Steel sheet weight – Calculator and tables

Sheet metal is a rolled piece of a specific material, most often steel, that is widely used in industrial production, construction, automotive and other industries.

Sheet steel is the most popular type of sheet blanks, which is produced using cold or hot rolling technology. In the first case, the steel will be called cold-rolled (maximum sheet thickness up to 5 mm), and in the second - hot-rolled.

The KALK.PRO sheet metal weight calculator allows you to calculate the weight of sheet steel based on known thickness and area. You can also familiarize yourself with the metal grade and regulatory documents in the corresponding tabs of the tool. The calculator operates on the basis of GOST 19903-74 “Hot-rolled sheet metal”.

Using the calculator, you can find the weight of rolled sheets of any size and thickness, for example sheets of 1, 3, 6, 8, 10 mm, etc., the standard material is carbon steel St3st with a density of 7850 kg/m3.

By default, the weight of 1m2 of sheet steel is considered.

In order to calculate the weight of sheet metal using our calculator, you must follow the instructions:

- Select the metal type (default is Steel ).

- Confirm the type of assortment - Sheet / Plate .

- Select the metal grade (default Steel St3st ).

- Specify the sheet parameters - thickness t (mm), width a (mm), length b (mm) .

- Enter the quantity of rolled metal, pcs .

Formula for calculating the weight of sheet metal

The weight of sheet metal can also be calculated independently using simple mathematical formulas and tables according to GOST.

- a – width;

- b – length;

- t – thickness;

- ρ – density.

Weight table for 1 m2 of sheet metal according to GOST 19903-74

| Sheet size (TxWxD), mm | Sheet thickness, mm | Weight of 1 square meter, kg | Sheet weight, kg |

| 0.5x1250x2500 | 0,5 | 3,93 | 12,27 |

| 0.7x1250x2500 | 0,7 | 5,5 | 17,17 |

| 0.8x1250x2500 | 0,8 | 6,28 | 19,63 |

| 1x1250x2500 | 1,0 | 7,85 | 24,53 |

| 1.2x1250x2500 | 1,2 | 9,42 | 29,44 |

| 1.5x1250x2500 | 1,5 | 11,78 | 36,80 |

| 2x1250x2500 | 2 | 15,70 | 49,06 |

| 2.5x1250x2500 | 2,5 | 19,63 | 61,33 |

| 3x1250x2500 | 3 | 23,55 | 73,59 |

| 3.5x1250x2500 | 3,5 | 27,48 | 85,86 |

| 4x1500x6000 | 4 | 31,40 | 282,60 |

| 5x1500x6000 | 5 | 39,25 | 353,25 |

| 6x1500x6000 | 6 | 47,10 | 423,90 |

| 7x1500x6000 | 7 | 54,95 | 494,55 |

| 8x1500x6000 | 8 | 62,80 | 565,20 |

| 1500x6000 | 9 | 70,65 | 635,85 |

| 10x1500x6000 | 10 | 78,50 | 706,50 |

| 12x1500x6000 | 12 | 94,20 | 847,80 |

| 14x1500x6000 | 14 | 109,90 | 989,10 |

| 16x1500x6000 | 16 | 125,60 | 1130,40 |

| 18x1500x6000 | 18 | 141,30 | 1271,70 |

| 20x1500x6000 | 20 | 157,00 | 1413,00 |

| 22x1500x6000 | 22 | 172,70 | 1554,30 |

| Sheet size (TxWxD), mm | Sheet thickness, mm | Weight of 1 square meter, kg | Sheet weight, kg |

| 25x1500x6000 | 25 | 196,25 | 1766,25 |

| 28x1500x6000 | 28 | 219,80 | 1978,20 |

| 30x1500x6000 | 30 | 235,50 | 2119,50 |

| 32x1500x6000 | 32 | 251,20 | 2260,80 |

| 35x1500x6000 | 35 | 274,75 | 2472,75 |

| 36x1500x6000 | 36 | 282,60 | 2543,40 |

| 40x1500x6000 | 40 | 314,00 | 2826,00 |

| 45x1500x6000 | 45 | 353,25 | 3179,25 |

| 50x1500x6000 | 50 | 392,50 | 3532,50 |

| 55x1500x6000 | 55 | 431,75 | 3885,75 |

| 60x1500x6000 | 60 | 471,00 | 4239,00 |

| 65x1500x6000 | 65 | 510,25 | 4592,25 |

| 70x1500x6000 | 70 | 549,50 | 4945,50 |

| 80x1500x6000 | 80 | 628,00 | 5652,00 |

| 90x1500x6000 | 90 | 706,50 | 6358,50 |

| 100x1500x6000 | 100 | 785,00 | 7065,00 |

| 110x1500x6000 | 110 | 863,50 | 7771,50 |

| 120x1500x6000 | 120 | 942,00 | 8478,00 |

| 130x1500x6000 | 130 | 1020,50 | 9184,50 |

| 140x1500x6000 | 140 | 1099,00 | 9891,00 |

| 150x1500x6000 | 150 | 1177,50 | 10597,50 |

| 160x1500x6000 | 160 | 1256,00 | 11304,00 |

All information on the site is provided for informational purposes only. The user is solely responsible for all possible consequences arising from the use of the information received. Under no circumstances or conditions can responsibility for the consequences that directly or indirectly result from the use of information or software posted on this site be assigned to the owners of the site and be the basis for legal proceedings or other prosecution. We accept payment:© 2014 — 2020 Kalk.Pro: Construction calculators online — 3D calculations of stairs, roofs, foundations.

Area Measure Calculator

Converting from one to another area units

Calculator - Area Area

is a quantitative characteristic of a two-dimensional surface or figure. The unit of area is a derivative of the unit of length. Thus, every unit of length has a corresponding unit of area. Area can be measured in square kilometers (km²), square meters (m²), square centimeters (cm²), square millimeters (mm²), square feet (ft²), square yards (yd²), square miles (mi²) and so on. The SI unit of area is the square meter. Without a doubt, area plays an important role in modern mathematics.

Area unit calculator

Convert from

Convert to

m²

=

ac

| Basic units of area | |

| Acre | ac |

| Hectare | ha |

| Square centimeter | cm² |

| Square Foot | ft² |

| Square inch | in² |

| Square kilometer | km² |

| Square meter | m² |

| Sotka (Ar) | a |

| 'Square Mile' | mil² |

| Square Yard | yd² |

| Other units | |

| Arpan | arp. |

| Barn | b |

| Circular inch | c in |

| Circular Mil | c mil |

| Cuerda | cuer. |

| Plaza | pl. |

| Rude | rod |

| Section | mi² |

| Square Chain | ch² |

| Square Decimeter | dm² |

| Square Decameter | dam² |

| Square Hectometer | hm² |

| Square Micrometer | µm² |

| Square Millimeter | mm² |

| Square Nanometer | n m² |

| Square Perch | rd² |

| Square Pole | rd² |

| Square rod | rd² |

| Strema | str. |

| Township | ts |

| Varas castellanas quadr | v.cl.c. |

| Varas conugueras quadr | v.cn.c. |

| Basic units of area | |

| Acre | ac |

| Hectare | ha |

| Square centimeter | cm² |

| Square Foot | ft² |

| Square inch | in² |

| Square kilometer | km² |

| Square meter | m² |

| Sotka (Ar) | a |

| 'Square Mile' | mil² |

| Square Yard | yd² |

| Other units | |

| Arpan | arp. |

| Barn | b |

| Circular inch | c in |

| Circular Mil | c mil |

| Cuerda | cuer. |

| Plaza | pl. |

| Rude | rod |

| Section | mi² |

| Square Chain | ch² |

| Square Decimeter | dm² |

| Square Decameter | dam² |

| Square Hectometer | hm² |

| Square Micrometer | µm² |

| Square Millimeter | mm² |

| Square Nanometer | n m² |

| Square Perch | rd² |

| Square Pole | rd² |

| Square rod | rd² |

| Strema | str. |

| Township | ts |

| Varas castellanas quadr | v.cl.c. |

| Varas conugueras quadr | v.cn.c. |

Conversion result:

Other conversions of units of measure

- Hundreds to Acres

- Weave to Hectares

- Hundreds in cm²

- Hundreds to Square Feet

- Hundreds to Square Inches

- Hundreds to km²

- Hundreds to Square meters

- Hundreds to Square Miles

- Hundreds to Square Yards

- Acres to Hectares

- Acres to cm²

- Acres to Square Feet

- Acres to Square Inches

- Acres to km²

- Acres to Square meters

- Acres to Square Miles

- Acres to Square Yards

- Hectares to Acres

- Hectares to cm²

- Hectares to Square Feet

- Hectares to Square Inches

- Hectares to km²

- Hectares to Square meters

- Hectares to Square Miles

- Hectares to Square Yards

- cm² to Acres

- cm² to Hectares

- cm² to Square Feet

- cm² to Square Inches

- cm² to km²

- cm² to Square meters

- cm² to Square Miles

- cm² to Square Yards

- km² to Acres

- km² to Hectares

- km² to cm²

- km² to Square Feet

- km² to Square Inches

- km² to Square meters

- km² to Square Miles

- km² to Square Yards

- Square Feet to Acres

- Square Feet to Hectares

- Square Feet to cm²

- Square Feet to Square Inches

- Square Feet to km²

- Square Feet to Square Meters

- Square Feet to Square Miles

- Square Feet to Square Yards

- Square Inches to Acres

- Square Inches to Hectares

- Square Inches to cm²

- Square Inches to Square Feet

- Square Inches to km²

- Square Inches to Square Meters

- Square Inches to Square Miles

- Square Inches to Square Yards

- Square Meters to Acres

- Square Meters to Hectares

- Square Meters to cm²

- Square Meters to Square Feet

- Square Meters to Square Inches

- Square Meters to km²

- Square Meters to Square Miles

- Square Meters to Square Yards

- Square Miles to Acres

- Square Miles to Hectares

- Square Miles to cm²

- Square Miles to Square Feet

- Square Miles to Square Inches

- Square Miles to km²

- Square Miles to Square Meters

- Square Miles to Square Yards

- Square Yards to Acres

- Square Yards to Hectares

- Square Yards to cm²

- Square Yards to Square Feet

- Square Yards to Square Inches

- Square Yards to km²

- Square Yards to Square Meters

- Square Yards to Square Miles

How to calculate the area of a metal sheet - Metalworker's Handbook

The issue of calculating the weight of rolled metal is relevant not only for specialists, but also for private developers and home craftsmen.

If you have a reference book at hand and, especially, an online metal calculator, it is not difficult to make the appropriate calculations.

What if you only have a tape measure and a calculator on your phone? It is difficult to obtain accurate results with such an arsenal, but it is quite possible to approximately determine the weight of some metal products.

We calculate the weight of rolled sheets

The simplest option is rolled steel sheets.

Definition! In all our calculations, the base value is the average density of steel - 7,850 kg/m3 according to the SI system.

First, let’s carry out a simple step - find out the mass of a square meter of steel sheet 1 mm thick. It looks like this - 1 m x 1 m x 0.001 m x 7850 kg/m3.

That is, we multiplied the length, width and thickness of the sheet (all values were taken in meters), and we got the volume of the product. The product of volume and density gives mass - 7.85 kg.

Thus, we found out that a square meter of steel sheet 1 mm thick weighs 7.85 kg.

And then all calculations are made by multiplying the value of 7.85 kg by the area and thickness of the real sheet. For example, you need to buy a sheet with a thickness of 4 mm and an area of 2 m2. The mass of such a product is determined by the formula 7.85x4x2 = 62.8 kg. A sheet of the same size, but 2 mm thick, weighs 7.85 x 2 x 2 = 31.4 kg.

If you are satisfied with the approximate calculation, round the value of 7.85 kg to 8 kg. Then calculations can be carried out even in your head without a calculator, and the error will be less than 2%.

We present the weights of steel sheets of the most popular sizes.

| Sheet thickness, mm | Sheet dimensions, m | Sheet weight, kg | Weight 1 m2, kg |

| 0,35 | 1.0x2.0 | 5,5 | 2,75 |

| 0,35 | 1.25x2.5 | 8,59 | |

| 0,5 | 1.0x2.0 | 7,85 | 3,93 |

| 0,5 | 1.25x2.5 | 12,27 | |

| 0,8 | 1.0x2.0 | 12,56 | 6,28 |

| 0,8 | 1.25x2.5 | 19,63 | |

| 1,0 | 1.0x2.0 | 15,7 | 7,85 |

| 1,0 | 1.25x2.5 | 24,53 | |

| 1,5 | 1.0x2.0 | 23,55 | 11,78 |

| 1,5 | 1.25x2.5 | 36,8 | |

| 2,0 | 1.0x2.0 | 31,4 | 15,7 |

| 2,0 | 1.25x2.5 | 49,06 | |

| 2,5 | 1.0x2.0 | 39,25 | 19,63 |

| 2,5 | 1.25x2.5 | 61,33 | |

| 3,0 | 1.0x2.0 | 47,1 | 23,55 |

| 3,0 | 1.25x2.5 | 73,59 | |

| 3,5 | 1.25x2.5 | 85,86 | 27,48 |

| 4,0 | 1.5x6.0 | 282,6 | 31,4 |

| 5,0 | 1.5x6.0 | 353,25 | 39,25 |

What is a conversion factor

Let's complicate the task. Suppose you need to buy a sheet of non-ferrous metal. Let's use a conversion factor, which is the ratio of the density of a particular metal or alloy to the average density of steel. By multiplying the weight of a steel product of a certain range and size by the coefficient of the desired metal or alloy, we obtain the weight of the part.

| Name of metal or alloy | Coefficient |

| Aluminum | 0,34 |

| Copper | 1,14 |

| Brass LS59 | 1,08 |

| Bronze OTS 5-5-5 | 1,12 |

| Gray cast iron | 0,9 |

Example - let's calculate the mass of a bronze sheet with a thickness of 2 mm and an area of 2 m2.

7.85x2x2x1.12 = 35.2 kg

Attention! The same simple algorithm can be applied to non-metallic sheet materials, for which there are also conversion factors. For example, for rubber - 0.17-0.23, organic glass - 0.15, caprolon - 0.15, textolite - 0.18, rubber - 0.17-0.23.

How to find out the mass of a pipe

To determine the mass of pipes, it is optimal to use tables.

| Nominal diameter, inch/mm | Wall thickness, mm | Weight, kg | Nominal diameter, inch/mm | Wall thickness, mm | Weight, kg |

| 1/4 (8) | 2,35 | 0,65 | 11/4 (32) | 3,25 | 3,14 |

| 1/2 (15) | 2,65 | 1,22 | 11/2 (40) | 3,25 | 3,61 |

| 3/4 (20) | 2,65 | 1,58 | 2 (50) | 3,65 | 5,1 |

| 1 (25) | 3,25 | 2,44 | 21/2 (65) | 3,65 | 6,51 |

If you don’t have access to reference materials, and simple geometric formulas are not an obstacle for you, calculate the weight yourself. To do this, we find the difference between the area of the circle along the outer radius and the area along the inner radius. We multiply the resulting difference by the length of the pipe and the density of the steel - 7,850 kg/m3.

For pipes made of non-ferrous metals, the conversion factors that we discussed above are used.

How to find out the mass of a cylinder using tables for a round bar

If you have access to tables for calculating the mass of round timber, then it is very easy to determine the mass of a cylinder with any wall thickness. To do this, find the weight of 1 m of rod along the outer diameter of the cylinder and subtract from it the weight of 1 m of rod along the inner diameter. Multiply the result by the height of the cylinder (in meters). The mass of the cylinder is found.

ABOUT. SOLOMKO, assistant, Department of Plant Science,

O.S. KLOCHKOVA, Ph.D. agricultural Sciences, Associate Professor,

EE "Belarusian State Agricultural Academy",

G.V. TSVETKOV, leading programmer

Photosynthesis is a fundamental factor in plant development and yield formation [1]. The productivity of plant photosynthesis is determined by two main indicators: the total leaf area (assimilation surface) and the rate of dry matter growth per unit leaf area per day [2].

The leaf area is the basis for subsequent calculations of net photosynthetic productivity, photosynthetic potential and other indicators. Determining the area of leaves is a very difficult technique, since their shape and size changes throughout the growing season. In addition, the shape of leaf blades is very variable and difficult to measure.

There are several methods that are used to determine leaf area. We analyzed the most commonly used ones and noted some disadvantages.

1. Method of measurements. From each sample, 10 green leaves are selected at random, weighed and the area determined by linear measurements along the length (L) and greatest width (W). The area of the measured leaves (S) is calculated using the formula:

where n is the number of measured leaves.

This method is suitable for cereals and other crops with linear leaf shapes [3].

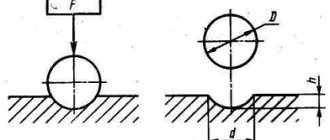

2. Die cutting method. Suitable for most agricultural crops. To do this, take an average sample of 10–15 plants (N), quickly cut off the leaves and determine their wet weight (Ml). The leaves are stacked and cut out with a drill of a certain diameter, 5-10 pieces from one sheet. The cuttings are taken so that both leaf blades and central veins are included in the sample. The mass of all raw cuttings (Mw) is determined.

The leaf area per plant is determined by the formula:

where S is the leaf area of one plant, m2; Ml – mass of leaves in the sample, g; Мв – mass of cuttings, g; a – number of cuttings, pcs; N – number of plants in the sample, pcs.; D – drill diameter, cm; – 3.14 [4].

This method is imperfect, since leaf veins that fall into the cuttings significantly increase their mass. In addition, the mass of cuttings taken in different places of the sheet will be different due to their different thicknesses at the base and top. Leaf wilting also causes measurement error. Leaves taken after rain will have an increased weight.

3. Drawing the contours of the sheet on graph paper. This method is accurate but time-consuming. Determining the area of one sheet takes 10–15 minutes (depending on the option), therefore, a lot of working time is spent on analysis.

4. Planimetric method [5]. The average sample of leaves is weighed and laid out on a moving belt of an electronic device - a planimeter. The device displays the leaf area in square centimeters. This method allows you to measure leaf area fairly quickly and accurately, but these devices are rarely used.

5. Scanning method. We propose a new method for determining the leaf area of field and other plants using computer technology.

We have developed a computer program “Leaf meter” to determine the area of leaves. "Listometer" is created on the basis of the universal graphic editor XnView and has several modes of use. The leaf area can be calculated both in aggregate and for each leaf individually. When using this program, the error of leaf wilting is eliminated; the size of the leaf area will not be affected by venation and leaf thickness.

To work with the Listometer you will need a scanner, transparent film, and a sheet of white paper.

Operating procedure.

1. Place a transparent thick film on the scanner.

2. Place leaves on top of the film, the surface of which should be dry, without dew or droplets of water.

3. Cover the leaves with a sheet of white paper.

4. Scan the image of the leaves.

5. We enter the scanned image into the program and after one minute we obtain an indicator of the area of the scanned object in the specified units of measurement.

The accuracy and suitability for use of our proposed method has been tested in work and comparative evaluation with known methods for determining leaf area.

As an example, we determined the leaf area of a spring rapeseed plant in the rosette phase. The control option was taken to measure leaves on graph paper (table).

Table. Results of leaf area measurements using various methods

| № p.p. | Method | Leaf area of 1 plant, cm2 | Deviation from control | |

| + cm2 | + % | |||

| 1 | Measuring on graph paper - control | 152,1 | – | – |

| 2 | By weight 100 die cuts | 156,1 | 4,0 | 2,6 |

| 3 | Leaf scanning | 151,0 | 1,1 | 0,7 |

As we can see from the table, measuring the leaf area using the cutting method gives a higher result than in other options.

Thus, the proposed method of scanning and determining the area of leaves using a computer program allows for a fairly quick and accurate analysis.

LITERATURE

1. Physiology of agricultural plants in 12 volumes / editorial board: Oparin A.I. (ed. volume) [etc.]. – Moscow University Publishing House, 1967. – 2 volumes. – 493 p.

2. Seeding rates, sowing methods and areas for feeding agricultural crops: collection of articles. Art. / under general ed. I.I. Sinyagina [and others]. – M.: “Kolos”, 1970. – 472 p.

3. Physiology and biochemistry of plants: method. instructions /N.P. Reshetsky [et al.] – Gorki, 2000. – 144 p.

4. Tarasenko S.A., Doroshkevich E.I. Workshop on physiology and biochemistry: Practical guide / S.A. Tarasenko, E.I. Doroshkevich, - Grodno: Oblidat, 1995. - 122 p.

5. Posypanov G.S. Methods for studying the biological fixation of air nitrogen: a reference manual / G.S. Posypanov. – M.: Agropromizdat, 1991. – 300 p.

How to calculate the area of a sheet of metal

We offer site visitors our new online rolled metal calculator. Perhaps this is the best tool, which has 5633 rolled metal units in its database!

Rolled metal calculator online

We tried to make the most convenient and complete tool that can answer any question that interests you.

All products are divided into categories, in each of which you can select a standard size, and then set either a known length or weight.

The calculator will instantly display online the information you are interested in - weight by length or length by known mass. If you want to calculate the mass of a pipe, use our pipe calculator.

How to use the rolled metal calculator?

The first step is to select the type of rolled metal from the proposed options. There are 22 such options:

- fittings A3-25G2S

- fittings A3-35GS

- fittings A3-A500S

- At800 fittings

- circle

- square

- band

- hot rolled channel

- cold-formed channel

- beam

- corner

- hot rolled sheet

- sheet cold rolled sheet

- corrugated sheet

- galvanized sheet

- rectangular pipe

- square pipe

- round pipe

- water-gas pipe (WGP)

- hot-deformed pipe

- cold-deformed pipe

- Larsen tongue and groove

After selecting the required type of rolled metal, you must select a standard size .

Then, in the input fields that appear, you need to enter known data - length or weight. In this case, the unknown parameter will be calculated automatically.

your mark

[179 Average: 4.2]

Rolled metal calculator Author admin average rating 4.2/5 — 179 user ratings

Sheet weight

24.12.2017

Manufacturers often have to deal with the manufacture or processing of any structures made of sheet metal of different thicknesses.

In this case, you have to transport it. And when transporting, it is simply necessary to know the weight of this metal so as not to overload the lifting mechanisms (crane, forklift, car).

The fact is that when sheet metal lies in a stack, its weight can be taken as the mass of a solid monolith, because there are practically no gaps between the sheets. To determine the weight of galvanized sheets, you need to know the mass of one sheet, and here you can go in two ways.

The first, most common, is to read the transportation markings painted on the end of the pack in accordance with GOST No. 14192-77. It should contain all the main parameters of steel, including weight.

The second method has to be used when for some reason this inscription with the metal data is not visible. Then you have to use the weight tables for steel and rolled products according to GOST No. 13567-78.

- 1 Calculation of the weight of 1 m2 of sheet and rolled stock

- 2 Weight of rolled steel

Calculation of the weight of 1 m2 of sheet and rolled stock

For example, we have a galvanized sheet with an area of S square meters. Using tabular data, we find out the weight of 1 m2 of rolled sheet with a thickness of 2,3,4,5,6,8,10 mm. By multiplying the value from the table by the area, we get the required sheet weight.

Calculation table for galvanized steel with polymer coating

If non-standard rolled sheets (of different thicknesses) are used, then you can safely use the formula:

M = L*W*T* (p) (7.85), where

T – rolled product thickness;

D – leaf length;

Р=7.85 – sheet steel data from the table;

W – product width.

When the weight of one steel sheet has been determined, it is necessary to calculate the weight of the entire bundle of rolled products, for which the result obtained is multiplied by the number of sheets in the package.

Rolled steel weight

And also to determine the weight of different sheets of hot-rolled steel st3sp/ps5, it is recommended to use another table:

For cold rolled steel the indicators will be completely different:

Cold rolled steel sheet 08ps/kp

And for galvanized steel, the regulatory data according to the GOST reference book are also different.

Galvanized steel 08ps/kp. Weight of 1m sheet

It must be remembered that the value from the table is the conditional weight of the steel sheet, since the actual weight of the steel sheet may differ slightly from the nominal value, depending on the grade of steel and the permissible rolling errors.

Weight of sheet steel Link to main publication

How to calculate the weight of metal - formulas and recommendations

If there is no possibility of direct weighing, the weight of scrap metal can be determined in other ways. The most accurate result will be given by calculation, but other possibilities should not be neglected.

So, in order not to burden readers with unnecessary formulas, which will still be there, but below, we will immediately designate the formulas for calculating the most popular products from rolled steel and pipes - rolled pipes.

Here you will not find an online calculator for calculating weight, only formulas that you remember once you no longer have to use special calculators.

For example, when dismantling metal structures or a chimney, you don’t always have a computer, the Internet or a reference book at hand, but the structures are all welded from rolled steel here and our formulas will help out!

Formula to calculate pipe weight

M=(Ds)*s*0.02466

, Where

- M—weight of one linear meter of pipe, kg;

- D is the outer diameter of the pipe being calculated, mm;

- s—pipe wall thickness, mm;

- 0.02466 is the coefficient for a steel density of 7.850 g/cm3.

This formula is very accurate. You can calculate the weight of the pipe and compare the calculated weight with the theoretical one in any range and the value according to the formula will be more accurate! You can also calculate

Calculating the weight of a sheet of metal

M=S*7.85

, Where

- M—mass of steel sheet, kg;

- S is the area of the calculated sheet, in square meters;

- 7.85 - weight of a sheet 1 mm thick and 1 square meter in area, in kilograms

This way you can calculate the weight of a sheet of metal of any size, for which you can calculate the area. The accuracy of calculations using this formula is higher than the theoretical mass in reference books, because

in the assortment, when calculating the mass of metal, the program rounds the values. Well, how can you find out the area of a sheet (of any shape - square, rectangle, parallelepiped, trapezoid, rhombus, etc.)

) - every person who graduated from high school should know.

How to calculate the weight of reinforcement and rod

For a circle, rod, smooth reinforcement, the formula for calculating the mass will be as follows:

M=(0.02466*D2)/4

, Where

- M—weight of 1 linear meter of circle/reinforcement/rod, kg;

- D—circle diameter;

- 0.02466 - coefficient for steel density equal to 7.850 g/cm3

To calculate the weight of corrugated reinforcement (A2, A3), you can and should use the same formula! There will be no discrepancies with the theoretical mass, despite the different cross-sectional designs.

It is, of course, impossible to calculate such a pile of scrap metal using formulas without weighing

Determination of leaf area by scanning method

Determining leaf area is a problem that needs to be solved in many quantitative plant physiological studies. Parameters such as photosynthetic productivity, pigment content, intensity of transpiration, respiration, etc. often lead to this value. Leaf area assessment is necessary as a morphometric indicator of plant growth. An important characteristic of plants is also the ratio between the area of their leaves and the total mass of the above-ground parts and height. It is of interest to study the distribution of leaves over area and the influence on this indicator of growth hormones, environmental factors, conditions of mineral nutrition and moisture supply.

Before the advent of modern computer data processing tools, leaf area measurements were carried out by weighing paper models, by calculating the product of height by width adjusted for the leaf shape factor, or using mechanical planimeters. All these methods are extremely labor-intensive and often cannot provide sufficient measurement accuracy.

This paper describes a method for determining leaf area using computer scanning, which significantly exceeds all other methods in speed and accuracy. It is based on the use of an optical scanner and subsequent data processing on a computer.

Purpose of the work: Determine the area of leaves and obtain a diagram of the distribution of leaves by area for an individual plant or part of it.

Progress. Plant leaves are placed in an optical scanner, covered on top with a sheet of thick white paper and scanned with a given resolution (for example, 200 dots per inch - dpi) in black-and-white halftone image mode.

| Rice. 1 Original photo | Rice. 2. Contrasting image |

The resulting image is saved as a *.bmp file (Fig. 1). Next, this file is opened with the ImageJ program, the control panel of which is shown in Fig. 3

Rice. 3. ImageJ program control panel.

Select the “Open” tab from the “File” menu, then specify the file to open (File®Open).

If for one reason or another it is necessary to process a previously obtained color image, it must be converted to black and white halftone. To do this, open a color image and select: Image ®Type ®16 bit.

The meaning of the next operation is to obtain a high-contrast black-and-white image from a halftone image, where the leaf blade will be solid black and the background will be white. For correct settings, so that the background does not have black spots, and the sheet does not have white spots (Fig. 2), it is necessary to adjust the intensity threshold, below which the program converts gray to black, and above – to white.

Select Image®Adjust®Threshould and then, by moving the scroll bar markers in the window that opens and simultaneously observing changes in the image, select the desired threshold values (Fig. 4).

Rice. 4. Window for controlling the brightness threshold.

After selecting the threshold, click the Apply button and close the dialog window. The window with the converted leaf image should remain open.

To subsequently measure leaf area, you must set the type of image analysis. Select Analyze®Set Measurements and check the Area option. Other measurement options should be left unchecked. The dialog box is closed.

Select Analyze®Analyse Particles. A window opens, the dialog settings of which should correspond to those shown in Figure 5.

Rice. 10. Window for managing particle analysis parameters.

After clicking OK, two windows appear, one of them shows the results of calculating the area of individual leaves, the other shows the total area of leaves:

Rice. 6. Results of calculations of the area of individual leaves and the total area of leaves.

The “Results” window may contain lines indicating objects of a very small area, only 1 - 2 pixels. You can either ignore them or get rid of them by adjusting the threshold.

At the next stage of measurements, it is necessary to recalculate the leaf area obtained in pixels into square centimeters. In our case, the scanner resolution was 200 dpi. This means that a square inch will correspond to the square of this value - 40,000 pixels. The area of the first sheet will be: 98058/40000 = 2.45 square inches. eConversion factor sq. inches to sq. see – 6.45. Thus, the area of the first sheet is 2.45 ´ 6.45 = 15.8 cm2.

Since the resolution of the scanner does not always exactly match that specified in its technical documentation, in order to make very accurate measurements it is necessary to calibrate the scanner. To do this, measure the area of a square of black paper of precisely known dimensions (standard) in the manner described above and calculate the correction as the ratio of the measured area to the actual area of the standard. Subsequently, the results of leaf measurements are multiplied by this correction.

The “Results” window is saved as a file with the extension *.xls (File®Save as). Subsequently, such a file can be opened with Exel, Statistica, Origin programs and processed data using the tools of these programs - calculate the average, maximum or minimum value, standard deviation, construct a diagram of the distribution of leaves by area.

Articles to read:

- Determination of winners and awards

- Defining a String Variable

Area calculation in SOKKIA CX series total stations

Similar articles:

- Methods for determining subcutaneous fat layer

Measuring subcutaneous fat or body composition is still a highly controversial issue. The reason for this is the fact that it is impossible to measure the percentage...

- Methods and art of programming

DESIGNING PROGRAMS The previous section on the Pascal language contains many example programs. However, when analyzing a finished program, more often...

Metal weight calculation

The metal is widely used in various industries. When creating metal structures, it is necessary to first calculate two important indicators: strength and total weight.

The strength of the structure can be calculated using the methods of the theory of strength of materials. Weight is calculated taking into account the following characteristics:

- standard sample density (determined by physical characteristics);

- metal shape (according to the existing assortment - rolled sheets, channel, angle, pipe, etc.);

- geometric shape, part dimensions.

Metal weight calculation

The presence of various forms of metal products requires an individual approach when calculating the following parameters:

- the mass of the entire metal structure;

- required volume of metal.

What is a conversion factor?

It allows you to calculate the weight of products made of any material. It is obtained as the ratio of the density of the selected material to the density of steel. Next, to calculate the required parameter, it is enough to calculate such a parameter of a steel product of a given shape. The resulting result will be multiplied by the conversion factor for this material.

The coefficient is a dimensionless quantity. It has its own specific meanings for various metals and alloys. For example, aluminum has 0.34, copper - 1.14, and 1.12 is used for OTS5-5-5 bronze.

To calculate the weight of a sheet made of the specified bronze, it is necessary to obtain the parameter of the same sheet of steel, multiplying with a conversion factor.

Metal conversion factor

The same calculation method, the use of a conversion factor, can be fairly applied to non-metallic rectangular products. For example, to textolite with a coefficient of 0.18, organic glass - 0.15. The results obtained will satisfy the accuracy requirements.

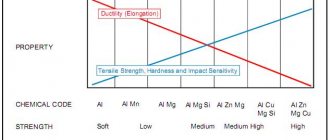

What makes calculating the weight of metal more difficult?

A serious difference in the data obtained for calculating the mass of a steel product is the technology of its production. The difference between cold-rolled metal and hot-rolled metal can be quite significant. We are talking about the accuracy of geometric characteristics while maintaining density along the entire length of the product.

The use of continuous heating and subsequent cooling leads to such negative phenomena as oxidation and recrystallization. The unevenness of these processes causes a change in such a parameter as thickness.

Metal weight

The accuracy of calculations for cold-rolled and hot-rolled metal profiles will differ. The error caused by thickness instability requires obtaining some average value.

How to calculate the mass of a rectangular profile?

A rectangular profile is a parallelepiped with a given wall thickness. The wall thickness is specified in the technical documentation for a specific sample.

Square profile

Mass calculation can be done in two ways. In the first method, the cross-sectional area is calculated: for a sheet of a given thickness. Calculate the mass of a rectangular parallelepiped based on its external dimensions. Then the same calculations are made for a parallelepiped with internal dimensions. The difference between the two values will be the desired characteristic.

In the second method, the weight of one wall of the structure is calculated. If the cross-section is square, multiply by four. If it is rectangular, the sizes of the smaller and larger walls will be calculated separately. Then multiply each value by two and add the results to get the final figure.

Square profile weight

To simplify the process, special tables have been developed.

Determining the weight of a round profile

Round metal products include solid rods, fittings, and pipes of various diameters. The approach to solving the problem remains the same. If the product is solid, it is necessary to calculate the volume, multiply by the density of the material. The volume of metal is calculated using known geometric formulas.

Round profile weight

If the round workpiece is hollow inside, you need to know the wall thickness. Next, you can use one of the methods applicable to calculate the value of rectangular rolled products. The only difference will be the calculated ratios for finding the volume.

How to find out the mass of a hexagonal profile?

Solid metal rods with a hexagonal cross-section are often used. The calculation method for such products remains the same. It is necessary to remember from the school geometry course how the volume of a regular hexagonal parallelepiped is calculated.

The task is greatly simplified if you know the size or number of such a rental. All numbers are given in a standardized table.

The hexagonal profile with the smallest number 10 weighs only 0.68 kg, the largest number 60 weighs 24.5 kg.

Hexagonal profile

The calculations are based on a formula for calculating the volume of a regular hexagonal prism. Having calculated this volume, it is multiplied by the density of the metal. A mass of hexagonal product is obtained.

It should be remembered that the use of simplified methods gives approximate results. They are used for express assessments. When developing design documentation in detail, more accurate indicators are used.

Finding the parameter of a metal pipe of any diameter is carried out similarly to the method for a round profile. Calculate the difference in the areas of two circles. The first has the outer radius of the pipe. The second has the inner radius of the pipe.

The resulting difference is multiplied by the length of the pipe, calculating the volume of metal. Multiplying by the density of steel, the mass of a pipe of a given length is found. Operations with non-ferrous metal products are simplified through the use of a conversion factor.

Pipe weight

When working with ready-made tables, you should find data for a 1 m bar with a radius equal to the outer diameter. Calculate the diameter of the rod, which is equal to the internal diameter. Subtract the smaller value from the larger value to get the desired result. It should be multiplied by the length of the sample.

How to calculate the mass of an angle, channel, I-beam

The parameter is calculated using data on the width of the shelf and the thickness of the metal. The product is considered as half of a rectangular profile.

There are ready-made calculation tables for the entire range of rolled metal products.

However, corners from different manufacturers have real weight characteristics that differ from the tabular data. They deliberately reduce the thickness of the shelf. They are motivated by the desire to reduce the cost of products. The parameter difference differs significantly from the parameters provided by GOST.

Weight of anglesWeight of channelWeight of I-beams

The weight characteristics of the channel and I-beams are determined according to the tables. This is caused by the difficulties of calculating the volume of complex geometric shapes.

, please select a piece of text and press Ctrl+Enter.

Calculation of sheet steel weight

All rolled products, depending on their shape, can be divided into four main groups:

a) grade steel;

b) sheet steel;

c) pipes;

d) special types of rental.

Rolled sheets of steel and non-ferrous metals are used in various industries and construction. In this regard, sheet steel, for example, is divided into automotive, transformer, roofing sheet, etc.

The production of sheet steel with tin, zinc, aluminum and plastic coatings, polymer coating, as well as flat, smooth and profiled: corrugated sheets, expanded metal, perforated, is expanding.

Sheet steel is divided into groups depending on the thickness of the section. Sheets more than 4 mm are classified as thick sheet steel, and sheets less than 4 mm are classified as thin sheet metal. In this case, there are the following types of sheet steel: shipbuilding, boiler, electrical, tin, acid- and heat-resistant, armor, etc.

The qualitative characteristics of flat products are determined by mechanical properties, chemical composition, molecular structure, use for further processing and, finally, smelting method. When producing rolled sheets, the thickness may have plus or minus tolerances, which entails changes in the actual weight of a square meter of sheet.

The larger the dimensional tolerance for a given flat product (the difference between the maximum and minimum dimensions of the flat product), the greater will be the difference between the theoretical weight of the sheet steel and the actual weight.

Hot rolled sheet of ordinary quality is made from thin sheet steel (thickness 0.5 mm - 3.9 mm) GOST 16523-89 and thick sheet steel (thickness 4 mm - 160 mm) GOST 14637-89. Flat sheets are widely used in the production of steel containers.

The assortment of steel sheet corresponds to GOST 19903-74, the chemical composition of steel corresponds to GOST 380-88. The assortment for cold-rolled sheet steel provides for the supply of sheets with a width of 600–1400 mm and a thickness of 0.2–3.9 mm. Sheet length 1200-3500 mm. Assortment standards for cold-rolled steel coils provide for the supply of strips with a width of 200-2300 mm and a thickness of 0.2-4 mm.

The current standards stipulate specific gravity, tolerances for sheet thickness and thickness variations, depending on the dimensions of the sheet or tape and delivery conditions. The standard includes standards for tensile strength and elongation. The permissible warpage per 1 linear line is also specified. m along the length and width of the sheet and control for decarbonization.

In some cases, the technical conditions stipulate tighter tolerances than in the standards.

Rolled sheets are divided into cold-rolled and hot-rolled

Cold-rolled sheet with a thickness of 1 mm, 1.2 mm, 1.5 mm, 2 mm, 3 mm, available from steel grades 08KP, 3SP/PS.

Hot rolled sheet thickness 2mm, 2.5mm, 3mm, sheet 4, 5, 6mm, 8-10mm, 12mm, 14-16mm, 18mm, 20-32mm, 35mm, 36mm, 40 mm, 45 mm, 50 mm, 60 mm, 65 mm, 70 mm, 80 mm, 90 mm, 103 mm, available in grade st 3SP/PS, steel 09G2S-12; thickness from 4 mm to 50 mm steel grade 45.

Galvanized sheet thickness 0.5 mm, 0.55 mm, 0.6 mm, 0.7 mm, 0.8 mm, 0.9 mm, 1 mm - galvanized iron + polymer coating.

Cold rolling has two great advantages over hot rolling: firstly, it allows the production of sheets and strips with a thickness of less than 0.8-1 mm, down to several microns, which is unattainable by hot rolling; secondly, it ensures products of higher quality in all respects - dimensional accuracy, surface finish, physical and mechanical properties. These advantages of cold rolling have led to its widespread use in both ferrous and non-ferrous metallurgy.

In the production of hot-rolled steel sheet, the metal is first heated and then deformed using special rolling mills by rolling. Cold rolling ensures uniform sheet thickness and also improves its properties by hardening the surface.

Hardening is formed as a result of changes in the structure of the steel sheet . sheet, metal grains are stretched and oriented along the direction of plastic flow of the metal with axes of greatest strength. A metal sheet acquires different properties along and across, i.e.

along the length and width of the steel strip . At large degrees of plastic deformation, all metal grains are almost identically oriented in the structure of rolled steel sheets . Plastic deformation during rolling of a steel sheet causes hardening of the metal - cold hardening or cold hardening.

In this regard, to restore plastic properties it is necessary to carry out annealing.

Hot-rolled and cold-rolled sheets are used in mechanical engineering, metal structures, construction, mining and other industries.

The actual scope of application determines the requirements for sheet metal.

For the manufacture of products by stamping, sheet metal is used: cold-rolled, hot-rolled, cold-rolled coil, galvanized steel in coils, strip metal.

This table is used when calculating the mass of rolled sheets based on the specific gravity of a square meter of sheet metal.

Sheet Metal Weight Table

Rolled sheet metal according to GOST

| thickness, mm | weight, kg/m2 | thickness, mm | weight, kg/m2 | thickness, mm | weight, kg/m2 | thickness, mm | weight, kg/m2 |

| 0,5 | 3,925 | 1,4 | 10,99 | 6 | 47,1 | 18 | 141,3 |

| 0,55 | 4,32 | 1,5 | 11,77 | 7 | 54,95 | 20 | 157 |

| 0,6 | 4,71 | 1,8 | 14,13 | 8 | 62,8 | 22 | 172,7 |

| 0,7 | 5,5 | 2 | 15,7 | 9 | 70,65 | 25 | 196,25 |

| 0,8 | 6,28 | 2,5 | 19,62 | 10 | 78,5 | 30 | 235,5 |

| 0,9 | 7,06 | 3 | 23,55 | 12 | 94,2 | 40 | 314 |

| 1 | 7,85 | 4 | 31,4 | 14 | 109,9 | 50 | 392,5 |

| 1,2 | 9,42 | 5 | 39,25 | 16 | 125,6 | 60 | 471 |

Calculation of how much 1m2 of steel sheet weighs using the formula

How to calculate the weight of sheet metal by area?

Using a simple calculator you can easily calculate the weight of a steel sheet without having a table of thickness and weight of 1m2.

The weight of a sheet of metal is calculated using a regular calculator using the formula:

P = H*B*L* 7.85 where

P- theoretical weight, kg

L is the length of the metal sheet in linear meters, m;

H—sheet thickness, mm;

B—width of rolled sheets, m;

7.85 kg/dm3 - density of black steel, specific gravity - corresponds to the weight of a square meter of steel 1 mm thick.

The weight of sheet metal is calculated in kilograms (kg), if the dimensions of the sheet thickness are substituted into the formula for calculating the weight of a sheet of metal in millimeters (mm), and the length and width of the sheet in meters (m). Knowing the weight of a steel sheet, you can easily calculate how many sheets are in a ton or pack of a certain mass.

To quickly calculate the weight of rolled sheets, use the “Metal Calculator” in the “Metal Assortment” section of the website.

The sheet weight calculator calculates the weight for different grades of steel, which is important if you need to calculate the weight of a stainless steel sheet or made of non-ferrous metal.

The sheet metal calculator calculates the weight based on the dimensions of the workpiece and thickness in mm, and the dimensions of the steel sheet (based on the total weight of the package and the thickness of the rolled sheet).

The assortment of sheet steel is needed primarily by suppliers for metal purchases to calculate the weight of rolled metal. If in the process of work the question often arises about how to find out the weight of sheet metal, but there is no assortment of rolled metal at hand, the best way to solve this problem is to calculate the weight of the sheet using the above formula on a calculator.

Weight of sheet steel - calculation methods depending on thickness and grade (95 photos)

Steel is an alloy of iron and carbon; the raw material for steel production is pig iron. In addition, production waste is used in the form of steel and cast iron scrap. The main methods used are converter, open-hearth and electric furnace steelmaking processes.

Steel is classified according to purpose, chemical composition, structure:

- by purpose - structural, spring-spring, instrumental, heat-resistant boiler, stainless, heat-resistant, acid-resistant;

- by chemical composition - carbon and alloyed;

- The structure of steel is austenitic, ferritic, martensitic, bainite and pearlitic.

Metal forming

A technological process as a result of which plastic deformation of the material occurs and the shape, size and properties of the metal change. It is divided into forging, rolling, stamping, pressing and drawing.

Rolling

Compression of a metal ingot between the rolls of a rolling mill. 90% of all steels are rolled.

The range of rolled steel is extensive: sections, profiles, sheets, pipes. A significant volume of the rolled products market is occupied by rolled steel sheets.

Sheet steel

Divided into groups depending on the thickness of the section. Sheets from 4 mm and above are thick sheet steel, up to 3.9 mm are thin sheet steel. Sheets are produced on rolling mills using hot and cold rolling.

How to find out the mass of a pipe

Finding the parameter of a metal pipe of any diameter is carried out similarly to the method for a round profile. Calculate the difference in the areas of two circles. The first has the outer radius of the pipe. The second has the inner radius of the pipe.

The resulting difference is multiplied by the length of the pipe, calculating the volume of metal. Multiplying by the density of steel, the mass of a pipe of a given length is found. Operations with non-ferrous metal products are simplified through the use of a conversion factor.

Pipe weight

When working with ready-made tables, you should find data for a 1 m bar with a radius equal to the outer diameter. Calculate the diameter of the rod, which is equal to the internal diameter. Subtract the smaller value from the larger value to get the desired result. It should be multiplied by the length of the sample.

How to calculate floor area?

So, how do you calculate square meters?

The simplest ones to formulate the floor area are square and rectangular shaped houses. To calculate the area of such a room, you need to measure the length and width of the room (measured in meters), and then multiply these two numbers by each other, obtaining the number that interests us. This option is not difficult to implement; there is no need to rearrange the sofa, wardrobe and other furniture - all you need to do is calculate the distance. The only problem will be a fireplace (if there is one, of course) in this case, it will be necessary to subtract S (area) of the fireplace from the final figure.

Formula: S room = A x B, where A is length, B is width.

Irregularly shaped rooms present a more complex calculation of the S floor. An apartment in the shape of a rectangle or square is called standard, however, if there are decorative changes (arches, niches), then the calculation is more complicated, since it requires the calculation of S figures included in the room.

First, the plan must be divided into two rectangles, and then their areas must be summed up

By calculating the final area of “non-standard figures”, for example, an L-shaped room, you can “split” the room into two squares or triangles and sum up their sum. This little trick allows you to find out the S of a given area in a matter of minutes without any mathematical calculation formulas. In some cases, the corner of an L-shaped room does not meet at an angle of 90º, which is a small but solvable problem. Intersecting at an indirect angle, the transition has the form of a triangle; the calculation must be carried out according to the familiar geometric law: “The area of a triangle is equal to the first leg multiplied by the second.”

Cylindrical and half-segmental particles, but how to calculate square meters based on a basic algebra and geometry course? It is much easier to divide the area into conventional triangles and squares, and then calculate and summarize the results of each individual element.

Formulas for area and geometric figures

There are living rooms in private houses that have different floor heights (protrusions, hills, slopes). To perform the calculation, it is necessary, as in the previous case, to divide the areas into individual elements, measuring each separately and summing up the results.

A tape measure is the best tool to help you calculate the S floor. However, in addition to the tape measure, you need to take a piece of paper and a pencil and write down the measurements, and only then carry out mathematical calculations (so as not to confuse and measure everything ten times).

Advice

Do not take measurements on the wall, as it may have defects and lead to inaccurate measurements. Places that have protrusions in the form of semicircles or zigzags should be counted separately.