The melting point of titanium is 1668°C. There are about 20 alloys

| Brand | Weldability | Technological features of welding |

| BT1-00, VT1-0, OT4-0, OT4-1 | good | Edge cleaning Mode with minimum heat input |

| 0T4, VT5, VT5-1 | Satisfactory | |

| VT6, VT3-1, VT9, VT14, VT16, VT20 | Limited | Soft mode with low cooling rates |

| VT22 | Subsequent heat treatment | |

| PT-7M, PT-3V, PT-1M | good | High cooling mode |

Welding difficulties

High chemical activity of the metal at high temperatures, especially in the molten state. Therefore, reliable protection from air is necessary not only for the weld pool, but also for the cooling sections of the seam and the heat-affected zone until their temperature drops to 250-300°C. Protection of the reverse side of the seam is also required, even if the metal was not melted, but only heated above this temperature.

The tendency of titanium alloys to grow metal grains in areas heated to high temperatures. This makes it difficult to select a welding mode - one in which heating of the heat-affected zone would be minimal.

The high melting point of titanium requires the use of concentrated heat sources. The low thermal conductivity of titanium leads to a decrease in the efficiency of the heating source compared to welding steels.

Pores and cold cracks in titanium welded joints arise due to harmful gas impurities and hydrogen. Therefore, it is necessary to ensure the cleanliness of the base metal and welding materials, including filler wire.

Near the melting point, the surface tension of titanium is 1.5 times higher than that of aluminum, which allows the weld root to be formed in weight. However, molten metal has low viscosity, and if parts are assembled poorly, burns can form.

Methods of welding titanium and its alloys

Taking into account the physical and chemical properties, titanium and titanium alloys are welded only by electric arc welding.

Basic methods of titanium welding:

- in a gas environment, with oxygen-free flux powder AN-11;

- electroslag for thick sheets, submerged arc AN-T2;

- contact in an atmosphere of protective gases.

Argon welding

During work, it is necessary to protect not only the working area, but also the reverse side of the connection from oxidizers. Therefore, titanium welding technology involves working in an isolated volume filled with an argon-based gas mixture. Additional protection is provided by using pads or butt welding parts.

GAS PROTECTION OF THE WELD BATH

There are three protection options:

- inkjet using special devices

- local in sealed chambers of small volume

- general in chambers with a controlled atmosphere (VKS-1, VUAS-1, USB-1)

When argon arc welding of titanium with a W-electrode, welding torches with the largest possible gas nozzle should be used, creating a wide protection zone. The flow of argon through the nozzle must be laminar, which is achieved by gas lenses installed inside the nozzle. Gas consumption, depending on the welding mode, ranges from 8 to 20 l/min. If the burner nozzle does not guarantee reliable protection, then it is supplemented with a special nozzle, box or other device. Additional protective devices are made of stainless steel. Inside there are splitters and gas lenses. The nozzle attached to the gas torch to protect the crystallizing weld pool should have a width of 40-50 mm and a length of 60-120 mm, depending on the welding mode. For welding tubular structures, circular rotary and non-rotary joints, local or small-sized protective chambers are used.

1- additional nozzle; 2 - gas lens

The quality of protection is determined by the appearance of the weld metal. A silver or straw-colored seam surface indicates good protection. The yellow-blue color indicates a violation of protection, although in some cases such seams are considered acceptable. A dark blue or bluish-gray color with spots of gray coating characterizes the poor quality of the seam.

Welding technology and modes

Manual welding of titanium and its alloys is carried out using tungsten electrodes with direct current of reverse polarity. During the work, equipment and additional devices are used to protect the working area and the heated area adjacent to the seam, and significant amounts of cooling suture material. These are special elongated nozzles with nozzles for supplying inert gases, visors, perforated backing plates with gas supply, etc. When connecting pipelines, the pipes are filled with protective gas from the inside.

Manual arc welding

Manual argon arc welding is most often used in the manufacture of unique products or in small-scale production, as well as when performing highly complex work for which it is not possible to program an automatic machine.

Manual arc welding

With a sheet thickness of up to 3 mm, the gap should be set from half a millimeter to one and a half, and welding can be done without adding filler wire. When using a 1.5 mm electrode and a 2 mm filler wire, the welding current for sheets 2 mm thick is chosen to be about 100 amperes, and for sheets 3-4 mm thick, the current is increased to 140 amperes.

The electrode is guided straight, without hesitation, and it should be inclined forward along the seam. If filler wire is used, it must be fed continuously and the electrode must be placed perpendicular to the workpiece.

After completing the seam and turning off the electric arc, it is necessary to supply protective gases for at least another one and a half to two minutes to allow the last section of the seam and the heat-affected zone to cool to 400 ° C. This protection prevents the formation of oxides. An oxidized seam is easily distinguishable by color:

- high-quality seam - yellow (straw);

- oxidized - gray-black, with a transition to blue.

Automatic welding

Automatic welding is carried out using tungsten electrodes using direct current.

If an infusible electrode is used, it is recommended to use straight polarity. The recommended diameter of the burner nozzles supplying shielding gas should be within 12-15 mm.

Ignition and extinguishing of the arc are performed not on the part itself, but on strips located near the beginning of the seam. This is due to the fact that at the beginning and end of the arc, during transient processes, voltage surges are possible, which can cause melting of the main part.

Titanium argon arc welding modes

When welding titanium with argon, they work with metal with a thickness of 0.8 to 3 millimeters.

Welding parameters depend on the sheet thickness:

- Electrode diameter 1 -3 mm;

- voltage 80-130 volts;

- current 45-220 A;

- electrode guiding speed is 18-22 meters per hour;

- gas consumption in the burner is 6-12 liters per minute;

- flow rate in the backing plate is 3-4 liters per minute.

Titanium submerged arc welding modes

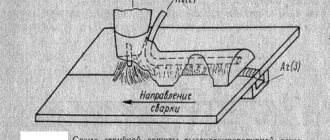

With this method, the weld line is sprinkled with a thick layer of flux powder. A cloud of inert gases is formed as the flux powder burns in the flame of an electric arc and covers both the weld pool and the heat-affected space.

Submerged arc welding diagram

The method allows you to work with thicker parts - up to 5 mm for butt and corner joints, and for overlap welding - only up to 3 mm. The current used is from 250 to 330 amperes, the operating voltage is 24-38 volts. This method provides increased welding speed - from 40 to 50 meters per hour (almost a meter per minute).

Electroslag welding of titanium alloys

This method is used less frequently, but allows one to achieve high efficiency when joining workpieces made of titanium alloys with the addition of aluminum and tin. The method is very energy-intensive; three-phase welding sources are used. Welding currents reach one and a half thousand amperes.

Plate electrodes with a cross section of 12×60 mm are used. They make it possible to obtain a high-quality seam, and the suture material is close in its basic mechanical parameters to the material of the parts.

For pressed titanium parts, welding is carried out using round 8 mm electrodes. At the same time, it is not possible to achieve the same high strength indicators as for plate ones.

Electroslag welding

When working with this method, it is not recommended to use fusible electrodes made of alloy alloys, due to excessive saturation of the pressed material with welding gases.

Titanium resistance welding

When resistance welding, electrodes are not used to ignite the arc; their purpose is only to supply electric current to the work area. The arc is ignited directly between small zones of parts brought together under the pressure of the electrodes. The method is used for welding relatively thin rolled sheets during the manufacture of vessels, bodies, etc.

Contact welding can be:

- butt;

- point;

- suture or roller;

- condenser

According to research, the best reflow rate when working with large workpieces should be 2-3 mm/s. An increase in speed causes a decrease in the strength characteristics of the seam, despite the argon protective atmosphere.

In preparation for welding work, the edges of the workpieces should be milled or cleaned with abrasive materials. It is also necessary to thoroughly degrease both the seam line and the heat-affected zone up to 20 cm. Since titanium has low thermal conductivity, it tends to overheat. Therefore, the settlement value is set 10-20% higher than for structural steels.

Titanium butt welding modes

Welding modes are determined, first of all, by the cross-sectional area of the workpieces being welded. The method allows you to weld parts with a cross-section from 150 to 10,000 mm2. However, other characteristics vary depending on the section:

- sedimentary pressure 2.9-9890 MN/m2;

- reach 25-200 mm;

- melting allowance 8-40 mm;

- draft allowance 3-15 mm;

- melting speed 6-2.5 mm/sec;

- operating current 1.5-50 A.

Titanium spot welding

This method allows you to obtain a leak-proof connection of sheet metal up to 4 mm thick. It is widely used for mechanism housings and protective casings, for assembling various support frames, etc. The electrode must be strong enough to withstand the high compressive force of the sheets. To weld long seams in order to increase productivity, several electrodes are used, located at the same pitch as the seam points.

Spot welding

Titanium spot welding modes are determined by the thickness of the rolled product:

- sheet thickness 0.8-2.5 mm;

- contact surface 4-8 mm;

- electrode pressure 1.9-6.8 kN;

- pulse duration 0.1-0.4 s;

- compression duration 0.1-0.4 s;

- pulse current 7-12 kA.

Seam roller welding of titanium

This method is used to create hermetically sealed welded joints. Electrodes are used in the form of power rollers, which roll along the seam line and compress the sheets of workpieces together. Powerful current pulses are periodically applied to them so that the oval-shaped fusion zones overlap each other by 10-15%. The chain of such welding points forms a continuous sealed seam. The method allows welding sheets with a thickness of 0.2 to 3 mm and is very popular in the manufacture of sealed containers of low pressure vessels, such as fuel tanks, bellows, etc.

Modes of capacitor butt welding of titanium pipes

The capacitor method is a subtype of seam welding and differs from it in that the energy of the electrical pulse is stored in a battery made up of powerful capacitors, and the control module is periodically supplied to the electrodes. Pipe blanks with a diameter of up to 23 mm and a wall thickness of up to 1.5 mm can be welded even without a protective atmosphere, since a powerful pulse burns out oxidizers in the welding zone.

The welding mode is also determined by the diameter of the pipe and the thickness of its wall. The capacitance of the capacitor bank ranges from 5,000 to 7,000 microfarads, the pulse voltage is from 800 to 2,100 volts, and the compression force is from 8 to 24 kN.

It is very important to maintain the distance the pipes leave the liners (from 1 to 1.8 mm), since if it is exceeded by more than 2.2 mm, the ends shift and incomplete weld penetration occurs.

GAS PROTECTION OF HOT AREAS

Special lining to protect the root of the seam heated to 250-300°C

Stainless steel guards for T-joints and corner joints

Possible defects

When welding titanium, if it is not done with a laser, defects are possible. According to GOST, defects appear due to non-compliance with technical conditions, violation of technology, after which the design becomes unsuitable.

According to GOST, defects are of the following types:

- cracks;

- pores;

- solid formations;

- lack of fusion;

- wrong seam;

- other defects.

Cracks and ruptures in the seam or adjacent areas, according to GOST, are unacceptable, since a center of destruction is created.

The formation of gaps is explained by the high content of carbon, nickel, hydrogen, and phosphorus in the molten metal. When welding with a laser, the probability of crack formation is reduced to zero.

To eliminate cracks, you need to drill the ends of the defect, then eliminate the crack mechanically and by gouging, after which the area is cleaned and welded.

Pores, according to GOST, are cavities filled with gas. Formed due to high gas formation.

The area with pores must be digested, having previously been cleaned mechanically, since the defect weakens the structure.

Solid inclusions according to GOST are foreign metallic and non-metallic substances in the seam, reducing the strength of the seam and concentrating stress, so the area with the defect is cut down to a healthy area and removed by gouging, then welded.

Video:

Non-fusion according to GOST is the lack of connection between the metal and the seam. Formed during arc welding due to non-melting of part of the joint edge.

This can happen if the corner shape is chosen incorrectly, the edges are poorly cleaned, or the welding mode is selected incorrectly. Such defects reduce the strength of the seam. The defect site must be cut out, cleaned and welded again.

Violation of the shape according to GOST - deviation of the shape of the seam from the established requirements.

The causes may be voltage fluctuations in the network, incorrect angle of inclination, etc. The consequence may be internal defects in the seam.

To eliminate the defect, a thin seam is welded with a small-diameter electrode.

PIPELINE SEAM PROTECTION

Flange welding protection

Protection when welding sectional bends

Contact

The use of contact technology can be quite justified if you need welding of titanium pipes. Key Features:

- For contact welding, pipes with a diameter of 1-2.5 centimeters and a wall thickness of about 1 millimeter are suitable. Such pipes do not require protection with inert gases.

- The optimal charging voltage in this case is 900 volts (for 10 mm X 1 mm pipes) or 2000 volts (for 25 mm X 1.5 mm pipes).

- Before welding, it is necessary to etch the edges of the pipes.

Preparation for welding

Titanium cutting and edge preparation for welding are performed mechanically. For thick-walled products, gas-thermal methods are also suitable, but with mandatory subsequent mechanical processing of the edges to a depth of at least 3-5 mm and a width of 15-20 mm. After this, the edges are cleaned with metal brushes, a scraper, etc. and degrease. Structures that experienced heating before welding - during rolling, forging, stamping, etc. — must be subjected to shot blasting or hydrosandblasting and then chemical treatment: loosening the oxide film, etching and brightening.

Chemical treatment regime for titanium and its alloys

| Solution | Processing time, min | |

| Purpose | Compound | |

| Loosening the oxide film | Sodium nitrite 150-200 g/l Sodium carbonate 500-700 g/l | 120 |

| Etching | Hydrofluoric acid 220-300 ml/l Nitric acid 480-550 ml/l | 60-1200 |

| Lightening | Nitric acid 600-750 ml/l Hydrofluoric acid 85-100 ml/l | 3-10 |

After this, the edges to be welded are washed with gasoline to a width of 20 mm and wiped with ethyl alcohol or acetone.

The welding wire is preliminarily vacuum annealed and degreased with acetone or alcohol. The oxidized part is removed with pliers. Surfaces prepared for welding should not be touched with unprotected hands.

Features of the manual welding method

Manual welding is used for the manufacture of single products or in small batches, when performing work of great complexity that an automatic machine cannot cope with. The current is chosen to be about 100-140 A. The electrode must be guided straight, tilted forward. The equipment is configured for direct current. The welding area is protected, which is not removed for 1-2 minutes after the current is turned off. The color of the seam indicates its quality: high - silver, low - blue or black.

We recommend reading: How to cook car wheels using argon

Required Electrodes

For welding titanium alloys, electrodes made of tungsten with the addition of a small amount of lanthanum oxide are used, which makes it possible to increase the current by 50%, extend service life and reduce the degree of contamination of the weld pool. The cone of the product is polished to reduce roughness.

Products with a cross section of 12x60 mm are used. With their help, a high-quality seam is obtained, similar in composition to the material being welded.

Manual and semi-automatic arc welding in a protective gas environment

In manual or semi-automatic mode, the procedure is carried out using a tungsten electrode and direct current of direct polarity. In addition, care should be taken to use protective gases, such as argon. Very often special devices are used that protect the welding site due to the entry of inert gases into them. Such devices can have different shapes and sizes, as well as methods of execution.

Manual work is carried out in cases where the thickness of the metal object does not exceed 3 millimeters. Otherwise, the use of filler material may be required. If the thickness of the product exceeds 10 millimeters, then it is more economical to use semi-automatic technology.

conclusions

Welding titanium alloys is a very difficult task, which can only be handled with the appropriate equipment, as well as knowledge and skills in this field. In many ways, the quality of such work depends on the characteristics of the inert gases used. If necessary, you can study the catalog of such products on the website by following the link https://www.propangaz.ru/?id=20.

In addition, we invite you to study the article on the topic of welding aluminum products.

How exactly is this procedure carried out?

When working with this material, the electric arc method is most often used, in which gas plays an important role, ensuring the creation of a protective environment. Argon or helium can be used as such a gas. This is due to the fact that upon contact with atmospheric air in a state of strong heating, titanium becomes too brittle. At the same time, the shielding gas makes it possible to prevent such contact. You can study our article on how argon welding is carried out using an electric arc.

special nozzle for working with pipes

The quality of the created unbreakable connection largely depends on how competently the preparatory work is carried out. The metal surface should be degreased and cleaned of dirt using alcohol or acetone, and also cleaned with sandpaper or a brush with metal bristles. It must be remembered that the Ti parts being joined are almost always covered with an oxide film, which can be removed by preparing a mixture of 30-40% nitric acid and 2-4% hydrofluoric acid. Etching should be carried out at a temperature of 60 degrees for half a minute.

Welding with steel workpieces

If the mass of the finished structure should not exceed a certain limit, titanium is welded with steel. This method is used in the construction of small and large structures.

But the differences between steels and titanium make it difficult to achieve high-strength joints. This is the main problem that shortens the life of structures.

This disadvantage is especially evident when titanium needs to be combined with stainless steel. Scientists are still exploring this area.

So far, there are only a few methods for welding titanium to steel:

- With the help of an explosion. To do this, another metal is laid between the steel and titanium blanks. For example, copper, silver or compounds of refractory metals;

- Diffusion welding. Best suited for combining titanium workpiece with stainless steel workpiece. The joint area will be less strong than the initial workpieces, but overall the seam will be reliable and tight;

- Wedge-press welding. This technique involves mechanical compression of workpieces under thermal influence. The seams are strong and less prone to corrosion;

- Spot welding and ultrasonic welding.