Repair work often involves painting various surfaces. To save time and get an even result, you can use a spray gun. But having this device in the house is not always possible; in such cases, you can build it from improvised means. You can make a spray gun with your own hands from a vacuum cleaner, and this does not require a lot of time and skills. This process will be discussed in more detail below.

Spray gun for vacuum cleaner: description

The spray gun for a vacuum cleaner is a design with a tank for coloring agents, located on top, ensuring a uniform supply of paint. Through a special hole, the paint and varnish material enters the spray gun. Its spraying occurs due to the air flow coming from the operation of the vacuum cleaner.

A homemade spray gun attachment for a vacuum cleaner is made from an ordinary lid for cans, covering an existing container with a volume of up to a liter. The hole on the lid should have a diameter of 30 millimeters; if there is no such hole, you can use a special adapter. This design is easy to make and is convenient for painting work.

The spray gun for a vacuum cleaner is a design with a tank for coloring agents, located on top, ensuring a uniform supply of paint.

Spray gun for vacuum cleaner

The device of a spray gun with a vacuum cleaner.

The Intertool PT-0303 paint sprayer is equipped with an upper tank, so the liquid falls onto the spray head under its own weight. After which it is pushed out by a stream of air supplied by a third-party source - a vacuum cleaner (or other compressor). The volume of the tank is 200 ml, the diameter of the nozzle is 0.5 mm. Operating pressure can vary from 3.5 to 5 Bar with an air flow of up to 130 liters per minute. This data is provided by the manufacturer.

The attachment in the form of a lid on a standard jar is put on a regular container with a capacity of 0.5 to 1 liter. The inlet hole on the cover is designed for a 30 mm hose, so if the diameter does not match, you should use an adapter. This device is very cheap and the best atomizer at home. Mainly used for water-soluble paints and lime mortar for whitewashing.

Operating principle of an air spray gun

To make it easier to build a properly working sprayer for a vacuum cleaner, it is useful to understand the operating principle of a factory paint sprayer. The spray gun operates using compressed air, so it requires a device that ensures this movement. In this case, this role is performed by a special compressor; its operation is carried out using gasoline or the electrical network.

Pneumatic spray guns work with powerful compressors, usually having large volumes of receivers - up to 30 liters, and are semi-stationary devices. Also on sale you can choose options with a smaller receiver volume; they are conveniently mounted on the shoulder. When it comes to a compressor in the form of a vacuum cleaner, then the lightweight second option is suitable, because you will get a low-pressure spray gun for a vacuum cleaner, while in pneumatics the pressure is higher.

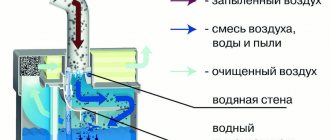

Speaking about the structure of the sprayer itself, it must be said that it consists of a body with a trigger, a needle, a nozzle, a spray part and a lower container. By pressing the trigger, the master moves the needle, the cone-shaped tip of which closes the flow of paint from the nozzle. There are two tubes in the container: short and long. The first is necessary for air penetration, the second for the supply of coloring agent. Due to air pressure, the liquid is pushed out of the container and exits through the nozzle; part of the air ends up in the channels of the air cap, subsequently following the liquid and breaking it into smaller fractions.

The spray gun operates using compressed air.

Making a spray gun with your own hands

Before you start making your own paint sprayer, you will need to prepare the initial apparatus. Also gather all the necessary parts and tools so that they are on hand.

Preparing the vacuum cleaner

First of all, remove the dust collectors included in the device - everything that accumulates and traps dust. This is especially true for filters. Wash other parts thoroughly and minimize exposure to dust before starting the assembly process. Carry out a wet cleaning in advance in the room where the assembly will take place.

Required parts and tools

To create a spray gun you will need:

- the apparatus itself, operating as a pressure source (vacuum cleaner with a hose);

- receiver (you can use a rubber bladder - a car one or from a ball);

- container for paint and varnish liquids of the required volume;

- pressure reducing valve;

- any of the suitable fastening materials.

Manufacturing process

To change the direction of draft in an old vacuum cleaner, you need to force its motor to rotate in the opposite direction, then the movement of the air flow will change. Try reversing the polarity of the terminals leading to the rotor and stator. But the reverse thrust force will still depend on the design of the impeller blades. If they are asymmetrical, then the reverse thrust will become significantly weaker than the original, standard one. If possible, it is better to replace the impeller with another one with symmetrical blades.

Next, you should ensure constant pressure using a receiver. The principle of a homemade sprayer is the same as that of a factory one: paint and varnish materials are sprayed from a container into which they are previously filled through a nozzle.

A pressure reducing valve is required, as it is responsible for the throughput of the sprayer.

If the old model does not have a special socket designed to connect a hose, you can create it yourself. There are two ways:

- Seal all air outlet openings (use any suitable material: polyurethane foam, hot melt adhesive, epoxy resin). At the location of the blower, cut a hole of the same diameter as the inside of the existing hose. Select a piece of PVC pipe of the appropriate size, insert it into the hole and glue it tightly. Calculate so that there is at least 7 cm of pipe outside. You will get a supercharger for a paint sprayer.

- The second method does not require making a hole in the case. You need a large durable bag, insulating tape and another hose - it will supply air. You place the device inside the bag, take the “original” hose out and tightly wrap everything with insulation. The outgoing air will fill the space of the bag and will flow through the second hose. The method will work reliably if the bag is quite dense and all possible holes are properly sealed.

The device needs to be cleaned. To do this, pour 100–150 g of solvent into the container and turn on the device for at least 10 minutes.

When spraying the solvent, try to adjust the operation of the nozzle and the pressure in the structure so that your homemade device does not spit paint materials, but applies them to the surface in an even layer.

Nuances

Be careful when choosing fasteners - they should seal the joints of all parts of the device as tightly as possible.

Already at the “design” stage and during the assembly process, it is possible to provide for the option of using different burners with nozzles of different widths. This will make the tool more versatile.

Types of spray guns for vacuum cleaners

In Soviet times, special sprayers for vacuum cleaners were sold; such a convenient rarity is almost impossible to find on sale at the moment. But modern analogues have appeared on the market.

So you need to purchase a spray nozzle for the vacuum cleaner. You can find such a spare part on sale. a part that is intended for an electric spray gun with a remote compressor.

In total such app. parts go on sale from two brands “ZUBRA” and “WAGNER”. Apart from these companies, no one else produces ready-made versions of sprayers separately.

You will need to purchase a spray nozzle for your vacuum cleaner.

Which vacuum cleaner to use

When choosing a vacuum cleaner that is suitable for painting work as an air blower, first of all, we focus on power. If there is not enough power, then the spraying will not work well enough. Also, the vacuum cleaner must have a special channel; if it is missing, they resort to closing all existing holes in the device so that suction occurs only from one place where the hose will be attached.

Options for vacuum cleaners that already have the necessary hole are the old Soviet models “Ural”, “Pioneer” and others. Among the new models we can note the Samsung SC4140.

But you can make do with the available equipment; this will be discussed later.

When choosing a vacuum cleaner that is suitable for painting work as an air blower, first of all, we focus on power.

Spray gun from a vacuum cleaner

This is a long-known design. To make it you will need:

- Vacuum cleaner. Most household models with a blowing function are not suitable due to the limited operating time in this mode. You need special construction vacuum cleaners or old Soviet models with a hose connected to the blowing air duct.

- Spray. You can use a homemade device of the design already discussed. It is necessary to take care of the adapter from the vacuum cleaner hose to the spray tube. You can use a special spray nozzle that was included with Soviet vacuum cleaners. It fits tightly onto a standard glass jar and is easy to use. Nowadays, very few manufacturers produce nozzles. They are expensive and only fit certain models of vacuum cleaners.

The ideal paint composition for painting with a vacuum cleaner is liquid paints or enamels diluted to this consistency. The vacuum cleaner is not powerful enough to spray more viscous paints. Increasing the force of the air flow by sealing the technological holes in the housing with tape or tow is a bad solution. The cooling of the engine will be disrupted, it will heat up, work under overload and quickly fail.

Advantages:

- ease of use;

- coloring quality.

Flaws:

- low air flow power;

- high paint consumption;

- short air hose.

Conclusions: a spray gun made from a vacuum cleaner is a design that has been tested for decades and gives good results. Scope of application: painting and whitewashing work in the house.

Advantages of a homemade device

An obvious positive factor of such a device is its low cost. You can make it from scrap materials; you don’t need to buy a lot of them. The homemade version copes well with the task and can significantly facilitate painting work. This attachment is also suitable for whitewashing a vacuum cleaner. In addition, if the device is manufactured correctly, it will be able to spray water-based and acrylic paints well, which factory sprayers cannot always spray.

The homemade version copes well with the task and can significantly facilitate painting work.

How to make

If you happen to have a special attachment at hand that came with Soviet vacuum cleaner models, then this is the fastest and easiest option. It is simply put on a liter jar. Next, the outlet hole is adjusted to the desired parameters. And the edge of the hose from the vacuum cleaner is adjusted to the air inlet to the sprayer; if necessary, an adapter is used to adjust the holes to each other. Other manufacturing options are described below.

The edge of the hose from the vacuum cleaner is adjusted to the air inlet to the sprayer.

Preparing the vacuum cleaner

First you need to remove the dust collectors in the device, no matter what they are. The remaining parts of the device need to be wiped and cleaned of dirt. Also, in the room where the paint sprayer for the vacuum cleaner will be assembled, wet cleaning should be carried out.

The room where the paint sprayer for the vacuum cleaner will be assembled should be wet cleaned.

Required parts and tools

To create this unit you will need the following tools and accessories:

- Vacuum cleaner;

- Receiver, a rubber inner tube or a ball is suitable for this purpose;

- Container where the paint will be poured;

- Reducing valve;

- Fasteners

To create this unit you will need special tools and devices.

Manufacturing process

It is necessary to change the direction of thrust in the old device. To do this, the engine should be forced to move in the other direction. You can reverse the terminals going to the rotor and stator. But still, the impeller blades will influence the traction force. If they have an asymmetrical shape, then it is better to change them to a version with symmetrical blades.

Then they proceed to preparing the required pressure on the sprayer. To do this, you need to perform one of the options for preparing any type of existing vacuum cleaner for work:

- All existing holes must be closed; for this purpose, polyurethane foam, hot melt adhesive, epoxy resin and other means are used that can ensure reliable sealing. At the blowing point, make a round hole suitable for the hose. Next, a piece of PVC pipe is placed in it; it should be left outside by about seven centimeters. This option is suitable for an old device that you don’t mind;

- A more humane method in relation to the device. You need to prepare a large, thick bag and a second hose. The vacuum cleaner itself is placed in a bag, and the hose from it is led out, it closes tightly; electrical tape is suitable for this. Thus, the air will circulate in the bag and then exit through the second hose. For the process to go smoothly, the bag must be reliable, and all holes must be properly sealed.

Then the device is cleaned, 150 grams of solvent is poured into the container, and the vacuum cleaner is turned on for ten minutes.

It is necessary to change the direction of thrust in the old device.

Testing and operating rules

You need to test the device first. To do this, it is advisable to paint a small area of the surface on the street, and you need to keep it at a distance of 20 cm from the object. It is better to keep the nozzle diameter to a minimum.

Operating rules:

- The coloring agent must be strained;

- The conductive channels are washed before and after work;

- Do not allow the spray unit to turn over during the painting process.

Do not allow the spray unit to turn over during the painting process.

DIY spray gun - how to make a spray gun from a vacuum cleaner

In order to paint walls or ceilings, a spray gun attachment for a vacuum cleaner is often used instead of a roller, which allows the job to be done much faster. The spray gun can be purchased in specialized stores or made by yourself.

Go to the store

With the right approach, the second option will be no less convenient than the first, but will cost several times less.

One option is a special attachment for a spray gun, which can be attached to a standard vacuum cleaner used as a compressor, and then used to quickly and efficiently paint walls with water-based or acrylic paint or ceilings with lime. Such a spray gun will be cheap, and if you make it yourself, it will be completely free, but the benefits from it are enormous.

Using such a device makes it possible not only to reduce the labor intensity of the painting process, but also to achieve ideal quality. Thus, the coating will last much longer and will not require updating too early.

Spray gun or roller?

Many craftsmen who do their own renovations in their apartments use ordinary rollers. But hand painting has several disadvantages when compared to using a spray gun. For example, the smoothness and thinness of the coating that a special sprayer gives cannot be achieved using a roller.

But this is far from the only positive side of using a spray gun. When used correctly, the surface will be neat and smooth. This effect cannot be achieved when using a roller, which often leaves lint and other imperfections. This debris deposit, which is very difficult to get rid of, is often very noticeable and spoils the overall impression of the renovation.

In addition, do not forget that the spray gun makes it possible to apply paint not only thinly, evenly and accurately, but also as quickly as possible. For people who value their time, this is an important plus. You can also forget about the need to thoroughly clean the space around the surface being treated. When using a roller, situations often occur when paint drips onto the floor, remains on furniture, etc. The spray gun makes it possible to carry out the surface painting procedure much more accurately. However, especially valuable things and items that cannot be washed afterwards should be put away. During the use of the device, a cloud of paint particles often forms, which can settle not only on the surface being painted, but also beyond it. However, when using spray gun attachments, you can achieve excellent results, and the cleanup after painting work will be minimal.

What kind of spray gun can it be?

Nowadays, several versions of the spray gun are used. They all differ in their power and the number of possible settings. For example, some designs, such as pneumatic options, are desirable to be used in large spaces. They are not suitable for painting walls in an ordinary apartment. Other mechanisms, such as manual ones, will be more economical and convenient for home repairs.

In total, experts distinguish 5 types of paint sprayers. These are pneumatic spray guns, manual, vacuum, electric, as well as a vacuum and pneumatic set. The first type of spray gun is the simplest, and even a beginner can easily handle its use. However, the use of such an installation requires careful handling. Otherwise, you may end up with uneven layers of paint. They will not be noticeable if you use the installation for painting walls with water-based emulsion or ceilings with lime. But you should not use such a device for painting a car or other metal coating.

An electric spray gun would be a much more convenient option. Such devices are widely used for home repairs. However, you need to take into account that electric options are somewhat more expensive if you purchase ready-made ones in a store. But a thrifty craftsman will always find a way to save money, since an electric device can be made from an ordinary vacuum cleaner if you make a special spray nozzle for it for a spray gun.

As for pneumatic and vacuum modifications, they are mostly used in factories and factories. Vacuum spray guns can most often be found in railway depots, where they are used to paint trains and tracks. In furniture factories, the most successful type of spray gun is considered to be a vacuum-pneumatic device. With its help, you can apply paint to the surface of wooden and metal products not only quickly, but also as smoothly as possible.

Paint sprayer from a vacuum cleaner

There are several options on how to save money and make a spray gun for home use with your own hands. One of the interesting and most convenient methods is a compressor from a vacuum cleaner. A special nozzle for a spray gun is put on its hose, through which paint will be sprayed under pressure.

Experts highly appreciate the useful qualities of such devices. It is believed that if you use a vacuum cleaner correctly as a paint sprayer, you can achieve excellent results and quickly process even complex surfaces. Craftsmen sometimes use such devices to paint a car, which is considered the height of difficulty in painting work. In addition, a spray gun from a vacuum cleaner is perfect for applying water-based emulsion to walls or whitewash to the ceiling.

This device is based on a regular vacuum cleaner. It must have a blowing mode. Experts recommend using those models that have powerful traction, which will make it possible to create high pressure.

If the household has an old Soviet vacuum cleaner, such as a Whirlwind or a Rocket, it can be used for painting work even without making or purchasing special attachments. The device itself is a compressor, to which a container of paint is attached and one of the nozzles is put on. This creates a powerful electric spray gun, with which you can get an even coating quickly and without much hassle.

If you can’t find an old vacuum cleaner, you can purchase one of the modern options. For example, the Intertool RT 0303 painting device is on sale. This is a kind of attachment for a spray gun with a paint container for which you need to select a compressor. Any vacuum cleaner with reverse draft can act as it. The only disadvantage of such a unit is that it is small in volume. You can fill no more than 200 ml of liquid into the paint container, so you will have to constantly replenish supplies.

A Rhythm 950 spray gun with a flexible hose will be much more convenient. This unit is usually offered as an addition to a vacuum cleaner. The set is very convenient, since with its help you can not only clean the room, but also carry out painting work, as well as inflate mattresses. Almost 1 liter of liquid can be loaded into the paint container. In this case, the solution consumption per minute reaches 180 ml. As a result, painting work is carried out very quickly.

There are also very simple, but no less convenient attachments for spray guns. They can even be sold without special tanks. For example, some nozzles have a separate bottle attached to which you need to pour paint. There is also a hole for connecting a vacuum cleaner hose. Such devices are inexpensive, and perform their functions as a sprayer simply perfectly. The main thing is to pay attention to such points as the diameter of the hole and the width of the hose. They must match completely. Otherwise, the painting installation will not be able to function properly.

How to turn a vacuum cleaner into a spray gun?

As for how to make a spray gun with your own hands, one of the most important points is the presence of reverse draft in the vacuum cleaner. In other words, its engine must function not only to suck in air, but also to blow it out. However, not every modern device has such a function. If possible, it is worth using an old Soviet unit for painting work, such as Chaika, Raketa, etc. However, nowadays it is difficult to find such vacuum cleaners, and modern models are rarely equipped with a reverse draft function. Therefore, some craftsmen resort to cunning and modify ordinary devices. If you have no previous experience of such work, then first you should take the simplest vacuum cleaner, which you won’t mind spoiling.

The main thing here is to make sure that the engine of the device begins to rotate in the opposite direction. This is not difficult, and in most models it is enough to reverse the polarity of the power terminals, which are responsible for the operation of the stator and rotor. In addition, it is necessary to create constant pressure. This is possible due to changes in the functions of the impeller. Difficulties often arise here, due to which the reverse thrust is too weak. This situation can be solved by replacing the impeller design.

The second important point is the manufacture of a suitable nozzle for the compressor. The most convenient option would be to take the old design that was included with some Soviet models. But finding such devices can be difficult, so you have to use other options.

Making your own spray valve is easy. For this you can use various materials. The simplest would be to use a regular nylon cover. A pair of holes are made in it, into which two identical thin tubes are inserted. One should be longer and the other shorter. Next, the lid is placed on the paint can. The long tube must reach almost to the bottom of the container. The second pipe is connected to the nozzle of the vacuum cleaner. This may be a small funnel with a thin spout. Its wide part is attached to the hose, and the narrow part goes directly to the end of the second tube, from where the paint will flow.

Thus, a design comes out with the help of which the vacuum cleaner engine produces reverse thrust, air under high pressure comes from a narrow hole through a tube and immediately sprays paint. The second pipe, which is shorter, is necessary in order to create pressure in the container and squeeze the paint onto the surface. Everything is as simple as possible and very convenient. With this spray gun you can not only paint walls and whitewash ceilings, but also treat vehicles. With minimal investment you can get a convenient and easy-to-use unit.

How to use a spray gun from a vacuum cleaner?

In order for painting work to be completed to the highest possible quality, it is necessary to take into account several rules that will help speed up and simplify this process. Experts recommend applying the solution through a telescopic spray gun in a circular motion. This allows for a more uniform surface treatment.

The paint sprayer must be held at an angle of 90º relative to the surface to be painted. Otherwise, the material consumption will be significantly greater.

Go to the store

You can’t stay in one place for a long time either. This will cause overuse of paint and uneven color. If the coating must be applied in several layers, you must wait until the previous one has completely dried.

Click " Like " and get the best posts on e!

Tips for use

You should start working with inconspicuous areas of the surface to be painted in order to be able to get used to the device. The more layers you make and the thinner they are, the better the result. When painting the main part of the surface, you need to move quickly horizontally, this way it’s easier to avoid smudges.

The more layers you make and the thinner they are, the better the result.

An attachment to a vacuum cleaner for painting can make the job much easier; doing it yourself is not that difficult. If you have a suitable vacuum cleaner, this process will not take much time. And the result will please the owner.