Vacuum pumps have found their application on sewage disposal machines, the main task of which is cleaning storm sewers and pumping sewage from cesspools (toilets) and settling tanks, with the exception of explosive, aggressive and flammable substances.

In fact, pumping occurs using an intake hose, due to the vacuum created in the tank of the machine, which is created by a special vacuum pump, such as KO-503, 503v, 505, 514.

As a rule, such equipment is used by public utilities or industrial enterprises.

Type of vacuum equipment

- A low vacuum pump is used when pressure needs to be reduced. In addition, the equipment creates pressure, which is typical for low vacuum.

- High vacuum – used when operating a system with low pressure. This system usually includes two pumps connected in a row.

- Booster – installed in the middle of the high-vacuum and fore-vacuum pumps. This combination makes it possible to balance the outlet and inlet pressure of the above equipment.

- Forevacuum – used to maintain high vacuum. Thanks to this feature, the equipment is able to provide the specified pumping parameters.

- Preliminary vacuum - used in cases where it is necessary to reduce the pressure in the pumped volume from atmospheric to a point that allows another vacuum pump to operate.

Do you know which mini-cultivator to choose for your garden: manual or electric?

And here you can find out the technical characteristics of tower cranes KB-403 and KB-100 3A.

What is a sewage disposal machine?

Since we are looking at pumps installed on sludge sucking machines, let us explain what a sewer pump is. This is a set of wheeled equipment that pumps out wastewater or sewage from cesspools, reservoirs, septic tanks, and settling tanks. After pumping out, the machine delivers the contents to disposal sites, where it unloads the sewage.

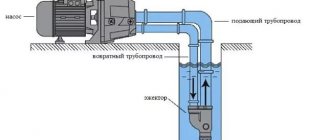

A typical sewer truck consists of the following main elements:

- storage tank. This is a steel cylindrical tank with a slight slope for ease of unloading;

- Vacuum pump;

- signaling and safety device. Its presence prevents the tank from overflowing and alerts the operator;

- receiving hatch with suction hose;

- pipeline control valve;

- additional electrical equipment.

Sludge pumping machine for sewer pumping KO 505A

The vacuum sewer pumping machine works on the following principle. All equipment is powered by a running engine. The suction hose is immersed in a container with the contents to be pumped out. The vacuum pump is turned on, creating a vacuum in the tank. The tank is filled with sewage. Once it is completely filled, a safety device is activated, shutting off the engine. After arriving at the unloading site, the tank is emptied by gravity or due to air pressure in the pump.

Advice: When calling a sewer truck to your site, ensure that it can easily travel to the pumping site.

Operating parameters

Among other parameters is the pumping speed, which determines the volume pumped out in a specific unit of time. In addition, the velocity is taken into account in a certain section at the pressure that was measured in this section.

The speed calculation is made in the input section of the operating equipment. The maximum starting pressure is the permissible pressure value at the inlet section of the equipment at which the pump can begin the operating cycle.

The maximum outlet pressure occurs at the outlet section of the equipment when the pump is still pumping out. The highest operating pressure is the permissible pressure in the pump inlet, thanks to which it maintains its nominal operating speed for a long time.

The maximum residual pressure is the pressure to which, indefinitely approaching, but never reaching it, the pressure in a standard test volume tends to with stably operating equipment.

The maximum productivity of equipment for liquid vapor determines the maximum amount of liquid vapor in weight units. The specified volume of liquid can be pumped out with a vacuum pump over a long period of time.

The maximum possible vapor pressure of a liquid is the maximum pressure measured at the inlet section of the pump. With the indicated pressure, gas ballast equipment can pump out liquid vapor for a long time.

The amount of pump compression determines the ratio of the volumes occupied by gases during the compression process in positive displacement pumps.

Purpose and operation of a vacuum pump

The vacuum pump for sewerage is designed to work in conjunction with other equipment installed on a sewer truck. With its help, the contents are pumped into a special tank, in which it is transported to the disposal site. The principle of operation of a vacuum pump is to create a vacuum in the working chamber in a short period of time . As soon as such a vacuum reaches the required value, the pumped-out substance (sewage, wastewater, steam) is sent to a storage tank. This type of pump is considered the most efficient in operation and safe for the environment.

Model KO-503

This pump is mounted on a sewer truck, which allows you to pump out sewage. For a diesel car, it is necessary to purchase equipment with right-hand rotary rotation.

Whereas a carburetor machine should be equipped with equipment with left-hand rotation.

To determine the direction of rotation, you need to look at the arrow shown on the body. In addition, if you look from the end side of the shaft, if it twists clockwise, this will mean that the torsion is right-handed, but if it’s the other way around, then it’s left-handed.

The equipment is created on the principle of capacitive vacuum air injection, as well as generating capacitive vacuum inside.

The tanks used are usually mounted on the GAZ-3309, 53 base.

In addition, the pump is used in PCF-3, PCF-4 tanks, which allows you to pump out or pump sewage inside. When using the equipment you must:

- guarantee the adjusted oil supply using the pump lubrication system;

- replace worn blades in a timely manner;

- Do not allow the pump to operate non-stop for more than 60 minutes.

The pump parameters allow it to operate in the temperature range from -20 to +40°C. Thanks to the vacuum created by the pump, the container is filled or emptied.

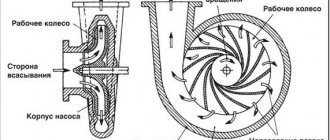

It should be noted that the pump body is made of cast iron. It is covered with caps with bearings that actually allow rotary rotation.

Blades are mounted in the rotor grooves. The pump body also has holes through which the equipment is lubricated.

In addition, an oil tank is attached to the frame, from where lubricant in the required volume, regulated by special screws, is supplied to lubricate the parts.

The marking KO-503 0214100 indicates that this is a pump with left-hand rotor torsion, while KO-503 0214100-02 indicates a pump with right-hand torsion.

Principle of operation

It is based on the action of rotary vane pumps. The centrifugal force that occurs when the rotor rotates pushes the plates out of its grooves and presses them against the body. The trapped air moves to the discharge channel. In this case, a vacuum is created on the inlet side, and pressure is created on the receiving side.

The suction process is almost similar to the operation of a vacuum cleaner. The contents of the sewer are completely sucked in and flow through the hose into the tank. Special equipment is provided to control its filling in order to prevent overflow, clogging of the hose and failure of the pump due to overload. It is put into operation from the vehicle engine by the operator, regulated and controlled by him.

There are two options available:

- Vacuum mode. The pump creates a vacuum in the tank. Under its influence, it is filled with the pumped out mass - liquid, feces, wastewater.

- Performing compressor functions. The pump creates excess pressure in the tank, as a result of which it is released from the previously pumped mass.

Pump operation

The process of using the pump requires compliance with certain conditions. In particular, it is necessary:

- keep the pump clean;

- carry out systematic flushing of the lubrication system, while filling it exclusively with purified oil;

- control oil consumption. The basic operating mode of the equipment requires an average of 90 g/hour.

Attention! The use of processed oils is prohibited. Non-stop operation of pumping equipment for more than 60 minutes is not allowed!

Equipment properties

The list of main properties includes the following:

- power consumption – 6 kW;

- output – 240 m³/h;

- indicated number of revolutions – 1450 rpm;

- direction of rotor torsion – left, right;

- maximum vacuum – 0.085 MPa;

- ultimate compression – 0.06 MPa;

- maximum temperature conditions of the equipment – 80 °C;

- efficiency factor – 0.8-0.9;

- weight – 90 kg.

Dimensions:

- length – 47 cm;

- width – 28 cm;

- height – 22.5 cm.

Cost - 12 thousand rubles.

Possible faults

Possible malfunctions may include the following:

- tight rotary rotation;

- drop in throughput;

- knocking on the pump;

- case overheating;

- interruptions in oil supply;

- low pump vacuum.

There are several main reasons that lead to malfunctions.

Stiff rotor rotation occurs due to inaccurate assembly of the pump. A drop in throughput occurs due to worn out or dirty rotor blades.

A knock in the pump indicates that the bearings are worn out, the blades are sunken, the inner side of the body has been subjected to mechanical impact from blades up to 0.2 cm deep, while the standard height of the blades is 3.7 cm.

Overheating of the housing occurs due to lack of lubrication or contamination of the pumping unit.

Interruptions in oil supply , as a rule, indicate that air is being sucked into the connecting fasteners or dirt has entered.

A weak pump vacuum occurs when the tightness of the connecting fasteners is weakened, the blades sink, and the rotor rubs against the pump cover.

Methods to eliminate the above reasons may be as follows:

- with tight rotary rotation, the pump must be disassembled, washed and reassembled;

- the drop in throughput can be eliminated by replacing worn parts; in case of jamming, wash the parts;

- if a knock is detected in the pump, you need to replace the bearings, blades or casing;

- overheating of the housing indicates the need to fill the system with lubricant, disassemble the equipment, wash parts, clean the pipeline;

- if there are interruptions in the oil supply, tighten the connecting fasteners and bleed the dropper with air;

- in the case of weak pump vacuum, you need to tighten the connecting fasteners, remove the rotor and wash the parts, check the height of the blades.

Construction of a sewage disposal machine

The machine is a mechanism for cleaning sewers, cesspools, and settling tanks. Consists of the following parts:

- Vacuum pump;

- reservoir for accumulation of substances. It is a large-volume metal tank placed at a slight angle. This is due to the convenience of unloading substances;

- signaling mechanism. Necessary to prevent tank overfilling;

- hatch with a hose for receiving liquid;

- valve for controlling the hose.

Principle of operation

The operating principle of the machine is as follows:

- The process occurs due to the car engine. The suction pipe is placed into the substance to be pumped out.

- The vacuum pump on the sewer truck turns on. After starting work, a vacuum forms in the container.

- When the tank is filled, a shut-off mechanism prevents the tank from overflowing.

- After moving to the disposal point, the tank is released using pump pressure.

Operating principle of KOKS MegaVac vacuum machines (video)

Application of machines

Vacuum pumps for sewer trucks are used to pump waste from cesspools and sewer networks. When repairing a water supply system, flushing pipes, water is pumped out to gain access to the object being repaired.

The vacuum pump for the sewer truck is used by housing and communal services and private companies. The operating temperature of the mechanisms for the sewer cleaning machine ranges from minus twenty to plus forty degrees Celsius.

Operating principle of sewer washing machine pumps

A vacuum pump for sewer cleaning machines is used in conjunction with equipment for a sewer cleaning machine. The pump pumps the substance into a specialized container. After which it is transported and disposed of.

A vacuum occurs in the chamber of the device over a short period of time. Upon reaching the required vacuum, the pumped mixture enters the container.

Characteristics of sewage pumps

Mechanisms for pumping out sewage have the following characteristics:

Equipment for the vacuum cleaner machine

- Starting pressure. Determines pressure indicators to start pumping.

- Pumping speed. Characterizes the amount of substance pumped out over a period of time.

- Outlet pressure. Determines the pressure indicator at the outlet of the equipment when the unit continues to pump out.

- Steam pumping performance. This indicator determines the amount of vapor being pumped out.

- Residual pressure indicator. Important when pumping out steam. Shows the maximum pressure at the inlet of the unit.

- The compression ratio of the device. Shows the degree of volume compression during compression.

Operating conditions for vacuum cleaner devices

For uninterrupted and high-quality operation of the devices, you should adhere to the operating rules.

- The lubrication system is washed with new high-quality oil. Used oil is not used due to operational irregularities.

- Vacuum pumps for sewer trucks are kept clean. If there is contamination, the unit will malfunction and break down.

- The oil volume must be at the required level. When the oil level is minimal, the operating mode is disrupted.

- Operation of the unit should not exceed one hour of continuous operation.

Before purchasing, you should familiarize yourself with the compatibility of the device with the type of car engine. Diesel engines are compatible with right-hand drive pumps. Carburetor-type vehicles are compatible with left-hand drive.

During operation, breakdowns of the units are possible.

How to deal with malfunctions?

Breakdowns of the vacuum pump on a sewer truck and their elimination can be as follows:

The process of pumping out liquid using a sewer machine

- Knocking sound when the device is operating. To troubleshoot problems, replace the bearings or blades of the mechanism.

- Irregular oil supply. To fix it, tighten the fasteners.

- Heavy rotation of the rotor. The structure is washed disassembled.

- Bandwidth reduced. To fix it, it is worth replacing the old parts.

- Heating of the case. The pipeline and parts are cleaned.

Almost all problems are associated with contamination of the mechanism. Therefore, to prevent breakdowns, it is necessary to periodically clean the supercharger and removable parts.

To maintain sanitary standards in your home, it is necessary to regularly clean the sewer pit. Thanks to the power of vacuum pumps on sewage disposal machines, the cleaning process will be quick and efficient.

Pump KO-505A

This pump serves to generate capacitive air injection and excess intracapacitive pressure. The equipment is mounted on the basis of ZIL, MAZ, KAMAZ, URAL.

The operating temperature of the KO-505 pump is from -20 to +40 °C. Filling and emptying of containers occurs due to the discharge of the pump.

The frame of the pump is made of cast iron, which is closed using lids. These covers contain bearings, due to which rotary rotation occurs.

The rotor grooves contain built-in textolite blades. The pump is also equipped with a lubrication system, which ensures forced lubrication of the equipment, so before starting operation it is necessary to adjust the oil flow.

Pump parameters

The list of main properties includes the following:

- power consumption – 9 kW;

- output – 310 m³/h;

- indicated number of revolutions – 1150 rpm;

- direction of rotor torsion – left, right;

- maximum vacuum – 0.085 MPa;

- ultimate compression – 0.06 MPa;

- maximum temperature conditions of the equipment – 80 °C;

- efficiency factor – 0.8-0.9;

- weight – 110 kg;

Dimensions:

- length – 52 cm;

- width – 30 cm;

- height – 29 cm;

Cost – 12 thousand 900 rubles.

Pump KO-510

The pump of this brand is suitable for machines with left-hand and right-hand rotation such as KO-510, 520, 523. In addition, such pumps are mounted on the basis of GAZ, ZIL, KAMAZ, MAZ, URAL.

This combination allows for manipulations with capacitive compression at operating temperatures from -20 to +40 °C. The arrow shown on the body makes it possible to determine the rotation of the pump.

The operating principle of the equipment is still based on the injection of air, as well as the generation of a capacitive vacuum inside. This is how sewage is dumped and pumped inside.

Two marking types of pumping equipment are standardly produced: KO-510 0216000-04 – right-hand torsion pump, and KO-510 0216000-05 – left-hand torsion pump.

Vacuum pump used for pumping out sewerage

If the site has an autonomous sewer system, it must be cleaned regularly. Failure to carry out this procedure in a timely manner leads to the fact that sanitary conditions on the site begin to deteriorate, and the cesspool or septic tank overflows. Subsequently, it will be much more difficult to maintain the sewer. To quickly and effectively pump out sewage, you should call a sewer truck, which is equipped with all the necessary equipment. The main element that is involved in the pumping process is the vacuum pump. With its help, the machine is able to clean the drainage structure in a few minutes.