There is an opinion that sewer ventilation in a private house, the scheme of which is developed at the building design stage, is necessary only for large cottages with several floors and a large number of plumbing structures. In fact, ensuring the flow of air and the removal of generated gases is necessary for any sewer system, although the design may vary significantly depending on individual conditions. The presence of ventilation, first of all, allows you to ensure a balance of pressure in the sewerage system. Thanks to this, it is possible to avoid the penetration of unpleasant odors into living spaces and the appearance of unpleasant sounds of water suction when low pressure zones form.

Preparatory actions before installation of equipment

Primary actions always begin with the acquisition of plumbing equipment, building materials and the necessary tools.

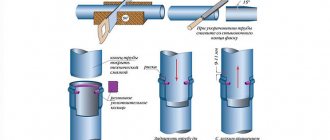

For sewerage installation, pipes made of PVC are selected, which are most suitable in terms of their characteristics and price. They are most often used when installing sewer systems due to their long service life and high technology when installing risers and the general system. Along with pipes, sealed gaskets for connections, as well as adapters, tees and couplings are purchased.

Sewage work is carried out with the simultaneous installation of ventilation elements.

- installation of special valves to relieve pressure of accumulated gases in the sewer system;

- installation of a background pipe on the roof of the house;

- septic tank ventilation.

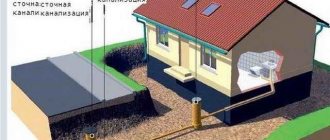

Sewer ventilation schematically.

Options for installing an external ventilation system

If the design documentation of the house does not provide for a sewer exhaust system, after putting it into operation it is necessary to install an external ventilation system. The pipe connected to the drain is brought outside and mounted in a place convenient for its location. One option for placing a ventilation pipe is to strengthen it on the external wall of the house. The connection is made not to the riser, as with internal ventilation, but directly to the wastewater drain.

The external exhaust pipe can be mounted on a fence, wall of an outbuilding or other vertical surfaces. With this installation option, you must keep in mind that disgusting-smelling miasma is released near the outlet, and position the exhaust pipe in such a way that the bad smell does not create inconvenience to neighbors in the area.

For owners of country houses, the simplest and at the same time effective installation option is to install an exhaust pipe directly into the fecal pit.

It is always located away from residential premises, so the bad smell will not bother household members. The height of the pipe above the ground may not exceed one meter.

Often, owners of small houses doubt that sewer ventilation is advisable, assuming that it will not function in the hot season during the period of especially intense decomposition of organic matter. These doubts have no basis, since the temperature of the wastewater will always differ from the ambient temperature, as a result of which a pressure difference arises, and air and heat exchange will occur.

A properly installed drain pipe ensures comfortable living by preventing the foul smell of sewage from appearing in living areas. Probably, the owners of private houses can be creative and come up with a hood of their own design. The main criterion is that she cope with the tasks assigned to her, and the household does not complain about the author of the project. The following is a video that provides useful information about installing a fan riser.

Any person living in a private household has at least once encountered a problem when, during strong winds or hot weather, “amber” from the sewer penetrated into the home. Gases formed as a result of the decomposition of organic matter smell unpleasant. In addition, you are probably familiar with sewer gurgling and “slurping” sounds when draining wastewater. This occurs due to changes in pressure in the sewer system and the formation of vacuum plugs. All these troubles are eliminated in a private home.

Ventilation is necessary for any type of sewage system: centralized, autonomous, isolated or non-insulated. It will not only provide the required volume of fresh air, but will also balance the pressure of the system, due to which the wastewater will drain silently. The sewer hood should ideally be designed during construction in a private house

In practice, it happens that attention is paid to its arrangement only when guests make a comment about the fragrant, persistent aroma in the room or area

The principle of natural ventilation

Before you begin to independently calculate natural ventilation in a private house, you need to understand the principle of its operation. All channels are located only in a vertical position. It is important to know that natural ventilation in a private house is established at the stage of its construction. Then the number of channels and their location are calculated.

Watch the video

The operating principle of natural ventilation is based on the difference in air temperature indoors and outdoors. Warm air has the property of rising and thus exchange occurs. For proper operation of the system, the following factors must be taken into account:

- mine thermal insulation,

- number of ventilation branches;

- traction force

- bottlenecks or other obstacles;

Draft during natural ventilation is affected by wind force. And due to the fact that no additional mechanisms are used during installation, it is simple, silent and durable.

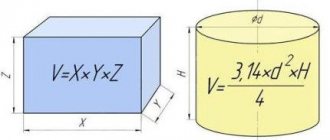

Calculation of ventilation ducts

To install ventilation yourself in a private house, it is better to take plastic pipes with a diameter of 15 cm. This figure will ensure air movement of up to 30 cubic meters per hour with a three-meter height of the air duct. If it is lower, the mechanism may not work or work with minimal traction.

If you want to increase the throughput, it is possible to increase both the cross-section of the air duct and its length. To ensure maximum draft in all rooms on the floor, it is worth taking care of the same length of the air duct.

Disadvantages of natural ventilation

The most important disadvantage is the dependence on temperature factors outside and inside the building. The greater the difference between these indicators, the more efficiently the ventilation works, and with a minimum indicator, the efficiency of the system decreases significantly.

In winter, a quarter of all warm air escapes through ventilation ducts, which provokes a decrease in temperature (this is especially felt during the heating season).

Forced ventilation

Watch the video

Is ventilation necessary in a septic tank?

The range of sealed containers for processing household wastewater is huge: in addition to various industrial models, from a simple storage tank to a biological water treatment plant, there are many homemade types made of concrete, brick and plastic.

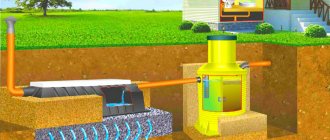

One of the options for installing a three-chamber septic tank

The most effective structures consist of 2-3 parts:

- in the first, sewage settles with sedimentation and fat floating;

- in the second - additional purification of the already clarified liquid;

- in the third – final filtration.

Factory models are initially equipped with equipment that ensures air movement. The fact is that the main mission in cleaning processes is performed by bacteria. It is their work that determines the characteristics of purified water, as well as the ability to use it in the future (for washing a car, watering a garden, etc.). Some bacteria - aerobic - cannot process biological waste without the presence of oxygen. Therefore, it is necessary to ensure air flow. Compounds of various chemical elements, including oxygen, form gases with an unpleasant odor. Some of them (for example, methane) are dangerous to people and animals.

Ventilation outlet in a concrete septic tank

Homemade devices made according to the simplest schemes are most often ventilated naturally - through hatch cracks or a gap in sewer pipes. What does this lead to? Firstly, to the spread of unpleasant “exhausts” from under the manhole cover, and secondly, to the appearance of the same specific smell inside the building. Poisonous gases entering a residential building signal that it is unsuitable for habitation.

It turns out that the correct ventilation of a septic tank in a private house solves two important problems: it increases the efficiency of the treatment plant and eliminates the danger of poisoning with harmful gases. There are several ways to arrange hoods:

- installation of pipes that allow air to enter the tank and return out of it;

- use of a set of vertical risers for air flow on the drainage field;

- installation of a vent pipe inside the building.

The safest is the integrated use of all methods, however, for a small dacha operating only in the summer, one is enough.

Diagram of the ventilated chamber

Forced ventilation of sewerage systems

In accordance with existing construction standards, low-rise individual buildings can be used without installing a drain pipe. This depends on the number of residents and the number of plumbing fixtures in use.

The size of the riser pipe also matters, because the siphons fail only when its cross-section is completely filled with waste. An alternative to a drain pipe is a vacuum valve, which reliably compensates for pressure drops in the sewage system.

Problems to be solved

A septic tank is a kind of drainage collector into which, through a drainage riser, comes everything that we try to get rid of in the toilet, kitchen, etc. The water passed through it is then directed through a drainage outlet either into a ditch or into filtration fields. This is a continuous process, because it’s rare that we don’t use the toilet, shower, etc. For the drainage mechanism to “work like a clock,” the ventilation of the cesspool must be well established. It must be done in such a way that at least two tasks are successfully solved:

- No “leakage” of unpleasant odor into rooms where it is not expected at all (toilet, bathroom, kitchen, etc.).

- Ensuring continuous and high-quality waste disposal through the septic tank.

The last condition predetermines the success of the actions of bacteria living in the drain collector. After all, it is they who perform the function of processing the mass of waste, decomposing it into gases, purified water and sludge. They operate in two groups:

- anaerobic, capable of producing methane from what enters through the drain into the thickness of the slurry of the 1st chamber of the septic tank (household waste of various origins);

- aerobic, “eating up” from the surface of the liquid what is left after the first group, and releasing hydrogen sulfide.

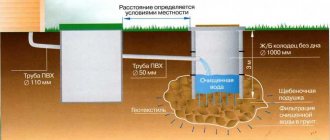

Construction of a two-chamber septic tank

In addition to these gases, other volatile compounds (phosphorus, arsenic, etc.) are also present in the “exhaust”. What could this lead to? If ventilation is not provided in such a gas-filled volume or is not made effective enough, then the products produced by bacteria will begin to flow through the sewer back into the house (toilet, bathroom, kitchen, etc.). In a favorable case, this will lead to a pervasive atmosphere of stench, and in a less fortunate case, it will lead to an explosion, quite possible due to the presence of methane.

Hoods for sewerage

Frequent 2 mistakes

There are at least two common misconceptions regarding such devices:

- Since I have a drain pipe in my house or apartment, that is, ventilation of the sewer riser (bed), it means that all unpleasant odors from the system must escape through it. However, we are very surprised if it doesn't work. But the whole point is that the most common source of stench is either damaged pipes or the lack of hydraulic valves due to the banal lack of use of any bathroom (a column of water can evaporate).

- But the second mistake concerns residents of the upper floors who have access to the drain pipe - when repairing or replacing plumbing equipment in a toilet or bathroom, it is removed altogether. The reason for this is the poor condition of this pipe - due to its long service life, they are pretty damaged by corrosion. But by plugging the riser, you create a problem not only for yourself, but also for all your neighbors living below on all floors. The smell will penetrate the apartments every time the toilet is flushed.

Let's start with the fact that ventilation from sewer pipes in a private house, especially if there is more than one toilet, should be at a height of at least 4 m from ground level. As a rule, the vent pipe is routed through the roof. This will keep the water in the hydraulic seals from evaporating too quickly, and will also help compensate for the difference in air pressure when flushing a toilet or two toilets from the tank at the same time.

When flushing water from the toilet, its volume completely fills the diameter of the pipe and, as it moves, thins out the air behind it, which leads to the sucking out of these same water seals. But the fan pipe compensates for this difference. As a result, you get no unpleasant odors in the room.

I already said about the diameter - it should be the same as in the system itself. But is it possible to use pipes made of a different material, for example, to combine the laying of a PVC system with an asbestos-cement or metal drain riser?

In any case, the answer here will be unequivocal - yes, it is possible. Only in this case another question will arise - is it necessary? It is best to use polyvinyl chloride for the fan riser, even if your wiring is made of metal or asbestos cement (this also happens) - PVC is very light, strong, and its service life is 50 years or more.

The ventilation insert is made at the highest point of the sewer system, made from the widest pipe. That is, if the main system has 110 mm, then the connections to it will be made from a diameter of 50 mm, but they, of course, will be higher, although it is advisable to make the insertion on the 110th pipe (it is possible on the 50th, but the effect is diminished ). Most often, this point is the toilet connection point.

One of the options is to vent ventilation through, as in the top photo - this will most likely increase the price of the structure, but this option is quite convenient. This letter G should be made of the same material as the system itself, and the riser can already be mounted from PVC.

Installation stages

Do-it-yourself ventilation in a private house from sewer pipes is quite simple. First you need to determine the type of system. There are 2 of them - natural and forced.

Natural is carried out due to traction, which arises from the difference in pressure on the surface and inside the pipes. In forced mode, this task is performed by a special device (fan). It builds up pressure inside the system and releases accumulated gases outside.

Figure 6. Natural ventilation diagram

It is worth noting that the use of lattice fans significantly reduces the amount of accumulated condensate.

Arrangement rules

Ventilation can be installed in an already prepared sewer cavity (in old apartments it is located in the bathroom and kitchen). Here all the details can be hidden from view and there is no need to carry out additional work to dismantle the walls. In the garage, you can run it along the wall or in the farthest corner, where it will not interfere when moving or performing any work.

Bends are insulated not only outdoors, but also indoors. To do this, you can use foil insulation or its analogues.

The outlets to the street and into the house are covered with bars. Outdoors, this will prevent snow from getting in, and indoors, it will prevent excess debris from getting inside.

Figure 7. Protection indoors and outdoors

You should not install ventilation near high-voltage wires. Craftsmen do not recommend doing this, since if it is necessary to change the wires, the ventilation system will also have to be destroyed.

Material calculation

The main point in the calculations is to select the correct length and cross-sectional area of the pipe. The longer and wider the pipe, the stronger the draft effect will be. This applies to both natural and forced systems.

The number of pipes is calculated using the same system. If one pipe is not enough, then you need to add another one nearby or use a larger diameter of the first one.

Equipment and tools

When installing a ventilation system, you will need high-quality tools. These are construction tools that can be found in the garage or purchased at a hardware store.

First of all, this is a hammer, a knife (ordinary or special, designed for cutting PVC pipes), a drill or a screwdriver for fixing fasteners. When constructing a shaft on the roof of a room, you may need bricks, cement and everything related.

A forced system will require a working blower (fan), which will be installed last from the inside of the room.

Building regulations for ventilation systems

For example, for a room of 25 square meters. m. it is better to use pipes with a diameter of 120 to 200 mm. This will be enough to provide air exchange with an intensity of 3 cubic meters. m. per hour (in accordance with the norms of sanitary services). The recommended length is from 5-8 m. The main thing is that the ventilation hood, or rather its end, rises above the roof of the building by at least 0.5-1 m.

Only pipes made of non-flammable or refractory materials should be used. These include PVC; it practically does not burn and is poorly susceptible to temperature changes.

Construction and maintenance

The installation of ventilation ducts is carried out at the final stage of installation of the septic tank. There are many descriptions about what and how to make the latter. Ventilation of a septic tank made of concrete rings (this is one of the typical construction methods, characterized by reliability and accessibility) will become possible, on the one hand, due to the presence of a pipe diverted from its second (last) chamber (but not from the first), and on the other hand, account of risers provided at the starting point of the sewer system, providing vacuum compensation.

If there are filtration fields, drains should also be equipped with ventilation pipes. The latter will be able to additionally serve as inspection windows and places for washing. The diameter of the pipes in the general case is ~100 mm. As for air circulation, it goes according to the following scheme:

- inflow through the second (if there are more of them, the last) chamber;

- passing through the connecting pipes and riser upward (the appearance of gases is accompanied by abundant heat, and this contributes to precisely this direction of flow);

- exit through a riser located at some elevation above the roof of the building (fan).

What can interfere with the free flow of air? In order for gases to pass through the system unhindered, it is necessary to fill the pipes from 1/3 to 2/3 of the internal diameter, no more. To improve traction, as well as to prevent precipitation from getting inside, it is necessary to equip the upper ends of the risers with protective caps.

Scheme of treatment facilities

In this case, it is mandatory to comply with a number of safety precautions. Here they are:

- there must be at least two attendants;

- it is necessary to use personal fall protection equipment;

- Smoking is not allowed in work areas.

If you do not want the products sent from the toilet through the toilet and flush cistern to poison your life, returning in gaseous form, be sure to provide and ensure optimal operation of the ventilation system for your septic tank. This will not only save your nerves by getting rid of the stench, but may even save your life.

Ventilation exit through the roof

It is not recommended to leave the sewer vent outlet in the attic as it is not properly ventilated and the odor can penetrate into the house. The pipe must be pulled through the roof. The work is performed in the following sequence:

- the installation of the exhaust pipe is completed in the attic;

- the end section of the pipe is fixed to the roof surface;

- Using a corrugated adapter, two sections of pipe are connected.

The end section of the pipe is fixed to the roof surface using a flexible and elastic adapter made of polymer material. Its cuff is sealed and securely fastened with screws or other fasteners. It is easiest and most reliable to use a factory-made ventilation outlet designed for a specific type of roof for installation on the roof.

Under normal conditions, the warm air that comes out of the ventilation duct prevents the sewer ventilation outlet from freezing. Note that in regions where the temperature in winter can drop below thirty degrees, ice freezes and the ventilation outlet becomes clogged. In this case, thermal insulation of both the ventilation duct section in the attic of the building and its outlet on the roof is necessary.

How to make a fan pipe deflector with your own hands

A deflector is installed at the outlet of the fan pipe. This is done to increase the efficiency of natural traction due to the aerodynamic properties of this structural element. The deflector increases the draft in the exhaust pipe by approximately thirty percent. You can buy a ventilation deflector, or you can make it yourself. To complete this work you will need the following materials and tools:

- small galvanized sheet;

- hardware for fastening;

- metal scissors;

- tape measure or ruler;

- carpenter's pencil.

A cone-shaped socket is marked on a sheet of metal. The cross section from below must correspond to the diameter of the ventilation pipe; from above this parameter increases by approximately fifteen percent. A skirt is placed in the middle part of the metal cone, and an umbrella-shaped visor is placed on top. All parts of the resulting structure are fastened with rivets, self-tapping screws or screws with nuts and installed on top of the outlet pipe.

Alternative option - vacuum valve

A vacuum or aeration valve, designed to equalize pressure, is a very conditional alternative to full-fledged ventilation equipment. It is installed when it is impossible to remove the drain pipe (due to the design features of the building), complex routing of waste pipes, and so on.

The vacuum valve consists of a soft spring and a sealing seal. The principle of operation is not complicated: when the pressure inside the sewer decreases, the valve opens and lets in outside air. Once the external and internal pressures are equalized, the valve closes.

In addition to the upper outlet of the sewer riser, vacuum valves are installed on horizontal sections of the pipeline network between the plumbing fixtures connected to it. Their location and quantity depend on how many drainage points are in the house and how they are located.

With increasing operating time, contaminants are deposited on the valve parts, the tightness is broken, so the aeration valve needs periodic cleaning, that is, maintenance is required. In addition, the mechanism works reliably only at positive ambient temperatures, and at negative temperatures the functioning is disrupted.

Building codes and regulations do not regulate the operation of such devices in any way, so they are installed exclusively by owners of private houses.

Basic issues related to the aeration plant

Most often, people living in private households have doubts or questions regarding the creation of a ventilation system in their sewer system. The main topics are:

Will ventilation cope with its functions in the hot summer, during the maximum decomposition of organic waste?

Yes, it will. This is explained by the difference in external and internal temperatures between the treatment plant and the environment, due to which constant heat and air exchange occurs. The temperature of sewer water will always differ from atmospheric air. This factor also contributes to the creation of a pressure difference in the installation and its effective ventilation.

Will the riser, which is an uninsulated (uninsulated) part of the structure, freeze in the winter?

In winter, wastewater is always warmer than the air, so the riser cannot freeze if the treatment plant is used regularly. In some regions, the riser facing the street should be insulated (insulated). For this, a pipe with a large diameter is used. For more detailed information, it is better to contact professionals.

Some time after the installation of aeration, foreign odors began to penetrate into the rooms. Why?

Siphons filled with water tend to dry out, letting in an unpleasant odor.

. This happens if the sewer has not been used for a long time: the riser accumulates rarefied air. There are several solutions: change (increase) the volume of siphons, install drain pipes or an aeration valve on the riser. The valve will allow atmospheric air to pass inside effectively and prevent air discharge in the pipes.

6054

Can sewer pipes be used for ventilation?

All builders and owners of private real estate know that to maintain a comfortable microclimate in a room, ventilation is needed. To answer the question whether sewer pipes can be used for ventilation, it is necessary to dwell on the advantages and disadvantages of this material.

Benefits include:

- Lightness of sections. The assembled air ducts do not place additional load on the walls and foundations of buildings and structures.

- Smooth inner surface. Dust and grease fumes do not linger on it. There is no need for regular cleaning of the canals.

- No emissions harmful to human health or the environment. Manufacturers make their products from environmentally friendly materials.

- Possibility of assembling structures of any complexity, for which fittings of different configurations are used. The structures can last no less than the building itself where they are installed.

Disadvantages include the appearance of the pipes, which do not always fit into a particular interior. The problem is solved in different ways: they paint the air duct, cover it with adhesive film, or cover it with decorative panels. Difficulties arise in connecting ventilation equipment to sewer pipes due to the lack of adapters that can correct this deficiency.

Sewer ventilation and 2 mistakes made during repairs

July 7, 2021 Specialization: master of interior and exterior finishing (plaster, putty, tiles, drywall, lining, laminate, etc.). In addition, plumbing, heating, electrical, conventional cladding and balcony extensions. That is, the renovation of an apartment or house was done on a turnkey basis with all the necessary types of work.

Sewage ventilation diagram in a private house - the drain pipe exits through the roof

Clean air in a residential area will always be one of the first needs, therefore, sewer ventilation in a private house - created with your own hands - is one of the conditions for installing plumbing. In addition, in some cases, ventilation must be installed in apartments in multi-story buildings.

I will now tell you how this is done, and also want to invite you to watch the video in this article.

Ventilation duct design

Exhaust ventilation in a private house consists of channels in the wall, the cross-section of which should not be less than 38 cm. The inlet openings are located under the ceiling slab itself.

The most effective location for such a pipe is considered to be a wall built in the central part of the house. From this point it will be easiest to make wiring to all rooms in the house, using ordinary plastic pipes with a cross-section of 10-12 cm.

It is desirable that there be a minimum number of horizontal branches from the main pipe. After all, the more branches, the less draft there will be, and the air flow will weaken significantly. All branches go to one common pipe and go outside through it.

Please note that the exhaust pipe must be lined with at least double brickwork so that in winter at sub-zero temperatures it does not freeze and does not cause the rooms in a private house to cool down by getting cold air inside.

The height of the main pipe is calculated according to the principle of just above the ridge, otherwise the traction will be impaired. To calculate the correct outlet height, we lay a straight line from the ridge to the pipe at an angle of 10 degrees, the latter should not be lower than the drawn straight line.

Principle of operation

The operation of a septic tank practically occurs differently in each case. The water clarified during the passage of the septic tank must leave constantly, because the septic tank is also constantly replenished. In reality, a slightly different process often occurs - the septic tank operates as long as water fills the container. This often happens due to a lack of understanding of the fact that a septic tank alone is not enough for successful sewerage operation. The removal of clarified waste must be ensured, and the ventilation of the septic tank must work. It is assumed that when using an expensive imported septic tank with aeration, it is possible to discharge wastewater into the nearest reservoirs.

The principle of operation of a septic tank.

If the water consumption in the house is less than 1 m³, the septic tank will be filled in just a couple of days. The clarified water should flow by gravity through the outlet pipe. Usually the water goes into a drainage pipe, then into a ditch or into filtration fields. Entering in small portions, wastewater in a properly designed septic tank should be kept at the same level. This level must be such that the outlet pipe can operate optimally.

It is known that for any sewer pipe the optimal filling is 1/3 of the diameter. This is why pipes with a diameter of less than 100 mm are unsuitable for external sewerage. This also applies to the outlet pipes from the septic tank. We can assume that the choice of the diameter of the local sewerage pipe has already been made; 100 mm is the required minimum. Theoretically, it never hurts to increase the diameter of the outlet pipe.

The problem will be to find a drainage pipe for the resorption field of large diameter on sale. If you wish, you can make it yourself by making the appropriate cuts in a regular sewer pipe. On the Internet you can find any recommendations for such owners who want to make drainage pipes more efficient. Usually, the outlet pipe from the septic tank quickly silts up, but making it larger is also not always possible, since ready-made septic tanks have outlet pipes of certain sizes.

Ventilation duct design

All exhaust systems are built using the same technology. The differences lie in their length, the presence of control sensors and other auxiliary devices. In all cases, the design provides for the capture of all premises in order to prevent the occurrence of stagnation.

A typical house ventilation duct consists of the following parts, components and mechanisms:

- External grille with mosquito net, fixed to the facade of the building. The mounting location is chosen in the farthest room. Depending on the layout and configuration of the room, the grille is installed on the end wall, above the window or behind the heating radiators.

- Air valve. The purpose of this device is to prevent the outflow of air in the opposite direction when weather conditions change.

- Air channel. It is assembled from links of different lengths, tees, elbows and plugs. Docking is carried out using sockets, inside of which there are rubber gaskets.

- Pocket filter. The device is designed to collect dust that is sucked into the exhaust duct. Garbage is removed as the storage tank fills.

- Main fan. Used constantly or in the absence of traction. Devices with a diameter of 100 mm fit tightly into sewer pipes with an outer diameter of 110 mm.

- Flexible inserts. They are used in places where there are obstacles along the route or where it is necessary to make a smooth turn.

- Output block. It consists of pipes, pressure plates, sealing gaskets, grille and umbrella.

Depending on the location of the ventilation duct in the house, it is finished with soundproofing devices to reduce noise from the fan and moving air.

Materials and tools

It is recommended to purchase plastic sections and fittings made by the same manufacturer. This way the parts fit together best. Despite the uniform standards, products from different companies may differ in size.

To assemble a ventilation duct made of polymer material, you will need the following tools and accessories:

- perforator;

- hacksaw for metal;

- oil level;

- roulette;

- marker;

- sharp knife;

- mallet;

- hammer;

- screwdriver;

- marker.

To assemble the ventilation system, you need to purchase the following materials:

- plastic pipe with an outer diameter of 110 mm;

- flexible inserts made of aluminum or silicone;

- fittings (corners, tees, plugs, contours);

- sandpaper;

- plastic dowels;

- clamps corresponding to the diameter of the pipes;

- screws;

- Silicone Grease.

It is recommended to purchase materials with a reserve of 10-15% to account for possible defects and errors.

Do-it-yourself ventilation of a septic tank made of concrete rings

A popular model of a homemade septic tank among summer residents is a tank made of concrete rings. The structure resembles a cesspool, only, unlike it, it has access to a filter chamber or to a drainage field. A more efficient design consists of two chambers; if desired, both containers can be equipped with separate hoods. The more active the air flows into the treatment plant, the faster the biological treatment process will occur.

Common side outlet for ventilation

Let's consider how to arrange ventilation in a concrete septic tank, or rather, in the most successful design, consisting of two chambers and a filter well. Either two chambers or all tanks are equipped with air inlets and outlets. The process proceeds as follows:

- we prepare segments of the required length with a cross-section of 110 mm;

- in the concrete covers with which the chambers are closed from above, we drill holes of the same diameter;

- we insert the elements into the holes intended for them (the lower part should not touch the drains, raise the upper part to the maximum possible height);

- we fix each part with sealant, mastic or cement mortar;

- The upper ends are equipped with a protective cap.

End caps prevent debris, water and snow from entering the tank and enhance air draft. Of course, any cleaning equipment requires maintenance from time to time. In this case, removal of solid waste and removal of blockages. At the same time, the ventilation pipe is also cleaned. Given that the gases are dangerous (they are a necessary result of biological decomposition), do not forget to use a safety belt and a respirator. It is better to carry out all work under the supervision of an assistant.

External pipe in a concrete septic tank cover

If a drainage field is provided at a summer cottage, external outlets are placed along it - they provide air access to the drains and remove the formed gases outside. More often, drains (perforated pipes from which waste water goes into the ground) are simply bent, brought to the surface and equipped with caps. Such devices play the role of technical holes, with their help you can check how the system functions. If water has accumulated in the lower part, the wastewater does not have time to be absorbed into the soil; a clean bottom indicates proper operation of the sewerage system.

Ventilation device on the drainage field

As you can see, proper ventilation of a septic tank brings significant benefits: it activates wastewater treatment and prevents the appearance of unpleasant odors. By doing all the work yourself, you can save on installation, but if you are not confident in your abilities, contact a specialized company.

Installation of a drain pipe

Effective ventilation of the sewer system riser is formed using a drain pipe. It is a kind of continuation of it. The principle of operation of the fan pipe is quite simple. Warm air inside the sewer riser rises to the outside. A kind of draft is formed in the system. It promotes the absorption of air from the room. Therefore, unpleasant odors will be able to leave the sewer system. As a result, the comfort of living of the owners will not be disturbed.

When installing a sewer riser using a waste pipe, the following rules should be followed:

- rises above the roof level by 500 mm (more is allowed);

- the diameter of the exhaust system must correspond to the diameter of the sewer riser;

- if there are 2-3 sewer risers, it is allowed to connect them at the top point and exit through a single drain pipe;

- It is strictly forbidden to combine a sewer hood with a stove or building ventilation;

- It is not advisable to install the vent pipeline near windows and balconies. This will cause an unpleasant odor to spread inside the building. The fan pipe moves away from the windows at a distance of 4 m;

- If there is a multi-slope roof, it is prohibited to route the ventilation pipeline under the slopes. It can break under the weight of snow cover;

- It is not recommended to install a deflector on the upper edge of the hood. There is a possibility of condensation forming. The resulting liquid freezes in winter at sub-zero temperatures, which will significantly reduce the efficiency of the hood;

- The sewer pipe is made from materials used for the production of sewer risers. Cast iron quickly deteriorates under the influence of the environment. It is unacceptable to use it.

Natural ventilation of sewerage facilities

Ensuring spontaneous air circulation in the ventilation system of drainage systems is ensured by the generation of heat in the mass of sewered products through the natural processes of their decomposition.

In this case, the generated gases have a higher temperature and rise upward, providing circulation and their release into the environment.

But they have one unpleasant feature - flammability.

Therefore, wastewater storage and accumulation facilities are flammable, and in large quantities can be explosive. Cesspools are especially dangerous in this regard.

Therefore, the presence of ventilation in such facilities is mandatory. Currently, the main material for ventilation devices is plastic pipes with a diameter of 100-110 millimeters. The pipe from under the cesspool cover is brought out at a distance of 4-5 meters to a ventilated place.

To increase the efficiency of the extraction process, a deflector is installed on it. In addition to protecting the upper end of the pipe from clogging with leaves and other debris, this device actively enhances the air flow, although active exhaust through the deflectors only works in windy weather.

In windless regions, it is advisable to use low-power axial fans for exhaust to ensure forced removal of gases from the sewer system.

In the same way, external ventilation is arranged in filter wells and septic tanks.

To eliminate strong odors in the cesspool itself, you can use chemicals.

Is ventilation of internal sewerage necessary?

Existing building codes and regulations make it possible not to install ventilation in the internal sewerage of houses with a small volume of wastewater discharge. In this case, the height of the building should not exceed two floors. In the case when the total volume of wastewater exceeds the diameter of the receiving sewer pipe, ventilation is required even in a one-story house.

As an example, imagine that the toilet drain pipe has a cross-section of eight centimeters, and the riser has a cross-section of twelve centimeters. If you flush water from one toilet, the riser will not block the flow of liquid, but if you flush two toilets at the same time, the sewer will overflow. Thus, it is possible to foresee the likely discharge of wastewater by possible plumbing fixtures and understand whether it is necessary to equip an internal sewerage hood. It is necessary in the following cases:

- if the cross-section of the riser is less than or equal to five centimeters;

- toilets and sinks are located on all floors of a building two or more stories high;

- the house has a large bathtub;

- There is an artificial reservoir in the form of a pond or swimming pool on the site.

The cause of an unpleasant odor can also be drying out of water in the siphon water seals.

These elements are designed with curved tubes that must always be filled with water to prevent sewer gases from escaping. If there is no water in the water seal, the living quarters of a private house are filled with miasma.

If such a problem occurs when residents are absent for a long time, to prevent the spread of odor from the sewer, you need to pour a little vegetable oil into the appropriate drain hole. Then the water in the water seal will not dry out, and the problem will not arise.

Prerequisites for ventilation devices for sewerage

The drain system, which does an excellent job of removing used water from each point, can present an unpleasant surprise when flushing two toilets at the same time, or while washing dishes while draining water from a large bathtub.

The situations may be different, but they have the same essence: the “standard” diameter of the central riser of the sewer system (10-11 cm) receives a volume of water that exceeds its capabilities. This leads to the retraction of water seals from almost all siphons due to pressure differences. And to avoid the appearance of an unpleasant odor, you will need to “update” the water plugs at every point in the entire house.

Therefore, for normal operation of the sewer system without “flushing” the water seal, in this situation it is recommended to create a separate ventilation duct to equalize the pressure. Its arrangement is required in every home when:

- The diameter of the central riser is five centimeters or less.

- Drains are regularly used to drain water from a swimming pool or large bathtub inside and outside a building.

- The building has several floors with fully equipped bathrooms on each.

- Strange “gurgling” sounds are regularly heard from the sink, and there is a smell from the septic tank.

- Modern siphons are used that require a small amount of water to create a seal.

New “economical” siphons dry out quickly enough, allowing odors from the septic tank to enter the room. You can cope with such negative air exchange in every sense by refusing to leave the house for a long time, or by installing separate ventilation for the sewer network.

Ventilation schemes

When sewer ventilation is planned when designing a house, it is most often done inside the house. In this case, the riser is brought to the roof in the form of a fan pipe. She seems to be his natural continuation. The diameter of both pipes must match (if the riser is 110 mm, then the drain pipe is 110 mm). The ventilation duct is designed in such a way that the vent pipe is located away from the windows (at least 4 meters) in order to timely and naturally eliminate unpleasant odors.

The elevation of the vent pipe above the roof depends on the type of roof and varies from 0.2 to 3 meters. Its height is regulated by the set of rules SP 30.13330.2012. For example, for a flat roof of a country house, at least 300 mm of elevation is required, and for a pitched roof - about 500 mm. The ventilation is equipped with a deflector on top, which serves as protection for the sewer system from the penetration of precipitation and to enhance air draft. In general, the deflector increases the efficiency of the ventilation system in the house.

Experts do not recommend connecting the ventilation riser to the pipes of a chimney or a general house exhaust system. But it can combine approaches from several sewer risers. When the vent pipe is installed sideways (into the wall), it is not placed under the roof overhang, since there is a great danger in winter that the outlet will be disrupted by a mass of snow or ice. It is also recommended to hide the exit hole behind a decorative rosette.

Country house ventilation schemes

The modern trend of suburban construction provides for maximum tightness of premises. Of course, this has a beneficial effect on the financial and economic performance of the building.

But, at the same time, the conditions for air exchange and safety of living are difficult. After all, one person needs about 30 cubic meters of air per hour for normal life.

For the correct formation of ventilation systems, it is necessary to take into account their certain features:

- Indoor air quality is significantly influenced by the external conditions of the construction region and the composition of the materials used in the construction process.

- Methods of controlling heating systems, air conditioning and ventilation devices are important.

- Do not use household chemicals that emit harmful substances and are not recommended for use in a confined environment.

- For premises for various purposes, there are specific standards for the composition of the air in them - for bathrooms, bedrooms, gyms and others.

- It is necessary to take into account the physiological characteristics of each person living in the house, for example, the presence of allergic reactions to certain substances and materials.

For high-quality ventilation of the premises of a country house, combined supply and exhaust systems are used, which operate according to the scheme below.

Difficulties in ventilation can arise for various reasons, but most often this occurs due to long horizontal sections in the pipeline system, as well as a large number of turns. In this case, forced ventilation of the premises is used.

Purpose of ventilation

Ventilation of the sewer system is intended to solve the following problems:

- eliminating unpleasant odors from plumbing fixtures;

- elimination of gases (hydrogen sulfide and methane) formed during the decomposition of waste in a septic tank (cesspool). Gases can harm human health (severe poisoning) and lead to an explosive situation;

- balance the pressure inside the sewer pipes. When draining water simultaneously in several plumbing fixtures, it leads to insufficient air in the sewer system and, as a result, the formation of a pressure difference. Timely supply of air will help eliminate this problem and maintain the integrity of the installed water seals.

Features of ventilation pipes

The first and main feature of air exchange pipes is their purpose of conducting air flows. Therefore, all ventilation pipes are made from environmentally friendly materials, which ensure that they do not in any way affect the air carried by the pipeline. In contrast, sewer pipes are not intended to carry air masses, and therefore this aspect may not be taken into account by manufacturers at all in the technological process. Although it is worth noting that in many cases, manufacturers of sewer structures insist on the environmental friendliness and safety of their products.

The second feature is the application of a special antistatic coating to the outer surface. Since the function of ventilation is to purify and not pollute the air, it is important that no accumulations of dust, dirt, various microorganisms, etc. form either inside the pipes or on their outer walls. Therefore, elements of ventilation pipelines are always treated with antistatic agents.

In turn, sewer pipes are never treated with antistatic agents, and therefore, when using them in ventilation systems, you should be prepared for the need to wash or wipe them frequently.

The third feature is weight. Ventilation elements of structures are much lighter than their counterparts intended for installation of sewer systems. This is a very important feature that must be taken into account when installing a suspended ventilation pipeline from sewer pipes.

Thus, having familiarized yourself with all the advantages and disadvantages of using sewer pipes when installing a hood and building a ventilation system, you can give or not give preference to this option. In any case, for various types of utility and domestic premises - for example, a garage, ventilation from sewer pipes is an excellent and inexpensive solution.