To select the right pipelines, it is imperative to take into account their geometric parameters. One of the most important indicators is the diameter of PVC, PPE, and cast iron sewer pipes.

A smoothly functioning sewer system is very important in a comfortable human home. The quality of life of each of us directly depends on the correctness of its installation. Only a well-designed and stably operating wastewater disposal system can guarantee cleanliness in a private home and in the larger city.

Type of pipes

For properly organized drainage of wastewater, pipes must be stable, durable and smooth on the inside. There are 2 main materials for making such products: metal and plastic. The latter are divided into 3 types:

- PVC – polyvinyl chloride. Durable and UV resistant, but cannot withstand high temperatures of hot water and exposure to aggressive environments. Used for internal and external sewers.

- PET – polyethylene. Operating functionality within temperatures of -40 +40 C°, not recommended for use in a hot water drain system.

- PP – polypropylene. They can last 100 years and are highly resistant to temperature changes and harsh chemicals. Used in domestic wastewater systems.

The cast iron drainage system is an outdated option. Despite the fact that it is durable and strong, it is completely replaced with plastic. This is not due to the disadvantages of metal, but due to the advantages of PVC.

Plastic pipes are also divided according to density and hardness. It depends on which highway they will be used:

- SN-2. Products made of lightweight material are used in areas with minimal load. The installation is carried out shallowly and not under transport roads.

- SN-4. They have a denser material and can be laid under roads with little traffic.

- SN-8. The densest and heaviest products are intended for use under highways and industrial enterprises.

PVC – polyvinyl chloride pipes

It is important to note that a PVC drainage system is not as durable as a cast iron one, but it is more flexible and easy to install. When properly installed, it can last 50 years.

General information about types of pipes

There is a huge selection of this material on the market. Let's consider all types of products for sewerage.

Sewer pipes are made of PVC, Cast Iron, Polypropylene, Polyethylene.

Cast iron pipes

Now this manufacturing material has lost ground, giving way to new technologies. But it’s worth giving credit to cast iron. Not every material can compete with its strength and durability.

The main advantages of cast iron pipes

Long service life- Rust resistance

- Large temperature range

- Cast iron does not ignite

- Does not harm the environment

Minuses

As for the shortcomings, alas, they also exist.

- The material is not plastic, it is fragile in bending

- Requires grounding installation

- Weight. Cast iron is heavy - this greatly complicates installation.

Cast iron products are available in two formats

- With bell

- Smooth

GOST standards

All products are cast in accordance with GOST

GOST - 6942 - these are pipes for sewerage with standard parameters: 50,75,100 mm. The largest diameter is 400 mm.

GOST – 9583 – these are cast pipes with other diameters. They are usually used for sewer pipelines where the pipes are 1000 mm.

There are cast iron pipes on the market, cast using new technology; they have flexibility close to carbon steel. The price of these products is much higher than usual.

PVC sewer pipes

PVC is an excellent alternative to cast iron

Pipes made of this material are especially popular when installing external sewage systems.

Advantages

Not exposed to aggressive environments- Corrosion is completely eliminated

- No electrical conductivity

- Lungs.

POLYVINYL CHLORIDE is close in density to water

Flaws

- Possible damage if temperature rises above 75 degrees

- The material is fragile.

PVC pipes are also manufactured according to GOST

GOST – 51613 provides a diameter from 10 mm to 315 mm

Attention!

Orange-colored pipes are used for assembling external sewage systems

When installing an internal drainage system, gray pipes are used.

Color acts as an indicator of strength.

Polypropylene pipes

Products made from this material have a wide range of applications.

Advantages

- Material resistant to various types of chemicals

- High elasticity

- Tolerates high temperatures well

- These pipes are widely used for installation of internal sewerage systems.

For the external sewer system, so-called corrugated pipes are used.

Polyethylene pipes

This material has good elasticity and strength.

Advantages

- The system can be easily rotated without the use of fittings

- Does not form cracks when frozen

- Well adapted to aggressive environments

Flaws

- Not stable at temperatures above 85 degrees

This type of product is produced in accordance with GOST - 22689.2.

Pipe dimensions and area of use

There are certain standards according to which the size of a sewer pipe depends on the area of its use. Thus, a pipeline with a diameter of 40–50 mm is installed in kitchen and sink drains, and 75–100 mm in diameter in the sewer leading from the toilet.

Dependence of diameter and area of use

Standard parameters depend on the volume of water that must leave the container in a certain time. For example, in an apartment in a multi-storey building there are standard toilets, from which a large volume of water along with waste must come out in a short period of time. Therefore, in most cases, for toilets, the diameter of plastic or cast iron pipes is chosen to be at least 110 mm.

Table on how to choose the internal diameter for a sewer pipe depending on the use of the outlet:

| For dishwasher, washing machine | 25 mm |

| For connecting pipelines to the drain of a bathroom, shower box, sink, kitchen sink | 32 mm |

| Ensuring the installation of a sewerage system in the premises | 50 mm |

| Installation of pressure pipes for external water supply, sewerage, drainpipes, selection of diameter for the toilet | From 110 to 200 mm |

If you have non-standard parameters of water supply systems, then before installing a sewer system you need to determine the relationship between the amount of wastewater and the rate of its discharge. For this, certain geometric parameters are calculated.

In addition to the fact that the correct diameter allows you to calculate the water drainage rate, pipe cleaning is also carried out taking this parameter into account. For example, the technology of sewer cleaning with Kärcher systems is now very popular, but they are used only on pipes with a diameter of 100 mm or more.

Scope of application of a sewer pipe with a diameter of 110 mm

Application example for 110 mm pipes

Sewer plastic products with a diameter of 110 mm are produced in two colors. Gray pipes are for internal wiring and a general riser. Not intended for use at low temperatures. Orange sewer pipes are for the external main. They have a higher strength coefficient and can withstand frost. A common drawback for all polymer products is the inability to operate at ultra-low temperatures, so in northern regions it is necessary to strictly follow installation rules and lay pipes below the ground freezing level. As an option, choose a different material for the sewerage system.

In addition to sewerage, a pipe with a diameter of 110 mm can be used:

- for casing a well, but it is necessary to immediately foresee which pump such a pipe will be suitable for;

- for organizing irrigation in summer cottages - a product with a diameter of 110 mm can act as a supply line from which small-section pipes for the drip system are extended;

- in drainage systems and storm sewers;

- for protecting electrical cables in industrial enterprises;

- for transportation of liquid waste, including chemically aggressive waste, the temperature of which does not exceed 45 degrees;

- for the construction of a water supply system, but only for cold liquid.

The strength of each material must be clarified when purchasing depending on the purpose of use. It may not be worth overpaying for some characteristics if the pipe section is on the ground surface and can be replaced at any time.

Pipe calculation

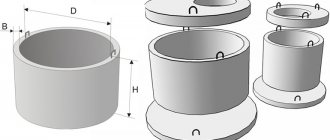

To individually select a pipe for installation in houses, cottages or in the country, it is necessary to calculate the permeability. To calculate the useful pipe diameter (internal d), you need to know the following parameters:

- D – outer (external) diameter, mm;

- B – wall thickness, mm;

- m – mass of a linear meter of pipe, g (necessary to take into account the number and type of fastenings if a complete replacement of the pipeline is needed);

- S – cross-sectional area, mm2.

Formulas for calculation:

d = D – 2 b;

S = π/4 (D2 – d2);

V = S * L;

m = ρ * V.

Pipe sizes

Many manufacturers of polyethylene pipes mark most of the required parameters on the communication. But, as a standard, only the outer diameter (D) and wall thickness of the outlet are initially known. The most important parameter is the internal diameter; it is used to connect the pipe to the main and to lay out the sewer system, select additional elements, fittings, etc.

Manufacturer's markings on pipes

Moreover, unlike polypropylene plastic pipes, cast iron sewer lines are initially specified by the manufacturer with a useful internal diameter. Like steel, it is designated DN. It can have different values, in whole numbers, for example, DN 110 or DN 200. This means that this pipe has a nominal water drainage diameter of 110 or 200 millimeters, respectively.

Dimensions

Pipe sizes are regulated by technical specifications. If you have a 110 mm pipe in front of you, then you can use it when laying non-pressure networks. The length of such products can vary from 500 to 6000 mm. The outer diameter is 110 mm. You should also be interested in the other sizes of 110 mm PVC sewer pipes. This should also include the internal diameter, which in the described case is 103.6 mm. The wall thickness remains unchanged, it is 3.2 mm.

Among the dimensions of a 110 mm sewer pipe, the length of the socket should also be highlighted. It can be normal or extended. In the first case, the length is 58 mm, in the second - 313 mm. Weight depends on diameter. For example, one linear meter of pipe will have a mass within 1 kg.

Determination of nominal diameter

Regardless of the material from which sewer pipes are made and the scope of their purpose, they have the current standard dimensions:

- D – outer diameter;

- d – diameter from the inside;

- S – wall thickness;

- Dy – conditional pass.

The internal diameter sign is placed on the marking of cast iron products, while the external dimensions are most often indicated on plastic products. The external width of the product for all categories remains unchanged, only the wall thickness changes. For example, if a pipe has D = 33.5 mm, then S can vary within 2.8-4 mm. The level of strength of the product and resistance to internal and external pressure depend on the thickness of the walls. Fluid dynamics engineers, for all internal diameters, use one approximate figure of 25 mm and call it the nominal bore.

Conditional diameter is the maximum throughput of the pipeline. The efficiency and performance of the structure directly depends on its size. If you know the dimensions of the internal lumen, you can choose the right connecting elements so that the sewage system has a holistic appearance without the threat of depressurization.

All products of domestic and foreign production have a nominal diameter that is most suitable to the nearest standard according to GOST 28338-89 and GOST 3262-75.

Determination of nominal diameter

In addition to the sewerage capacity, it is also necessary to calculate its angle of inclination. These parameters directly depend on the size of the product and the material it is made of. Formula for calculating the angle of inclination: V× (H / D)½ ≥ K. Where:

V – speed of wastewater movement; H – degree of filling; D – outer diameter; K is the roughness value of the internal walls, for polymers = 0.5.

Pipe diameter with slope

The greater the slope, the higher the waste flow rate. The sewage system is less clogged and is able to serve a larger number of premises.

Some advice from experts:

Despite the fact that the riser is located vertically, it must have the largest diameter, at least 100 mm. This ensures unimpeded drainage of the maximum volume of wastewater. The outlet design should have a minimum number of turns to minimize the likelihood of clogging. Since it is in these places that hardening most often occurs. The recommended slope should not be less than 12 mm per linear meter. This applies to all categories of sewer pipes. If possible, a 90°C turn should be replaced with two 45°C turns, this reduces the likelihood of solid deposits building up inside the structure.

Compliance with generally accepted rules for organizing wastewater disposal guarantees uninterrupted functionality of the system. In modern projects, a hidden type of installation of the structure is increasingly being practiced. This means that if the installation is carried out incorrectly, difficulties will arise during repair work.

How to choose the right PVC pipes for sewerage

On the sketch of the future sewer system, it is recommended to indicate the length and width of the pipe, angle of inclination, connection points with plumbing, etc. Based on the drawing, calculate the number of plumbing fittings, connecting elements, fittings. Transfer the diagram to the walls and floor, double-check its meaning and calculations. After this, you can begin gating ditches for the structure. Their dimensions must match the diameter of the pipes.

How to choose the right PVC pipes for sewerage

The exiting private pipe must match the width of the riser into which it enters. In multi-storey buildings, the diameter of the main line can be either 110 mm or 200 mm, depending on the number of apartments in the building. If several houses are connected to an underground communication, the diameter can reach 300 mm or more. Underground connections are most often flanged, and above-ground connections are socket-type.

Types of pipes for external sewerage

Pipes for external sewerage are divided into two types: cast iron and plastic.

Cast iron materials have been used for decades. Their service life is estimated at an average of 80 years. The positive factors of cast iron products include their durability and high degree of strength. But one cannot fail to note the shortcomings. Cast iron products are quite heavy, which makes installation work difficult. Also, the surface of cast iron has roughness, which to some extent prevents the passage of water flows and allows elements to build up. As a result, the sewer becomes clogged. And most importantly, this type of pipes has a high price.

Not so long ago, plastic pipes appeared on sale, which turned out to be a good replacement for cast iron. They, in turn, are divided into the following types:

- PVC pipes have a number of characteristics, such as the ability to use them at low temperatures and a high degree of mechanical and chemical stress. But they are afraid of high temperatures. For example, the maximum temperature that the material can withstand is 4000C. They have different strength indicators, depending on which their scope is determined:

- Light level of strength, for arranging sewer pipelines that are installed at shallow depths without exerting any pressure on them.

- With medium strength, PVC pipes can be laid across small roads.

- Heavy PVC pipes are used in industry and can be laid under highways.

- Polypropylene materials. This type of material is not used for arranging external sewage systems. It is better to use them in conditions where placement in the ground is not required. Usually this is the arrangement of internal sewerage. This is due to the fact that this material differs from PVC in less rigidity, and most importantly, the possibility of damage by rodents. But it is resistant to high temperatures up to 8000C.

- Polyethylene corrugation. This is one of the most common types of pipes for external sewerage. Their diameter section varies from 200 mm to 800 mm. This is a fairly durable material, it can be laid to a depth of up to 15 m. It consists of two layers: an outer corrugated one, which is made of thick polyethylene, and a smooth inner one, which has a smaller thickness.

How to determine pipe sizes

Foreign-made polypropylene, polyvinyl chloride and other plastic communications are most often designated by inches. It may also be that you need to install fasteners on the pipeline, but its dimensions are also given in inches, while the pipe is indicated in mm.

Pipe inch thread

To do this, you need to convert the known inch dimensions into millimeter ones. According to the data, 1 inch is 25.4 mm. It turns out that a pipe with a diameter of 2 inches = 50.8 mm, etc. Fractional values are very often used, this is how clamps, fittings, couplings and communications are marked.

Let's look at their meaning in the table:

| In inches | In millimeters | In inches | In millimeters |

| 1/8 | 3,2 | 1 1/8 | 28,6 |

| 1/4 | 6,4 | 1 1/4 | 31,8 |

| 3/8 | 9,5 | 1 3/8 | 34,9 |

| 1/2 | 12,7 | 1 1/2 | 38,1 |

| 5/8 | 15,9 | 1 5/8 | 41,3 |

| 3/4 | 19 | 1 3/4 | 44,4 |

| 7/8 | 22,2 | 1 7/8 | 47,6 |

| 2 1/8 | 54 | 3 1/8 | 79,4 |

| 2 1/4 | 57,2 | 3 1/4 | 82,6 |

| 2 3/8 | 60,3 | 3 3/8 | 85,7 |

| 2 1/2 | 63,5 | 3 1/2 | 88,9 |

| 2 5/8 | 66,7 | 3 5/8 | 92,1 |

| 2 3/4 | 69,8 | 3 3/4 | 95,2 |

| 2 7/8 | 73 | 3 7/8 | 98,4 |

PVC pipes of different diameters

But, when measuring a socket manually, for example, with a ruler, the nearest minimum size is always taken. For example, the diameter in millimeters of a sewer pipe for a sink is 34. It turns out that the outer diameter is 1 ¼ inches. Be careful when selecting sizes, otherwise you will have to buy additional spacers or adapters. But the coupling is selected based on the nearest larger indicator, i.e., 34 mm will be considered 1 3/8 inches.

Video: Joining pipes of different diameters in the sewer system.

Steel two-way communications may have different indicators on different sides; you need to double-check the data. This can be done by experimental measurements with a caliper or plug gauge.

Table: Diameters of ceramic pipes

List of sewer fittings

Only fittings are capable of combining pipes of different types and sizes. Used to connect branches and when turning a structure. The reliability of the system's sealing depends on correctly selected connecting parts.

| Name of the connecting element | Functionality |

| Tee 110×110 mm | Large fitting, used to connect to the central riser and toilet. |

| Reduction 110×50 mm | A special type of fitting that connects pipes with a diameter of 50 mm to a diameter of 110 mm. |

| Bends | Elbows designed to change the direction of pipelines. Suitable for all sewer sizes. Can be installed at an angle of 90° or 45°. |

| Tees | Several pipes are connected into one system. Can be all sizes identical or different. |

| Audit | Designed for places with an increased risk of contamination, equipped with special removable covers. |

| Stubs | They are selected for a certain pipeline diameter and installed at the ends. |