Well filter

The above indicates that the water in the well is not of high quality, so before use it must be purified using a filter.

In addition to the obvious factors indicating low quality water (sand, silt, etc.), it contains a lot of harmful impurities:

- Iron. Its permissible limit is 0.3 mg/l. When the threshold value is increased, the water becomes cloudy, leaves stains on plumbing fixtures and has an unpleasant odor. A properly selected filter will help solve this problem.

- Hydrogen sulfide. Its presence is indicated by an unpleasant odor. You should not drink this water: it can be poisonous.

- Increased mineralization. The salt content in drinking water should not exceed 1000 mg/l. Otherwise the liquid will be salty.

- Nitrates. They can negatively affect the heart and blood vessels. Their norm is 45 mg/l for adults and 10 mg/l for children.

- Bacteria and viruses. They can cause various pathologies. These harmful microorganisms enter the water from the environment.

A properly selected filter will help protect against problems caused by poor water quality. Its installation is especially relevant in water pipelines originating in wells that are subject to frequent clogging.

The filter must be changed regularly. The period of its correct functioning directly depends on the quality of the water. It increases with regular cleaning of the water source.

Purification can be carried out not only from various debris (for example, sand or silt), but also from harmful microorganisms and substances that affect water quality.

Such events cannot be carried out independently. To do this, specialists from the sanitary and epidemiological station should be involved. In this case, the water from the well will not be drinkable for a certain period of time.

Archimedes' laws in the service of a summer resident

This is a method that allows you to independently clean a well from sand and silt, resorting to the laws of Archimedes, known for several thousand years. A well shaft is a kind of vessel with liquid. It is necessary to lower a pipe into it, into the bottom of which air under significant pressure is supplied through a compressor. Due to this, an air-foam mixture appears in the pipe. Thus, the water column rises through the pipe and comes out.

Well cleaning with a compressor should be monitored. Blowing stops when the water runs out. Together with the water, all the debris present in it rises through the pipe.

Preventing blockages

To prevent the well from silting up, you should adhere to the following rules for operating a well source:

- The electric pump used and water consumption must correspond to the flow rate of the well; with significantly higher rates of the latter, the likelihood of stagnation in the source and, accordingly, siltation increases.

- The immersion height of the electric pump from the bottom level must match the recommendations given in the instructions.

- Under no circumstances should submersible vibration pumps be used for water intake - in addition to low performance, they create vibrations that contribute to the compaction of sand and silt deposits in the bottom area.

- It is necessary to avoid interrupting the operation of the source for a period of more than two months. If possible, at least 100 liters of water should be pumped out during this period.

- To avoid penetration of surface and ground water and dirt into the borehole channel, be sure to use a cap or cover that covers the end of the upper pipe of the casing.

Rice. 15 Cleaning work

When solving the problem of how to clean a well with your own hands, they use various methods using electric pumps, compressors, mechanical devices in the form of bailers or heavy blanks. When carrying out work on your own, it is better to start with the simplest operations - the source is cleaned by pumping with a vibration pump or compressor; if the result is negative, you can move on to the technology of lifting soil with a bailer or water hammer. If these operations do not bring results, you can always use the help of specialized drilling companies that are highly likely to cope with the task in a short time.

Preventive measures

It is almost impossible to prevent contamination of wells with silt and sand, since these materials carry groundwater with them, and the violation of the integrity of the soil structure is an excellent place for their accumulation. But it’s not difficult to protect yourself from various debris getting into the mine. To do this, you need to close it carefully. This can be done with various materials, such as sheets of tin.

If the mine has a shallow depth, then the shaft can be lined with wood, concrete, etc. Often, ordinary wells act as a place for water intake. They are finished with reinforced concrete rings.

It is worth understanding that even timely preventive measures taken do not provide a 100% guarantee that the well will not be clogged. They only allow you to increase the time between cleaning. In other words, a well-maintained well can be cleaned once every 2 years, and an unmaintained well can sometimes be cleaned several times a season.

Clean and replace filters in a timely manner, and then you will be provided with clean and tasty water all year round. Moreover, carrying out cleaning activities will not require a lot of effort, time and money from you. Surely one of the above five methods is ideal for you.

Cleaning with a vibration pump

Cleaning of water wells can be carried out using a conventional or special pump designed to pump out a mixture of sand and debris with small stones. Cleaning a well from sand using this method is quite simple. To carry it out, you must perform the following steps:

- lower the hydraulic machine to the bottom and start it;

- all small debris present at the bottom will fall into the water supply and will be discharged outside; this method is also acceptable for those people who do not know how to clean clay from a well;

- during the cleaning process, it is necessary to periodically pass clean water through the system;

- You won’t be able to quickly clean the well with your own hands, because during operation the pump housing can become very hot and must be allowed to rest.

Cleaning wells with a standard “Malysh” pumping unit is permissible if their depth does not exceed 40 meters.

Well cleaning with a vibration pump

Industrially produced electric vibration pumps (Malysh, Rucheek, Rodnichok, Whirlwind) have a standard maximum pressure of 40 m, another modification is capable of lifting water from depths of up to 80 m - these characteristics allow the use of units of this type for cleaning any wells in sand.

Advice: Since during cleaning procedures the electric pump draws water into the bottom area of the well, it is rational to use modifications of vibratory pumps with lower water intake.

Do-it-yourself well cleaning using a pump is carried out in the following way:

- Connect the electric pump to the pressure hose, tie a holding cable to it, tie together the electric power cable, supply hose and cable with ties.

- The vibration pump is lowered to the bottom of the well, after contact with sand, the pump is raised by 100 - 200 mm, fixed to the surface and turned on.

Note: To maintain a constant distance to the bottom, sometimes a large-diameter rigid hose made of rubber or elastic plastic about 200 mm long is inserted into the lower part of the pump housing, securing it to the shell with an external clamp.

- The water raised to the surface is poured into a large-volume container for settling and further use for irrigation and other household needs, or it is redirected to a ditch outside the site.

- As the sand-clay mixture is pumped out, the vibration pump is lowered lower, the cleaning is repeated until clean water appears at the outlet at a pump lowering depth that corresponds to the immersion distance of the main centrifugal electric pump.

When cleaning a well with one vibrating electric pump, it is useful to loosen the bottom layer of silt deposits; for this you can use a massive mechanical pin with teeth or a piece of pipe with sharpened edges and a tied cable. Before pumping, pointed metal objects are thrown into the well several times and then retrieved to the surface using a cable.

Cleaning a well with a pump - diagram of immersion and arrangement of the unit

Method 5: using an airlift

How to clean a well in a country house from sand and silt using an airlift? The method is to use Archimedes' law. What exactly is a well? This is a vessel with water. A water-lifting pipe is placed in it, into the lower part of which compressed air is supplied using an air compressor. A mixture of air and foam forms in the pipe. The water column presses from below on the water-lifting pipe - the process begins, it needs to be controlled so that the water in the well being cleaned does not run out.

Since the bottom of the pipe is located almost on the sand, the sand and water rise and are absorbed by the water-lifting pipe. The task of the person involved in cleaning is to monitor the water level in the well.

Cleaning with an airlift pump is also an effective method. Compressed air is supplied under pressure; at the bottom of the pipe, silt, water, and small stones rise, are absorbed by the pipe and pushed to the surface

As a rule, the wells in the areas are shallow, and a standard vibrating pump or bailer is suitable for cleaning. If the well depth is significant, you can try the mechanized cleaning method. When using a fire engine hose, cleaning the well will be very fast, but it is expensive. Unfortunately, this method often leads to damage, which entails additional costs. If the main source of water in your dacha is a well, choose a cleaning method that is convenient for you and periodically clean it so that there are no interruptions in the water supply, because water at the dacha is the main condition for a comfortable stay.

Conclusions and useful video on the topic

In conclusion, here is a useful video that shows step by step the available method for flushing a clogged well:

Note that cleaning a well from sand and silt can be a very difficult task. And it’s not a fact that you can do this on your own. And by carelessly wielding mechanical projectiles, you can generally cause significant damage to a water source .

At the same time, there is a special technique that very effectively and to a large extent restores the characteristics of wells.

Do you have personal experience in cleaning wells on site? Do you want to share effective methods or ask questions on the topic? Please leave comments - the feedback form is located below.

Main causes of failure

Before deciding how to flush the well, you need to identify the cause of the breakdown. A lot of them. The most common are:

- not off-season use;

- errors made during the drilling process;

- changing the direction of groundwater flow;

- lack of protection against debris entering the mouth;

- incorrect operation of the pumping mechanism and untimely maintenance of hydraulic machines responsible for water supply.

When deciding how to clean a well from sand, stones and other things that impede the water supply, you need to take into account the type of well. It can be with or without a filter device. In any case, well cleaning can be carried out using three methods:

- washing;

- pumping;

- purging.

Cleaning a well with your own hands can be done much faster if there is no filter in its design. This is due to the fact that the equipment for cleaning activities can be lowered to the very bottom.

Of the three cleaning methods proposed above, pumping is the most accessible. It is most often taken into account by people thinking about how to clear sand from a well.

Causes of pollution

It is important for any well owner to know and be able to correctly determine the cause of a sharp deterioration in water quality indicators. Most often, you may encounter siltation of water, which is accompanied by rapid depletion of the resource of the filter system, which does not fully cope with a significant amount of impurities and contaminants. The presence of cloudy or unpleasant-smelling water with foreign matter is most often the result of clogging with silt as a result of:

- movements of soil layers;

- ingress of surface debris;

- crumbling of the walls of the structure;

- long breaks and inconsistent use or violations of re-preservation rules;

- leaching of components from the aquifer;

- violations of well drilling technology.

Pollution is often caused by the use of rotary water pumps, which can only be used at a depth of no more than ten meters. To clean this type of device, you need to use a vibration pump. It is lowered gradually into the well to the very bottom. It is impossible to manually clean the bottom , therefore, in order to fully remove all dirt and sand, you will need to use special equipment that can rid the structure of even very small particles.

How to choose the right cleaning option

It can be difficult even for a specialist to determine exactly why a well’s production rate has dropped. As a rule, pollution is complex. If the pump “drives” sand with water, this does not mean that the soil is not silted.

When cleaning a well with your own hands, you should be patient. You may have to apply several methods in succession and try hard before obtaining a satisfactory result.

We recommend starting with the simplest: pumping with a vibration pump. If pumping does not help, move on to flushing. We start with washing if the source has almost dried up. If there is a lot of sand at the bottom, a bailer will help to scoop out sand.

But it cannot be used for plastic casings, only for steel ones. For polymer barrels we use only bubbling. If there is neither sand nor water in the steel casing, we move on to water hammer technology.

This is, of course, if the aquifer itself has not dried up. Renting a washing machine, of course, costs a pretty penny, but the cleaning efficiency is noticeably higher than when using homemade methods.

How to clean a well at home?

According to the good old tradition, you must first say that the best solution in any case would be to turn to specialists, since they know exactly what to do in a given situation. However, owners will be able to combat pollution in the initial stages on their own. If the amount of work to be done is large, then sometimes it is not possible to cope with the task.

Before you start searching for information, choosing a method of disposal and moving on to preparations, you need to find out what the main signs are that indicate a blockage. These include:

- serious decrease in water pressure;

- its uneven supply;

- very unpleasant smell;

- appearance of sediment.

In the same way, you first need to understand which of the “treatment” options is optimal for the owners and the source, since there are several ways to clean a well at home: washing with water, blowing with air, cleaning with a bailer, water hammer, pump (or two), or (as an addition) the use of chemicals.

There are complex methods that involve hard physical labor and full-fledged “strength training.” There are also simpler technologies where the main work is performed not by people, but by units. But it’s better to start getting acquainted with all the options with the most popular, but not easy, solution.

Cleaning the well with a bailer

This device is the only design that allows you to clean the source manually. A bailer can be made at home, or you can buy it, since these devices are produced by factories and are even used for cleaning industrial wells. This device is a piece of pipe, the lower end of which is often notched. At the bottom of the bailer there is a valve that works only in one direction. This function is played by either a ball or rotating plates.

The operating principle of such a device is as simple as possible. He is abruptly lowered to the bottom of the well. In this case, most of the bottom dirt gets inside the bailer through the check valve. It closes, preventing her from coming back out. After lifting the working tool to the surface, it is emptied, then the operation is repeated. To raise and lower the bailer for shallow water intakes, use a manual winch. When the well is deep, an electric motor (homemade electric winch) is used.

It cannot be said that this option does not have disadvantages. It is advisable to free the casing from liquid. If a manual gate is used, then even two craftsmen will have hard work. In addition, the bailer will be useless when it is necessary to clean a clogged filter and the soil adjacent to it. When working with the device, it is important to act carefully, because if you accidentally miss, you can damage the filter itself. For this reason, at the very bottom it is better to use a different method.

Pumping a well with a vibrating pump

This method differs from the previous one in its maximum simplicity and lack of physical activity. A vibration pump is not recommended for use as a permanent working equipment, but it is the optimal solution for cleaning a source of sand. The reasons are the “omnivorous”, unpretentiousness of the device. He is not afraid of sand or small stones. If the check valve is damaged, replacing it is easy and not at all costly.

As a rule, one of two candidates is used in this capacity: either Baby or Brook. It is unlikely that the equipment will be able to cope with heavy siltation, but it will be effective if the owners need to get rid of a large amount of sand that has appeared in the casing. To purify sources, devices with bottom water intake are used. The vibration pump is lowered almost to the very bottom: the distance from it is only a few centimeters.

As the water intake gets rid of sand, the pump is lowered lower. The maximum duration of the working period is half an hour. After this period, the unit is turned off for a quarter of an hour to rinse and allow it to “come to its senses” - to cool. This method is simple, but it is not effective in all cases, and the operation takes a lot of time. However, if this method does not work, then you can always try another option that may be more effective.

Flushing with one pump

This is another answer to the question of how to clean a well at home. You can get the same result by doing things differently. We are talking about flushing the source using a unit that will be located not in the water column, but on the surface. For such an operation, it is not recommended to use water from a natural reservoir: closed-cycle washing is considered the ideal option. To do this, you need to find a container that can accommodate the entire volume of liquid located in the well casing.

The principle of such cyclic work is also elementary. As the liquid circulates, it will gradually clear itself as dirt passing through the reservoir will settle in it. In this case, a powerful pump is needed; gentle chemicals can be added to the water. An example is food-grade phosphoric acid, which does not cause much harm to the environment, but successfully dissolves lime deposits and rust. It must be quenched with soda; after using such a solution, the source must be washed for at least 6 hours.

The head of the wellhead is replaced with a nozzle, which should direct the reverse flow into the container. Another possible option is to use your neighbors' water supply, but in this case you need to ensure that the dirty liquid drains away: it cannot get into the source. The length of the hose must be sufficient: it is optimal if its end lies at the bottom. The advantage of this method is excellent, safe cleaning of the bottom filter. In this case, he is not in danger of being damaged.

Water purification with two pumps

This washing technology is used for very deep sources, which neither a vibration pump nor a single surface unit can clean. The vibrating equipment simply does not have enough power, so some of the agitated dirt will settle back to the bottom. Two devices will help solve the problem of deep wells. For this double operation, two different types of pumps are used - surface and deep.

The first device will freely supply water to the bottom, and the second will pump it out, simultaneously removing silt and sand from the water intake. As a rule, the downhole “workhorse” acts as a downhole unit; you don’t even have to touch (move) the device. In this case, the liquid supply hose is also lowered to the very bottom. Since operating equipment in “dirty conditions” can hardly be considered easy, you must be prepared for increased wear.

Air purging or bubbling

This method is suitable for shallow wells - up to 30 m. This cleaning is carried out using a compressor, which delivers a powerful stream of compressed air (pressure - 10-15 atmospheres) to the bottom through a sprayer. Along with the bubbles rising to the surface, dirt will also be carried away. In order to guarantee high-quality flushing, it is necessary to organize the supply of new portions of liquid. This part of the operation can be done manually or using a pump.

The second option is a combination. This method involves purging combined with cyclic washing. This technology has a disadvantage: it is the maximum amount of time that the operation takes. If the well is heavily contaminated, it may take several days. A very bad scenario - a couple of weeks. Plus - gentle conditions for the casing of the source itself, and its relatively fragile filter.

Getting rid of dirt with water hammer

This is another method that allows you to successfully deal with silt deposits. Its main disadvantage is its labor intensity. In this case, the working tool is a fairly heavy piece of pipe. Its diameter should be slightly smaller than that of the casing. The end of such a device is tightly welded, and on the opposite side eyelets are made to connect it to the cable.

The well is filled with several meters of water. Additionally, orthophosphoric acid can be used. The work is as simple as possible; it is very similar to manipulating a bailer. The projectile is dropped, then raised, then the operation is repeated. After several hours of continuous operation, the column is filled with water. Then it is washed or pumped. If the effect is not what was expected, then the operation is repeated.

Express method

This simplest option can be considered as an alternative method if the owners have the desire and opportunity to “invite” a fire truck. This method is the fastest and is used when the well is heavily contaminated. The liquid is supplied through a fire hose into the casing pipe, and the dirt is instantly pushed out. Super-high-speed technology has some disadvantages: high costs and potential damage to either the filter or the well shaft elements.

Different types of wells and reasons for their clogging

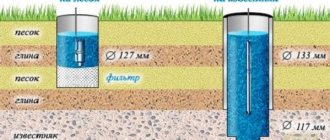

It should be noted that all types of wells, depending on the drilling depth, are divided into three classes: Abyssinian, sandy and artesian.

Modern Abyssinian shallow wells up to 30 m below ground level are constructed from a lightweight casing in the form of plastic pipes of various diameters; due to its low weight, if installed correctly, it is not lowered to the bottom of the underground water layer. Therefore, water from a properly installed Abyssinian well has a small amount of sand and dissolved clay impurities and, accordingly, rarely needs to be cleaned.

Another nuance of Abyssinian wells is the frequent use of a pipeline made of low-pressure polyethylene pipe (LDPE) of various lengths as casing. This allows you to clean the filters and the area below by simply removing the pipe section from the borehole channel.

In deep artesian wells, the bottom of which (bottom area) is located at a distance of 100 m and below from the surface of the earth, a column of casing pipes is installed on a dense limestone bottom - thanks to this, the well practically does not become clogged, and its service life without cleaning works reaches 50 years .

The most problematic from the point of view of operation are wells in sand, the optimal depth of which varies in the range of 30 - 70 m. When installing them, a massive column of casing pipes rests on a sandy-clay bottom, while sand and clay not only enter the water, but and during operation they gradually clog the filter holes, settling in the bottom in a layer that is constantly increasing in height.

Well pumping

In addition to natural inevitable processes, other reasons for the rapid clogging of sand wells are:

- Technical errors during well construction, for example, an incorrectly selected filter at the end of the casing pipes. The fact is that any well in sand has a certain size of sand particles at the bottom - this is taken into account when installing the terminal filter. If its cells are too large, sand will accumulate in the face, the height of the sand layer will increase and it will block all channels of water flow - the flow rate will decrease and the well will have to be cleaned.

- Also, unscrupulous drillers can hand over to the user a well source with fine dispersed sand - such a well will silt up in 1 - 2 years and no amount of cleaning will help.

- Interruptions in operation often cause the well to silt up due to lack of flow as a result of sedimentation and compaction of sand and clay particles suspended in the water. A similar situation occurs in a high-productivity well with a low volume of water taken.

- The use of vibrating electric pumps leads to the fact that, as a result of constant vibrations, bottom sediments of clay and sand are compacted and prevent the flow of water into the borehole channel.

- Incorrect placement of the electric pump also leads to silting; if it is suspended at too great a distance from the bottom, stagnation occurs in the bottom - as a result, sand and clay particles calmly settle to the bottom and gradually clog the filter holes.

Bailer and cleaning scheme

Possible causes of blockage

It is worth mentioning the types of well clogging; this will help identify the causes of the problems and determine how to properly clean the well with your own hands.

No. 1 - penetration of sand into the casing pipe

“Sanding” is a problem encountered in shallow sand wells where the aquifer is located in a sand and gravel layer. In a well-constructed well, sand penetrates into the casing in small quantities.

If the productivity of the source decreases, and grains of sand appear in the water, one of the following happens:

- Sand penetrates from the surface - the head and caisson are not sealed.

- The filter is not chosen rationally; the cells are too large.

- The integrity of the filter is compromised.

- The tightness between the casing sections is broken. The thread is not fully tightened, the welding is performed poorly, corrosion has “eaten” a hole in the steel casing pipe, mechanical damage to the plastic one.

It is not possible to eliminate leaks that appear inside the well. Fine sand constantly makes its way through the filter, but it is easier to remove it; it is partially washed out when the water rises.

Worse, if coarse sand penetrates into the well, over time the source may “float.” That is why special attention should be paid to the quality of installation of casing elements and selection of filters.

Installing a sand separator in the casing significantly reduces sand buildup in the filter and extends the service life of the sand well.

No. 2 - silting of an unexploited well

Over time, tiny particles of clay, rust, calcium deposits, and sediment accumulate in the soil in the filter area.

When their number becomes too large, the pores in the aquifer and the cells of the mesh (perforated, slotted) filter become clogged, and it becomes more difficult for water to penetrate through the mine shaft.

The well's flow rate drops, and it becomes “silted” until the water completely disappears. In a source that is used regularly, the process occurs slowly, stretching over decades. Without regular pumping, a well can become silted in a year or two.

If the well is cleared of silt in a timely manner, without waiting for it to completely dry up, there is a high probability of giving the source a “second life”. Water will be supplied in a volume sufficient to supply water to a private home.

The water entering the well through the filter carries with it small particles of silt. The soil near the filter becomes silted. Calcium salts also accumulate in the suction zone if the water hardness is high

How to prevent clogging of a well

There are no “eternal” wells for water supply. Unfortunately, sooner or later, the owner of an individual water source will face problems. It’s bad if the aquifer has dried up, you’ll have to drill again or deepen the existing excavation. This is difficult and very expensive.

It’s a different matter if a well becomes clogged—it’s easier and cheaper to prevent it than to “treat it.”

Extending the service life of the source is facilitated by following several operating rules:

- Strictly adhere to the selected drilling technology. Carefully monitor the tightness of the casing pipe and the integrity of the filter.

- Immediately after completion of drilling work, flush the source until clean water appears.

- Protect the well from the penetration of surface water and pollution by installing a caisson and cap. As a temporary solution, simply seal the top of the casing.

- Before starting operation, select the correct submersible pump and install it at the required height, always taking into account the flow rate of the well.

- It is advisable not to use a vibration pump to supply water. Vibrating in the casing, depending on the type of soil, it, to a greater or lesser extent, provokes the penetration of sand into the well or contributes to siltation of the adjacent soil. A cheap and simple vibration generator can be used for a short time; for continuous operation you need a centrifugal pump.

- The well should not stand idle without drawing water. The ideal operating mode is daily pumping of several tens or hundreds of liters of water. It is provided if people live in the house permanently. If this is not possible, you should regularly, at least once every 2 months, pump out at least 100 liters of water from the well.

Following these recommendations, of course, will not avoid clogging of the well in the future. However, it will delay this trouble by ensuring the maximum possible resource for efficient operation for a given source.

Proper construction of a well is the key to its longevity. It is necessary to install a special head on the casing pipe, which seals it and serves for reliable installation of equipment

This is interesting: How to properly insulate an attic floor with your own hands: we explain carefully

How not to damage the well during the cleaning process

To prevent damage to the well during cleaning, you should adhere to the following rules:

- Do not use cleaning equipment that is larger than the diameter of the casing, or equipment that is not suitable for cleaning;

- Keep the cleaning work under control at all times, and do not leave the well and pumps unattended;

- If the cleaning is not effective, or large plastic or metal elements are observed in the water that is being pumped out, it is urgent to complete the cleaning and invite specialists to solve the problem.

Method 2: cleaning the well with a bailer

If the well is slightly clogged, and at the same time shallow in itself, you can use a bailer. In other cases, its use will be ineffective. If the depth is 30m or more, you will need a winch, and this method of cleaning will require considerable effort from two strong men.

A bailer is a piece of pipe on a cable with a mesh at the top and a hole at the bottom. It sinks to the bottom, then rises to a height of 0.5 m and drops sharply. Water is drawn inside; inside the cylinder there is a metal ball, which rises after a couple of seconds, and then falls and closes the hole. This cycle of raising and lowering is repeated three to four times, then the bailer is raised and cleared of sand. To make it more convenient to work, you can use a tripod. About 0.5 kg of sand gets into the cylinder at a time, so by cleaning in this way, you can find out how quickly the well becomes clogged.

Photo and diagram of the bailer device. Reviews about this method of well cleaning are both positive and negative. Some people find this method of cleaning very labor-intensive and ineffective, while others only use it. If you can make a bailer yourself, such cleaning will not require any extra expenses, and this is already a plus

You can make a bailer with a ball valve yourself or buy a ready-made one in a store.

This is interesting: Design of a bedroom with a loggia - let's find out in detail

Influence of well type on clogging

Clogging of a well, which reduces its productivity, depends to the greatest extent on its type. Artesian species, the casing of which is located in the area of hard calcareous rocks, are practically not susceptible to blockages - this makes it impossible for suspended impurities to enter the water and affect its functioning.

Shallow Abyssinian wells, in which the casing is located in an aquifer, also produce clean water with a small amount of suspended particles - this significantly reduces the likelihood of clogging.

Wells in sand, the casing of which rests on a sandy-clay bottom, are most susceptible to blockages. At the same time, the likelihood of blockages is highly influenced by the size of the sand fractions - the smaller they are, the more often the well needs to be cleaned. The factor of the size of sand particles is taken into account when drilling - if the sand is highly dispersed, the installation of the casing is abandoned altogether or the well channel is deepened to an aquifer with a more suitable low-disperse soil.

Figure 2. Structural design of well PVC-U filters