Why and what is this for?

There are several cases where it is necessary to replace sewer cast iron pipes with a diameter of 110 mm with plastic ones :

- during the construction of a private house, when it is necessary to “cut into” the central pipeline;

- with a complete update of communication systems, if a major renovation of the home is being carried out;

- when installing new or replacing old meters.

When they update plumbing or change the sewer system, they often encounter unpleasant surprises. The most common among them is the presence of old cast iron risers, which need to be somehow connected to new plastic pipes.

But before you begin installation, you need to consider that:

- sewer pipelines cannot narrow in the direction of movement of the filling medium;

- the presence of protrusions and burrs should not be allowed, as they will cause clogging of the pipe in the future;

- In cases where liquids transfer from plastic pipes to cast iron, it is necessary that the plastic is inserted into the cast iron, and not vice versa. Only in such cases will there be an expansion.

Table. Dependence of price on linear parameters of plastic pipes

In everyday life, plastic pipes with diameters of 50 and 110 mm are very popular for laying water supply or sewer systems. A significant advantage of these products is their reasonable price, as can be seen by looking at the table.

| Dn, mm | E, mm | Length, mm | Price 1 piece, USD |

| 50 | 1,8 | 500 | 0,52 |

| 50 | 1,8 | 1000 | 0,97 |

| 50 | 1,8 | 3000 | 2,68 |

| 50 | 3,2 | 1000 | 1,56 |

| 50 | 3,2 | 2000 | 2,92 |

| 110 | 2,2 | 500 | 1,22 |

| 110 | 2,2 | 1500 | 3,45 |

| 110 | 2,2 | 3000 | 6,20 |

| 110 | 3,2 | 1000 | 2,92 |

| 110 | 3,2 | 2000 | 5,52 |

Characteristics and range of materials plus GOST standards

To create high quality industrial products, standardization was introduced. This also applies to polymer communications. Each enterprise engaged in the production of polypropylene, polyvinyl chloride, polyethylene pipes is guided by GOST standards. These regulatory documents reflect the main requirements for manufactured products, determine their technical characteristics and parameters.

Information about quality indicators and the scope of application of polypropylene pipes is reflected in regulatory documents, the main one of which is GOST R 52134, which came into force in 2003.

Important! The standard regulates not only the quality, but also determines the main parameters of pipes made of various plastic materials. Plus, the document contains the necessary requirements for fittings used in heating and water supply networks.

GOST also defines those indicators that directly affect the service life of products:

- duration of operation;

- pressure;

- temperature range of application;

- safety factor.

Products for sewer communications must comply with GOST 32414, which came into force in 2013. In addition to the usual linear dimensions, the document indicates how the wall thickness of the product corresponds to its diameter. Both indicators increase simultaneously. For example, for products with a diameter of 110 mm, the wall thickness is from 3.4 to 4.0 mm - S16 series, and from 2.7 to 3.2 mm - S20 series (both series belong to the “Sewer pipes” category).

GOST standards for polypropylene communications provide not only requirements for diameter, length, and the ability to operate in a certain temperature range at different pressures.

In addition to these parameters, according to GOST R 52134, there are a number of other general requirements:

- round cross-section shape;

- mandatory belonging to the pressure type;

- Possibility of use for industrial purposes, in residential and non-residential premises;

- a real opportunity to withstand the transportation of coolants, drinking and industrial water.

We use a 110 mm cuff

What is the best way to switch from cast iron risers to plastic sewer pipes with a diameter of 110?

Cuff diameter 110 mm

There are several ways to switch from cast iron to plastic with a diameter of 110 mm. The simplest and cheapest is the transition with a cuff. Preparations for work should begin by dismantling unnecessary sections of the old cast iron pipe. The easiest way to do this is with a grinder. To avoid all sorts of negative consequences, you should wear goggles and a respirator before work.

You need to start cutting approximately from the middle of the pipe, and then try to rotate it around its axis, if possible. The rest of the pipe may either burst into several pieces, or you can simply pull it out. In any case, it is necessary to clear the space for the new plastic riser. After this, begin cleaning the outer and inner parts of the socket from the possible presence of rust, old sealant, and hardened pieces of cement mortar. After this, using coarse sandpaper, polish as much as possible the inside of the bell, dry it, remove unnecessary dirt and dust, and degrease it.

Important! You should remember that cast iron is fragile, so cleaning must be done very carefully so as not to damage the socket. Now you can begin installation.

To do this you need:

- Apply silicone sealant to the inside of the socket.

- Coat the outer part of the rubber cuff with sealant.

- Place the cuff inside the socket, making sure that it fits completely into the hole.

- Insert a plastic pipe into the socket, securely fix it and secure it with a clamp or other means.

Since now you can purchase a cuff, adapter, seal of any parameters, in this way you can make the transition from cast iron to plastic not only DN 110, but also for other nominal diameters.

For example, when replacing a section of an external sewer system, a taper or a 110x124 transition coupling is used, which ensures a smooth transition from cast iron to plastic.

The minimum price of this method of connecting cast iron and plastic pipes is the main advantage of this relatively easy technical operation.

The main methods of connecting a plastic pipe to a cast iron pipe

The choice of method for connecting cast iron and plastic pipes is based on the diameter of the remaining section of the old pipeline and the cross-sectional area of the new pipe. Ideally, the plastic pipe should be smaller in diameter than the cast iron frame so that it can be placed inside and the resulting gap can be sealed using available means.

We recommend that you read: 5 ways to connect metal-plastic pipes

Connection using a press fitting

If the diameter of both pipes is almost the same (usually 50 and 110 mm pipes are sold in stores, which corresponds to the size of cast iron pipes in old apartments), then compression fittings are used for connection.

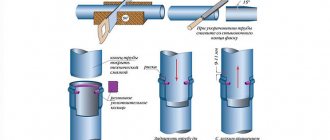

A press fitting is a product that has a metal thread at one end and a plastic socket at the other. To connect cast iron and PP pipes, a fitting is placed with a thread on a section of cast iron pipe, after which a plastic pipe is inserted into the socket.

To seal the joint, an additional rubber gasket (seal) is used. Procedure for connecting plastic and cast iron pipes:

- a section of an old sewer pipe or riser is cut off with a grinder and cleaned of rust and dirt;

- the remaining edge is cut again so that a chamfer is obtained at an angle of 45-60 degrees;

- the chamfer is treated with technical lubricant (for example, grease);

- using a special device, a thread 30-50 mm long is made on a cast iron pipe;

- Apply plumbing paste to the resulting thread and wrap it with tow;

- screw a press fitting onto the prepared thread;

- a plastic pipe is inserted into the plastic socket, having first put an o-ring on it.

Attention! There is no need to apply excessive physical force when installing the fitting on a cast iron pipe. Due to the fragility of the metal, a crack may form on the pipe, which will further complicate the task - you will have to work with the grinder again.

Connection using an adapter

This method is suitable if the plastic pipe and the rest of the cast iron riser have almost the same diameter. Using an adapter, you can easily connect two pipeline elements, achieving a sealed joint.

This adapter is a flexible and elastic rubber cuff that is very easy to install:

- the cast iron pipe is cut to the required size and cleaned of burrs, rust and dirt;

- sealant is applied to the pipe section to a width of 50 mm;

- a rubber cuff is placed on a cast iron socket;

- A plastic pipe is inserted into the free end of the adapter.

We recommend that you read: Choosing a machine for high-quality welding of polyethylene pipes

Important! Sealant is not only possible, but also necessary to be used if a section of cast iron pipe is very worn out and has chips and cavities on the inner surface. In this case, using liquid silicone you can compensate for this defect, achieving a high quality connection.

Pipe caulking

This is the oldest, but quite reliable connection method, which was used for any metal pipes of different diameters. The essence of the method is simple: a fragment of a pipe of a smaller cross-section is inserted into a pipe of larger diameter, and the resulting internal gap is filled with tow and a special polymerizing solution.

Connecting a cast iron and plastic pipe using this method looks like this:

- plumbing paste, flax tow or FUM tape are applied to the edge of a PVC or polypropylene pipe;

- the prepared plastic pipe is inserted into the socket of the cast iron cut;

- tow is stuffed into the gap between the pipes to 2/3 of the height, using a screwdriver or a simple wooden stick;

- A sealing compound is poured over the tow layer.

Attention! The composition can be prepared with your own hands from a dry cement mixture, water and PVA glue. After filling the gap, you must wait 24 hours for the sealing layer to harden. Until this time, the use of sewerage is prohibited.

Silicone sealing

This is the simplest, easiest and most affordable way to connect two pipes from different materials, taking a minimum of time. Its essence consists of applying a thick layer of paste-like silicone to a plastic pipe, which is then inserted into a cast iron socket. To do this, it is advisable to buy a special sealant at a hardware store.

Pipes can be sealed with silicone only if three mandatory conditions are met:

- the cast iron socket remaining after cutting the pipe must be intact and free of damage;

- the difference in diameters of cast iron and plastic pipes is no more than 2 mm;

- A plastic pipe is placed in a cast iron pipe, and not vice versa.

Connecting pipes using silicone is carried out as follows:

- The cast iron pipe is cut with a grinder and cleaned of burrs.

- The joint on the cast iron pipe is cleaned of dirt and degreased using a special solution.

- Silicone sealant is applied to the end of a section of plastic pipe 30-50 mm wide.

- The plastic pipe is inserted with force into the cast iron pipe so that a small amount of sealing material comes out.

- The connected pipes are left in this form for 3-5 hours for the silicone to polymerize. At this time, you must not touch, move, or twist the pipes.

We recommend that you read: Application and design features of gate valves

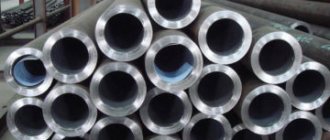

Flange connection

This method of combining plastic and cast iron pipes is used quite rarely, often in industrial settings.

To make a flange connection, you need to put a flange element of suitable diameter on top of two pipes and weld it using a welding machine or fix it with hardware.

Using a coupling

If you want to connect cast iron and plastic of the same diameter, then use a conventional coupling to carry out this procedure. Before installation, it is necessary to thoroughly clean the desired part of the surface of the cast iron pipe from contamination and rust, and then sand it with coarse and fine-grained sandpaper. Then connect the pipes, and for greater security, tighten the edges of the coupling with clamps. If the pipes are of different diameters, then you can use a taper or a transition coupling.

Transition with and without bell

Let's consider 2 cases of how you can qualitatively connect a plastic pipe to a cast iron one: with a socket and without a socket.

So, we have a pipe with a socket to which we must connect a plastic pipe.

In order to connect “plastic” to it, you need:

- purchase a cuff of the required diameter;

- clean the bell from dirt and remnants of old embossing, after which it should be dried;

- Apply silicone along the inner contour of the socket, making sure that even the smallest recesses are tightly filled;

- apply silicone sealant to the outer part of the cuff;

- insert the rubber seal into the socket;

- insert a plastic pipe into the cuff.

After the silicone has dried, you need to check the functioning of the system.

If there is no socket, you should carefully cut the pipe, clean and align the end. In order to carefully insert a cast-iron riser into plastic, an adapter pipe made of plastic with a larger diameter than in a cast-iron product is often used.

The work is carried out in the following sequence:

- clean the old riser from dirt and dry it;

- in the place of future joining, cover the cast iron pipe with sealant and put a cuff on it;

- Slowly, slowly, so as not to damage the product, put a plastic pipe on the other end of the cuff.

Further up to this adapter, you can connect other pipeline elements.

Installation rules

The connection is made in several ways. The choice depends on the possibility of caulking the fasteners. In addition to rigid fittings, rubber sewer products are used - cuffs or reductions. They find their application when connecting washing machines and dishwashers whose drain holes have a diameter of 32 mm.

Experts do not recommend using silicone, linen cables or sealants when joining plastic products. They are successfully replaced by rubber sealing rings. If leaks appear after installation, the skewed ring should be corrected.

Elastic seals have quite high rigidity, so installation difficulties arise. In this case, the end on which the seal is placed is coated with liquid detergent.

Rubber cuff

If the old pipe was pulled out of the socket easily and the integrity of the cast iron surface was preserved, the end of the plastic pipe is inserted into the extension by 3 or 8 cm. A quick and high-quality connection can last 8 years.

For plumbing fixtures that are located close to each other, there are 2 outlets to the riser. One with a diameter of 100 mm is used when connecting drains from a bidet and toilet, the second - with a diameter of 50 mm, for sinks, bathtubs and showers.

Algorithm for connecting polymer wiring to a cast iron socket:

- the inside of the cuff is cleaned of rust and dirt;

- to prevent leaks, sealant is applied to the outside of the rubber product;

- insert the tape.

At the last stage, a connection is made to the polymer pipe.

Plastic fitting

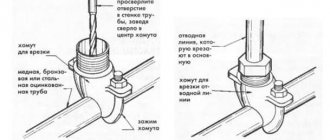

Sewage adapters from cast iron to plastic are used in cases where the cut of the metal pipe does not have a socket. In addition, cast products often have diameters that differ from the standard, for example 60 mm. The connection is made using a 50/72 mm taper.

According to the diagram, the assembly looks like this: plastic pipe, coupling 50/50, rubber ring, adapter itself 50/72, elastic cuff, seal, cast iron pipeline d 60 mm.

Procedure:

- the old metal pipe is cut evenly;

- put a rubber cuff on the stripped end;

- apply sealant to its inner edge and the top of the plastic fitting;

- insert the adapter into the seal.

All that remains is to insert the polymer pipe into the prepared end through the coupling. The size of the cuff and taper must match each other.

Application of a special press fitting

To eliminate problems in the existing sewer system, as well as when combining cast iron pipes with plastic ones, you can use a special press fitting (see photo).

Its advantage: increased service life (within 50 years!) and the ability to withstand high pressure.

Installation should begin by cutting off part of the old pipe, regardless of whether there is a socket or not. To remove burrs, clean the cut end well with coarse sandpaper, straighten it with a file, and then spread it with grease or mineral oil.

After this, you need to cut a thread (4-5 cm wide), onto which you wind a special thread for plumbing work. Then take a press fitting (GOST ISO 2531-2012), and without much effort screw it to the ends of the plastic and cast iron pipe. After supplying water to the system, it is necessary to tighten the connecting product again. Simple and reliable.

Connecting cast iron with plastic: main difficulties

The main difficulties in repairing sewer structures arise when switching from cast iron to plastic and vice versa. This is due to the need to preserve the basic functions of the sewage system, consisting of dissimilar materials - tightness and minimizing clogging.

Cast iron, due to its relative fragility, requires a careful approach during installation. As for plastic elements, they have a number of restrictions on such a parameter as the temperature coefficient of linear expansion.

The difficulty of switching to cast iron and back is often associated with different diametrical sizes of the pipes being connected. Sometimes it is very difficult to select an element that will ensure the tightest possible connection in a socket due to the difference in the cross-section of the products being fastened.

In this case, special adapters, compensators and fittings are used along with sealants, FUM tapes and other materials that can provide the required level of sealing of the connection.

As a rule, the sewer system is not subject to excessive internal pressure due to the absence of a large pressure of sewage and wastewater, therefore the method of replacing individual sections is most often used.

Options for switching from cast iron pipes to plastic in our catalog

Rubber collar for transition from cast iron to plastic

Transition from PVC to cast iron (without cuff)

Transition to cast iron complete with rubber cuff for external sewerage

Transferring to the smooth end of a cast iron pipe from the smooth end of a plastic pipe

Tips and tricks

In order to make the transition from a cast iron pipe to a plastic one without any problems, you need to follow the practical advice and recommendations of experts.

- Proper preparation should be made for repair work. This means that you first need to decide on the area that requires replacement and the amount of material needed.

- Prepare all the necessary tools: an adjustable wrench, gas (pipe) wrenches, a grinder, a mallet or rubber hammer, a sealant, etc. Depending on which joining method is chosen, other materials and tools may also be needed during the work process.

- Thoroughly clean the bell from dirt, mortar residues or other old sealant, and sand with coarse sandpaper.

It should be remembered that:

- The easiest way to dismantle old cast iron pipes is with a grinder;

- you cannot break off an old cut pipe, since you cannot foresee how it will break off;

- to avoid chipping, strike the pipe with a wooden or rubber hammer;

- it is necessary to equip an inspection hatch;

- to avoid paying twice, do not use cheap, not always high-quality, Chinese fittings;

- You can get rid of cracks using silicone;

- when using silicone, avoid mechanical impact on the joints for 4-6 hours until the polymerization process of the substance is completed;

- Sealing with silicone is possible only if the joints are completely immobile, otherwise the tightness may be broken;

- You can get rid of old sulfur filling using a blowtorch or gas torch. Doing it carefully in any other way will not work. Remember that sulfur vapor is toxic, so it is best to wear a gas mask when performing work;

- To prevent damage to plumbing fixtures, it is better to disconnect the bathtub, toilet, and washbasin from the system. If a cement base is also used to secure the toilet, then it is better to immediately break it and remove it in parts, since it is unlikely to be able to be carefully removed;

- During installation, do not forget that there is a big difference in the coefficients of thermal expansion between cast iron and plastic.

Preparatory stage

During repair work with cast iron and plastic pipes, care should be taken; it is advisable to use a rubber or wooden hammer. This is necessary to avoid accidentally splitting the fragile cast iron and causing clogging of the channel.

During the installation of plastic pipes, it is worth taking care of the presence of inspection hatches. They will allow in the future to diagnose the condition of the pipe in case of any problems. Please note that for a riser with a cross-section of 110 mm, it is optimal to use pipes with a diameter of 50 mm.

To connect sewer pipes from cast iron to plastic, you will need the following devices and consumables:

- plastic pipe of the required size;

- connecting elements;

- adjustable wrench;

- grinder or hacksaw for cutting pipes;

- hammer with a wooden or rubber head.

Connecting elements can be all kinds of fittings, adapters, couplings, sealing gaskets.