Anchor bolt with nut - weight, dimensions: what does GOST tell us?

Since all fasteners are complex installation products, they all have appropriate technical documentation. It is from such documents that we can find out technical parameters if necessary. For example, when choosing this or that fastener, we want to know whether the anchor fastening will withstand a weight of 100 kilograms or not. Thanks to the fact that there is documentation, we will receive an answer to our question.

The smallest anchor, whose dimensions are 5x6.5x18 mm, according to the manufacturer's stated characteristics, is capable of withstanding a pullout load of up to 800 kgf. To make it clearer, kgf is the designation of kilogram/force, where the calculation takes into account the mass of one kilogram and the force with which this kilogram exerts pressure on the scale. Further calculations are quite simple, 1 kgf is equal to approximately one kilogram of any object, based on this, such an anchor will support a product weighing 800 kilograms.

Also, absolutely any bolt has a corresponding GOST, which divides all fastening structures into varieties according to their ability to withstand a certain load, the size and diameter of the fastening element. On large construction sites, such documentation helps in the selection of fastening elements and the purchase of appropriate materials.

Load bearing capacity

Performance characteristics of fastenings at a standard embedment depth in a base made of heavy concrete B20 (C20/25).

Each type of bolt has its own load-bearing capacity, which is characterized by the load that the bolt can withstand without destruction and without violating the integrity of the bond with the material. First of all, the load-bearing capacity will depend on the material from which the fasteners are made. For this purpose, they mainly use various types of high-quality steel - anti-corrosion, structural, stainless, as well as non-ferrous metals. With the exception of brass, almost all non-ferrous metals have the lowest strength. As a rule, the load-bearing capacity is indicated on the packaging or on the product itself.

Connection reliability

Breakout calculation.

This inspection is carried out directly at the place of work. Depending on the wall material, the reliability of the connection can be determined. If the material is brick or concrete, the pullout load will be about 350 kg. For fastening fairly heavy objects, this indicator is quite sufficient. When the material is cellular concrete, its load will be within 230 kg. It should be borne in mind that the installation of fasteners must be carried out in accordance with the requirements and performance properties of the material. For high-rise installation, for example, this will not be enough - here it is recommended to choose chemical ones, which have a pull-out load of approximately 700 kg.

The principle of operation of anchors - how do they cope with loads?

The principle of operation lies in their technology and special prefabricated structure, due to which the load has a completely different character. The fact is that when installed, the anchor bolt already expands in the wall; it cannot be pulled back out with any effort, like a nail, dowel or screw.

It is impossible to remove the anchor bolt from the wall

In this case, the load is distributed over a small surface area into which the bolt was installed, and not at one point, as with standard fixations. To enhance its ability, a metal sheet is additionally mounted with it, which takes up most of the load and distributes it across the entire plane of the sheet, and the larger the sheet area, the more load the bolt can withstand.

When anchoring, the load is distributed over a small area

Anchor bolt mounting options

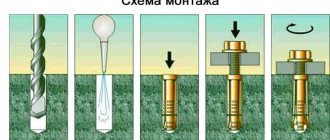

There are three main methods for installing fasteners:

- mechanical impact on a part in order to modify it;

- the use of special fillers with fixing properties;

- vibrocaulking.

There are several types of fastening:

- Wedge: an open sleeve is located on the cone. The nut is installed together with the washer, which provides better fixation. The rod comes into contact with the metal bushing, and during the screwing process the bushing becomes wedged.

- Sleeve: the length of the sleeve is equal to the rod. During installation, the diameter of the bushing expands. This results in a fixed fit to the walls of the two parts of the hole. This option is suitable for working with porous and heterogeneous surfaces.

- Driven: fastened using percussion tools.

- Expanding: an expansion spring is used for a tight fit. The bushing changes shape, due to which the system can withstand heavy loads and perform the assigned tasks.

- Special: manufactured to solve special problems.

Manufacturing options

The most common types of wood anchors are:

- hex head bolt. It is used for attaching various brackets, plates and other flat and large structures with lugs to wooden bases;

- a stud with a nut, which is screwed in with a wrench (open-end or adjustable);

- a hook that acts as a strong suspension and is suitable for mounting chandeliers, hanging shelves, lanterns, and so on;

- the ring performs the same functions as the hook. Its main distinguishing feature is that the ring prevents the suspended product from jumping off it when moving in space (for example, the ring can be used to create a children's swing). To attach a suspended structure to it, threaded or spring carabiners are used.

Anchor bolts - types and principle of operation

Content

Anchor bolts - if we consider the principle of operation of the two main types of fasteners - anchor and dowel, then the anchor has a significant advantage. The metal anchor, in addition to the frictional force, is held at the base using a “stop” in the form of a kind of anchor, obtained due to the spacer part of the shank. To friction is added the force of resistance to the destruction of the material.

There are also chemical anchors; instead of a metal sleeve, they use quick-hardening adhesive compounds that are introduced into the hole before installing the anchor bolt. The result is a monolithic connection with the base.

There is a large range of anchors on the market, but they can all be divided into several classes.

What is an anchor bolt from Wikipedia

An anchor (German Anker - anchor) is a fastener that is fixed in a load-bearing base and holds any structure.

The following types of anchors are distinguished:

Foundation bolt

Bolt molly

ru.wikipedia.org/wiki/Anchor_bolt

Selection rules

The selection of anchors with nuts is made depending on:

- depending on the type of fastening element;

- on the size of the fastener capable of supporting a certain weight of the structure being fixed.

Main types of anchors with nuts

Anchors equipped with locking nuts can be one of the following types:

- standard products (as shown in the picture above). They are used mainly for household purposes, for example, for hanging a bookshelf, attaching a hanger, a door, and so on;

- double-expansion anchors - standard fasteners are supplemented with one or two, depending on the design, expansion sleeves, which allows for a more durable fastening. Double-expansion anchor bolts are primarily used when it is necessary to fasten any fixtures to concrete or brick that has cracks and/or small voids;

Mounting anchor with two expansion sleeves

- hook or loop anchors. The main difference is the presence of an additional device (hook, loop) with a nut. Such fasteners are used when it is necessary to hang certain types of objects, for example, lamps, from the ceiling or walls;

Anchor bolt for hanging

- stud bolt. This type is used when it is necessary to perform through fastening or connecting parts to each other.

Through-connection anchor

Sizing

The choice of anchor is also based on the size of the fastener.

The main dimensions are:

- anchor bolt length;

- the diameter of the fastening element, which determines the diameter of the drill required for correct installation with a maximum safety margin;

- anchoring depth, that is, the distance to which the mounting bolt must be inserted into the base;

- minimum length of through installation;

- thread diameter, on the basis of which the size of the fixing nut is selected, for example, M 16.

Based on the dimensions of the bolt, the technical characteristics of the fastening are established, which include:

- thickness of the object being fixed;

- rotation force;

- bending moment;

- torque.

Selection of anchors with nuts by size

To put it in simple words, the larger the size of the anchor bolt, the larger the size and weight of the structure the fastening element can withstand.

Set of tools

Installation Procedure

For such work you need the following tools:

- drill with a set of drills;

- hammer drill with a set of drills;

- open-end wrench;

- hammer.

Concrete materials are much denser than most building products. It will take some effort to make a hole in them. Drills must be coated with special strength alloys. In order to make a hole for a bolt with smooth edges, a simple drill will not work; it is best to use a hammer drill.

To properly secure a bolt, the hole in the concrete must be made smooth and its diameter must match the outer diameter of the bolt. In no case does the anchor need to be disassembled - it is inserted entirely “as is”. Some people still try to take it apart and then insert it. But this can only be done when an anchor with a nut is used, and even in this case you can only twist the nut, nothing more. When the bolt is inserted into the hole, it must be tightened clockwise. For the installation to be successful, you need to select fasteners depending on the weight of the attached structure. It should be optimal in both diameter and length.

Aerated concrete blocks: characteristics. Features and properties of expanded clay concrete. Construction concrete. Read more>>

Wood fasteners

Fasteners suitable for connecting wooden structures have several features:

- the large thread diameter (from 6 mm to 14 mm or more) compensates for the relatively low mechanical strength of the base;

- the moisture content of wood can fluctuate significantly at different times of the year and under different indoor conditions, therefore, to avoid corrosion, fasteners must be protected by brassing or galvanizing, or be entirely made of corrosion-resistant materials;

- the large diameter of the rod requires significant force when screwing it in. Since slots for a Phillips or flat-head screwdriver are not designed for such loads, the “anchor” is most often equipped with a hex head rather than a slotted one. For screwing, use an open-end or socket wrench, or a socket head.

This is interesting: Criteria for choosing a drill for confirmation. How to avoid mistakes?

Types and methods of fastening

Anchoring is performed by various types of steel products, where one or several acting forces are used simultaneously - friction, thrust and intermolecular bonding during gluing.

Anchors are classified according to the following characteristics:

- purpose - foundation, ceiling, frame, universal;

- shape - straight or curved;

- design - solid or prefabricated;

- surface - smooth or threaded;

- contact area - for dense or porous material;

- installation method: hammering, screwing, gluing, through fastening.

Spacers

To solve critical problems, expansion anchors for concrete with nuts are used, where the friction force operates. They are a threaded stud with a conical tip and a sleeve. When screwed in, it wedges and firmly holds the bolt in the body of the concrete.

Advantages of these wedge fasteners:

- ease of installation of anchors in concrete;

- possibility of through installation;

- high load-bearing capacity.

Wedge hardware is used only for dense concrete. They need to be immersed deep enough and cannot be reused.

If a bracket is installed at the end of the rod instead of a nut, equipment can be suspended from such a mount.

Varieties of wedge anchors are sleeve or sleeve hardware. Available in the form of a bolt with a special wedging nut at the end or a stud with a conical widening. To ensure uniform distribution of internal stress, they are reinforced with double thrust.

These hardware are used in high and medium density concrete. A sufficient contact area with a small diameter of the rod allows it to withstand significant loads.

Drivers

For dense concrete, short drive-in anchors with metric threads and an internal cone are used. It wedges the base when screwing in a bolt or stud.

The mount is simply made and does not protrude to the surface. This option is used for installation of ceiling air ducts, ducts and other engineering equipment.

Hardware is hammered into the drilled hole, wedged with a center punch and a threaded rod of any length is screwed in.

Driven ones include a ceiling anchor or a dowel-nail, which is attached to the base through a part. This is a convenient connection for Armstrong ceilings, suspensions, slats, and mounting mortgages. Since the bolts are non-removable, they are often used as vandal-proof and fireproof fasteners.

Frame

Designed for securing window or door frames. The sleeve is cut along its entire length, and when tightened, a small wedging nut presses the structure against the opening to the desired position.

In the upper part of the sleeve, stops are located to protect against rotation and displacement around the axis.

Self-tapping screws for concrete

A strong connection is created by threads along the entire length of the hardware. When screwed into concrete, there is a high resistance to shear or pullout of the product. Thanks to this, the load-bearing capacity of the fastening is very high.

Concrete screws accept up to 100 kg of load, are easy to install and reliable in operation.

Expanding

These include the Molly bolt, commonly called a “butterfly”. Designed for mounting lamps, shelves, cornices, pictures in hollow concrete structures with low load-bearing capacity.

The collet on a bolt or screw is a drop-down skirt; when the rod is screwed in, it rests against the inside of the base cavity.

Special spikes on the outside of the collet go deep into the concrete and prevent the hardware from turning or moving during installation. The “butterfly” can be sold without a screw.

Chemical

A chemical anchor is a semi-liquid, quick-hardening mass with which studs or bolts are glued into the base.

The compositions provide a strong bond with concrete without point or local stresses. The load is evenly distributed along the length of the connection.

Areas of use

One of the reliable and high-strength means of fastening is an expansion anchor (anchoring expansion bolt). It can be used to attach various structures or equipment to bases that have solid material. The bolt allows you to create uniform friction with great force along its entire length, due to this, high retention capacity is ensured, however, the material of the structure must have good density and solidity.

The bolt has a sleeve made of metal, at one end there is a 4-segment spacer part, the other end has a thread on which there is a nut for adjustment and a washer. The principle of operation of the bolt is quite simple: when the nail located inside the sleeve is driven into the structure, the lower part of the anchor expands and the bolt is attached to the base. It is easy to install and can also be removed without problems.

A bolt with spacers is usually used if it is necessary to attach any structural part to the base using a through-hole installation method. You can make facade fasteners. It is good if the base for fastening is made of concrete or stone with a high degree of adhesion. The presence of cracks in the material will affect the load of the bolt; they will reduce it several times.

The expansion anchor can also be used for fastening:

- Frames of windows and doors.

- Stairs.

- Suspended ceilings.

- Svetilnikov.

- Scaffolding.

- Gate.

- Pipes and air ducts.

- Balustrade.

- Communications in the field of engineering.

- Steel structures.

- Consoles.

- Payment terminals.

Anchor bolts are made from special alloys. Main characteristics of the bolt :

- High strength and reliability.

- Excellent quality.

- Resistance to shock, water and other chemical and mechanical influences.

- Convenient and quick fastening.

- Efficient fastening element.

And this article talks about chemical anchors.

Other types of fasteners

What other ways can wooden structures be connected?

Overlays, corners

A variety of perforated steel plates and angles do not compete with wood anchors, but complement them:

- Corners allow you to join floor joist boards with beams or crowns end-to-end, without cutting;

In the photo, galvanized corners are used to connect the rafters to the rafters.

- The use of plates makes it possible to connect boards in the same way, end-to-end, when splicing joists or rafters.

An important point: in order for such a connection to be strong, the length of the plate must be at least five times the width of the board. In addition, to fasten boards with overlays, it is better to use bolts with wide washers rather than anchors or self-tapping screws.

Hairpins

The stud performs the same function as the bolt. It differs favorably from it in that the presence of nuts on both sides allows you to tighten the fastening without turning the stud itself, which is often jammed by the parts being connected. If the fastener is long, the force required for this can be quite significant.

How to choose an expansion anchor

The choice of anchor should be made based on the following parameters:

Anchor type

Modern manufacturers produce expansion anchors of the following types:

- Bolts and washer are the most common type of fastening anchors. Wide popularity achieved due to ease of fastening and maximum strength. Anchors with washers can be used for concrete, brick and other monolithic bases, as well as bases with slight porosity.

Mounting anchors complete with washers

- Anchors with fixing nuts are mainly used for fastening heavy and large-sized objects, since a pre-installed nut allows you to reduce the time for fixing and, accordingly, holding the object “in weight”.

Anchors: their effectiveness and types

The effectiveness of anchor bolts speaks for itself, this is the latest modern device that is quickly gaining popularity due to its ease of use and practicality. At the moment, there are no analogues for them that could compare in terms of economy and physical characteristics. Taking the physical laws of load distribution along a plane as a basis, experts came to a very effective solution and created this device.

Anchor bolts are divided into several types

Anchors come in different types, have approximately the same properties and functions, each has a fundamental difference. They are divided into the following types and subtypes:

- Mechanical: – mortgage; – spacer; – driving; – wedge; – a bolt with a ring or hook; – frame; – hairpin; – façade; – ceiling; – spring.

- Chemical: – monolithic fasteners; – for external and internal work; – for fastening in loose and thin-walled substrates; – resistant to vibrations; – long-serving;

- Plastic.

- Ground.

- For foundation construction.

- Height adjustable. Choosing the right type is not difficult

Screw anchor

Has a special design. The slots in the sleeve are not cut completely and end with a ring with a nut. Closer to the head and in the middle of the liner, the lamellas are weakened. When tightening the screw, the nut moves and pushes the lamellas apart in the middle.

Specially designed for weak and hollow substrates. It can be produced not only with a screw, but also with pins, hooks, and rings.

Anchor bolt with ring

Preparing to install an anchor in concrete

The question “how to install an anchor in concrete” means not only the installation procedure itself, but also the choice of the standard size of the hardware. After all, the wrong choice of fasteners is fraught with negative consequences. In this case, destruction or cracks in the concrete, breakage of the fastening element, its bending or tearing, and premature corrosion are possible.

When choosing an anchor, you should familiarize yourself with its technical characteristics indicated on the packaging (for example, 8 10/60-115). It means:

- The first number is the thread diameter. It is important for choosing a key if there is a hex head on the outside.

- The second is the outer diameter of the sleeve. A drill is selected based on it.

- The third is the depth of the installation hole. Necessary for selecting an anchor based on wall thickness.

- And the last one is the total length of the fastener.

This is interesting: Copper ore - copper mining, refining, deposits

General recommendations

In order to correctly install anchor bolts, it is necessary to take into account the type and strength of the base, select the optimal type of anchor for a particular part and determine its load capacity.

And although some types do not require high precision hole drilling (for example, expanding), the more accurate it is, the more reliable the anchor’s adhesion to the base.

Information to note : Liquid glass , Solvent 646, white spirit.

Anchor bolt. Installation, principle of operation.

How to properly install an anchor bolt with a nut - step-by-step diagram

Step 1: Anchor Hole Diameter

Before drilling a hole for the fastening, you need to select a concrete drill for a hammer drill of the required diameter. In this case, first of all, be guided by the dimensions of your mount. It is under no circumstances recommended to drill a hole if the bushing does not fit into it. It is better to go through the same diameter drill again, and the hole will become a little larger. If you drill out the fastening point with a drill of a larger diameter, the bushing can freely “walk” in it, while the spacer mechanism simply cannot perform its holding functions.

Step 2: Clear the mounting area of debris

It is no secret that after drilling, debris remains in the finished hole after using a hammer drill. It is these crumbs and dust that interfere with the installation of the bolt at the installation site. It is especially difficult to install a double-spacer mechanism into an uncleaned hole; such fasteners have a sleeve that is slightly wider than usual. Therefore, before installation, thoroughly clean the hole; if necessary, use a construction or household vacuum cleaner.

Step 3: Correct installation of heavy elements

After you have inserted the bolt into the hole, do not rush to mount your device while tightening the nuts; there is a more practical solution. After installing the anchor, without hanging the product, tighten the bolt with a wrench until it stops. Tightening must be carried out until the pin opens the bushing, and the fastening, so to speak, assumes operating mode. After this, you can place the nut on the studs, which are already firmly held in the mounting hole, install the device, and calmly tighten it with the nuts.

General recommendations for installing anchors in concrete

The anchor works well with materials such as concrete, stone and masonry, because these materials are strong and do not bend under load. If you take concrete separately, the anchor is held in it by friction, bonding with concrete and stop. When using these fasteners for the first time, it is better to consult with a specialist to know how best to use them. They have their own specifics that must be taken into account.

Installation of anchors in the foundation

In order for the fastening bolt to work with the load for which it is designed, it is necessary to calculate the correct installation of the anchor bolt in the concrete. It is best if the anchor is inserted into the poured concrete before it hardens. Here, precise placement is possible according to the layout of the house, just under the walls, external and internal. To install an anchor bolt in concrete, it must be immersed so that the protruding part with the thread is about 6 cm. Do not forget to protect the thread itself from contamination by concrete and wrap it with any film. The distance should be 40 cm from each other, exactly in the middle of the future wall. It is important to maintain a horizontal installation; for this it is better to use special devices, conductors, which are attached to the formwork.

If the bolt is installed before pouring, it is welded to the reinforcement or tied with wire for tying.

Anchor bolt installed before pouring the foundation

The question often arises of how to fix an anchor bolt in concrete that has already hardened. To do this, drill holes of the required diameter and install fasteners there.

Then fixation is applied with a sleeve and a nut, either with a nut or with a wedge - it all depends on the type of fastening chosen. We select the bolt size according to the load taken plus 15-20% margin.

Differences when installing chemical and drive-in anchors

There is a method using a special glue, which ensures the mutual penetration of metal and concrete molecules, thereby ensuring a very strong connection, or other adhesives similar in action to epoxy. They consist of two components, for example, cement and highly reactive resin.

How to install an anchor bolt and nut in concrete

For fixation in concrete, different types of anchors are used, which are selected in accordance with the expected load and characteristics of the concrete. When attaching reinforcement, console or channel to concrete without voids, it is better to use an anchor with a nut. The nut can be either with a pressed-on washer or with a detachable washer.

Step-by-step recommendations on how to screw an anchor bolt into concrete:

Step-by-step process for installing anchors in concrete

1 – drilling holes according to preliminary markings, with a hole diameter that must correspond to the spacer part and its depth corresponding to the length of the spacer part (for this we use a tool with a depth gauge);

2 – cleaning the resulting holes from concrete fragments and crumbs for more accurate installation of the anchor in the concrete (you can use either a construction vacuum cleaner or an ordinary rubber blower);

3 – the jacket (spacer sleeve) of the anchor is installed in the finished hole and carefully driven in with a hammer so that the edges of the sleeve do not protrude from the top of the concrete, leaving the head of the fastener above the surface;

4 – screw the nut onto the head of the fastening anchor using a wrench, causing the spacer part to deform and firmly fix it in the base of the concrete.

You need to tighten it to the last turn, but be careful not to strip the thread of the nut. To do this, use torque wrenches. The nuts are made using casting followed by heat treatment and can withstand heavy loads. Single expansion and double expansion anchor nuts are manufactured.

How to Attach Impact Anchors for Concrete

In addition to fasteners with a nut, fasteners with and without a wedge are used. Fastening with a wedge is used for more massive structures. Next, we’ll look at how to properly use wedge anchor bolts for concrete.

When driving the fastener into the hole, a special wedge, which is located inside the shirt, pushes the shirt apart along the spacers. This creates a fairly strong connection. Compared to the previous type of connection, here the hole does not need to be prepared so carefully both in size and cleanliness of the hole. Anchors without a wedge, or in other words, impact anchors on concrete, are attached in a different way. They consist of such parts.

This is interesting: Martensite and martensitic steels: types, structure, transformation

1 – A hollow collar with a thread in the upper part, into which the nut is screwed, and with a spacer sleeve in the lower part. The spacer sleeve has slots on the sides.

2 – A rod, which, under the influence of an impact tool, pushes the coupling along the slots and locks the bolt in the material.

3 – Nuts with washer, used to attach a wall to concrete, such as a foundation.

Installation principle of wedge bolt

It is not difficult to learn how to work with this type of fastener. A clip is inserted into the holes drilled using a hammer drill or impact drill, and a rod is driven in, which pushes the petals apart. Then the nut and lock washer are screwed on. Before installing anchors in concrete, the hole must be well prepared.

How to fix a hex anchor bolt into concrete

By design, this is a standard bolt, but with two conical ends. It is mounted by unclamping the jacket using a shank. As with any method, the hole is well prepared, a shirt is hammered into it and the head is screwed in the form of a hexagon. The head can also be made in the form of a hook or ring.

Screw anchors for concrete and features of their installation

Screw anchors differ in their design from other types of anchor fasteners in that the slots are located in the middle part of the hollow cage. Their weakened design allows them to expand when they are mounted in concrete. There is a nut on the bottom of the bushing.

Let's look at how to attach this type of anchor bolts to concrete. It should be noted that this type is used in lightweight concrete (foam concrete), brick wall and similar materials, in no case hollow.

This type of anchor, like other fasteners, is produced according to the standard, so it is easy to select the diameter of the drill for them. After drilling, clean the prepared hole from concrete or brick residues. Remember that the hole should be 0.5 mm smaller than the size of the bolt. The clip must go in with force. We calculate the depth of the hole taking into account the layer of finishing material, which is much softer than the wall. You should not tighten such anchors until the last turn, otherwise the surface layer may be damaged.

Screw anchors

It is better to fasten this type of wall with concrete anchors using chemical hardeners in pre-prepared holes, so such connections are very reliable and durable.

Installation of drive-in anchors in concrete

Learning how to attach a drive-in anchor to concrete and installing it correctly is actually not difficult. Their design is the simplest; there is no wedge in it. The rod and sleeve are made of different materials, the sleeve is made of a softer material, and the rod is made of a harder one.

This type of fastening does not require very careful preparation of holes and precise markings, since it is used at the beginning of construction to fasten fairly dense massive walls and building structures. In this case, the thickness of the structure is not limited, but the thickness of the base must be at least 100 mm.

To install the anchor, we drill a hole with a diameter that provides tension, but with a depth greater than the length of the anchor. Then we clean it from dirt. We hammer a sleeve into it, which expands along the cut lines, thereby ensuring a tight fastening. We screw in either a pin or a bolt, depending on the design.

Fastening a four-segment anchor to concrete

This type of fastener is considered the most durable, and it is used for mounting structures of large size and weight.

Its sleeve contains 4 segments, which provide increased reliability and greater wedging. Due to this, it is used in both hard and light materials, but homogeneous and without voids. The sleeve, which has both restraining springs and a spacer, is inserted into the prepared hole and carefully hammered in. Then a bolt is screwed in, which at this moment wedges the segments and ensures reliable fastening.

Since this fastener is made of hardened, durable metal, especially the bolt, removing it from the wall is much more difficult than hammering it in. Therefore, before installing it, you need to measure everything well.

How to remove an anchor bolt from a concrete wall

If you still need to remove the bolt, this can be done in several ways.

The simplest one:

a) unscrew the nut;

b) hammer it as deep as possible by hitting the central rod;

c) use pliers to hook the sleeve and remove it.

There is an option to use a drill to drill out the place where the rod and nut are attached, knock the rod inward, and remove the sleeve.

Removing the anchor, one way

If the bolt is large in diameter, drill a hole inside it, cut a hole with a tap and screw the bolt into it along the cut diameter. Then we secure the small bolt with pliers and turn the nut together with the sleeve. After removing the lock nut, cut off the outer nut and punch the rod inside the structure.

A piece of wall is roughly destroyed with a hammer drill and the fasteners are removed.

This once again proves that any work must be approached responsibly. It is necessary to first calculate the dimensions of the structure, check the load using tables, decide which method is right for you, how to correctly install the anchor bolt on concrete, and only then proceed. After all, an anchor bolt in skillful hands is a very reliable fastener. The main thing is to install it correctly.

Types of anchor bolts

- With a nut. The budget version of the fastening system guarantees the reliability of the connection. The structure of such a bolt consists of a screw, a steel tube and a nut. During installation, the bolt moves along the length of the rod. As a result, its tip becomes thicker. Bolts with a nut are suitable when working with concrete structures, brick, and natural stone. Anchor bolts of this type are found in a diameter range from 6 to 28 millimeters. The length of such a product can reach 3 centimeters.

- Wedges. This is an improved version of the anchor bolt with nut. The main difference is the bushing at the end. The other part contains a nut and washer. To avoid damage due to corrosion, the bolts are galvanized. The products themselves are made from carbon and stainless steel. They differ from each other in diameter (from 6 to 12 mm), permissible thickness of the product that you plan to mount (up to 2 cm), surface thickness during installation (up to 53 mm), and strength. A standard set of tools will be sufficient for installation. The fastening method is no different from conventional anchors. Wedge bolts can withstand heavy loads. Due to the high internal tension, the tearing force increases, which makes it possible to mount heavy objects into walls.

- Hexagonal. Designed to work with surfaces of increased hardness. They are in demand in the construction and repair sectors. The hex head, which distinguishes them from other types, rotates along the threads of the spacer bolt. Due to this, an expanded bushing is obtained. The products are made of galvanized steel, which protects against corrosion.

- Drums. Suitable for mounting massive objects when aesthetics do not play a special role. Used when working with building structures, plumbing fixtures and other heavy parts. The base on which you plan to install the anchor must be sufficiently dense. The bolts differ from each other in length (up to 5 cm), diameter (up to 2 cm), and the magnitude of the pulling force. The key rule is that the surface thickness must be at least 10 cm. The wall installation process includes several stages. First you need to make a hole in the surface. It should be longer than the bolt itself. Then we clear the hole from dust. We hammer in the bushing, which, when exposed to impact tools, adjusts to the desired diameter. Screw in the bolt. Keep the anchor bolt perpendicular to the surface at all times.

- Four-segment. Designed for large items. Due to the special design, it is possible to guarantee increased reliability of the fastening system. Used in durable homogeneous rocks and porous walls. The structure of the bushing has four segments. One pair is fastened with a ring, the second with a spring. There is a spacer element. The bolt moves along the length of the anchor when screwed in. Reliable fixation is ensured along the entire length of the fastening element.

- Screw. Reinforcing bars are used for production. They are fixed in the hole using special fillers. The kit includes a rod, washer and nut.