Sometimes there are complaints from users that they have blowing from the sewer in their apartment. This is a fairly common problem, caused by the difference in air pressure in the system and in the room.

This is due to several physical effects occurring in the wastewater system riser. The appearance of air flow from the sewer is accompanied by the spread of a bad smell, which quickly spreads throughout the apartment. There is no need to delay solving the problem, since biogas from the system is harmful to people and animals. Let's take a closer look at this issue.

How is sewerage installed in a private house?

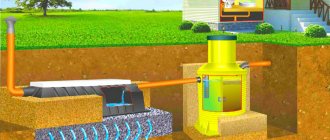

Every sink, bathtub, and toilet in the house is connected by a common sewer system that leads everything to the street. When the toilet is flushed, all feces are sent to the septic tank, which is usually located outside the house. Over a sufficiently long time, all biological residues that have ever entered the sewer decompose, emitting a rather unpleasant odor.

The simple design of the septic tank does not provide for tightness, which allows odors to freely escape without entering the apartment or house.

Also, to protect against unpleasant odors, each sanitary unit has a water seal that serves as a barrier to gases. Gas cannot pass through such a barrier. As a result, all unpleasant odors remain within the sewer and septic tank, which does not cause inconvenience.

But cases often occur when the water seal remains empty. For various reasons, the liquid that should be in the water seal is simply not there. A good example of this is the renovation work of replacing a bathtub, toilet or sink.

It is also not uncommon for water to be pumped out itself as a result of the formation of a vacuum, which simply empties all water seals. The reason for the formation of such a situation may be the passage of a large amount of liquid through the sewer. As is known from physics, a piston (and in this case it is water passing to a septic tank), passing through the cylinder, draws in a fairly large amount of air, and in its absence, draws in all the liquids that are located in the water seal.

When this happens, the decomposition products of feces and other objects that are in the septic tank enter the home. Of course, such a problem can be easily eliminated by refilling the barriers, but when this problem appears, the gases will already be in the living room.

Ventilation in this situation will serve as an excellent way to remove unpleasant odors, preventing it from reaching the premises, which will preserve not only a comfortable environment in the house, but also the health of the residents.

Operating principle of a fan pipe

This device is designed to provide ventilation to the waste system. It connects the structure of sewer pipes to the atmosphere or to a specially constructed ventilation duct. The shape and length of the device can be arbitrary. You can find straight, bent at an angle, vertical and horizontal parts.

When installing a sewer system, the installation of a drain pipe - a ventilated riser - is most often performed. The operation of the device prevents the smell of sewage from entering the apartment

The principle of operation of the fan pipe is quite simple. Wastewater discharged into a vertical riser creates a vacuum in the pipeline. It can be partially compensated for by water in the siphons of plumbing equipment. But with a powerful drain or a high riser height, the vacuum formed in the sewer pipe, with a characteristic “slurping” sound, breaks the water seals of the equipment, draining the siphons. In this case, there are no obstacles to the smell from the sewer.

In systems equipped with a drain pipe, everything happens a little differently. The vacuum created in the sewer pipeline does not have time to “suck” water out of the siphons. This is prevented by atmospheric air, which begins to be sucked into the system simultaneously with the appearance of vacuum in it. Thus, the water seals in the plumbing equipment remain in place and successfully prevent unpleasant sewer odors from entering the apartment.

How to properly design a fan ventilation system and how to avoid mistakes in doing so, read our material:

Sewer ventilation system design

There are two most common and accessible ways to prevent unpleasant odors from entering a room:

- Water seal

- Fan pipe

- Air valve

Application of a water seal

If we look at the design of the water seal in more detail, we will notice that it has the shape of the letter U. That is, when water enters from one edge, the tank is filled from both sides. Since the threshold on the side of the connection with the sewer pipe is lower, the water drains from that side, allowing all waste to be discharged outside. After the water is turned off, the lower part of the valve remains filled with clean water, which acts as a barrier to the gas escaping inside.

It is worth mentioning that if you do not turn on the water for a long time, it is necessary to refresh the water in the seal so that it does not stagnate and begin to become a source of an unpleasant odor.

Installation of a drain pipe

If we simply talk about the design of the ventilation riser, we can say that it is similar to a conventional system of ventilation networks in apartment buildings. The drain pipe is a ventilation system that is connected to the main riser at its highest points to prevent wastewater from entering the system.

The other end of the vent pipe is located on the roof to exhaust air directly to the street without creating unpleasant odors in the room.

If there are water seals at each node, this design copes with the removal of gases to the street, but if we return to the situation of vacuum formation, then the entire system in general will not be of any use, since the water seals will be drained.

Application of air valve

The essence of this design is to ensure air flow while draining large amounts of water. In such a situation, instead of draining the valves, air will enter the pipe. Since it has less resistance than water, the valves will remain filled and clean air will fill the pipe. The design is designed in such a way that supply air is taken from the utility room of the building. For example, an attic.

Clean air will flow from the attic into the created area with rarefied air, and after the water has passed, all the unpleasant odor will go out through the drain pipe to the street.

Sewer riser installation

Before you begin to understand why it is blowing from a sewer pipe, you need to understand how the vertical section of the drainage system—the riser—is designed. This is a pipe with a diameter of 110 mm, plastic or cast iron, to which apartment horizontal lines are connected on each floor. Typically, one branch per floor is connected to the riser so as not to overload the pipeline. From below (in the basement) the riser goes into a horizontal pipeline called a basement riser. Its diameter is 110 or 160 mm, connected to the first manhole. The upper part of the riser goes into a pipe that is led out through the roof of the house. It is called a fan pipe. The end is open and serves for ventilation of the system.

The role of the drain pipe is very important. When water is drained in one burst, a vacuum occurs in the riser. The drains act like a piston, pushing the air down from the pipe. There is excess pressure in the lower part and lack of pressure in the upper part. Because of this, sometimes it blows from the sewer in the apartment if the water plug in the siphon could not withstand the vacuum. Failure of the water seal is an extremely undesirable situation, which can be corrected with a drain pipe. It allows air to pass through, balancing the pressure at the top of the riser.

Sometimes, if the riser structure is damaged, a ventilation (or sewer) valve is used. it performs the same function as a fan pipe - when a vacuum occurs, it opens and lets air in, equalizing the pressure and protecting the water seal. However, if air from the sewer enters the apartment, it means that the pressure in the riser is excessive. In such a situation, the air valve will not help; it only works when a vacuum appears. The problem will have to be solved by other means, the main one of which is cleaning the outlet of the drain pipe.

Materials for organizing ventilation

In the modern world there are a lot of materials that can be used as sewer pipes and for ventilation.

For years, fairly massive and heavy cast iron pipes served as the main material. In multi-storey buildings that were built during the Soviet Union, the use of cast iron or steel systems is quite common. Most often, this structure is repeatedly damaged, or rather damaged by corrosion. It is recommended to replace such pipes immediately. As a last resort, carry out local repairs using modern materials that can combine pipes of different diameters. There are a lot of disadvantages when using cast iron:

- Difficult to install.

- Additional loads on the floor.

- Requires regular maintenance.

- Subject to corrosion.

- High price.

All this together caused quite a lot of inconvenience, which was eliminated when plastic pipes were released for sale.

- The first thing I would like to note is that this material is absolutely not susceptible to corrosion, which increases the service life tens of times.

- Each pipe, as well as each corner, is equipped with rubber cuffs that prevent water and unpleasant odors from escaping.

- Any design is easy to assemble, which greatly reduces installation time.

- Use minimal effort for maintenance. If the structure is not disassembled, then when assembled it can last more than 10 years. Important. For long-term use, cleaning is necessary. To do this, it is enough to use one of the chemicals, of which there are quite a lot on the shelves of household chemical stores. Since the procedure is performed quite rarely, it is not worth saving on it. It is better to purchase a high-quality product that can properly remove plaque.

- The cost of plastic is much lower than the cost of metal, making it even cheaper to design everything from scratch.

The ventilation system uses the same pipe as the main riser. That is, the diameter of the pipes must be completely consistent. In addition, the connection will be much easier.

Installation rules

To properly install a fan riser, you must comply with the following requirements:

- The outlet of the riser should not go into the attic, but into the street. If sewer gases escape into the attic, it will smell bad and the humidity will increase (which will lead to mold).

- The diameter of the drain riser must be no less than the diameter of the sewer riser. More is acceptable, but not required.

- The pipe outlet should not be located close to a wall or near other structures (windows, balconies). Otherwise, stains from gas emissions may appear on the wall, and an unpleasant odor will be felt in the rooms near the outlet.

- The outlet should not go under the roof overhang, otherwise in winter the pipe may be damaged (due to ice or melted snow).

- For private houses, it is enough to use 1 vent riser. Lines from all plumbing points must be cut into it using tees, crosses and adapters.

- There must be a temperature difference between the lower and upper points of the pipelines (it’s warm at the bottom, cold at the top).

- The fan riser can be laid in the ventilation shaft, in one box. However, it should not be connected to ventilation ducts leading to residential premises and chimneys (according to SNiP).

- It is permissible to connect several sewer pipes to one drain riser.

Installation rules (video)

Types of scheme

According to the “direction” of the output, there are 2 options for laying:

- Horizontal - when the pipe is discharged not through the roof, but through the wall. The method is relatively rare and can only be used in private construction, in cases where for some reason the output cannot be made through the roof. In this case, a grille is installed on the hole, not a deflector.

- Vertically - the most common option: the riser is led up through the roof.

Vertical passage, in turn, is divided into 3 more subtypes:

- An outlet with a slope of 90 degrees: a branch is made from the riser at a right angle, from which there is then another branch, and from this there is a straight section extending above the roof.

- An exit with a slope of 45 degrees: a branch is made from the riser at an angle of 45 degrees, another branch is made from it, and from this there is a straight section extending above the roof.

- Vertical outlet: The riser simply continues until it exits above the roof.

The exhaust pipe exits through the roof: how is it done and what height should it be?

The section of the vent riser located outside, above the roof, must meet certain requirements:

- The height above the roofing material of the roof in use must be at least 3 meters.

- The height above a flat roof that is not in use must be at least 30 cm.

- The height above the pitched roof must be at least 50 cm.

- The horizontal distance between the pipe outlet and the nearest window (balcony) must be at least 4 meters.

- The outlet should be covered by a deflector on top. It is needed to prevent debris, insects, birds, and precipitation from getting inside.

If it is possible to draw a line through the pediment, it is better to implement this option rather than passing through the roof. In this way, you can save yourself from troublesome work with roofing material and further sealing.

How is the output through the roof made? (video)

Installation errors

The installation of a ventilation riser for a sewer system may be carried out with errors. Of the most common:

- Dismantling the riser (intentionally or unknowingly) in apartments (multi-storey buildings).

- Output under the roof overhang.

- The use of pipes of different diameters when creating a sewer system.

- Output of the riser to the attic.

- Fastening the riser to the external wall of the building.

Do you need soundproofing for a drain pipe?

Sound insulation is needed if the pipe passes through living rooms. In this case, the noise of water and air will be heard in the rooms. The pipeline itself will also make noise due to vibration and resonance.

Noise insulation of areas passing through non-residential premises is not required. If the riser is laid in the wall, and the thickness of the partition is small, then at the construction (repair) stage it is recommended to perform at least “light” sound insulation.

Ideally, the issue of sound insulation should be addressed at the design and construction stage of the building. The riser needs to be “hidden” in a separate box (shaft), or planned so that it does not pass through the living quarters. It is also recommended to use special “silent” pipes (thick-walled polypropylene products).

The sound insulation process itself is carried out using “shells” or roll insulators that are wound onto the pipeline. The thicker the layer, the more effective the insulation will be.

Is it necessary to insulate the drain pipe?

Insulation of fan risers is necessary more often than sound insulation - because warm, moist air, rising up the pipe, will condense on the walls and freeze. As a result, the pipeline freezes, becomes clogged, and stops working properly.

Insulated section of pipeline in the attic

It is necessary to insulate areas passing through unheated rooms (attic, basement).

Insulation is done in the same way as sound insulation: using rolled heat insulators or “shells”, which are fixed around the pipe.

Replacing a drain pipe: operating rules

It is necessary to replace the pipe (a section or the whole) if it is damaged or severely clogged (important for old cast iron structures).

In short, the replacement process is divided into 2 stages:

- Dismantling the old line.

- Installation of a new line.

The main rule of work when replacing a riser in apartment buildings: before replacing a section in your apartment, you must notify your neighbors about the time of the work. During this period, residents will not be able to use the toilet, sink, sink, bathtub, or washing machine.

Briefly, the dismantling process looks like this:

- The riser is completely turned off.

- All connections to the riser are cut off.

- The riser itself is dismantled.

After this, a new line is installed, to which the taps are connected in series.

How and why is fire protection of air ducts done?

Where are fabric air ducts used and why are they good: a review of textile ventilation

Related Posts

The use of sewer ventilation in a private house

Often, when building a new house, the question arises: is sewer ventilation necessary in a private house?

It is certainly necessary to use a ventilation system for private housing construction, even though the system of a private house does not allow such a large amount of water to pass through as a multi-storey one, a ventilation system must be installed.

This is done for your own safety. In order to avoid poisoning from decomposition products, it is necessary to allow air flow into the pipe.

Fan ventilation on the roof

Exiting the vent riser to the roof

Why does the vent pipe have to go through the roof? If in a multi-storey private house there is a bathroom on each floor, and it is connected to a common sewer line, then when sewage enters the common riser, a rarefaction of air occurs. It is to this zone that the air will tend to. In this case, an exhaust pipe is required from the roof to the bathroom ventilation system. Thanks to the flow of fresh air from the roof, the pressure in the sewer system will be balanced.

The vent pipe is installed only on the roof and does not end in the attic. It is also not recommended that the pipe go to the gable. This will promote the development of fungus due to the escaping fumes. Although, as an option, the wall of the house can be treated with antifungal agents. Another important condition is that this pipe must be installed at a distance of 4 m from the windows of the house.

The SNiP requirements state:

- the exhaust pipe of the sewer riser is led to the roof of the house at a distance of 0.2 m, if the roof is pitched or flat;

- the distance from the balcony should be 4 m.

If the attic is cold, then the background pipe must be insulated. According to current regulations, it is prohibited to install a protective structure against precipitation on top of the pipe (clause 8.2.18 of SP 30.13330.2012). You can equip the pipe with a grill; it will protect the system from birds or other small animals.