An alternative to gas torches running on acetylene is hydrogen welding. It is used to join various materials, not just metals. Compact units are used in dentistry, jewelry, and auto repair shops. If you wish, you can make an installation that generates a gas mixture with your own hands. Hydrogen welding is used in everyday life and in production.

The essence of hydrogen welding

Hydrogen welding is based on the ability of H2 to burn with high heat release. The flame requires a gas mixture with a high hydrogen content. Oxygen is bound by flammable organic liquids; only a small amount is required. The hydrogen flame is not visible during the daytime; the devices use special sensors that control the gas supply.

Electrolyzers are used to generate the hydrogen mixture. Water breaks down into its constituent molecules under the influence of electric current. The result is a flammable gas mixture with the required ratio of hydrogen and oxygen.

Among industrial equipment, domestic welding machines of the “League” series deserve attention. They operate from a standard 220 V network, are filled with distilled water, which is used as a medium for electrolysis. Under the influence of current, the molecules break down into oxygen and hydrogen. The mixture of gases enters the cooler-enricher, where excess moisture condenses. Flammable liquids are added from the gas mixture:

- benzene;

- alcohol;

- petrol;

- toluene;

- other hydrocarbon compositions.

As with other hot work, safety precautions must be observed when welding with an electrolyzer.

Components of the apparatus

Traditionally, the main elements of hydrogen welding devices are:

- burner;

- hose;

- filling device;

- spare nozzle;

- cooler-enricher.

The burner is designed to supply gas to the area where the workpieces are joined. The flame temperature can be adjusted in the range of 600-2600 degrees. The welding machine is quite powerful and allows for manual and automatic welding. If the user has basic skills in working with gas-flame equipment, operating electrolyzers for hydrogen welding will not be a problem. Now let's look at the processing of workpieces in more detail.

Advantages and disadvantages

Hydrogen technology, in comparison with other types of thermal joining of metals, wins in many respects:

- efficiency;

- security;

- environmental friendliness

Compact devices are convenient for joining many materials:

- carbon, low-alloy and steels;

- glass;

- cast iron;

- some non-ferrous alloys;

- glass;

- ceramics;

- composite materials.

The welding process does not involve frequent charging of equipment, which saves a lot of time. It takes no more than 5 minutes to generate gas. Despite their small dimensions, the devices have high operating power. Unlike acetylene welding, hydrogen welding does not pollute the atmosphere with combustion products or nitrogen vapor. The equipment is fireproof; the design has minimal risks of fire and explosions. During operation, the seams do not oxidize.

Advantages and disadvantages

Hydrogen welding has a number of positive qualities:

- high level of efficiency,

- high safety during the working process,

- environmental benefits - no pollution,

- portability and convenience,

- you can work with different materials: metals, glass, alloys,

- Can only operate on water and does not need to be recharged.

But even with such advantages, the method has its negative sides:

- conventional devices are suitable only for parts of small thickness, and for large elements you will need more powerful equipment,

- welds in copper parts will be porous.

The liquefied hydrogen fire is not visible in daylight.

Application of hydrogen welding machine

Using atomic-hydrogen welding machines, we produce:

- metal soldering;

- welding of steel blanks of any size;

- protective powder coating;

- oxygen cutting of rolled products;

- surfacing of parts.

Hydrogen welding is used not only in construction work; due to its compactness, the devices are used:

- repair specialists for refrigeration equipment and radiators;

- dentists;

- jewelers;

- radio amateurs;

- workshops engaged in auto body repairs.

The range of use of the devices is extensive. Using the capabilities of atomic hydrogen welding, cast iron products are repaired (the metal is characterized by high fluidity). The only limitation to the use of electrolyzers is high exothermia. This is an increased risk factor; cooling systems are used when welding with hydrogen.

Electrical equipment, light, lighting

0 votes

+

Vote for!

—

Vote against!

The hydrogen flame can be used as an alternative to acetylene flame for cutting, soldering and welding. Unlike official methods, hydrogen welding is practically harmless. This is due to the steam that is a combustion product in this process. If you have gas welding skills, you can quickly learn hydrogen welding. If not, it will take a little more time, but the result will be worth it. In this article we will tell you how you can do hydrogen welding with your own hands.

Features of hydrogen welding

Gas welding has been used for over a hundred years. Acetylene is used as the main combustible gas. The results of the studies showed that the use of hydrogen instead of acetylene is more productive. When welding materials, the same production and quality of the weld is obtained. The only difficulty is that the acetylene flame reduces iron, while the hydrogen flame oxidizes it.

Hydrogen welding is a type of flame processing that occurs using oxygen and a mixture of flammable gas. When hydrogen is used as a combustible gas, the weld pool is covered with a large layer of slag, and the weld becomes thin and porous. But this problem was solved. Organic substances tend to bind oxygen, so the decision was made to use them. Hydrocarbons that have a boiling point of 30-80° began to be used. These are hexane, toluene, gasoline, heptane, benzene. A minimum quantity is required for welding.

When the technological issues were successfully resolved, another difficulty arose. There was no effective source of oxygen. Hydrogen cylinders are a source of increased danger, so their use is unprofitable. High concentrations of liquefied hydrogen can cause dizziness, suffocation and severe frostbite. But the main danger of a hydrogen flame is its invisibility in daylight.

During the day, hydrogen flames can be detected using special sensors. This problem was solved by combining water with hydrogen and oxygen under the influence of electricity. Electrolyzers are devices that, using electrical energy, can produce hydrogen and oxygen simultaneously.

It is worth noting that hydrogen, which is suitable for welding various products made of iron and low-carbon steels, is completely unsuitable for welding stainless steels. This is due to its dissolution in molten nickel. When the metal hardens, it releases back, forming cracks and pores. Oxygen-hydrogen welding is also unsuitable for copper. But its advantage is that the hydrogen atmosphere protects the welded surface from oxidation.

Acetylene generators and cylinders are necessary for use in field conditions when there are no power sources nearby. But in other cases, massive gas welding equipment can be replaced by lightweight and convenient hydrogen devices.

Options for using hydrogen devices

The hydrogen welding machine operates from a three-phase and household electrical network and has different power. The device can be used in manual and automatic mode. A mixture of hydrogen and oxygen is supplied to a standard acetylene torch through a hose, and the temperature of the clean flame can be adjusted from 600 to 2600 degrees.

Hydrogen welding machines are very easy to use. They do not need to be recharged often, and the labor intensity is low. As a rule, they enter operating mode in just a couple of minutes, which depends on the required gas consumption and room temperature. With small-sized equipment, the device can be very powerful.

Hydrogen welding is very environmentally friendly, unlike acetylene, working with which pollutes the environment with toxic substances. In hydrogen devices, the only combustion product is completely harmless steam. In addition, these devices are completely safe during operation and storage. But do not neglect protective clothing - mittens, thick overalls and goggles for gas welding.

Such devices solve almost all problems posed to the flame processing of materials. Using these devices, you can carry out welding, soldering, powder coating, manual and machine oxygen cutting, surfacing, heat strengthening, and powder surfacing. There are various operating modes that provide the ability to perform a wide range of work - from welding minimal thickness to cutting thick steel sheets. Even small portable devices with little power can weld and cut sheets of ferrous and non-ferrous metal up to two millimeters in thickness.

Hydrogen welding machines are very popular among jewelers, dentists and refrigerator repair specialists. Models with higher power allow you to weld material up to three millimeters thick. They are very popular at equipment service stations, since the use of dangerous oxygen and propane cylinders is prohibited in these places.

Hydrogen welding machines can be used during body work, when repairing batteries, engine blocks and hubs. When the maximum level of pressure and electrolyte is reached, the built-in control system itself generates a signal. In this case, the device is automatically disconnected from the power source. By observing such safety measures, good fire and explosion safety is ensured.

For employees of emergency companies, special options have been developed that weld pipes with a wall thickness of up to five millimeters. Such devices can be used for welding areas with defects in cast iron and non-ferrous castings, machine and manual cutting of metals up to thirty millimeters in wall thickness. These welding methods are carried out with power to the flame-heating torch from the device and oxygen supply from a cylinder.

Thanks to this technology, a very clean cut is obtained, in comparison with acetylene and propane. There are also no emissions of nitrogen oxide and burrs, the metal is not saturated with carbon and is hardened. Such welding machines are often used in wells, tunnels and subways, since the use of propane and acetylene is also prohibited there. There are types that provide the opportunity to carry out hydrogen welding at sub-zero temperatures.

Hydrogen welding at home

A hydrogen welding device will be useful to every home craftsman. Hydrogen devices are quite expensive. In addition, purchased devices are very difficult to use for working with small parts. You can make a similar welding machine at home. All units can be assembled from ordinary materials. Let's look at how this is done correctly.

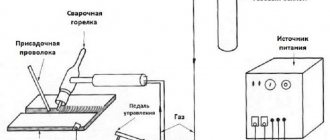

The hydrogen mixture is obtained by electrolysis of an aqueous solution of alkali - caustic soda. The current source can be made from a rectifier to charge batteries from a car. For home use, a small output will be enough, so the design can be simplified.

Electrolysis occurs in a vessel, so for plumbing welding at home you can use a 0.5 liter glass jar with a polyethylene lid. It is necessary to make points in the cover for the terminals of the contact plates of the electrodes and for the sleeve of the tube for removing the resulting gases. After this, all terminals and the cover itself should be sealed; regular Moment glue will do. It is worth noting that the snake-curved electrodes are 4-centimeter wide stainless steel plates.

Through the gas outlet fitting, it is necessary to fill the jar with electrolyte (8-10% mixture of sodium hydroxide in purified water) using a 50 ml syringe. The function of a water dispenser is performed by a second vessel, in which the resulting gases are bubbling and saturated with vapors of flammable substances when passing through 60-70% of their solution in water.

This mixture should flow into a third container of water, which serves as a seal for the release of gases. Operational safety is enhanced by the use of two bolts, which are located in series and prevent the passage of flame from the apparatus into the electrolyzer. For added security, you can make a second shutter out of plastic.

Gas with oxygen, hydrogen and vapors of flammable substances exits through the medical needle. The flame can reach a temperature of 2500 degrees, but this can be adjusted by changing the applied voltage. Make sure that the burning process is stable. If you change the voltage on the electrodes, the current strength will also change, which affects the dose of gas released.

You can easily check this by calculating using the famous Faraday formula. For bushings, you can use tubes from helium pens, droppers, etc., as shown in the video about hydrogen welding. Remember that the diameter of the welding machine needle should be from 0.6 to 0.8 millimeters, and for the third vessel you must use a plastic jar. The resulting structure must be placed in a housing of suitable size.

During electrolysis, water is consumed, but the amount of alkali remains the same. Alkali breaks down into ions and increases the electrical conductivity of the solution. You can replenish the fuel mixture using a regular medical syringe with a needle. For the needle holder, you can use a wooden tool handle, in which a point along the diameter of the tube is also drilled. Be sure to place cotton swabs inside the syringe tube, at its base and end. This precaution will prevent the flame from passing through the tube into the vessel with the alcohol composition.

You can assemble the rectifier yourself using diodes by connecting them in a half-wave circuit. You can use any suitable transformer with a power of at least 180 W. A transformer from old Soviet TVs is perfect. It is necessary to remove the secondary windings and wind new ones using a thick copper winding wire of 4 millimeters. It is advisable to make taps to regulate the output voltage, which ensure operation of the electrolyzer under load. A good voltage on the electrodes should be regulated within 3V, because there is only one galvanic gap in the device.

The flame temperature depends on the fuel mixture. You can use acetone or ethyl alcohol. In the case of acetone, you cannot use sleeves from tubes from helium pens, since they will dissolve in it. If the amount of alcohol in the exhaust gas mixture is reduced and oxygen predominates, the flame may go out. When assembling a homemade hydrogen welding machine, remember all the above rules, especially about cotton swabs and a third plastic vessel. Remember that a well-assembled and sealed device will work for a very long time if used correctly.

Safety requirements for hydrogen welding

Hydrogen welding can be very dangerous. Accidents may occur due to the explosion of mixtures, ignition of oxygen reducers, and backfire. You should be thoroughly familiar with safety precautions before attempting hydrogen welding. Here we give the basic rules.

- Gas welding must not be carried out too close to flammable or flammable substances. If you are welding indoors, in boilers, or in confined spaces, take regular breaks and get some fresh air. In closed and semi-enclosed spaces, harmful gases must be removed using local suction. If you are welding in tanks, a second person must be outside to observe the process.

- When welding and cutting, be sure to use special safety glasses. Otherwise, bright rays can negatively affect the retina and blood membrane of the eyes, including cataracts and blindness. Splashes of metal and slag also pose a great danger to open eyes.

- When using gas cylinders, it is better to carry them on a stretcher or on a trolley, with the obligatory use of a protective cap. Conventional transportation methods are unsafe. During transportation, gas cylinders must not touch each other or fall. Oxygen cylinders must not be stored in the metal cutting or welding area. Moving over short distances is carried out by turning it over with a slight tilt. If a mixture of oxygen and flammable gas occurs in the cylinder (when the oxygen pressure in the cylinder is lower than the operating pressure of the regulator), an explosion may occur. Therefore, gearboxes with working pressure gauges should be used.

- During welding, it is necessary to direct the torch flame to the side that is on the other side of the power source. If you cannot fulfill this condition, protect the source with an iron shield. When working, gas-conducting hoses must be close to the welder. During a break, be sure to extinguish the burner flame.

- If there are more than ten welding stations, the gas supply must go through the wires of acetylene stations. The acetylene generator should be installed in a room with a fan and a temperature of at least five degrees. Make sure that the water plug is filled to the required level. It is prohibited to work if the water valve is faulty or disconnected.

The technology of gas welding using hydrogen is the same as that of gas welding. The only difference is the use of a hydrogen mixture. Before you do hydrogen welding yourself, first

How to make hydrogen welding yourself

It is not difficult to make a small apparatus for hydrogen welding with your own hands. The drawing can be found on the websites; everything you need can be found in a hardware store.

Structural elements:

- Container for alkali solution, hydrogen is released upon dissociation. Use glass containers - a 0.5 liter jar. Two holes are made in the nylon cover for the wires going to the electrodes. To seal the structure, Moment glue is used; it is necessary to limit the access of oxygen to the liquid.

- The electrodes are made from strips of stainless steel, the recommended height is 4 cm. The plates are fastened with dielectric pins at a great distance from each other in order to use the entire volume of liquid. The terminals are fixed with bolts so that there are minuses at the edges and a plus in the center. Current will be supplied to them.

- The outlet fitting for the gas outlet is made of a flexible tube; a 10% NaOH solution is pumped through it using a syringe. The alkali is diluted in distilled water. In working condition, a homemade electrolyzer heats up to +80°C.

- The water seal is another container filled with water to 1/3 of the volume. The end of the outlet fitting is placed into it.

- The working nozzle from which the flammable mixture of gases emerges must be metal. Craftsmen use medical needles.

- DC source - battery voltage up to 12 V or rectifier. The production of gases depends on the strength of the current. By changing the indicators, the flame power is adjusted. For welding thin-walled workpieces, a voltage of 3 volts is sufficient.

Hydrogen production

Hydrogen can be obtained by electrolysis of water, more precisely, an alkaline solution of sodium hydroxide (caustic soda, caustic soda, these are all names for the same substance). Hydroxide is added to water to speed up the reaction.

To produce hydrogen, it is enough to lower two electrodes into the solution and apply direct current to them. During the electrolysis process, oxygen will be released on the positive electrode, and hydrogen will be released on the negative electrode. The volume of hydrogen released will be twice as large as the volume of oxygen released.

In chemical terms, the reaction looks like this:

All that remains is to technically separate the two gases and prevent them from mixing, since the result is a mixture with enormous potential energy. Leaving the process uncontrolled is extremely dangerous.

For welding, hydrogen is produced using special devices - electrolyzers. To power them, electricity with a voltage of 230 V is required. Electrolyzers, depending on the design, can operate on three-phase and single-phase current.

Safety precautions when welding with hydrogen

Industrial devices for hydrogen and atomic-hydrogen welding are equipped with an automatic shutdown system. When the pressure of the gas mixture increases, the current supply stops automatically, without the participation of the welder. As with other hot work, safety precautions must be observed when welding with an electrolyzer.

Basic Rules:

- The gas burner is located away from flammable and flammable substances. During operation, the nozzle is held in the opposite direction from the power source. Use barrier screens.

- The enclosed space must be ventilated periodically.

- Flame negatively affects the retina and eyeball. When hydrogen welding, it is recommended to use dark glasses.

- During transportation, a protective cap is put on gas cylinders, metal tanks are installed in lattice stands so that the cylinders do not come into contact with each other and do not fall during transport.

- Oxygen is not stored in the welding area; during moments of rest, the welding equipment is turned off.

It is safe to work if you follow the operating rules. High-quality compounds are obtained without harm to yourself and the environment.

At home

To use hydrogen welding at home, it is not necessary to buy devices for producing hydrogen. They usually have great performance and power. In addition, such generators are bulky and expensive.

In domestic conditions, small amounts of welding work are often required, so it is advisable to make equipment for hydrogen welding yourself.

Power and working fluid

Power can be supplied from a car charger or from a homemade rectifier, which can be made with a suitable transformer and a few semiconductor diodes.

Sodium hydroxide solution should be used as the working fluid. It will be a better electrolyte than plain water. As the solution level decreases, you simply need to add water. The amount of sodium hydroxide will always be constant.

Housing and tubes

As a housing for the hydrogen generator, you can use a regular liter jar with a polyethylene lid. It is necessary to drill holes in the lid to match the diameter of the glass tubes.

The tubes will be used to remove the resulting gases. The length of the tubes must be sufficient for the lower ends to be immersed in the solution.

Electrodes must be placed inside the tubes, through which direct current is supplied. The places where the tubes pass through the lid must be sealed with any silicone sealant.

Hydrogen removal

Hydrogen will be released from the tube containing the negative electrode. It is necessary to provide for the possibility of draining it using a hose. Hydrogen must be removed through a water seal.

It is another half-liter jar of water, with two tubes built into the lid. One of them, through which hydrogen is supplied from the generator, is immersed in water. The second removes the hydrogen that has passed through the water from the valve and supplies it to the burner through hoses or elastic tubes.

A water seal is necessary to prevent the flame from the burner from passing into the generator when the hydrogen pressure drops.

Burner

The burner can be made from a needle from a medical syringe. Its thickness should be 0.6-0.8 mm. For the needle holder, you can adapt suitable plastic tubes, parts of the bodies of ballpoint pens, and automatic pencils. It is also necessary to provide an oxygen supply to the burner from the generator.

The rate of formation of hydrogen and oxygen in the generator will depend on the magnitude of the applied voltage. By experimenting with these parameters, you can achieve a burner flame temperature of 2000-2500 °C.

A self-made device that performs hydrogen welding can be successfully used for cutting or for joining by welding or soldering various small parts made of ferrous and non-ferrous metal. This may be needed when repairing various household items, car parts, and various metal tools.