What is plasma and how does it occur?

Plasma is the state of a gas when it is partially or completely ionized. This means that it can consist not only of neutral molecules and atoms, but also of electrons and ions

having a certain electrical charge or consisting entirely of charged particles. To transform a gas into a plasma state, most of its molecules and atoms must be ionized. To achieve this, it is necessary to apply a force to the electron that is part of the atom that exceeds its binding energy with the nucleus and help break away from it.

For this, certain conditions must be created, which were developed in the field of producing a plasma arc.

The first mention of the development of plasma welding was in 1950. In 1960, some principles for producing plasma flow were introduced and plasma welding technology and equipment were introduced. In our country, research in this area and the development of technology were carried out at the Institute of Metals named after. A. A. Baykova, led the project N.N. Rykalin. After studying the physical properties and energy of a compressed electric arc in an argon environment, converted into a plasma jet, its technical capabilities in the field of welding were determined and special equipment was developed.

Equipment used

Plasma welding installations are widely used not only in large-scale production, but also in domestic conditions. It is worth noting that the demand for this equipment is constantly growing, which once again confirms its relevance.

Installation of equipment for welding.

All equipment designed to perform this work can be divided into the following features:

- type of impact;

- arc stabilization method;

- current strength.

In terms of its capabilities, the plasma arc is second only to several technologies based on laser and electron beams. Compared to other methods, plasma has higher efficiency and productivity.

It is worth noting that we should not forget about other technologies. Thus, argon arc welding is widely used for welding parts in serious industries, for example, in aircraft manufacturing and aerospace.

Plasma, in turn, is most often used for cutting metals, since it allows this process to be carried out at high speed.

It becomes especially indispensable when processing alloys with minimal subsequent warping and the development of stresses, as well as deformations.

Scheme for obtaining a plasma jet

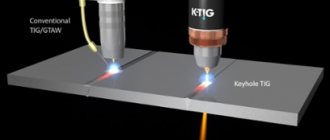

Plasma conversion is achieved by applying a strong electric field, created by the arc as it passes through the gas, to the forced gas entering through the torch nozzle.

Thus, to transform an electric arc into an electrified plasma jet, two conditions must be met:

- compress it;

- run a special gas through it to create plasma.

Compression is provided by a special plasma torch device. As a result, the thickness of the jet decreases and the pressure increases. At the same time, gas is supplied to the arc, which, under its influence, heats up and turns into plasma. Due to heating, the gas expands and increases in volume. As a result, it rushes out of the nozzle at high speed. Moreover, if a conventional electric discharge has a temperature of about 5000-7000°C, then the plasma can reach 30,000°C.

To form plasma, argon is used mainly with the addition of a small amount of helium. The electrode must also be protected with neutral argon. Tungsten products with the addition of thorium or yttrium are chosen as the electrode.

Plasma welding technology is characterized by high temperature and small arc diameter, which provides significant power.

Gas injection

When working, it is necessary to take into account a significant drawback - in a homemade device for plasma welding, the argon consumption will be unreasonably high. Therefore, when cutting metals or other materials, it is advisable to use compressed air or water vapor. But they can only be used for cutting, since both air and steam are not chemically neutral to the metal and can cause oxidation of the seam.

Compressors are used to pump compressed air. It is better to connect the compressor to the plasma torch not directly, but through a receiver - a cylinder in which air is accumulated under some pressure.

If the receiver is not used, the air supply will be uneven and the quality of the plasma arc will be poor. Various steam generators are used to supply water steam.

Key Features and Benefits

By obtaining a plasma arc, you can significantly expand your welding capabilities. Its main differences from conventional argon welding are:

- high plasma temperature reaching 30000oC;

- small cross-section of the arc;

- the conical shape of the arc, characteristic of argon welding, has been changed to a cylindrical shape;

- the small diameter of the jet allows you to significantly increase the pressure with which it acts on the metal. It is almost 10 times higher than with argon welding.

- The welding process can be supported by a small current ranging from 0.2 to 3.0 amperes.

Such plasma properties provide significant possibilities for this welding before argon arc welding:

- deeper weld penetration is ensured;

- the melting zone is reduced without cutting the welded edges;

- Due to its cylindrical shape and the ability to increase in length, a plasma arc can be used to weld hard-to-reach places.

Types of plasma welding

Plasma devices work primarily with torches that use direct current.

Two work schemes are used:

- Using an arc formed between an infusible electrode and the metal surface to be welded;

- Using a plasma jet formed between an infusible electrode and the plasma torch body.

The connection of metals using plasma is also divided according to the value of the current used. The following types of welding are used:

- microplasma type, passing in the current range from 0.1 to 25 amperes;

- welding using medium currents ranging from 50 to 150 amperes;

- welding using currents of more than 150 amperes.

During microplasma welding, the metal practically does not burn through. In the case of using high currents, complete penetration of the seam is achieved with the separation of products and their subsequent welding.

Application area

Thanks to working at temperatures reaching up to 30,000 degrees, the technology allows you to work with many types of metals: stainless steel, carbon steel, cast iron, copper, brass, bronze, titanium, aluminum and others. Together with the high precision of work, this leads to the following areas of use of the technology:

- food industry;

- energy sector;

- chemical production;

- jewelry making;

- mechanical engineering;

- instrument making;

- medical equipment;

- production of high precision parts.

We recommend! Welding aluminum with argon for beginners

Design and principle of operation of the plasma torch

A device that acts as a plasma generator is called a plasmatron.

It is a device that uses electrical energy to create a plasma state of gas and further use the plasma to form a welding arc. Two types of plasma torch designs are used, operating according to the scheme of indirect or direct arc formation.

For plasma welding, a plasma torch is predominantly used, operating in a direct scheme, when a tungsten electrode serves as the cathode and the surface to be welded as the anode. It is then that the arc takes the shape of a cylinder. With an indirect operating scheme, the plasma jet has the usual conical shape.

The main components of such a device are:

- tungsten electrode (cathode), which forms one connection with the plasma-forming gas supply device;

- device body;

- nozzle with a shaping tip;

- heat-resistant insulator;

- cooling system using a water jet;

- starting device.

To excite the main arc, a positively charged cable is connected to the metal surface from the apparatus.

The resulting arc ionizes the gas coming from the cylinder or compressor into the chamber under pressure. When heated during ionization, the gas expands and is ejected in the form of a plasma jet from the chamber space with high kinetic energy.

In order to facilitate ignition of the main arc, an auxiliary electrode is built into the plasmatron chamber, acting as an anode. When the plasma torch is connected to the network and started, this electrode receives a positive charge, forming an arc with a tungsten cathode. The resulting plasma jet heats the metal being welded and provokes the ignition of the main powerful plasma arc according to the “tungsten cathode-metal surface” scheme. Having fulfilled its function, the duty plasma arc is extinguished, and the device continues to operate on the main plasma jet.

Technological process

It includes several necessary steps: preparing parts, connecting electrodes, starting the burner and warming it up, making a seam while maintaining the desired temperature regime and moving the burner to the site of a new operation and checking the readiness of the burner itself.

Interesting: Do-it-yourself plasma welding

Plasma welding technology

The preparation of parts consists of pre-sorting them or delivering them to the workplace already sorted. If the parts are obtained by thermal cutting or rough mechanical cutting, then the edges are processed until the metal is clean and degreased to obtain a high-quality seam.

After this, the parts are brought into contact along the seam line. In production, this is not done “on the knee” as during repairs, but with the help of devices.

Hot seam from plasma welding

If required, fluxes are applied to the weld line. Usually these are strong reducing agents for work at high temperatures (welding fluxes), mixed with low-melting binders, which themselves are reducing agents, or provide a minimum of difficult-to-remove carbon deposits (slag). The molten slag protects the bath from the action of oxygen, and the reducing agent takes it away from the oxides that have already formed. Fluxes are not required for all metals or their pairs.

The burner is started by a high voltage pulse or contact between the nozzle and the cathode for a fraction of a second. The arc lights up, working and protective gases are supplied to the torch, as well as cooling water is supplied to the anode body (for powerful long-lasting torches). The torch warms up until the plasma stabilizes and the welding operation begins.

During welding, the joined edges of the part are melted, and filler material in the form of a tape or rod is introduced into this melt. In automatic welding, the feed is mechanized. Welding is considered as a continuous process of melting and solidification of metal in the weld area and should ensure the solidity of the seam, the same mechanical properties along the entire length, equal thickness of the seam, and the complete absence of cavities, foreign inclusions and impurities.

The molten seam is quite defenseless in relation to many factors, so to obtain quality it is necessary to create special conditions: before the bath, in it itself, and after, in the area of crystallization of the melt. These conditions greatly depend on the metals being welded.

Plasma cutter welding process

After finishing the seam, the readiness of the torch for the next operation is checked, so that the seam does not have to be stopped during the welding process without completing it. Any such interruption, if forced, creates unnecessary mechanical stress, which will then be either difficult or impossible to remove. For this reason, welding of critical seams: vessels (tanks) for rocketry, hulls of sea vessels, especially submarines, vessels for nuclear technology, etc. cooked with a continuous supply of cathodes on burners with powerful cooling of the nozzles.