Preparatory stage of bending plexiglass

The required shape can be given even at home. There are various methods and various devices for this.

Common to all methods are preparatory operations for processing. Preparation includes:

- cleaning plexiglass;

- drying sheets.

Cleaning plexiglass. It is produced without the use of abrasive materials and aggressive chemicals. The workpieces are washed with warm water and a small amount of detergent using a soft cloth or sponge. This is quite enough. To remove oil stains, you can use gasoline or kerosene. Do not use solvents, they can damage the glass.

You can use a sponge with the soft side to clean plexiglass

Drying sheets . It is better to dry naturally or with a hairdryer at a temperature of about 80 degrees. Drying must be carried out efficiently. The thicker the sheet, the longer it takes to dry. The calculation is as follows: for 1 mm of thickness the required heating time is 1 hour.

Plexiglas bending methods

Cold bending can be applied to acrylic glass, but in this case the bend must have a sufficiently large radius, at least 230 times the thickness of the sheet.

Therefore, plexiglass is bent in a heated state. It is necessary to take into account that plexiglass is afraid of open fire. Hot bending can be done with hot air or hot water.

You should not heat the entire workpiece; you only need to heat the bend points. For this purpose, a narrow heat source in the form of a stretched nichrome wire is used.

Thermal bending using a string

Plexiglas stands

To make various stands with smooth edges (for phones, price tags, promotional products), bending string is often used. This is nothing more than a tightly stretched nichrome wire connected to a source of electricity.

Plexiglass is placed over the wire, and it heats up in a matter of minutes strictly along the fold line.

The glass is immediately bent at the desired angle and fixed in this position until it cools. It is unacceptable to overheat the material to prevent it from melting and the appearance of air bubbles inside.

Disadvantages of the string:

- sags when heated and the uniformity of heating is disturbed, it is necessary to tighten it somehow;

- if the top and bottom sides of the sheet are heated unevenly, a stepped bend may result;

- to prevent the occurrence of stepped bending, you need to reduce the power and warm up longer;

- prolonged use of the wire leads to its burnout;

- the uneven thickness of such wire does not provide uniform heating along the bend line and an arc may result when bending;

- the possibility of a “saber” effect appearing when working with extruded plexiglass, when bending occurs along the extrusion line and shrinkage occurs.

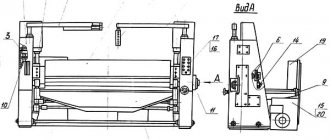

Thermal bending of plexiglass using a bending machine

In order to improve the bending of plexiglass, special machines have been developed - thermal designers. They automatically heat the plexiglass sheet, bend it in a straight line and cool it.

HRK machines for bending plexiglass

The heating element of this machine is also a nichrome thread, but not bare, but placed in a glass flask.

Some machines have several heating elements that can be moved at certain distances from each other.

The thickness of the processed plexiglass sheets is 0.3–200 mm, the width of the sheets can also be different - 0.6–2.4 meters.

The devices are equipped with an electromechanical or pneumatic drive. The machine body is water cooled to avoid overheating.

Characteristics of Plexiglas Bending Machine

Machines for bending plexiglass have a variety of models: intended for personal use or for industrial use.

For personal purposes, manually driven machines are used. There is also a foot drive, which frees your hands and is more convenient.

Industrial machines for bending acrylic are produced with an electromechanical or pneumatic drive.

The operating principle of all bending machines for plexiglass (thermal designers) is the same for all manufacturers:

Thermobending machine

- heating the acrylic surface;

- hot bending;

- cooling.

A special feature of plexiglass is its plasticity. When hot, it can be given any shape. Upon subsequent cooling, it retains this new shape.

Machines for bending plexiglass differ only in productivity, complexity and accuracy of work.

The new model of the Thermal Designer bending machine allows you to:

- install and maintain 16 lines simultaneously;

- microprocessor ensures high accuracy of heating time and temperature adjustment;

- The device is powered from a 220-volt electrical network, and the power consumption does not exceed 0.8 kW.

Variety of equipment options

There are quite a lot of configuration options for a machine for bending plexiglass.

The standard version contains:

- 2 main heating lines;

- 2 spare strings for bending;

- string length 1000 mm;

- the machines are equipped with a mini-table 80 mm wide and a stop-conductor, which move freely and are secured with screw clamps;

- digital countdown timer has light and sound alarm;

- More tables can be installed if necessary by completing the machine. Thus, the table surface can be increased to 400 mm.

Master1000-17 - standard acrylic bending machine

Some models have an upper frame that allows heating of the surface of the bending material on both sides. This option is necessary for thermobending thick plexiglass.

Warming up is carried out in a gentle mode. This saves electrical energy and extends the service life of the string.

The gap between the nichrome wire and the surface of the plexiglass is smoothly adjustable in the range of 9 mm with a visual indicator.

Plexiglas bending machine - complete set

Bending machines: thermobending of plexiglass, thermobending of acrylic and PET

Shannon bending machines are high-quality professional equipment for thermobending plexiglass, thermobending acrylic and thermobending PET and polymer materials of various thicknesses. The line of thermal design machines covers all the necessary needs for bending plexiglass. Depending on the specific task, be it bending plexiglass or bending acrylic for the production of POS materials, manufacturing translucent structures or implementing complex industrial projects, our specialists will help you select the necessary equipment.HR bending machinesA simple, professional bending machine ideal for technical universities, designers, prototype production, etc. The HR family of machines is equipped with one heating element and has a large number of working surface length options (from 50 to 300 cm). The maximum thickness of the bendable material is 10 mm. | |

HRT bending machinesHRT are reliable machines for bending thermoplastic sheets. They are successfully used for the production of stands, displays, price tags and other products requiring complex and multiple bends (up to 4 at a time). The maximum thickness of bendable material is 8 mm. Working surface length from 65 to 300 cm. | |

HRM bending machinesShannon HRM is a high-performance HRT-based machine equipped with bottom heating. The upper clamping frames allow you to reduce the heating time of workpieces and increase the productivity of the machine. Working surface length 125 cm. | |

HRK bending machinesShannon HRK is a modular, productive and quickly transformable semi-automatic machine with bottom and top heating for the production of products with complex bending shapes from polymer sheets. The upper frame is controlled pneumatically using a foot switch and timer. The maximum thickness of the bendable material is 20 mm. Working surface length 65 and 125 cm. | |

Plastic bending machine AFFShannon HRK is a modular, productive and quickly transformable semi-automatic machine with bottom and top heating for the production of products with complex bending shapes from polymer sheets. The upper frame is controlled pneumatically using a foot switch and timer. The maximum thickness of the bendable material is 20 mm. Working surface length 65 and 125 cm. | |

Bending machines HRP/SShannon HRP/S is an easily transformable, semi-automatic machine for the production of products with multiple bends of thermoplastic sheets, in industrial production, equipped with lower and upper heating elements. Designed to work with materials with a thickness of 1 to 15 mm. Working surface length 220 and 300 cm. | |

HRP bending machinesShannon bending machines of the HRP model range are reliable, quickly transformable semi-automatic machines with double-sided heating for the production of large-sized products requiring complex and multiple bending of thermoplastic sheets in industrial production. They are designed to work with materials with a thickness of 1 to 20 mm. The length of the working surface is 220 and 300 cm. The distance between the reflective elements varies in the range from 20 to 1000 mm. | |

HRP/D bending machinesShannon HRP/D is a productive, quickly transformable semi-automatic machine with double-sided heating for bending thermoplastic sheets. The machine allows you to provide a conveyor system for the production of both large-sized and small serial products. The maximum thickness of the bendable material is 20 mm. | |

Bending machines HRT/DThe HRT/D machine is a modification of the HRP/D without an upper frame. Shannon HRT/D is equipped with a transport system and, like HRP/D, can process 2000 - 3000 workpieces per hour. The maximum thickness of the bendable material is 10 mm. | |

FBM bending machinesShannon FBM is a high-performance automatic bending machine for the production of large series of thin polymer films. The machine is designed for bending polymer films of materials such as polyvinyl chloride (PVC), polyethylene terephthalate (PET-G) and others with a thickness of 0.4 to 1 mm. |

Advantages of using the machine

A machine for bending plexiglass has many advantages compared to manual bending:

One of the advantages of bending machines is that the products are perfectly straight.

- high productivity due to the possibility of increasing the number of working lines;

- use of 220 volt voltage, economical power consumption;

- individual setting of each heating line;

- possibility of heating the surface of the material from both sides;

- ease of control, presence of a timer with sound and light alarm;

- The heating mode is gentle, extends the operating time of the device and improves the quality of the products produced;

- the ability to customize operating parameters taking into account individual requirements.

Purposes of processing personal information of Users

2.1. The website spectrum-laser.ru processes the User’s personal information for the following purposes:

2.1.1. Communication with the User, including sending notifications, requests and information regarding the use of the spectrum-laser.ru website, execution of agreements and contracts, as well as processing requests and applications from the User.

After sending personal information, the User automatically subscribes to the spectrum-laser.ru website newsletter (unsubscribe links are located at the end of each letter).

2.2.2. Improving the quality of the website spectrum-laser.ru, ease of use;

2.2.3. Targeting of advertising materials;

2.2.4. Conducting statistical and other studies based on anonymized data.

Making a hot bending machine with your own hands

With this bending machine you can bend plexiglass and plastic using nichrome thread. Heating is carried out at a distance from the surface of the material using a nichrome wire connected to a power source. The heating lines can be turned on and off separately. The electric voltage is 24 V. A power regulator and a timer are installed to count the heating time.

The tension of a nichrome thread can be calculated by its length and thickness. There is quite a lot of information on the Internet on this issue.

Stages of manufacturing a bending machine

Assembly sequence:

- First you need to weld a frame from a 20x20 mm profile pipe.

- The frame dimensions are 70x70x30 cm, but this is not important. You can make it longer if necessary.

- The frame needs to be powder coated and lugs welded to the top to secure the aluminum channels.

- Attach aluminum channels to the frame. They will be guides for the heating lines.

- At the top of the frame, you need to weld two more tubes to attach the machine control unit.

- Next, a housing for the control unit is selected, measuring approximately 30x30x12 cm.

- The body needs to be painted and installed on the frame.

- To accurately position the workpiece, it is necessary to make a stop bar. A piece of aluminum channel and a corner are suitable for it.

- The corner needs to be placed inside the channel and riveted. The corner should be 2–3 mm higher than the channel ribs.

- Cut the channel for the heating line. It should be 20 cm longer than the nichrome wire (string).

- At one end of the channel the string is fixed motionless. At the other end, the string is screwed to a movable PCB plate.

- The string should not touch the channel. The PCB plate is attracted to the end of the channel using an installed spring.

- The power cable is a two-core copper wire with double insulation with a cross-section of at least 1.5.

- The power source can be an industrial switching power supply 350 W with a voltage of 24 V. It is enough for 2 heating lines.

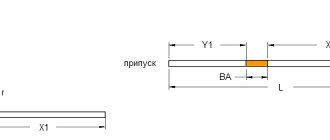

Drawing of a bending machine for plexiglass

June 19, 2020

The section on fiber optic emitters has been expanded and updated .

November 01, 2019

The line of laser machines for metal cutting has been expanded. Catalog of machines. In the coming season, we offer supplies at affordable prices.

September 09, 2019

Available for order Manual laser welding machine TST-W2000F

June 6, 2019

Laser tubes LA SEA CL-1600, 80W have arrived at the warehouse

March 6, 2019

Promotion!

Reduced price for laser welding machine TST-W200JH

January 09, 2019

Due to changes in VAT, prices may vary!

05 December 2018

Reduced prices for optics for fiber optic machines.

November 16, 2018

Promotion until the end of the year! Laser machine 1kW with cast iron frame at the best price! 3 year warranty!

September 27, 2018

Special offer for a 1kW metal laser cutting machine, metal cutting up to 12mm

September 10, 2018

Prices have been reduced for the entire line of laser markers, both

fiber optic and CO2

August 24, 2018

The line of fiber laser machines has been expanded

with a robotic 3D complex

July 20, 2018

The TST-500 CNC laser welding machine for handles into in the city of Dimitrovgrad

June 06, 2018

The TST-W200XT3 laser welding machine was put into operation in the city of Volzhsk

May 04, 2018

Used TST-1290 machine for sale

April 10, 2018

We offer used TST- 5030 40W good condition, with warranty.

January 22, 2018

The “Laser Machines” section has been updated, new series of machines have been added, now there is a machine just for you!

December 28, 2017

Happy New Year 2021 everyone!!!)))

December 11, 2017

The line of fiber optic metal cutting machines has been updated !

The price has fallen, the quality has increased!!! October 12, 2017

the TST-W200JH laser welding machine has arrived at the warehouse , we invite you to familiarize yourself with the equipment.

September 7, 2017

An exhibition machine for sale at a discount - engraver TST-5030 50 W with a guarantee .

engraver TST-5030 50 W September 7, 2017

We are also reducing prices for CO2 markers .

Fiber optic markers September 6, 2017

Autumn price reduction for markers .

Fiber optic markers July 20, 2017

The range

of machines for the production of three-dimensional letters . Added notching machines: TST-SN01 and TST-SN02 . Inexpensive production automation tool. Allows you to greatly speed up the process of manufacturing the end of three-dimensional letters from a metal strip. Machines for making three-dimensional letters

May 22, 2017

TST-W500L

machine has appeared in the section of laser welding machines May 12, 2017

A fiber optic marker has appeared in stock:

-

TST-F20A laser marker

May 10, 2017

A used fiber optic marker has appeared in stock

-

TST- Laser marker F10 10W

April 21, 2017

For sale is an exhibition copy

of TSB-1006 , minimal wear, with a guarantee. April 19, 2017

Updated laser welding machines, power increased to 200 w.:

—

TST-W200J laser welding machine — TST-W200JH laser welding machine

March 1, 2017

New arrival of equipment:

—

TST-9060 80W laser machine — TST-1290 80W laser machine

01 February 2017

Holders for laser tubes are now on sale -

Holder for laser tube (set)

January 27, 2017

A new machine has appeared on sale -

Laser machine TST-1509 2x150W

January 13, 2017

We now have laser tubes "PURI" of the highest quality 40W, 50W, 60W, 80W, 100W, 120W, 150W, 180W -

Laser tubes "PURI"

October 06, 2016

An updated series of machines for making three-dimensional letters has been released - a bending machine for letters -

The machines have become more advanced, the price is more affordable!

July 21, 2016

New lenses 25=D appeared on sale –

Lens d=25.4 f=3.0” (76.2) – Lens d=25.4 f=2.5” (63.5) – Lens d=25.4 f=2” (50.8)

July 08, 2016

New lenses 20=D appeared on sale -

Lens d=20 f=50 - Lens d=20 f=63 - Lens d=20 f=76

June 16, 2016

Prices have been reduced for popular laser emitters of the CL and F series -

Laser emitters CL - series - Laser emitters F - series

May 26, 2016

New machines have appeared on sale -

Laser marking machine TST-M2020 60/80W - Laser marking machine TST-M1010 60/80W

April 26, 2016

TSB series machines are now equipped with Wi-Fi

, no wire needed!

March 24, 2016

Reduced prices for Fiber Optic Markers

March 22, 2016

Reduced prices for General Purpose Laser Machines

March 15, 2016

A new material has appeared on sale - Section:

Materials for engraving

February 18, 2016

Reduced prices for machines:

Universal laser machines (metal/non-metal) -

Universal laser cutting and engraving machine TST-1390 180W for metal and non-metal - Universal precision laser cutting machine TST- 1325M 150W for metal and non-metal

February 15, 2016

PROMOTION ON MACHINES!!! 10% DISCOUNT UNTIL 03/01/16 - Laser machine TST-1309 60W - Laser machine TST-1325 130W

January 4, 2016

New equipment arrivals:

Laser emitters of the CL and F series have arrived at the warehouse -

Laser tube CL-1200, 60W - Laser tube F2, 80W

October 20, 2015

Used

TST-5030 50W machine for sale.

August 4, 2015

Great offer on: Fiber optic metal laser cutting machines

August 4, 2015

New equipment arrivals: Laser marker TST-F20 mini

Features of homemade equipment

Plexiglas can be bent using a regular hair dryer, or you can make a simple homemade thermal bender using nichrome wire. But such bending methods are only suitable for material with a thickness of no more than 6 mm. Even with a workpiece thickness of 8 mm, it is necessary to increase the heating time and turn the workpiece over. Bending acrylic with a thickness of 10 mm or more is difficult, especially with one-sided heating.

For serious work involving the production of large quantities of products, an appropriate bending machine is required. The variety of models offered will allow you to implement a variety of plans.

And the scope of application of thermobending products is very wide. These are elements of industrial structures, stands for jewelry and perfumes, price tags and information stands for stores, booklets and other advertising products.