Characteristics of cast iron

The material is an iron alloy containing a large amount of carbon.

The substance gives cast iron hardness. Carbon, which is not a metal, is not capable of forming bonds with iron; it is contained in the alloy in the form of graphite inclusions.

The alloy has the following characteristics:

- Porosity of the structure. The voids quickly fill with gases or absorb oil.

- Relatively low melting point (1200-1250 °C). This explains the high fluidity of the alloy when heated.

- Fragility. Cast iron is not recommended for the manufacture of structures subject to high loads.

- Low ductility.

- Resistant to acids and alkalis. At the same time, the material is sensitive to prolonged exposure to moisture.

Connection methods

There are the following methods of welding cast iron:

- Gas welding of cast iron. Necessary where casting defects need to be eliminated. The peculiarities of welding cast iron in this way are that propane-butane or acetylene is used, and several torches can be used for work. For gas welding of cast iron with filler wire, it is worth using a material that contains a large amount of silicon.

- Manual welding using an arc. Before arc welding begins, the parts are given a temperature of 600-650 degrees Celsius. This ensures even heating and cooling. The most popular welding of cast iron is argon.

- Mechanized welding using an arc. The part is also preheated to high temperatures. To prevent liquid metal from flowing out of the weld pool, the area of the part to be welded can be molded with graphite plates.

- Electroslag welding. Cast iron welding technology includes the use of plate electrodes and fluoride fluxes. To preheat the part, use a gas burner flame or a non-consumable electrode.

- Thermite welding. The peculiarities of welding cast iron in this way are to use very hot metal obtained by burning thermites to heat it. Cast iron is cooked provided that the thermite mixture is heated to a temperature above 1300 degrees Celsius.

MNCh-2 electrodes for welding cast iron

What polarity should be used to cook cast iron? Before answering this question, we emphasize that the choice of polarity depends on the type of electrodes, and not on spatial position or other criteria. For example, MNC-2 electrodes require the use of straight polarity. In other cases, the polarity is reversed.

Properties of cast iron

Cast iron is an alloy of iron and carbon. The carbon content in cast iron ranges from 2.14% to 6.67%. Carbon gives iron alloys hardness and reduces ductility and toughness. Carbon in cast iron is contained in the form of cementite and graphite.

The melting point of cast iron is from 1,150 to 1,200 °C, which is 300 °C lower than that of pure iron. The thermal conductivity of cast iron is lower than that of steel, and the coefficient of thermal expansion is the same. The electrical conductivity of cast iron depends on the distribution of graphite inclusions.

When cast iron is rapidly cooled from a metal temperature of more than 750°C, graphite turns into cementite, and the cast iron turns from gray to white. A hardened structure is formed with internal stresses leading to cracks.

Multilayer welding using annealing bead technology

This method is used for welding cracks in thin-walled parts - thickness up to 8 mm. The rollers are applied in a certain sequence, in which each subsequent one acts thermally on the previous one, reducing its hardness.

A V-shaped cutting of the edges is made along the crack at an angle of 45º. First, preparatory beads are welded randomly on one edge, then on the other, and annealing beads are welded onto them in sections 40-50 mm long.

When moving to another section, allow the welding zone to cool to 50º-60º and hammer it with light blows of a hammer, knocking off the scale. Thanks to this, the preparatory rollers warm up more and then cool down more slowly. In the hardened part of the seam, partial tempering and normalization occur.

When the beads are placed on both sides of the crack, the final connecting layer is welded in the same separate sections. The edges of the last layer should be 3-4 mm from the nearest penetration boundaries.

Features of welding cast iron.

This material is a compound of iron (F), carbon (C) and impurities: silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), etc.

In the marking designation: the first numbers are the tensile strength in kg/mm2, and the second numbers are for gray cast iron, the bending strength, for malleable and high-strength, relative elongation in%.

By annealing at high temperature - 1000º C, due to graphitization, white turns into malleable cast iron. To increase wear resistance, chromium (Cr), nickel (Ni), tungsten (W), etc. is added. This metal is called alloyed.

For alloyed grades, letters indicate alloying elements, and numbers indicate their average percentage content. For example: ChN19X3 – cast iron containing 19% nickel and 3% chromium. If there is a spherical form of graphite, the letter Ш is placed at the end of the marking.

Due to increased fragility and hardness, the process becomes more complicated. But welding cast iron with an electrode in home workshops is possible under certain conditions. By following the technology and having some skills, you can achieve a high-quality result, but the structure of the seam will differ greatly from the structure of the base material.

Stud welding method

The fusion zone is the most vulnerable joint due to peeling of the weld metal. To relieve it during cooling and shrinkage, steel pins (wraps) are used.

When the workpiece thickness is 6 mm, the edges of the crack are cut at an angle of 45º.

The studs are screwed tightly into the prepared threaded holes in a checkerboard pattern. The protruding part of the wrap is welded along the contour. Then it is welded with the entire mass of the seam by applying annealing beads.

When load is applied to a joint, most of it is transferred to the metal with the studs rather than to the weld, making it more durable.

Preparation for welding

Preparatory operations must be carried out carefully and carefully, as this is one of the fundamental principles of obtaining a high-quality connection:

- the structure is cleaned of dirt, debris and dust;

- then you should degrease the parts with a solvent, for example, acetone;

- when working with thin cast iron, you need to use pads to remove heat;

- edge cutting should be done before welding thick-walled products; for this, a file or grinder is used;

- cracks must be drilled along the edges and cut to their entire length; an alternative method is to cut out the cracks and round the ends;

Preliminary preparation of products

At home, cast iron welding begins with proper preparation of components and parts for the welding process:

- clean and cut the welded edges;

- mill or drill out defective areas along the edges with cutting down to bare metal;

- Clean, degrease and dry working surfaces.

To prevent overheating of the material, the welded edges are cut at an angle of 45º with a chisel or an emery wheel. This promotes uniform heating of the work surface.

Degrease with gasoline, acetone or other organic solvents, and heavily contaminated areas are burned with a burner flame. Cracks must be processed - to the entire depth of the crack for sufficient welding of the metal. The cutting length should be 5-6mm longer than the defective area on both sides. Drill the ends of the cracks or cut them out and round them.

For thin-walled parts, graphite pads are placed to prevent leakage of molten metal. This maintains a heated zone and maintains the shape of the part.

Devices and consumables

To carry out welding work, you need to use special equipment. Experts recommend using devices that generate direct current (inverters). Welding equipment that uses transformers has low efficiency and worsens the final result.

To operate the inverter you will need consumables in the form of electrodes. Their diameter must be at least 3 mm. Welding cast iron with electrodes allows you to make a better-quality seam than when working with a semi-automatic machine. The best consumables for this alloy are considered to be OZCh-2 and MNCh-2.

Cast iron can be cooked with argon. For this, copper-plated wire is used. The process of working with this equipment is similar to using an inverter. Using argon welding, plates up to 4 mm thick can be welded.

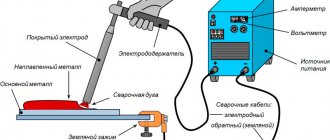

Welders

The purpose of the device is to reduce the voltage of the electric current of the network, increasing its strength to the value necessary for welding. The process is carried out using welding machines: transformers, rectifiers, inverters.

Depending on the process, welding machines are:

- manual arc MMA;

- semi-automatic MIG-MAG;

- argon arc TIG;

- point;

- plasma;

- gas.

Welding cast iron with a conventional electrode is best done with an inverter, which has an advantage over other types of devices:

- current stability during voltage fluctuations in the network;

- smooth adjustment of operating mode,

- during prolonged operation at maximum mode – automatic shutdown;

- protection against overheating, changes in network current parameters;

- microprocessor control and programming of welding processes;

- stabilization and maintenance of arc parameters at the same level under external influence;

- welding with coated electrodes of any brand on direct and alternating current;

- high-quality seam formation;

- welding of metals even with limited weldability.

A household inverter is a compact and lightweight device. However, it is not suitable for long-term operation and has low productivity.

How to brew cast iron correctly

The special properties of the metal cause increased demands on the welding process. The right approach requires careful preparation. The work area must be well cleaned of any contamination. Used: grinder, metal brushes, sandpaper. Oil stains are removed with solvents. For severe contamination, use torches or sandblasting.

A common occurrence is cracks on the surface along the edges of cast iron products. Their sealing requires a special approach. The cracks are cut and cleaned to their full length to ensure complete filling with the melt. If necessary, the workpieces are drilled along the edges, and the ends are cut at the angle required for welding.

Cast iron can be brewed in several ways, and it is important to choose the right option.

Welding technology and methods

There are 3 main methods of welding cast iron, depending on preheating:

- Hot method. Before welding, parts are heated to 600-680 °C, which increases the plasticity of the metal and reduces the risk of cracking. This technique is ideal for production environments where special ovens are available. It is extremely difficult and dangerous to provide such heating in a house.

- Semi-hot technology. The metal is preheated to 320-360 °C. Heating is done with special hair dryers. It is difficult to implement this method at home, but if you have a separate workshop, you can carry out the process.

- Cold welding. This is the most common technique for working at home. Preheating is not performed or does not exceed 60–80 °C. With this method, you will have to take into account all the difficulties of working with cast iron.

When choosing a method, you must take into account safety, the type of metal and the availability of the necessary equipment.

Stud welding

The grain structure of the alloy does not always allow parts to be welded in a multilayer manner. In difficult cases, threaded studs are installed. They are mounted in a checkerboard pattern along the edges of the workpieces being joined.

When choosing the size of studs, consider the following recommendations:

- The diameter of the fastening element should be 30-40% of the thickness of the workpieces being connected. The maximum value is 1.2 cm.

- The pin is screwed in 1.5 times the diameter. However, the length of the screwed-in section should not exceed half the thickness of the parts being welded;

- The size of the protruding part should be 0.7-1.2 times the cross-section of the stud.

After placing the studs, several layers are welded along their perimeter.

To avoid overheating, the operation is performed alternately on different sides. At the final stage, the deposited metal is welded in several seams.

Cold welding of cast iron

Cold welding for cast iron is performed mainly in domestic conditions. The advantage of the cold method is that there is no need for additional equipment to complete the work. When applying a seam, the following types of electrodes for cold welding are used:

- Copper-iron.

- Copper-nickel.

- Iron-nickel.

- Steel.

- Cast iron.

Surfacing is performed by laying one or more weld beads. When using steel electrodes, it is necessary to install studs to increase the strength of the connection. Any electrodes that contain iron and nickel are mainly used to repair minor damage.

The technology of cold welding of cast iron also involves the correction of large surface defects. For these purposes, cast iron electrodes coated with graphite are used.

The cold method cannot provide a high-quality and long-lasting seam. The use of the cold method is limited to parts with minor defects and non-load-bearing structures.

In a gas environment

Gas is used to protect and heat the treated area. When welding cast iron, a propane-butane mixture or acetylene is often used. The electrode is replaced with a filler wire made of the same metal or nickel. To reduce the likelihood of oxidation, the rod is treated with flux. Sometimes the wire is heated by the reducing part of the burner.

To obtain a welded joint using the gas method, perform the following steps:

- Gradually heat up the welding area. The appropriate temperature is selected empirically.

- Once the desired temperature is achieved, a connection is formed. Gradually remove the burner, achieving slow cooling.

- Clean the welded joint from slag and grind it if necessary.

Arc welding with electrodes

This method is approved for use, but it is characterized by high cost and lack of advantages over other methods. Cast iron does not require careful protection from oxidation.

When arc welding with argon, the following rules are observed:

- prevent overheating of the treated areas;

- gradually increase the temperature of the weld pool;

- slowly cool the finished structure.

The welding process includes the following steps:

- fixing parts in the correct position using a vice or clamp;

- formation of a protective gas cloud (argon supply starts 15 seconds before arc initiation, stops 7 seconds after completion of work);

- setting up the machine (current strength and supply speed of consumables are selected taking into account the thickness of the workpieces being welded);

- suture placement (the electrode is guided in the direction of the connection);

- completion of welding by gradually reducing the arc power with a rheostat.

With argon-arc technology, a semi-automatic device with nickel wire or non-consumable electrodes is used.

Features of welding at home with an inverter

For electric welding at home, you can use a regular inverter or a special home semi-automatic machine. The most common method is cold welding with electrodes, when an inverter is used as a current source. When connecting the device, the polarity is reversed. It is turned on at the minimum power for this type of electrode. Welding is done with short seams 40–50 mm long.

There are 2 ways to ensure the strength of the weld:

- Welding with studs. As a rule, steel studs with a diameter of up to 0.4 times the thickness of the cast iron workpiece are used. They are inserted into holes drilled along the edges. Their projection does not exceed 4–5 mm, and the installation pitch is up to 5 diameters. At the initial stage, the protruding part is scalded around, and the melt fills the seam. Then, the metal is welded from stud to stud, forming a circular weld. Gradually, the entire surface at the joint should be evenly filled with the deposited metal.

- Multilayer welding. After careful preparation of the edges of the workpieces and the formation of chamfers, the parts are joined and the layer-by-layer formation of the weld begins. After applying the first layer, it is carefully forged with a hammer. Then, the procedure is repeated with the second layer, etc. If flat workpieces are to be cooked, then after applying each layer, the parts are turned over and the layer is applied on the reverse side.

Reference! When welding, it is important to remember that the metal cannot be overheated, and therefore frequent stops of the process are necessary.

What electrodes are used for welding cast iron

The peculiarity of welding cast iron using electrodes is that when the electrode burns out, a certain amount of carbon located in the metal itself also burns out. When burned out, pores are formed that affect the quality and strength of the weld joint.

Therefore, for welding cast iron products, electrodes containing nickel and copper are used. There is a reasonable explanation for this, related to the characteristics of these metals:

- Nickel - dissolves without residue in the iron that is part of cast iron. In this case, nickel is completely neutral with respect to carbon and enters into a chemical reaction with it. This provides certain advantages. The weld seam applied with a nickel electrode is not hardened during the work and remains soft and pliable for further processing.

- Copper - the special electrodes used for welding heat-resistant cast iron are made of this metal. Copper does not dissolve in iron and as a result forms a harder weld, which is often required when processing the material.

If we talk about brands of electrodes for welding and surfacing, then there are about a dozen types of products on the market designed for specific purposes and having their own specific properties. Namely:

- Welding electrodes for cast iron SCh 20 – for work with gray cast iron, electrodes with a graphite coating are used. Electrodes SCh 20 allow you to obtain a weld that is completely identical in structure and chemical composition to the metal being processed.

- Electrodes for cast iron TsCh 4 - used for cold work. The main purpose of TsCh 4 electrodes is to carry out minor repairs of surface defects. It is also recommended to use TsCh 4 electrodes for welding cast iron with steel, provided that low-polarity direct current is supplied.

- Welding cast iron with a stainless steel electrode is another effective way to process black cast iron. The technology for working with a stainless steel electrode includes mandatory heating of the workpiece and the application of several welds.

- Welding with copper electrodes - this class includes the most “rare” MNCh-2 consumables. MNCh-2 electrodes allow you to obtain the highest quality seam. MNCh-2 can be used for both cold and hot welding.

You can independently make electrodes similar in composition to those listed above. Especially considering that MNC-2 is rare and in short supply, making its analogue at home is quite justified. For production you will need to do the following:

- Remove the coating from the conventional electrode. Grind the resulting composition and mix in equal proportions of iron powder. Small chips can be used.

- Liquid glass is poured into a separate container. The mixture is gradually poured into liquid glass, bringing the composition to the consistency of thick sour cream. Welding with copper electrodes is quite expensive, and making homemade coating significantly reduces the cost of repair work.

- Take copper wire marked M2, M3. The wire is cleaned with sandpaper, then degreased and cut to the required length.

- The resulting blanks are dipped in coating. The result should be an electrode with copper wire no more than 1.5 mm thick. In order for the properties of manufactured consumables to be almost identical, they must be processed for the same time.

- The blanks are hung in a vertical position and wait for the mixture to dry completely and harden.

It is strictly forbidden to use brass wire as a rod. Brass wire contains a large amount of zinc, which is poisonous. When the electrode is burned, a toxic substance will evaporate, which can cause serious poisoning.

What markings are used to indicate electrodes that can be used for welding?

- OZCH-2, OZCH-6 - these electrodes are made by applying ferrite powder to a copper rod. The purpose of the OZCh-2 and OZCH-6 electrodes is to eliminate small defects using cold work. According to their characteristics, copper electrodes for OZCh-2 and OZCH-6 cast iron resemble home-made products that can be made at home.

- OZZHN-1, OZCH-3, OZCH-4 - these consumables contain a large amount of nickel. According to GOST, the percentage of nickel can reach 90% of the total mass. The group OZZHN-1, OZCh-3, OZCh-4 includes both nickel and nickel-iron electrodes.

- MNC-2 are the rarest of all types of products. The composition of MNP-2 includes nickel, copper, and iron. This ensures a high-quality and even seam of high strength.

Welding cast iron with simple electrodes (on steel)

Welding cast iron with conventional steel electrodes does not provide good weld quality.

Consumables of this type are used due to their availability and low cost. To reduce the negative consequences of using steel electrodes, it is necessary to use special TsCh-4 rods. This brand is one of the most popular and in demand among welders. Therefore, it is important to know how to properly cook cast iron with TsCh-4 electrodes. This grade is intended for surfacing the first cladding layers with subsequent continuation of the welding process with conventional materials (in the picture). In addition, TsCh-4 is suitable for both hot and cold welding of cast iron, sealing defects and joining steel to cast iron.

As for the SSSI. Often performers wonder about UONI electrodes, whether it is possible to cook cast iron with this brand. It should be noted that conventional electrodes can only be used when welding small defects in non-critical structures. Since the quality of the connection will not be high. To obtain more or less satisfactory quality, you should follow the same rules as when welding with special electrodes. Another effective way to improve the quality of the connection is a slight preheating to 150-200°C and slow cooling.

Welding electrodes "UONI-13/55" in packaging.

When welding cast iron with general purpose electrodes, the weakest point is the heat-affected zone at the fusion boundary. This zone is characterized by fragility and the presence of cracks. These defects often lead to peeling of the deposited layer from the base metal. To avoid this, you must use steel studs or bolts.

The studs are threaded and screwed into the surface to be welded. The dimensions depend on the thickness of the work product. There are recommendations regarding stud sizes:

- the diameter should be 0.3-0.4 of the thickness of the part, but not more than 12 mm;

- screw-in depth - 1.5 times the diameter of the stud, but not more than half the thickness of the products being welded;

- the height of the protruding part of the pin is 0.75-1.2 of its diameter.

The studs are placed in the beveled edges of the parts in a checkerboard pattern at a distance of 4-6 diameters.

The protruding parts of the studs are scalded around the perimeter, gradually filling the seam. First of all, all studs are welded with circumferential seams using electrodes whose diameter is 3 mm. A low voltage is used. Welding is done randomly to avoid severe overheating. Afterwards, circular seams are placed around the welding site until the entire surface is covered with a layer of deposited metal.

We hope that presenting here the above rules and recommendations will help you figure out how to weld cast iron correctly with electrodes and successfully complete the work.

Welding cast iron with non-consumable electrodes

Cast iron can be welded with different types of non-consumable electrodes: tungsten, carbon or graphite. Cast iron or special filler rods containing nickel, aluminum, copper and other metals are used as filler material. To protect the welding zone, inert gases are used, most often argon or fluxes, the main component of which is borax. The most popular technology is AC TIG - welding with a tungsten electrode using alternating current in an argon environment.

Welding cast iron with coated electrodes

Cast iron electrodes are special materials for correcting defects in cast iron, which are cast round rods coated with different compositions. In most cases, the connection is made using direct current, but it is also possible to use alternating current. The current value is determined at the rate of 50-60 A per 1 mm. electrode.

The quality of the seam obtained as a result of cold welding with cast iron electrodes is heterogeneous. Therefore, semi-hot welding should be performed.

How to properly cook cast iron with electrodes, the video is presented below.

After reviewing the entire range of information, the performer will be able to choose the best electrode for cast iron.

How to cook cast iron using electric welding at home using a cold method

For minor damage, minor defects of unloaded parts, when there are no special requirements for the quality of the connection, this technology is quite suitable.

With the cold method, the temperature in the welding zone cannot be increased. To do this, the seam is applied in small parts 30-50 mm long. with breaks for cooling to 50º-60º. Thus, the risk of cracks is minimal.

To prevent overheating, the process is carried out at constant current, and the electrode is connected to the positive of the inverter (reverse polarity). For the same purpose, when working, the welder moves the electrode not in a straight line, but in zigzags or in a circle.

It is necessary to control the speed of the electrode. If the speed is too high, lack of penetration may occur. If it is insufficient, overheating and burning through the metal being welded, especially thin metal, is possible.

Surfacing of cast iron

Surfacing of cast iron can be done using special electrodes of the following brands:

MNCh-2, used for critical joints, surfacing is performed without heating. OZZHN-1 are intended for repairing serious defects. OZCH-2 are used for surfacing ductile and gray cast iron. The technology of cast iron surfacing is presented in the article “Metal surfacing: electrode and others.”

Gas surfacing is carried out using the heat generated by the combustion of a mixture of acetylene (acetylene substitutes) and oxygen. Cast rods and fluxes are used as consumables.

Inverter welding technology

After preparing the product, how to weld cast iron with a regular electrode so that the seam turns out without flaws. First of all, you need to choose the right type of electrode and technology for performing the work.

Basically, welding of cast iron is carried out using three methods:

- hot – before welding, the parts are heated to 600º-650º;

- semi-hot – heating up to 300º-350º;

- cold - without heating the products.

The hot method is a labor-intensive and complex process. Used in production to work with large and complex workpieces.

First, the entire surface of the part is well heated to avoid temperature changes. In production, cast iron products are heated using a forge, an induction furnace, or in a pit lined with refractory bricks.

Cast iron begins to melt at a temperature of 750º, so heating should not exceed 600º-700º. Heating is carried out at a speed of 150º per hour. Cast iron becomes like plasticine and is easy to work with.

After welding is completed, the workpiece must be cooled slowly. To do this, the parts are covered with sand, covered with an asbestos blanket or heated, gradually lowering the temperature.

With this method, cracks and pores are practically not formed, and the seams are obtained without defects.

The semi-hot method is similar to the hot method, but preheating reduces the cooling rate after welding. The metal is bleached to a lesser extent, which means the risk of cracks is reduced.

Safety precautions when welding cast iron

Carrying out work with cast iron requires compliance with safety measures aimed at ensuring proper conditions in the workplace. In this case, the following nuances must be taken into account:

- Electric welding of cast iron at home should be carried out in a well-lit and ventilated area.

- The device must be grounded.

- Metal does not respond well to rapid cooling. It is necessary to protect its surface from moisture.

- It is mandatory to use personal protective equipment:

- gloves

- points

- workwear

When working with cast iron using the electric welding method, all basic requirements apply to all welding work without exception. The master is required to adhere to the rules for the safe operation of electrical welding equipment.

Multilayer

Welding of cast iron can be carried out using electrodes for ordinary carbon steels, laying the metal in several layers. The first, due to rapid cooling, will be the most fragile and hard.

In the second, the amount of base metal will decrease even more. At the same time, hardening it will continue to give a high risk of cracking.

In the third and subsequent layers, the carbon content will decrease and plasticity will increase.

At the same time, the strength of the seam is low and a similar method can be recommended for connections that are more of a decorative nature.

Electrodes and wire

Metal cored wire is a layer of flux “wrapped” in metal . Its various types are used for both hot and cold processes. It is designated by the abbreviation PPCh-1 (cored wire for cast iron), PPCh-2, etc.

To weld parts using semi-automatic machines, wire type ESAB OK Nicore 55 is used. It can only be used in an argon environment.

It is used for malleable and high-strength cast irons, allowing to obtain a durable, easy-to-process seam. For electrode welding, electrodes of the TsCh-4 type with a rod made of low-carbon wire and a coating of a slag-forming flux mixture are used .

In addition to them, there are other types, in particular OZCh, OZZHN, etc. Which electrodes to use to cook cast iron is decided in each specific case, depending on the conditions, grade of metal, required strength, etc.