Autogenous welding involves thermal exposure of steel parts with a mixture of gas (acetylene, butane or kerosene vapor) and an oxidizing agent. The separation of structural elements occurs due to the burnout of the material and the removal of products from the seam zone by an oxygen flow. A cutter is used to feed and adjust the ratio of mixture components. The flame temperature depends on the proportion of oxidizer and the type of gaseous medium.

Autogenous welding is a process of joining parts, which involves gradual melting.

How does autogen work?

The classic base of the device consists of a set:

- oxygen cylinder,

- flammable gas cylinder,

- pressure gauge with gearbox,

- gas hoses,

- torch (cutter), which can be used both for welding low-alloy steel and for cutting ferrous or non-ferrous metals.

The cutter is supplied with hoses containing oxygen and acetylene, instead of which propane/butane can be used. However, it is rational to use propane autogen for cutting metal surfaces, and the welding process with its help is ineffective because the temperature of the flame jet is lower than when using acetylene.

This is not noticeable when welding parts with thin walls, but when processing pipes and thick-walled parts it slows down the process.

Principle of operation

The gas cutting technique refers to the technology of gas-flame processing of metals, in which the flame of a burning gas-air mixture heats the workpiece to a high temperature to perform cutting, surface hardening, surfacing or other technological operations.

The basic principle of gas cutting is the ability of metal to ignite in an environment of chemically pure oxygen. For the technical implementation of this complex physical and chemical process, a special metal cutter is used, which performs the following functions:

- mixing in a certain proportion of flammable gas (acetylene, propane, natural gas) with oxygen to form a heating gas-oxygen mixture;

- ignition of the heating mixture and heating it with a metal flame along the cut line;

- separate supply of a flow of heating mixture and a stream of oxygen to the cutting site.

- Preparation for cutting, which consists in heating the local zone of the workpiece to the ignition temperature of the metal. Heating is carried out by a flame torch of the burning heating mixture. At the site of the start of the cut, the metal is heated to white heat, which corresponds to heating to a temperature within 1100 degrees. C.

The local preheating mode is necessary so that the metal of the workpiece ignites in a stream of oxygen along the cut line without the use of an external ignition initiator.

- Direct gas cutting of a workpiece, which consists of burning the metal in a stream of oxygen supplied under pressure and blowing out the resulting combustion products in the form of hot particles from the working area. The cutting process proceeds in the following sequence:

- an oxygen stream under a pressure of 5-12 atm is supplied to the heated zone;

- upon contact with a heated surface, oxygen ignites;

- under the influence of an oxygen jet, the metal in the cut zone burns;

- combustion products - oxides - are blown out of the cutting zone in a stream, leaving behind a narrow groove.

Oxidation of the material of the cut workpiece occurs only in the area of action of the oxygen jet, so the penetration of oxides into the metal is excluded.

Operating principle and method of application

The technology of welding and cutting with the device is based on the property of metals to melt. A high-temperature flame jet softens the metal surface to a liquid state, and with the help of pressure it cuts the metal with an autogenous gas or connects parts using filler metal rods.

For restoration welding, different rods are used, whose parameters depend on the assortment of metal and the area of the products.

Autogen design

The modern design of an autogen is based on the interaction of its constituent parts:

- tip,

- mouthpieces,

- barrel body with a chamber for obtaining a mixture of gases,

- valves,

- fittings.

A decrease in pressure to the required level is formed inside the injection barrel. Some of the oxygen comes here. A stream of flame emerges from the barrel into the cavity of the outer mouthpiece. The other part of the oxygen enters the channel of the internal mouthpiece, forming a flame jet.

In the mixing chamber of the device, acetylene or propane vapors are combined with oxygen, forming a mixture for the flame jet. It is fed between the mouthpieces of the tip, which is attached to the barrel with an ordinary nut.

The designs of models from different brands may differ slightly, but their operating principle remains virtually unchanged. Additional device configuration elements increase the level of safety during operation and provide additional convenience during operation. Simple operations can be performed with a self-assembled autogen.

Manufacturing

The manufacturing process occurs in several sequential stages:

- A gas supply needle is made, which acts as the tip of a gas cutter. On the needle used to inflate balls, a small incision is made using a needle file at a distance of about 2 cm from the end.

- An air (oxygen) supply needle is made. To do this, you need to take the needle from the dropper, file off the sharp tip with a sharpener, and bend it at 45 degrees at the same distance (about 2 cm). After this, the curved needle is inserted into the hole that was previously made in the large one.

- If necessary, the protruding ends of the resulting structure of two needles are leveled with a file or a sharpening stone.

- To seal the joint and fix the connection of the needles to each other, it is necessary to wrap it with copper wire, prepared in advance and cleaned of oxide. After this, the winding is coated with flux used for soldering and carefully but carefully soldered with tin.

- Dropper tubes are attached to the rear ends of the needles. In this case, the clamps are not removed from them, since they will be used to regulate the size of the flame.

- A container is made for oxygen (or ordinary air under pressure). To do this, a hole is cut in the bottom of the prepared plastic bottle for a nipple from a car camera, which is installed there using glue and a special nut. This design will allow you to pump compressed air into the bottle using an ordinary car pump. As an alternative and more convenient option, an aquarium compressor or even an electric car pump can be used.

- A hole is made in the cap of the PVC bottle to install a dropper in it, which is pre-cut to the so-called “skirt”. The connection between the cap and the dropper must also be carefully sealed using thermal adhesive.

- The resulting structure is connected using a dropper tube to the hole of a small needle. Thus, the part of the cutter through which the compressed air will have to flow is almost complete.

- A second line is made, intended for the passage of gas from the cylinder, which is used to refill lighters. It is necessary to make a hole in the plastic lid of the can, the diameter of which must coincide with the dropper tube. The tube is then inserted into the resulting hole. A special nozzle is installed at its end, which is usually supplied with the cylinder. The connection must be as tight, airtight and durable as possible. After this, the tube with the installed nozzle is fixed in the plastic cover so that in the closed position it puts pressure on the nipple of the balloon.

Your own gas cutter for metal is ready.

Classification

The range of devices for gas cutting is divided into models according to purpose:

- for specific work,

- universal,

- portable autogens.

A burning jet can form in them:

- oxygen,

- kerosene vapors,

- acetylene,

- propane/butane

It doesn’t matter what model of autogenous gas welder is in the hands of a gas welder, the main thing is that it corresponds to the specifics of the work and the parameters of the elements for cutting or welding. Universal models can cut metal at any angle. In addition, they are very comfortable and lightweight. One of the latest developments is piezo ignition, which allows you to turn on the tool with a button.

Models of industrial welding equipment can be used with any gas. For home use, the best option is a propane/butane tool, which is easier to buy and less dangerous.

According to the design and method of mixing the components, the equipment is divided into classes:

- injection,

- non-injector.

Exploitation

Using the device makes it possible to cut and weld metal surfaces of any complexity. Equipment running on kerosene is in demand for the coal and mining industries, because there is no risk of the device itself exploding. Due to the complexity of the design, such an autogen is not suitable for small household work.

Propane products are used for cutting cast iron batteries, pipes, and other types of metals. Acetylene machines are a good choice for processing thick parts of varying complexity, because such a combustible mixture forms the maximum flame temperature.

One of the problems in operating the instrument is the rapid wear of the nozzle and mouthpieces. Increased tool life depends on regular cleaning of the nozzle cavity with a soft copper rod. The main thing is to choose the right rod size.

Welding rules

Compliance with the rules of equipment operation ensures high-quality results and safe operation. To do this, you need to know how to use it and check that the equipment is ready for use:

- the correct location of all components of the device,

- tightness of hose connections,

- serviceability of pressure gauges.

Blow out the gas hoses with compressed air, and the mouthpieces with special needles. Treat rubber seals with glycerin or special lubricant. Use valves to adjust the parameters of the cutting flame jet depending on the thickness and size of the workpiece. The flame must have a regular, symmetrical shape.

Professionals use two welding methods. With the “left” method, when the flame moves from right to left, it is convenient for the master to navigate along the edges that have not yet been welded. Thanks to this control, the seam is neat. With the “right” one, zigzag movements are necessary to allow the metal to cool. To complete the work, first close the gas supply valve, then the oxygen valve. The very hot tip is cooled with cold water.

Surface cutting

Users, of course, are interested in the following question: how to use the cutter during shape cutting. This technique is performed using a tool nozzle, while the molten slag heats the metal, but without exceeding the melting point . The cutter is positioned at an angle of up to 80 degrees, and after oxygen is supplied, the angle changes within 18-450.

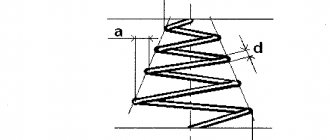

Grooves are formed when adjusting the cutting speed; if a larger size is needed, then change the angle of the mouthpiece and slow down the cutting speed slightly, adjusting the oxygen supply. The width of the grooves is changed by adjusting the supply of a jet of burning gas through the nozzle; this parameter is equal to 1 to 6, while care must be taken to ensure that there are no backflows.

To keep the edges of the recess clean, you need to increase the oxygen supply.

What you need to know

A gas welder with an autogen in his hands must take care of safety during work. Autogen gas welding technology involves processing:

- carbon steel with a thickness of no more than 5 mm,

- non-ferrous metals,

- tool, anti-corrosion steel,

- cast iron and its alloys.

The technique of cutting metal with gas using an autogen is simple, but it is better to practice before connecting critical parts.

Cutting Features

The cutter must be moved smoothly along the cutting line and monitor the angle of inclination, which deviates 5-6 degrees against the movement of the tool. When the metal thickness is more than 0.95 m, the deflection is increased by cutting through the metal to a depth of about 20 mm, and the deflection angle decreases again. We have already explained in detail how to cut with a cutter so that the cut is even in the previous section.

How much gas is consumed?

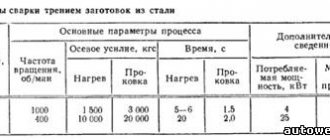

Gas consumption when cutting metal with a propane-oxygen cutter depends on the thickness of the structure and the configuration of the cut. For clarity, we present the table below:

| Workpiece size (thickness), mm | Hole time, sec | Cut size (width), mm | Consumption, per m3 cut | |

| propane | oxygen | |||

| 4,0 | 5—8 | 2,5 | 0,035 | 0,289 |

| 10,0 | 8—13 | 3,0 | 0,041 | 0,415 |

| 20,0 | 13—18 | 4,0 | 0,051 | 0,623 |

| 40,0 | 22—28 | 4,5 | 0,071 | 1,037 |

| 60,0 | 25—30 | 5,0 | 0,087 | 1,461 |

Gas consumption is significantly reduced when surfacing or soldering is performed.

Nuances

The main task of the performer is to maintain the speed correctly:

- normal mode - sparks fly at right angles relative to the surface of the workpiece;

- low speed - flying away from the performer and an angle of less than 85 degrees.

After the process is completed, the oxygen supply is turned off first, and the propane is turned off last.

T. N. Ishkulov, education: vocational school, specialty: fifth-class welder, work experience: since 2005: “Performers who perform cutting for the first time using oxygen equipment must remember that they must start a new cut after a sudden stop from a different point, and not where the process was over."

Negative deformation

Beginning welders are concerned with the question of how to properly use a propane-oxygen cutter so that warping of the surface of the part does not occur. First you need to figure out what factors contribute to the occurrence of these defects:

- with uneven heating of the surface;

- a high cutting speed was selected;

- there was a sharp cooling of the heating area.

To eliminate the occurrence of the listed factors on the workpieces, they are first securely fixed and heated, and the speed is increased gradually. If warping does occur, then the original shape can be returned by firing or tempering, and the sheets can be straightened on rollers.

Kickback hazard

If the jet burns in an incorrect mode, a bang occurs and the flame is drawn inside the product, which leads to an explosion, as the fire spreads through the hoses and reaches containers with gases. To prevent a dangerous situation, the cutter is equipped with a non-return valve, which cuts off the flame and prevents it from spreading.

Terms of use

They are similar to safety precautions when welding, but have specific additions:

- It is not recommended to neglect protective equipment, as this leads to injury in the form of skin burns or damage to the cornea of the eyes from flying sparks, so goggles and gloves with long bells up to the elbow are required.

- The performer's clothing and shoes are made of non-flammable material.

- Gas cylinders are located no closer than five meters from the cutting site.

- The flame of the cutter is directed only in the direction opposite to the hoses.

- Cutting is carried out in rooms equipped with strong ventilation or in open areas.

If the equipment is idle for a long time, it is necessary to carry out preventive maintenance before using the cutter for its intended purpose.

Autogen welding algorithm

Before cutting with an autogen, professionals recommend doing the following:

- opening the oxygen valve,

- opening the acetylene tap,

- igniting the flame on a gas burner.

- adjusting the flame jet to the required temperature.

The workflow is:

- flame treatment of metal until the surface is white,

- adding a welding electrode to the stream,

- filling the seam as the electrode rod melts,

- cooling the part with water,

- removing the formed slag by tapping with a hammer,

- checking the seam tightness.

Safety requirements

When welding metal products using an autogen, extreme caution is required and compliance with the operating rules of the device:

- To avoid an explosion, contact between the oxygen cylinder and fuels and lubricants, especially oil, is prohibited.

- during welding, periodically check the cylinders for gas leaks,

- There must be a fire extinguisher at the welding site,

- You should work away from flammable objects.

- transportation of cylinders should be carried out in vehicles equipped for the transportation of explosive materials,

- cylinders should be stored outdoors or in a ventilated cabinet.

It is not advisable to wear synthetic clothing or uncomfortable shoes so that nothing interferes with movement in an unforeseen situation.

Necessary tool

To make a portable autogen with your own hands, you will need the following tool:

Autogenous welding is widely used for joining various metals, incl. colored. Its use is especially in demand in remote and rural areas, when carrying out repair work directly on site. You can make a fairly miniature autogen with an independent gas generator yourself.

Source

The principle of producing hydrogen by electrolysis of an aqueous alkali solution is used. Thanks to the small external dimensions of the electrolyser, there is a place for it on a small workbench, and the use of a standard rectifier for recharging batteries as a power supply unit facilitates the manufacture of the installation and makes working with it safe.

How to make a mini autogen with your own hands

Instead of bulky standard models, manufacturers began to produce compact mini autogens for use in hard-to-reach places or at home. This small hand tool fits into a compact case. To store gas, such devices are equipped with small cans of oxygen, butane, and propane.

Outwardly, such an autogen looks like a simple device. Essentially, this is a lighter with a gas cutter nozzle, which is located on top of the product. At the same time, it has sufficient flame pressure, which allows it to work even in strong winds. But more often such devices are used by jewelers and household appliance repairmen, because they are convenient for working with small objects.

A compact mini cutter can be made using oxygen and hydrogen obtained from the electrolysis of an aqueous-alkaline solution. The design of such a homemade autogen consists of the following kit:

- two special boards connected by 4 pins,

- batteries of electrodes made of steel panels separated by rubber rings,

- silicone tubes for gas movement,

- a needle from a syringe that acts as a burner.

To avoid troubles, you need to borrow only circuits with a water seal at the outlet pipes, because autogenous soldering with hydrolytic hydrogen is also explosive as with an apparatus operating with acetylene.

Making a gas burner

For a simple gas burner, you will need dropper needles equipped with restrictive clamps.

For a home mini-autogen you can make a fairly reliable one with a very simple design. In Fig. 2 shows a diagram of such a design.

To supply the gas mixture, it is recommended to use a needle for inflating footballs. At a distance of up to 20 mm, an incision is made using a needle file, through which a thinner needle from the dropper is inserted, previously bent at 45ºC at a distance of 15-20 mm. The structure is fixed with copper wire and carefully soldered, all gaps are sealed with varnish.

The output of the large needle is connected to the electrolyzer, i.e. designed for supplying a flammable gas mixture. Additional enrichment of it with oxygen is carried out through a small needle, which is connected to a container filled with compressed air.

The simplest container can be a ball chamber inflated by a pump or a polymer bottle into which air is forced by the same pump.

This completes the production of a simple mini-autogen. After ensuring the supply of both gas streams to the burner, they, connecting, are directed in one stream through the needle to the outside; The escaping gas is ignited and welding occurs. The temperature in the welding zone reaches 1,600ºС, which is enough to melt the edges of the metals and the filler rod.