of polypropylene is not afraid of erosion by suspended matter carried by wastewater, and maintains a smooth internal surface throughout its entire service life.

Due to this property, polypropylene is also popular as a material for pressure pipes.

- The ring stiffness, on the other hand, is much lower than that of PVC. If a plastic sewer pipe made of PVC can withstand the weight of an adult man without destruction or deformation, then the polypropylene product will most likely crack.

- And this plastic is characterized by extreme resistance to alkalis, acids and aggressive products of biological origin.

- Finally, the main thing: polypropylene melts only at 170 degrees; thermal deformation begins at 140 C. The maximum long-term operating temperature at which plastic sewer pipes made from it can perform their functions indefinitely is 95 C.

Why is this so important?

- It is the value of 95 C that limits the maximum water temperature in the utilities of a residential building . To put it simply, if you open hot water in winter and leave, a plastic sewer pipe made of PVC may become deformed, while a polypropylene pipe will survive prolonged heating without incident.

- The same 95 C - maximum water heating for automatic washing machines.

Please note: since the machine does not drain water, but a hot solution of rather aggressive surfactants, the chemical resistance of polypropylene will also come in handy.

Polyethylene

The most popular among all plastics, polyethylene is a polymerization product of the already familiar ethylene, a product of petroleum refining.

It is supplied from chemical plants in translucent granules.

Let us highlight from the complete list of its properties the most important in practical terms.

- Like the previously discussed plastics, polyethylene is resistant to alkalis and acids. There is, however, an exception: in a 50% solution of nitric acid it decomposes at room temperature; but without heating it does not dissolve in any of the known organic solvents.

- Resistance to high temperatures is minimal. Already at 80 degrees, polyethylene plastic pipes for sewerage can become deformed; The maximum long-term operating temperature is limited to 40 degrees.

- Polyethylene pipes are also not particularly rigid. This plastic is elastic, and this property is retained at low temperatures. It is quite easy to deform a polyethylene pipe; but breaking, splitting or tearing it with excess pressure is problematic.

Areas of use

Since the physical properties of the plastics used differ, the priority areas for their application will also differ.

- Polypropylene is used primarily where high heat resistance is required: plastic sewer pipes made from it are used to create an internal sewerage system. Pipes are of little use for laying in the ground due to their low ring rigidity.

- Polyvinyl chloride is used in both external and internal wastewater systems. At the same time, as you might guess, it is not worth using it for hot waste: prolonged exposure to boiling water will immediately affect the plastic.

Products for external sewerage are usually painted orange.

- The destiny of polyethylene is external sewerage with its low temperatures. For large-diameter pipes, the problem of insufficient rigidity is solved by corrugation, which makes the product resistant to compression at a moderate weight (and, accordingly, production costs). Plastic sewer pipes made from polyethylene are valued precisely for the elasticity of the material: soil movements will not lead to cracks and destruction of the sewage system. Moreover: even an ice plug that can rupture a durable cast-iron pipe is safe for polyethylene, which is elastic at low temperatures. The sewer section under ice pressure will only slightly increase its diameter, and after the ice plug melts it will return to its original size.

Standards

According to what regulatory documents are plastic sewer pipes produced?

The answer depends on the material used to produce them.

- For PVC, GOST 28117 “Pipes made of unplasticized polyvinyl chloride” is valid.

- Plastic sewer pipes are made from polyethylene according to standard number 22689. However, according to this document, the maximum diameter of products is limited to 110 millimeters; therefore, corrugated polyethylene pipes for waste systems for several houses or for collectors are produced according to the specifications agreed with the customer.

- Production from polypropylene is also regulated by technical specifications (in particular, TU 4926-002-88742502-00). But the technical conditions determine only the basic requirements that plastic sewer pipes must meet - the dimensions are again taken from GOST 22689.

No. 6. Copper and steel sewer pipes

Copper and steel pipes can be called ideal in terms of durability, strength and corrosion resistance. They can withstand any temperature and pressure, are characterized by minimal thermal expansion, and have a smooth, non-overgrowing inner surface.

The main disadvantage is the high price. In addition, copper pipes require specific installation, which only a professional can handle.

It is justified to use such an extravagant version of sewer pipes when open installation is carried out, and plastic pipes will look ridiculous. Copper pipes are often used when creating a retro interior with a claw-foot bathtub.

No. 7. Size and diameter of sewer pipes

Before you start purchasing and installing sewer pipes, it is best to draw up a project where you indicate all the drain points and the type of plumbing equipment.

This will help you figure out what diameter and length of pipes are needed. At this stage, it also doesn’t hurt to determine the number of auxiliary parts, which will depend on the number of turns and branches. Take into account the change in pipeline diameter in individual sections.

Depending on the type of plumbing fixture being connected, pipes with different diameters are selected:

- a sewer pipe with a diameter of 25 mm is suitable for a dishwasher and washing machine;

- for bathrooms, showers and kitchen sinks – 40-50 mm;

- for washbasin and bidet – 30-40 mm;

- for pipe routing – 40-50 mm;

- bends from the riser – 65-75 mm;

- the central riser and pipe from the toilet are 100-110 mm.

It is better to add a margin of 10% to the calculated length.

Pos

Pipe diameter for sewer systems

The sewer system consists of pipes, the internal diameter of which varies from 25 mm to 1.1 m; pipes of different internal diameters have different purposes. There are two types of pipes by diameter: for internal use and external.

We recommend that you read: How to choose and use a pipe cutter for plastic pipes

Pipes of the first of these categories have an internal diameter from 25 mm to 11 cm, the second - from 15 cm to 1.1 m.

Pipes of smaller diameter (2.5 cm) are installed to drain water from washing machines and dishwashers. For bathtubs, showers and sinks, pipes with an internal diameter of 3-5 cm are required.

For a combined drain in the bathroom, for example, for a sink, shower and washing machine, install a diameter of 5 cm. The diameter for individual risers is 7-9 cm, and for the toilet and central riser - 10-11 cm.

Pipes that are laid outside the premises are called external. Their diameter is several times greater than the diameter of the internal pipes. It is also determined based on what it is intended for. The diameter of the sewage drain from the house to the general sewer must be at least 15 cm, if the house has a bathhouse - 20 cm, if the pool - 30 cm.

The diameter of pipes used for the construction of urban sewer systems can reach 1.1 m.