Specifications

The 1500 series machine has the following set of characteristics:

- The diameter of the workpiece being processed is up to 2.5 m.

- The vertical length of the products is 1.6 m.

- The size of the faceplate is 225 cm.

- Workpiece weight – up to 16t.

- The number of faceplate rotations per minute is from 16 to 80.

- The material feed speed is up to 16 millimeters per revolution.

- Torque – up to 67 kN*m.

- Electric motor power – 45 kW.

- The vertical moving capacity of the supports is up to 1.2 m.

- The horizontal moving capacity of the supports is up to 1.7 m.

- The speed of movement of the installation is 2 m/min.

- The cross-section of the cutter holders is 63mm.

- Machine size – 5.07m/6.34m/5.1m.

- The weight of the device is 35.5 tons.

Vertical turning lathe 1525 technical specifications

Home » Machine » Rotary lathe 1525 technical specifications

Universal two-column vertical turning lathe with manual control 1525.300

Price as of January 28, 2018 - request price

| Buy | Add to comparison |

The universal two-column vertical turning lathe with manual control 1525.300 is designed for productive roughing and finishing machining of various workpieces made of ferrous and non-ferrous metals.

The machines can perform the following work:

- Turning and boring of cylindrical and conical surfaces;

- Grinding of end surfaces, including at a constant cutting speed;

- Grooving and parting;

- Drilling, countersinking and reaming of central holes.

Technical data of machine 1525.300

| Maximum diameter of the workpiece, mm | 2500 |

| Maximum height of the workpiece, mm | 1600 |

| Maximum mass of workpiece processed, kg | 16000 |

| Faceplate diameter, mm | 2250 |

| Faceplate rotation speed range, rpm | 1.6-80 |

| Range of working feeds, mm/rev | 0.04-16 |

| Main drive motor power, kW | 45 |

| Threading and taper machining | By order |

| Processing curved surfaces using a copier | By order |

| Side caliper | By order |

| Vertical slide with 5-position turret instead of boring | By order |

| Dimensions (LxBxH), mm | 5070x6340x5100 |

| Weight 1525.300 machine, kg | 35500 |

rustan.ru

Vertical turning lathe 1525

Manufacturer: Russia

The rotary turning lathe 1525 is designed for productive roughing and finishing processing of various workpieces made of ferrous and non-ferrous metals.

The machines can perform the following work:

Turning and boring of cylindrical and conical surfaces;

Grinding of end surfaces, including at a constant cutting speed;

Grooving and parting;

Drilling, countersinking and reaming of central holes.

Machines with index F1 are equipped with a digital display device

Technical characteristics of rotary turning machines 1525, 1525F1, 1L532, 1L532F1

Technical data of machines 1525, 1525F1 1L532, 1L532F1

| Maximum diameter of the workpiece, mm | 2500 | 3200 |

| Maximum height of the workpiece, mm | 1600 | |

| Maximum mass of workpiece processed, kg | 16000 | |

| Faceplate diameter, mm | 2250 | 2800 |

| Faceplate rotation speed range, rpm | 1.6-80 | 1.25-63 |

| Range of working feeds, mm/rev | 0.04-16 | |

| Main drive motor power, kW | 45 | 55 |

| Threading and taper machining | By order | |

| Processing curved surfaces using a copier | By order | |

| Side caliper | By order | |

| Vertical slide with 5-position turret instead of boring | By order | |

| Dimensions (LxBxH), mm | 5070x6340x5100 | 5490x6540x5100 |

| Machine weight, kg | 35500 | 43000 |

www.russtanko.ru

1525F1 machine characteristics

Buy this machine without intermediaries:

Specifications:

Machines model 1525f1 are designed for productive roughing and finishing processing of various workpieces made of ferrous and non-ferrous metals. The machines can be used to: · Turning and boring of cylindrical and conical surfaces, · Turning of end surfaces, including at a constant cutting speed, · Grooving and cutting, · Drilling, countersinking and reaming of central holes

The largest diameter of the processed part mm 2500 The largest height of the processed part mm 1600 diameter of the planhayba mm 2240 The largest part of the processed part KG 16000 is the largest section of the section of the cutter mm 63 The largest stroke of the upper calipers MM 1390 The largest stroke length of the upper calipers mm 1200 Number of rotation speeds faceplates 18 Faceplate rotation speed limits rpm 1.6-80 Number of caliper feed stages 18 Caliper feed rate along each axis mm/rev 0.04-16 Highest speed of caliper installation movements m/min 2 Maximum cross member movement mm 1240 Maximum permissible torque torque kNm 50 Main motion electric motor power kW 45 Overall dimensions mm 6420x5070x5100 Machine weight kg 36000

Buy this machine without intermediaries:

mashinform.ru

i-perf.ru

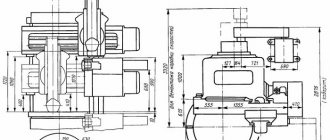

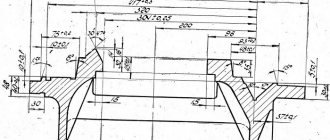

Dimensions of the working space of the machine 1525

The 1525 rotary lathe has large dimensions, so it will require a lot of space.

In the passport of the 1525 rotary lathe you will find information about the working space, which is presented in the form of a drawing.

For normal operation, a space of 1-2 m around the device is required.

Universal two-column vertical turning lathe with manual control 1525.300

The universal two-column vertical turning lathe with manual control 1525.300 is designed for productive roughing and finishing machining of various workpieces made of ferrous and non-ferrous metals.

The machines can perform the following work:

- Turning and boring of cylindrical and conical surfaces;

- Grinding of end surfaces, including at a constant cutting speed;

- Grooving and parting;

- Drilling, countersinking and reaming of central holes.

Technical characteristics of the rotary lathe 1525.300

| Machine technical data | 1525.300 |

| Maximum diameter of the workpiece, mm | 2500 |

| Maximum height of the workpiece, mm | 1600 |

| Maximum mass of workpiece processed, kg | 16000 |

| Faceplate diameter, mm | 2250 |

| Faceplate rotation speed range, rpm | 1.6-80 |

| Range of working feeds, mm/rev | 0.04-16 |

| Main drive motor power, kW | 45 |

| Threading and taper machining | By order |

| Processing curved surfaces using a copier | By order |

| Side caliper | By order |

| Vertical slide with 5-position turret instead of boring | By order |

| Dimensions (LxBxH), mm | 5070x6340x5100 |

| Weight 1525.300 machine, kg | 35500 |

rustan.ru

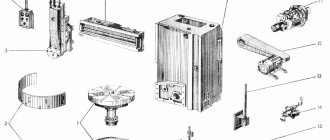

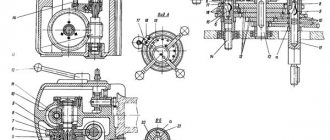

Location and list of components

- Racks are the basis for supporting equipment parts.

- The mechanism for transmitting movement to the feed is located on the outer side of each leaf.

- Gearbox. It is located in the inner part of the structure, next to the motor.

- Casing.

- Table.

- Faceplate.

- Crossbar. It is located in the center, fastening the 2 doors.

- Moving mechanism. It is located on top, above the sash.

- Two vertical supports. They are located in the lower part of the caliper moving mechanism, on the right and left.

- Two gearboxes - located in the inside of the device, next to the motor mechanism, on the left and right.

- Remote Control. Located outside the structure, on the right. Attached to the moving mechanism of the cross member.

- Control panel suspension. It is attached to the moving mechanism at the top, securing it to the remote control.

- Machine power sensor. Allows you to monitor the power and energy consumption of work operations, as well as establish control over them.

- Electrical cabinet Located on the outside of the equipment. Receives workpieces for processing.

Machine 1525. Rotary lathe. Manual

This “ Operating Manual for Vertical Lathe 1525 ” contains information necessary both for the operating personnel of this machine and for the employee directly involved in working on this machine. This manual is an electronic version in PDF format of the original paper version. This documentation contains the Passport and Manual (instructions) for the operation of the 1525 rotary lathe.

CONTENT

Technical description

- Purpose and scope of machines

- Machine composition

- Design and operation of the machine and its components

- Kinematic scheme

- Gearbox

- Table

- Feed motion transmission mechanism

- Gearbox

- Cross member and cross member moving mechanism

- Lower left caliper

- Upper revolving non-rotating support

- Adjusting the turret head rotation and clamping mechanism

- Sensors horizontal and vertical

- Lubrication system

- Description of work

- User manual

- Safety instructions

- Installation procedure

- Installation of machines

- Setup, adjustment and operating modes

- Regulation

- Features of disassembly and assembly during repairs

- Machine repair

Passport

- General information

- Basic technical data and characteristics

- Repair information

- Information about changes to the machine

- Contents of delivery

- Certificate of acceptance

- Certificate of conservation

- Guarantees

download the operating manual for the 1525 rotary lathe in good quality from the link below.

Controls

The controls are used to adjust the speeds of the machine. They are located on the sides of two gearboxes. The lowest control is located on the table, on top.

Characteristics of electrical equipment

It is a complex system consisting of electric motors, switches and controls.

The rotary lathe is equipped with 6 electric motors, which have a short-circuit rotor.

List of components of electrical equipment:

- Main drive IM1.

- Oil pump drive IM2.

- Cross member mover IM3.

- IM4 cross member clamp and releaser.

- The installation slider for the right and left caliper is 2MI and 3MI.

Manual

Before you start working with the equipment, it must be installed.

Since the machine is large in size, it needs to be disassembled in parts and placed in wooden boxes. After unloading them, you can assemble the device.

The main operating mode is divided into several stages:

- Control of the main drive using the main console. Regulates the number of revolutions of the faceplate, starting and stopping the faceplate

- Control of feeds and movements of calipers. Switches 8 and 16 must be moved to a position that will correspond to feed or movement.

- Manual movements. They are carried out using flywheels.

- Control of the cross member mover. For control, use the 2 left buttons of the pendant.

- Fastening tools. They are mounted in the holes of the sliders on tightening wedges.

- Fastening the workpiece. Clamping jaws are used for fastening to the washer.