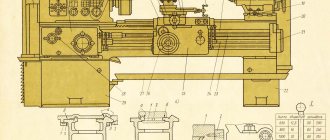

Bearings for screw-cutting lathe 16K20

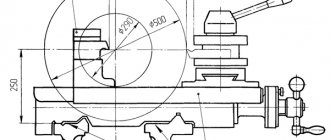

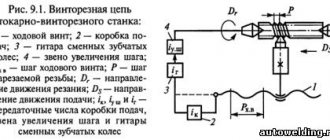

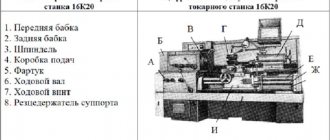

Scheme for installing bearings on a 16k20 screw-cutting lathe

Bearing installation diagram for screw-cutting lathe 16k20

List of bearings for screw-cutting lathe 16k20

List of bearings for screw-cutting lathe 16k20

Spindle bearings for screw-cutting lathe 16k20

Spindle bearings for lathe 1K620

adjusted at the factory and do not require additional adjustment.

However, in case of emergency, the consumer can resort to adjusting the spindle supports using highly qualified specialists.

The need for adjustment may arise after replacing bearings and other repairs.

Before adjustment, it is necessary to check the rigidity of the spindle assembly . To do this, a jack with a laboratory-tested dynamometer is installed on the frame under the spindle flange, and a force directed vertically from bottom to top is applied to its flange through a gasket that protects the spindle from damage.

The spindle displacement is controlled by a certified indicator with a division value of no more than 0.001 mm, installed on the spindle head and touching the upper part of the spindle flange with its measuring tip. A spindle deflection of 0.001 mm should occur with an applied force of at least 45-50 kgf. If the load value at a displacement of 0.001 mm is significantly lower than specified, then the bearing must be adjusted.

Note. Spindle bearings are not regulated by order. Machines can be equipped with two types of front spindle bearings:

1st option of a set of spindle bearings (see Fig. 14):

- 24. Front bearing No. 4-3182120 - double-row radial roller

- 20. Rear bearing No. 5-46216L - single-row angular contact ball, GOST 831-62

- 21. Rear bearing No. 5-46216L - single-row angular contact ball, GOST 831-62

2nd version of the spindle bearing set (see Fig. 97):

- 24. Front bearing No. 2-697920Л - angular contact with tapered rollers

- 20. Rear bearing No. 2-17716L - single-row tapered roller, accuracy class 4, TUST 5434

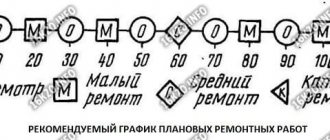

Repair cost

| Type of work | Price |

| Spindle Prevention | 9,000 rub. |

| Troubleshooting clamping devices | 19,000 rub. |

| Burnout (damage) of the stator winding | 30,000 rub. |

| Replacing bearings with rotor balancing | 50,000 rub. |

| Replacing spindle sensors | 10,000 rub. |

| Maintenance | 10,000 rub. |

| Non-standard work | 10,000 rub. |

| Major renovation | 50,000 rub. |

| Modernization of machine tools | 30,000 rub. |

Our main specialization is machine repair

If your machine does not work, our specialist will arrive as soon as possible and fix it. Call and consult by phone: 8

Technologies

Thanks to the use of modern devices, we can more accurately identify faults. And we save your money on repairs

Ideas

If your machine does not break down as usual. We will send it to our technicians and they will solve any problem

Speed.

You need the machine to work as quickly as possible. Our desires coincide.

Read useful information:

How to set up a machine correctly

But before you start working, all the machines need to be set up. How this happens and what it means is written below in the article.

Further

Overhaul of machines

Not one unit can work forever. To restore the functionality of turning equipment, they often resort to major repairs. It is difficult to carry out this process on your own, so it is worth contacting a company that specializes in repairing these units.

Further

Repair of coordinate machines

What is a coordinate machine? How to repair it yourself and is it worth it?

Further

Machine bed repair

The accuracy of its operation depends on the condition of the guide frames of turning equipment. Therefore, it is necessary to carry out timely repairs of equipment and its hotel elements.

Further

Repair of turret lathe

Any equipment fails sooner or later, this also applies to a commodity turret machine. In order for the machine to serve for a long time, and for the products made on it to meet the standards, it is necessary to carry out repairs and maintenance regularly.

Further

When concluding a long-term service agreement, you receive a discount of up to 20%. Don't forget, we have a guarantee on all types of work.

- engineer - mechanic

- CNC programmer

- Service engineer

- Electrician

- Electronics engineer

- Locksmith - repairman

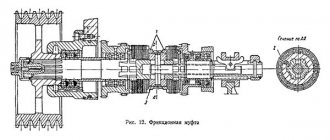

Adjustment of spindle units with bearing No. 3182120

Spindle head of lathe 16k20 with bearing No. 3182120

Photo of the spindle head of a screw-cutting lathe 16k20

The spindle bearing supports (front - double-row roller and rear - radial thrust bearings) are adjusted at the factory and do not require any adjustment.

During repairs, the bearings are adjusted as follows. The front spindle bearing is adjusted by nut 233 (Fig. l4), located inside the headstock housing, in the following order: release the screw and turn the nut in the required direction. By turning this nut, axial movement of the inner ring of the bearing on the conical neck of the spindle is carried out.

When the nut is turned to the right, the inner ring of the bearing is tensioned onto the conical journal of the spindle. In this case, the ring is deformed, its outer diameter increases, ensuring a tight fit of all rollers to the surfaces of the inner and outer rings of the bearing, which reduces the radial clearance in the bearing. After adjustment, tighten the screw again.

The axial clearance of the radial thrust bearings of the rear spindle support is adjusted outside the headstock housing with a nut through a thermal compensator. The tension is carried out by turning the nut to the right at an angle of 18..20° before the gaps are selected in the joints between the bearings and attachments. The outer rings are installed tightly against the stop with a nut.

Repair of main components

bed

The 16K20 bed is a cast structure with stiffening ribs on which all other equipment of the lathe is mounted. On the top of the bed there are four longitudinal guides of the lathe: two flat and two prismatic. The positioning accuracy of the tailstock and caliper carriage, as well as the alignment of the front and rear stock, depends on the condition of their surfaces. The composition and procedure for performing the work is regulated by section 6.1 of the technical manual “Repair of a 16K20 screw-cutting lathe.”

There are four machining methods used to repair lathe guides:

- manual scraping;

- grinding using portable grinding equipment;

- grinding on surface grinding equipment;

- planing on a longitudinal planing machine;

In general, if the wear is less than 15 microns per 1000 mm, the surface geometry is restored by manual scraping. If more, use machine tools or the spraying method.

Scraping is performed using hand tools, so its labor intensity is several times higher than with mechanized processing.

In addition, only non-hardened surfaces can be treated with this method. It is possible to scrape the bed of a lathe without dismantling the bed, therefore, along with manual grinding, this is the most common method of restoring guide surfaces.

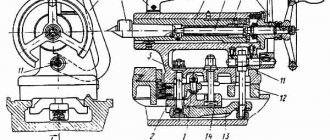

Adjustment of spindle units with bearing No. 697920L

Lathe spindle 16k20 with bearing No. 697920L

In Fig. 97 shows the spindle assembly of a 16K20 screw-cutting lathe. The front support of the spindle is a tapered double-row roller bearing 6 with a small cone angle at the inner ring and a shoulder on the outer ring. The rear end of the spindle rests on a tapered single-row roller bearing 2 with a small cone angle and automatic clearance elimination.

Adjustment of spindle bearings should only be done if absolutely necessary, and be sure to first check the unit for rigidity. The check is carried out using a dynamometer and an indicator with a division value of 1 micron. The force from the dynamometer, directed vertically from bottom to top, is transmitted to the spindle through flange 7. The spindle movement is measured with an indicator mounted on the spindle head and its tip resting on the spindle flange. The bearing assembly is not subject to adjustment if the spindle shifts by 1 micron when a load of at least 45-50 kgf is applied. If this load is significantly lower, adjustment is necessary.

Adjustment of the front bearing is carried out by grinding the half rings 8, to which the inner bearing ring is pressed using a nut 5 with a lock nut 4. The radial clearance in the bearing is eliminated due to deformations of the inner bearing ring when sliding it onto the conical neck of the spindle. In order to remove the half rings, it is necessary to remove the parts covering the half rings from the front end of the spindle, unscrew nuts 4 and 5 and move the inner ring of the bearing.

The clearances in the rear bearing are selected automatically using springs 9 resting against washer 3. Pre-compression of the springs is carried out by screwing nut 1 onto the threaded end

Technical characteristics of bearing 3182120

Bearing No. 3182120 is a double-row radial roller, with short cylindrical rollers, with a flangeless outer ring, with a conical bore (1:12), a groove and holes for introducing lubricant.

A set of rolling elements with an inner ring can move relative to the outer ring in both directions. Double-row roller bearings are capable of providing high load capacity and rigidity with their small dimensions (primarily the distance between the outer and inner rings). This type, like most roller bearings in this series, is currently produced only in high-precision, second or fourth class, since the main area of application is precision machines, during which unacceptably high runout is used. Products with low degrees of accuracy (6) are available from storage. The main manufacturer of bearings of this design has always been considered the Moscow GPZ-1, but now its production has been transferred to the city of Volzhsky, to a branch of the Aviation Bearing Plant at 15 GPZ (all plants are united under the auspices of the European Bearing Corporation), so bearings marked GPZ-1 are sold with storage (or there may also be counterfeit goods). Currently, two different modifications are being manufactured - 2-3182120K, 4-3182120K, which differ in accuracy class. In addition to these factories, this type was also produced by 10 gas processing plants (Rostov-on-Don). After the collapse of the domestic industry, there was an oversupply of bearings of this type on the market, which were removed from equipment, sold from warehouse balances, etc. Among such products there can be both very high quality and inexpensive, and unsuitable for use.

You can buy factory bearings, the long-term performance of which is guaranteed by the manufacturer, with minimal trade margins from official representatives of EPK (the estimated price is about 6,500 rubles, and the accuracy class does not affect it much), illiquid products and bearings from storage can be purchased from companies located in major industrial centers of the past.

Imported bearings of this size are designated NN3020K (the presence of the letter K in the number is mandatory, as it indicates a tapered fit). In Russia, the most common products are from the following manufacturers: FAG, SKF, NACHI, IBC. Just like domestic bearings, imported ones are also widely sold as non-liquid items, primarily these are products of Eastern European manufacturers - URB (Romania) and FLT (Poland), produced and imported into the country during the existence of the Union. Chinese bearings CX, SZPK, ZWZ and others can also be sold under the guise of imported ones.

Dimensions and characteristics of bearing 3182120 (NN3020K)

- Inner diameter (d): – 100 mm;

- Outer diameter (D): – 150 mm;

- Width (H): – 37 mm;

- Weight: – 2.17 kg;

- Roller dimensions: - 11x11 mm;

- Number of rollers: - 60 pcs;

- Dynamic load capacity: - 160 kN;

- Static load capacity: - 247 kN;

- Maximum rated speed: - 6000 rpm.

Bearing diagram 3182120

Photo of bearing 3182120

Technical characteristics of bearing 46216

Bearing 46216 is a single row angular contact ball bearing with a contact angle of 26°.

Since there is only one row of balls, this type can only absorb axial load in one direction. If necessary, fix the shaft in both directions. Bearings are installed in pairs. Bearings that are lapped to each other at the factory with exactly matching contact angles (so-called “duplexes”) are placed on the shafts with high precision. They are sold as a set and are marked 446216. The direction of the perceived loads is radial and axial in one direction only. Axial load - up to 150% of unused permissible radial load.

The main plant for the production of angular contact bearings in our country is Saratov. The following modifications of this type are manufactured here: T-46216L, 4-46216L, 6-46216L, 46216L (T, 4, 6 are accuracy classes. Zero accuracy is not displayed in the number). This type of assembly is also carried out in Samara at SPZ-4 (the approximate price can be found here). Bearings from this manufacturer are much cheaper, but also worse.

Imported bearings (for example, SKF and FAG) of this type are marked according to ISO - 7216A. The brass separator is reflected by the presence of the letter M in the number.

Bearing dimensions and characteristics 46216 (7216A):

- Inner diameter (d): – 80 mm;

- Outer diameter (D): – 140 mm;

- Width (height) (H): – 26 mm;

- Weight: – 1.68 kg;

- Ball diameter: – 19.05 mm;

- Number of balls in the bearing: – 15 pcs.;

- Outer ring flange diameter: – 121.4 mm;

- Inner ring flange diameter: – 98.6 mm;

- Dynamic load capacity: – 87.9 kN;

- Static load capacity: – 60 kN;

- Rated rotation speed: – 5600 rpm.

Bearing diagram 46216

Photo of bearing 46216

Technical characteristics of bearing 697920L

Bearing No. 697920L The bearing is a roller, angular contact, conical (or this type is also called “with conical rollers”), double-row, wide series.

A distinctive feature is the presence of a bead on the outer ring, which simplifies the processing of mounting holes in the body. Bearings are manufactured with a predetermined axial clearance. The wide outer ring and increased cross-section allow installation without pressing. A different number of rollers in the rows helps dampen the resonant vibration of the spindle. Bearings are produced only with a high degree of accuracy (2 and 4), with brass cages, according to TU 37.006.107: 2-697920L1U and 4-697920L1U. The only manufacturer of this type is the Volzhsky Bearing Plant (former name - 15 GPZ), although formally the Samara Aviation Bearing Plant, a branch in Volzhsky, is considered the manufacturer. Both enterprises are part of the European Bearing Corporation. The sale of bearings is carried out by the EPK Trading House and a dealer network (buying bearings from dealers may be more profitable than at the Trading House, since they have a significant discount). The approximate price for a quality product with passports and a valid factory warranty is about 11,500 for a bearing of the second accuracy class. A 4th class product costs 800 - 1000 rubles less. In addition to representatives of the EPK, the bearing is sold en masse in companies that deal with illiquid products, and counterfeit bearings of this type have also been spotted, the markings on which are clearly falsified. All these products are distinguished by prices that are significantly lower than indicated.

This type is one of the few from the 697000 series, which is still very widely used in machines for various purposes at many enterprises in the country.

Technical characteristics of bearing 697920

- Inner diameter – 98.425 mm;

- Outer diameter – 152.4/159.34 mm;

- Width – 92 mm;

- Weight – 5.49 kg;

- Dynamic load capacity - 303 kN;

- Static load capacity - 559 kN;

- The maximum rated speed is 3300 rpm.

Bearing diagram 697920L

Photo of bearing 697920L

Technical characteristics of bearing No. 17716

Bearing 17716 is a roller, angular contact, tapered (or this type is also called “with tapered rollers”), single row.

This type is produced in accordance with TU 37.006.133. Contact angle? for this type it ranges from 10 to 18°, which allows it to be used under conditions of high radial and axial loads. A characteristic feature of products in this series is the presence of springs on the outer ring. Bearings of this type are currently produced only at one enterprise in the country - JSC Aviation Bearings Plant, or rather in its branch at 15 gas processing plants in the city of Volzhsky. Two modifications are manufactured: 2-17716 L4 and 4-17716 L4 (the difference is in the accuracy class). You can buy factory bearings at minimal prices only directly from dealers of the European Bearing Corporation, to which the manufacturer belongs, at a price of about 6,400 rubles (2nd degree of accuracy) and 5,000 (4th degree of accuracy), but it is extremely problematic. It is worth noting that this type of previous years of production can be purchased much cheaper (they are in abundance in the warehouses of companies engaged in buying out illiquid bearings), but in this case no one will give a guarantee of their performance.

Dimensions and characteristics of bearing 17716

- Inner diameter (d): – 80 mm;

- Outer diameter (D): – 100 mm;

- Width (H): – 77.07 mm;

- Weight: – 3.11 kg;

- Roller dimensions: - mm;

- Number of rollers: - pcs;

- Dynamic load capacity: - 153 kN;

- Static load capacity: - 211 kN;

- Maximum rated speed: - 4700 rpm.

Bearing diagram 17716

Photo of bearing 17716

Symbols of bearings according to GOST 3189-89 and GOST 520-2002

Russian marking system for rolling bearings. Main and additional digital designation:

Bearing symbols

Explanation of the digital designation of bearing No. 4-3182120:

The decoding of the designation should always start from the right edge of the marking:

№ 4-3182120

- code for the internal diameter of the inner ring - multiply the number in the designation (20) by a step of 5 mm, in our case the diameter is 100 mm .

№ 4-3182120

— designation of the series of diameters of the outer ring together with the seventh character (3000100), indicating the series of widths (heights), determines the dimensional series (dimension) of the bearing, GOST 3478

№ 4-3182120

— symbol of the bearing type. In our case - Radial roller with short cylindrical rollers

№ 4-3182120

— design of the bearing in accordance with GOST 3395. In our case: (182000) Radial roller bearing with short cylindrical, double-row with a tapered hole 1:12, with flanges on the inner ring, GOST 7634

№ 4-3182120

— Designation of the width series (3000100). Together with the third character, indicating a series of diameters, it determines the dimensional series (dimension) of the bearing.

№ 4-3182120

— Designation of the bearing accuracy class according to GOST 520-2002. In our case, accuracy class 4 is high.

Explanation of the digital designation of bearing No. 2-697920Л:

No. 2-697920Л

- code for the internal diameter of the inner ring - multiply the number in the designation (20) by a step of 5 mm, in our case the diameter is 100 mm .

No. 2-697920L

— designation of the series of diameters (6000900) of the outer ring, together with the seventh character indicating the series of widths (heights), determines the dimensional series (dimension) of the bearing.

No. 2-697920L

— design of the bearing in accordance with GOST 3395. In our case: (97000) Double-row tapered angular contact roller bearing with an internal spacer ring, GOST 6364

No. 2-697920L

— Designation of the width series (6000900). Defines the dimensional series (dimension) of the bearing.

No. 2-697920L

— In our case — accuracy class 2 — high (precision).

No. 2-697920L

—

Simplified table of bearing accuracy classes

The modern bearing marking system (GOST 520-2002), adopted in our country, distinguishes the following accuracy classes (in order of decreasing tolerances and increasing accuracy):

8, 7, 0, normal, 6X, 6, 5, 4, T, 2

- Highest accuracy classes - 5, 4, T, 2 precision.

- The lowest accuracy classes are 0, normal, 6X bearings for general use. (Class 6X - designated as X. Normal class, analogous to designation 0, may not be designated)

- Additional accuracy classes (below zero) - 7, 8

Bearings of higher accuracy classes 4, T, and 2 can cost several times more than lower classes - 5, 6, 0.

Letter designations of bearing accuracy class

Modern bearing accuracy class designations

Accuracy classes of bearings for machine spindles

Spindle bearings

Along with the usual requirements for rolling bearings in terms of their performance criteria, spindle rolling bearings are subject to additional requirements regarding the operating conditions of the spindle unit and the entire machine. These requirements include high rotational accuracy, increased radial and axial stiffness, low heat generation and low thermal deformation.

High rotational accuracy of the spindle assembly is achieved primarily through high precision manufacturing of rolling bearings. In table 11 shows the recommended accuracy classes of bearings for machine spindles.

Geometric errors of bearings with precision requirements above class C should be within 1-2 microns, the waviness of the ring raceways should be 0.1-0.2 microns, and the size difference and out-of-roundness of the rolling elements should be approximately 0.3 microns. The runout ∆ of the end of the spindle, limited by the requirements of processing accuracy, is associated with the runout of the front δA and rear δB supports, if they are directed in different directions (Fig. 20, a), a simple geometric relationship

If, when assembling the spindle assembly in accordance with the technical specifications, the installation of bearings is guaranteed (by rotating one of them in the housing) in such a way that their runout is directed in one direction (Fig. 20, b), then this sharply reduces the runout of the spindle end.

The choice of seating of rolling bearings has a great influence on the accuracy of spindle rotation, as well as on other criteria for the performance of the spindle assembly. As the interference increases, the shape of the raceways deteriorates, but at the same time, the averaging of bearing errors occurs to an even greater extent. The averaging of errors increases after eliminating the gaps in the bearing and increasing the tension to a certain value, which. and determines the appropriate choice of plantings.

For spindles of machine tools of accuracy classes N and P, it is recommended to install the outer and inner rings of angular contact ball bearings using the P1p fit, and the outer rings of roller bearings of type 3182100 using the H1p fit. In spindles of precision machines (accuracy classes B, A and C), it is desirable to guarantee a fit interference of up to 5 microns.

The stiffness of rolling bearings depends mainly on the type of bearing, its diameter and the amount of preload. The radial and axial stiffness of spindle bearings of the most common types are shown in Fig. 21. The stiffness of bearings is influenced by manufacturing errors. Non-perpendicularity of the end of the bearing ring of its axis can reduce the axial stiffness by 2-2.5 times; Increased bearing clearances significantly reduce both radial and axial stiffness.

Preload in rolling bearings used to support spindles is necessary to improve rotational accuracy and rigidity. During assembly, angular contact ball and tapered roller bearings are installed in pairs with preload.