The possibility of a welding process in a marine environment was first discussed at the end of the 19th century: due to the displacement of liquid by evaporating gases formed during the melting of electrodes, arc combustion is maintained.

Underwater welding was officially recognized in 1932. Engineer Konstantin Khrenov, wearing long rubber gloves, welded parts in a flush tank with running water; he covered the electrode with waterproof coating.

The first practical application of the technology was registered in 1936; underwater welding was used when lifting a vessel in the Black Sea. Two years later, divers-welders without a plant in the DOK repaired the steamship Ussuri, then restored the tightness of the bottom of the icebreaker Sibiryakov after being removed from the rocky shoal.

At the beginning of 1942, a special laboratory was created in one of the Moscow institutes. Underwater welding was carried out in a huge training chamber, and new ways of creating strong welded joints under water were invented. Now there are many such training centers. The technology is being improved, new types of surfacing materials and equipment are being developed.

Features of underwater welding

First, about the human factor:

- During work, the body of an underwater welder experiences pressure from the water column; it is difficult to work with the equipment;

- due to rising bubbles and foaming of water, the visibility of the weld pool is reduced, and displacement of the deposit occurs more often;

- There is a high risk of electric shock - water conducts electricity well, any breakdown is deadly.

The main differences of the welding process:

- ignition of the electrode is difficult due to a layer of rust;

- you can only work from top to bottom;

- under the pressure of water on the air bubble, the seam is melted deeply;

- the metal immediately cools down, pressed scales form on the joint;

- work is carried out at high currents;

- With rapid crystallization, the metal becomes brittle.

It is clear that the work is carried out only by an experienced welder with diver training.

Underwater cutting of metals

Cutting metals under water is of great importance when performing ship repair, ship lifting and rescue work.

Cutting metals underwater has many specific features. The metal being cut is in water and is intensively cooled, which makes it difficult to cut through it sufficiently. A carver working underwater is constrained in his movements, as he is wearing special diving equipment. Visibility when cutting underwater is also limited.

There are three types of underwater metal cutting:

- gas-flame;

- arc;

- oxygen-arc.

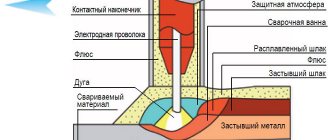

With any method, cutting is performed in a gas environment, which is created artificially or occurs naturally during the cutting process. Heating of metal when cutting under water is ensured by the creation of a gas bubble, which pushes water away from both the flame and the heated area of the metal being cut.

For underwater oxy-fuel cutting, special cutters are used that operate on gaseous hydrogen or liquid flammable gasoline. Under water, metal cools more intensely than in air, so heating it requires a flame 10-15 times more powerful than for similar work in air.

Underwater torches have devices to create and maintain a gas bubble that pushes water away from the flame. To form a protective gas bubble, carbon dioxide, carbon monoxide and additionally blown air are used.

The head of the hydrogen-oxygen cutter consists of a cap 3 and mouthpieces 1 and 2. Cutting oxygen 4 flows through the central channel of mouthpiece 1, and a hydrogen-oxygen mixture 5 flows through the annular channel between mouthpieces 1 and 2, forming a heating flame 7. Outside the mouthpiece 2 there is cap 3, through which compressed air 6 enters, which serves to form a bubble 9 around the flame. The flame of the cutter is ignited above the water, after which compressed air 6 is supplied to the mouthpiece and the cutter is lowered under water 10 (8 - a stream of cutting oxygen). If the flame goes out under water, then raise the cutter, light and regulate the heating flame, and perform a secondary immersion. When working at great depths, underwater ignition of the torch flame is used. For this purpose, a “fire board” and a rechargeable battery are used.

Figure 1 — Diagram of the head of a hydrogen-oxygen cutter for underwater cutting

A cutter for hydrogen-oxygen underwater cutting is shown in Figure 2. The hydrogen-oxygen cutter cuts steel up to 70 mm thick at a depth of up to 30 m. The cutter consists of a mouthpiece 1, a head 2, a cap 7, valves 4 and 6 and a handle 5. Cutting oxygen supplied through valve 4 in the central channel of the mouthpiece 1. The hydrogen-oxygen mixture enters the head 2 through tube 3, and compressed air into the cap 7 through valve 6. Hydrogen and oxygen enter the cutter through hoses from cylinders. Air is supplied through a separate hose from a compressor or cylinders. The hydrogen-oxygen flame does not have a pronounced core (there are no carbon particles in the flame), which makes it difficult to control. Therefore, it is more convenient to use gasoline as a fuel. When cutting metals under water, gasoline does not evaporate, but is sprayed with oxygen. Sprayed gasoline is supplied to the heating flame zone, which has time to evaporate and burn in oxygen.

Figure 2 — Cutter for hydrogen-oxygen cutting

A cutter for gasoline-oxygen cutting is shown in Figure 3. The gasoline cutter consists of a head 1, connecting tubes 2 and a body with a handle 3. There are three valves on the body of the cutter handle - valve 4 for gasoline, 5 and 6 for oxygen. Gasoline is supplied from a pressure tank; the necessary pressure is created by nitrogen supplied from a cylinder through a reducer.

Figure 3 — Cutter for gasoline-oxygen underwater cutting

The essence of electric oxygen underwater cutting is that the cut site is heated by a direct arc burning between the product and a tubular steel electrode through which cutting oxygen is supplied. Oxygen is supplied to the electrode through an electrode holder; to release oxygen, the holder is equipped with a valve. For electric oxygen cutting, metal, carbon or graphite electrodes are used; steel electrodes are most widely used. For the manufacture of electrodes, seamless steel tubes with an outer diameter of 5-7 mm, an inner diameter of 2-3 mm, and a length of 450 mm with a special waterproof coating are used. DC installations are used for power supply. When cutting, straight polarity is used, the current does not exceed 400 A. Electrical oxygen cutting can be performed at significant depths of up to 100 m. Oxygen consumption is 6-10 m3/h. The disadvantage of electric oxygen cutting with a steel electrode is the high consumption of electrodes. An electrode 450 mm long is consumed on average within 1 minute.

a — steel tubular electrode; 1 — thick-walled steel tube, 2 — coating, 3 — channel for oxygen; b - carbon electrode; 1 - carbon electrode or graphite rod, 2 - metal shell, 3 - oxygen tube, 4 - coating; c — carborundum electrode; 1 - carborundum rod, 2 - metal shell, 3 - channel for oxygen, 4 - coating

Figure 4 - Cross section

Carbon or graphite electrodes are also used for cutting. A copper or quartz tube is inserted into the axial channel of the electrode. To increase the electrical conductivity of the electrode and increase the mechanical strength, the rods are coated on the outside with a metal sheath, on the surface of which a waterproof coating layer is applied. A carbon electrode 250 mm long burns for 10-12 minutes.

The disadvantages of carbon electrodes include a significant outer diameter of 15-18 mm, which does not allow the electrode to be inserted into the cutting cavity. For electric-oxygen underwater cutting, tubular carborundum electrodes with a steel shell and a waterproof coating have been used. The service life of a carborundum electrode with a length of 250 mm and a diameter of 12-15 mm is 15-20 minutes.

Types of underwater welding

There are several ways to weld metal in water:

- with isolation of the working area (in a deep-sea or working chamber, portable box);

- directly in the water;

- using manual or automatic equipment.

Dry underwater welding in a box or chamber is rarely used, the costs are too high:

- on lifting and transport mechanisms holding the insulating structure;

- air blowers;

- devices that monitor the performance of the created environment.

Only when it is necessary to obtain strong connections do they resort to dry methods.

Hyperbaric welding is a partial combination of wet and dry welding: the diver-welder is in an aquatic environment, and the welding process takes place in a small box from which air displaces liquid.

Wet underwater welding involves igniting the electrode in water and does not require preliminary preparation, but the quality of the connection suffers in this case.

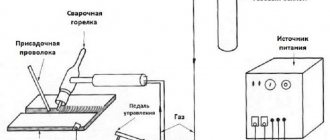

Manual underwater welding is used in emergency cases, when tightness is important, the seam does not resist fracture or torsion. For operation, special electrodes with waterproof coating are required. Semi-automatic using flux-cored wire is used to create uniform, strong welds of long lengths. The result is good. It is easier to control the process than using electrodes for two reasons:

- the wire has a small diameter;

- there is no air-foaming coating.

It is easier to operate semi-automatic machines in a liquid environment.

Dry methods are used when it is necessary to obtain strong connections.

How to make at home

It is not recommended to carry out such work at home. To do this, you need to have not only the skills of a high-class welder, but also a diver, and it is unlikely that you will be able to obtain them on your own. If you have the appropriate skills, equipment and an assistant, you can weld underwater at home.

Security requirements

When carrying out such welding work, the following rules must be observed:

- work must be carried out with direct current;

- there must be an emergency switch in the electrical circuit;

- there must be high-quality communication between the welder and the inspector;

- the diver's suit must provide a high degree of isolation of the welder from the parts being welded;

- Explosive gas pockets may appear behind the workpiece, so you must be careful and careful during such work; voltage is supplied only during direct welding or cutting; at other times the equipment must be turned off;

- the welder must constantly monitor his position so as not to end up between the grounded product and the electrode holder and become part of the electrical circuit;

- connections must be reliable and the ground clamp must be strong;

- when replacing the electrode, the current must be turned off;

- The electrode holder is handled with care and should not be pointed at yourself or other people.

We recommend reading Methods for welding gates at home

The diver's suit must provide a high degree of insulation for the welder.

Required tools and equipment

To perform underwater cooking, you will need special electrodes and a universal holder. There is no need to supply oxygen, so no equipment is required. To create and maintain an electric arc, you will need a DC generator, such as the BROCO BR-22.

Hydrogen removal

During the work, water, under the influence of current and high temperature, is converted into oxygen and hydrogen. Since the resulting gas is lighter than water, it rises on its own, and new bubbles form in its place.

General description of the process

There are 2 types of welding that can be done underwater:

- Self-regulating. Here the electrode is moved relative to the welding line in a perpendicular direction and slightly pressed against the part so that it is in constant contact with it. A series of stitches is made by moving the electrode across the joint line. A strong seam is obtained at a length equal to the diameter of the electrode; if it is 4 mm, then the welds are each 4 mm wide. When carrying out vertical welding, they move from top to bottom so that the resulting gas does not impair visibility.

- Managed. The welder performs arcuate movements with the electrode, moving it from side to side, without touching the products being welded. Used when it is necessary to obtain a long straight or slightly curved seam. In this way, the vertical seam is made both from top to bottom and vice versa.

Self-regulating and controlled welding can be performed underwater.

Underwater welding technology

The principle of any welding process is the melting of metal under the influence of an electric arc. When the electrode is ignited, a gas bubble is formed - water decomposes under the influence of electric current. The resulting gas frees up space for further combustion of the electric arc.

The melt is instantly cooled by the surrounding liquid without the formation of a slag layer. The temperature of salty sea or ocean water can be below zero. The metal does not have time to absorb hydrogen and oxidize. The process of bubble formation during arc burning is continuous. When using electrodes, their number increases; when working with welding wire, there are fewer of them.

Seam shape

Butt joints are difficult to make in poor visibility. For deep work, T-welds and overlap welding are acceptable. The weld bead is smooth, and the position of the additive can be adjusted by touch.

Monitoring the process and correcting defects

When welding underwater is performed with electrodes, it is associated with a number of problems:

- large splashing of metal;

- poor arc stability;

- the appearance of gas pores and slag inclusions;

- poor seam formation.

When welding underwater is performed with electrodes, metal spatter occurs.

A large amount of gas impairs visibility, resulting in defects such as lack of penetration and lack of fusion. The quality of the seam largely depends on the qualifications of the welder, therefore only welders with a high category are allowed to perform underwater work.

The use of sealed mechanized equipment using special wire helps to solve the described problems. This allows you to reduce emissions of welding gases, improve the quality of the weld and obtain the required characteristics.

Equipment and consumables

Underwater welding is carried out by standard current generators: transformers, inverters, rectifiers. Recommended parameters of the equipment used:

- voltage 80 – 120 V;

- amperage 180 – 220 A.

Cables and hoses must comply with electrical safety standards; underwater welding is associated with electric shock, especially in sea water with a high salt content. When energy is lost, arc combustion worsens.

Electrodes for underwater welding are made with a paraffin or nitro-varnish coating; SV-08, SV-08GA and the like are often used. Recommended flux-cored wire – SV-08G2S, PPS-AN1. The size is selected depending on the thickness of the metals being welded.

Underwater welding is impossible without the use of a diving suit. When deep-sea metal is used, it is important to maintain a distance to the working area so that a discharge does not occur between the instrument and the suit.

What does a welder need?

To weld underwater, you will need power equipment; its design is almost no different from what is used on land. What is designed to work at greater depths may have some differences in design.

Cables and special hoses

The technology for performing work, as well as compliance with electrical safety measures, impose special requirements on the integrity of cables and hoses through which power is supplied, water is pumped out, wire and shielding gas are supplied. Often such work is carried out in sea water, which is a good conductor of electricity. The presence of twists on the cables can not only cause current leakage, but also be dangerous for the welder.

To perform work underwater, you will need special hoses.

Space suit or similar equipment

The welder is forced to work at great depths, so he will need special equipment, this could be a spacesuit or similar equipment. Salt water is highly conductive, so an arc can form at a distance from the parts being welded.

When positive conductivity is established between them and the metal parts of the suit and when the distance from them to the electrode is reduced, a discharge may appear.

Electrodes, wires, etc.

Electrodes made of low-carbon steel are used, because... they are less susceptible to the negative effects of liquid. The coating on them is additionally coated with protective agents, which, by creating a waterproof layer, prevent it from deteriorating prematurely.

The work is performed with electrodes with a diameter of 4-6 mm, for example, brand Sv-08 and similar. For semi-automatic welding, wire SV-08G2S and similar ones are used. When changing the electrode, the equipment turns off.

For underwater welding, low-carbon steel electrodes are used.

Requirements for welding divers

The depth of underwater welding underwater is limited by the capabilities of the human body. During a sharp ascent, decompression occurs - gas bubbles form in the blood. The diver-welder undergoes double training:

- professional welder course for the assignment of a high category;

- professional training of divers, it is important to learn how to use scuba gear correctly, calculate the time spent under water, and determine the time intervals of depth exposure during ascent to the surface.

In the process of personnel training, special attention is paid to safety precautions; a specialist must be able to swim well, check equipment, and know the nuances of the welding process. In difficult conditions, it is important to properly organize the workplace so that unnecessary interference from currents and waves is not created. There should be no loose objects in the work area.

For underwater work, it is necessary to have an understanding of the hull structure of ships being repaired, the features of hydraulic structures, and bridge structures being erected. Training of divers-welders is carried out in specialized centers where there are swimming pools and a variety of welding equipment.

Where is it mainly used

This method of connecting parts is used when performing various works on objects located under water:

- oil, gas, water pipelines;

- ship hulls;

- piers and bridges;

- oil and gas production platforms;

- dams;

- other buildings.

Underwater welding is used when working with pipelines.