A floating sewer (as opposed to an export sewer) transports wastewater through a pipeline. It is built, if possible, without pressure and according to the terrain.

A properly designed drainage network ensures a self-cleaning flow rate with minimal penetration into the ground:

- the sewer slope, pipe material, and the filling of their cross-section are correctly selected;

- Installation and excavation work was skillfully completed.

It is prohibited to lay a sewer pipeline on or above the surface of the ground within the boundaries of a populated area.

SNIP requirements for inclination angle

A pipeline that receives wastewater from the internal sewer system and transports it to a septic tank or to the city network is an external sewer system. However, the volume of runoff from low-rise buildings and outbuildings is small (for a private house 1–5 m3 per day). Its supply and degree of pollution are uneven. Therefore, it makes sense to use the rules and regulations governing the construction of both city and internal sewerage systems.

Design parameters of the drainage pipeline connecting the internal and street networks:

- the smallest diameter and sufficient for efficient operation is 150 mm;

- its characteristic slope values are 0.008–0.01 (for 200 mm pipes - 0.007).

In practice, for an autonomous gravity-flow sewer system in a cottage, the minimum diameter is taken to be 100 mm (then the water supply is “deviated” more strongly).

A prerequisite for installing a floating sewer system is the presence of a water supply system in the building. It will provide a volume of flow (at least 60 liters per inhabitant per day), capable of diluting pollution to an extent that will allow it to be transported by gravity in a closed channel.

Average daily water disposal is assumed to be equal to average daily water consumption minus the volume of water for irrigation. (The presence of hot water supply in the cottage increases the daily consumption - up to 250 liters per person).

The choice of sewerage system (autonomous, local, centralized), the method of treatment and disposal of wastewater are consistent with Rospotrebnadzor, and when discharged into a water body, with Rosprirodnadzor and Rosvodresursy.

Pipeline bottom elevations are determined by thermal engineering calculations or analysis of the use of existing communications in a given area. As a last resort, pipes up to 500 mm in diameter are buried 0.3 m above the lowest level of soil freezing.

One way or another, burial is considered safe if at least 70 cm remains from its top to the surface of the earth (if vehicle passage is excluded - 50 cm).

The maximum drop in pipeline marks is 15 cm per meter. (The highest design flow velocity of the medium is 8 m/s in metal and plastic pipes, 4 m/s in concrete).

The penetration may also be excessive. The weight of which soil layer the structure can withstand is determined by the calculation based on soil conditions, material and size.

When designing an autonomous sewer system, it is necessary to take into account the sanitary and hygienic requirements for autonomous water supply (in particular, to reduce to zero the likelihood of contamination of aquifers due to leaks from underground filtration structures).

Everything about sewerage in a private house: diagram, installation depth, calculations.

Carrying out sewer installation work in a private house with your own hands - read on.

Reliable drainage system around the house: do-it-yourself device.

What rules must be followed when determining the slope?

Summarizing what has been said, we can draw up a list of basic rules regarding the angle of inclination for a sewer pipe.

List of rules:

- Sloping in horizontal sections is necessary only for gravity-flow pipelines.

- Both too small and too large an angle of inclination negatively affect the throughput of the sewer system.

- In most cases, recommended slope values are in the range of 0.01–0.05. The optimal value is 0.02, the maximum is 0.15.

- When laying a pipeline, one must strive for the optimal filling level of the pipe.

Before starting work, it is recommended to draw a network profile with basic data for laying the pipeline and for the future sewer system. Instructions for the content of this document are specified in GOST 21.604-82.

How to choose sewer pipes

Pipes for drainage are selected from the sewer assortment, non-pressure (if the slope allows drainage by gravity and the height of the sewerage facility does not exceed 10 m). The composition and temperature of the liquid, soil properties, the presence of groundwater, its composition, and the depth of the structure are taken into account.

If possible, calculations determine:

- the average daily volume of liquid discharged into the system, the diameter for its passage while maintaining a non-pressure mode of movement;

- slope of the gravity pipeline (depending on roughness, average flow speed, nature of the flow);

- change in transverse shape from pressure from inside and outside.

Pipe materials for gravity sewerage (strong, smooth, waterproof, resistant to corrosion, abrasion): cast iron, ceramics, asbestos cement, polymers (including fiberglass, basalt plastic).

Sewage pipes are designed to transport contaminated water at a temperature of 75 °C (90 °C for a short time).

Unified diameters of synthetic sewer pipes: 32, 40, 50, 75, 90, 110, 160 (mm), ceramic - 150–600 mm (length 8, 10, 12 m), concrete socket pipes - 200–2500 mm, asbestos-cement pipes - 100 –600 mm.

Pipe stiffness is affected by:

- diameter (the smaller it is, the stiffer the product);

- elastic modulus of the material (it is greater for polymer bends, for fiberglass and PVC, less for LDPE).

What diameter of a polymer pipe is considered nominal depends on the method of its manufacture: external - when produced by extrusion, internal - by winding.

Concrete and reinforced concrete are corroded by the transported medium, the gases it produces (hydrogen sulfide, carbon dioxide), and groundwater. Therefore, products made from these materials must be specifically designed for sewerage: have a high density, special additives in cement and are carefully insulated. At the same time, concrete sewer pipes, even of normal strength, are laid to a depth of up to 4 m.

Asbestos-cement is smooth, lightweight, has low thermal conductivity, resists tensile forces well, and is easy to saw and grind. But asbestos cement is fragile and is easily abraded by sand.

Choosing long pipes will reduce the number of connections. Concrete and ceramic pipes are short, structures made from them are demanding in terms of foundation reliability, and are least effective when there is a large influx of groundwater.

Wooden closed trays (rectangular, triangular) made of antiseptic boards can act as a temporary structure.

All the pipe materials described are applicable for neutral or slightly alkaline reactions of the transported medium; for slightly acidic conditions, ceramics and asbestos cement are good.

In a liter of water discharged from the plumbing fixtures of a residential building, harmful substances (mainly nitrogen and phosphorus compounds) are present in quantities of several milligrams. Alkaline and acidic reactions are typical for industrial wastewater.

Features of installing internal sewerage

The features of the slope in the toilet room and kitchen depend on the availability of plumbing in the house. Pipes with a cross-section of no more than 50 mm and an angle of three and a half centimeters are suitable for the sink. One hundred millimeter pipes will fit under the toilet, the slope will be 2 cm.

The required level, as a rule, is laid out using cement, since the pipes are hidden behind a plasterboard box and decorative tiles, or a groove is used, but not every house has thick walls. Wedges and stands are used for laying kitchen pipes. Then the pipeline network is attached to the walls with holders, the distance between the fasteners does not exceed forty centimeters.

Attention! When pulling the pipe, it is better to turn the sockets against the flow of water; the likely occurrence of leaks at the joints is reduced.

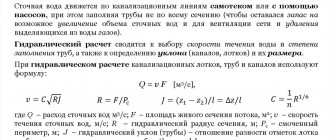

Pipe filling calculation

Filling - the ratio of flow depth to the internal diameter of the pipe (h / d) - can be complete or incomplete (expressed as a dimensionless number from 0.1 to 1.0 or as a percentage).

The sewer pipeline is often designed for free-flow operation with a partially filled cross-section (maximum 0.95). A reserve in the cross-section of a closed channel is needed to pass a flow rate exceeding the calculated one for ventilation.

The flow rate is also important, which will not allow the formation of indelible deposits.

The speed of movement of wastewater should increase along the way.

The calculation of sewer pipelines is carried out by assigning a speed of movement of the waste liquid (v) of at least 0.7 m / s, filling - at least 30%, and so that the condition is met:

- v ∙ (h / d)-2 ≥ 0.5 - for plastic, fiberglass;

- v ∙ (h / d)-2 ≥ 0.6 - for other materials.

If the water flow is so small that it is impossible to fulfill this condition, then the calculated slope for a sewer with a diameter of 100 mm is assigned to 0.02. A smaller drop in meter markings is acceptable for larger diameters, but is not recommended.

The slope of an external sewer system of 160 mm in practice is taken to be no less than 0.02.

The filling, as a rule, turns out to be 0.35–0.4. At the highest design filling, the minimum speeds are:

- v min = 0.7 m/s - at d = 150–250 mm (h/d = 0.6);

- v min = 0.8 m/s - at d = 300–400 mm (h/d = 0.7).

Calculation of sewer pipe diameter

The diameters of the pipes used depend on the number of plumbing fixtures connected to the system, as well as on the slope. There are formulas that can be used to calculate the appropriate diameter depending on the following factors.

Namely:

- number of turns and joints;

- slope;

- number of plumbing fixtures.

In practice, formulas, for example, for installing a sewer system in a private house or inside an apartment, are used extremely rarely, since this is simply not necessary.

Pipes of 100-150 mm in diameter are installed on the section connecting the riser to the sewer well, as well as on the riser itself. If the previous pipe had a diameter of 200 millimeters, then the diameter of the new one should be the same.

Internal horizontal wiring, as a rule, involves the installation of pipes of 100 mm diameter when connecting to the toilet riser. In other cases, pipes of 50mm diameter are used.

Advice! For normal operation of the system and to prevent blockages, the slope of the sewer pipe and its diameter must ensure a flow rate equal to or higher than 0.7 m/s, as well as a pipe fullness of at least 0.3 of the vertical diameter of the pipe.

Minimum slopes of external sewerage

Wastewater received by the internal sewer system of the building (domestic, drainage) passes into the external one. The drainage in the building is discharged by gravity. The outlet lines of the yard network can also be pressure, but only if the terrain and soil do not allow creating the necessary slope of the pipeline (to create a flushing speed in particular) or if it is necessary to drain the basement.

The most important stage in sewer design is drawing up its diagram. Tracing comes down to drawing sewerage elements onto the plan of the sewer object: networks, septic tank (storage tank), wells, etc.

The solution to the scheme is individual for each case, since it is influenced by many local factors:

- configuration, size, object;

- the location of the street sewer or reservoir relative to it;

- terrain;

- ground conditions;

- sanitary requirements;

- economic considerations.

Usually the route is oriented in the direction of large slopes to local treatment facilities, or along the shortest path to the street sewer, parallel to the outer wall of the house, no closer than 3 meters from it.

If the slope of the area is insufficient, then increase the diameter of the pipeline. If the relief falls unevenly, a zone scheme may be required, in which runoff from an elevated area of the terrain is drained by gravity, and from a lower area by a pressure pipeline.

The gravity sewerage pipeline is straight. Only in wells (rotary) can you change its horizontal direction, slope and diameter.

The rotation (without a difference in marks) is performed at an obtuse or right angle.

Inspection wells (for cleaning and inspection of sewers) are installed both in straight sections, if their length reaches four to five tens of meters, and at the point of connection to the street network. They are made of brick, reinforced concrete, polymer materials, with a diameter of at least a meter, and are equipped with a tray connecting the pipes.

Connections of gravity sewerage pipeline parts:

- detachable bell-shaped;

- glued (seam pipes);

- welded (resistance welding), or on threaded metal connections (synthetic pipes).

The thermal elongation of the pipe is less if the water supply is pinched by the soil (due to friction). Temperature deformation is compensated by socket joints (with soft sealing rings). At the edge of the trench, permanent connections are preferred.

The trench along the bottom is made at least 40 cm wider than the diameter. A sand cushion (no thinner than 10 cm) is especially needed for dense, hard soils. The base can also be natural soil (undisturbed, dry during installation).

In order for a hollow horizontal cylinder to withstand greater pressure, it is important to organize a bed that follows its contour - so that it is in close contact with the ground along its entire length, at least a quarter of its circumference.

If the bearing capacity of the soil is weak (or if there is a risk that it will decrease), artificial foundations are needed:

- a layer of crushed stone, gravel, coarse sand 15–20 cm thick (with drainage trays in it) - in water-saturated soil, on a rock;

- pile foundation - in quicksand, peat bogs.

The backfill must be preceded by covering it with soft soil or sand, a layer no thinner than 0.3 m. The backfill is compacted with a hand tool - above the pipe, with a hand mechanized one - at the walls of the trench, every 10 cm.

The crushing resistance of the pipe will increase if you especially carefully compact the soil in the spaces between it and the trench wall.

Atmospheric water can be discharged together with domestic waste and separately - through trays, ditches, ditches. The semi-separated network contains spillway chambers. When rainwater flows are low, they are transferred to the domestic sewer system, and during a rainstorm, they are discharged into the street drainage system or reservoir.

The pipeline is insulated if it is located above the freezing depth: with slag, expanded clay, heat-insulating sleeves.

Slope of trays why and how

Stormwater inlet trays are gravity-flow systems that, for proper functioning, need to create a constant, uniform slope towards the inlet collector. The entire range of characteristics of storm and domestic sewage systems is described in SNIP 2.04.03-85. This document regulates materials, technical requirements, as well as methods of hydraulic calculation and calculation of wastewater volumes. Of course, the main reference when determining the volume of rainwater is to the region, the intensity of precipitation in it, as well as the coverage around the storm channel. The minimum slope of the tray depends on this, which is 3 millimeters per meter of highway.

However, this value is minimal and depends on the coverage around the trays, as well as on the catchment area. The higher the area and the worse the surface absorbs water, the higher the hydraulic cross-section and slope of the system. Do not forget that water drained from the roofs of houses is often discharged here, into the storm drain. Therefore, in this case, the system must have high throughput.

The creation of storm drainage systems largely involves a large amount of excavation work. To minimize excavation work, the industry produces a tray with an internal slope, which greatly simplifies the installation of the entire system. These products already have the required slope. At the same time, the tray itself remains its characteristic shape, and only the inner gutter is subject to slope. In addition, the use of such water conduits significantly reduces the risks of errors and subsequent malfunction of the storm sewer. Such trays are often made of plastic, since it is quite easy to control its shape during production. However, a concrete tray with a slope, which is also produced, is no exception in this series. Such gutters are created by vibration compaction, which allows achieving high geometric accuracy, including the minimum required slope.

Much, when determining the required slope of the system, depends on the roughness of the inner surface of the tray. The lower it is, the less resistance the flowing water flow experiences, which means the higher its speed and the throughput of the entire system. The leader here, of course, are plastic trays, which have minimal surface roughness. This means that the slope of storm gutters made from such gutters can be made smaller.

However, we should not forget that any storm drainage system is not only gutters. Also a mandatory element of the system are sand traps, which work as small settling tanks in which a suspension of large fractions settles. To minimize the frequency of cleaning sand traps, the trays are often equipped with grates that protect the entire system from large debris.

Autonomous sewer ventilation diagram

The presence of ventilation in the sewer pipeline connecting it to the atmosphere affects the flow rarefaction. (∆p, mm water column). Without ventilation, it depends on the flow rate of the water-air mixture. (Air is entrained by wastewater, the more intensely, the smaller the pipe diameter, and hence the flow rate).

The principle of supply and exhaust ventilation is the difference in pressure between outside air and gases in the system. Pressure equalization, compensation for vacuum flow by suction from outside, prevents breakdown of hydraulic valves of internal sewerage.

In addition, ventilation prevents the formation of an aggressive environment: it removes gases (hydrogen sulfide, ammonia, carbon dioxide, methane, ammonia) and vapors that are emitted by the wastewater itself.

Free-flow sewer lines are reliable if the pipes and connections are resistant to corrosion damage not only by the transported liquid, but also by the gaseous environment of the above-water space.

Exhaust ventilation is implemented through elements of the internal sewer network - risers. They are led outside the building through the attic and roof.

The exhaust part of the riser (the one located above the attic floor) is brought to the height:

- 0.3 m from the roof plane;

- from the pitched roof - 0.5 m;

- 3 m - from the roof being used.

The air flow occurs through the covers of the inspection wells, which do not fit tightly to the hatches.

Organization of slope in a private house

The volume of wastewater in a country house is significantly less than in an apartment building. Under these conditions, even with a minimum slope determined from a hydraulic calculation table or formula, the filling level will be insufficient for self-cleaning of the pipe.

It is impossible to reduce the slope even more, since the flow rate will become too slow. Sand with other solid inclusions will settle to the bottom, and the pipe will probably clog. In such a situation, the required angle of inclination of the pipeline is determined by a non-calculation method.

Non-calculation method for determining slope

According to regulatory documents, the non-calculation method is used in cases where, due to the small volume of wastewater, it is impossible to fulfill the condition for the relationship between the optimal and actual filling level.

The old version of SNiP 2.04.01-85 set out the following recommendations on slope for undesigned sections of gravity pipelines:

- Pipe diameter 40 or 50 mm – 0.03

- Pipe diameter 85 or 100 mm – 0.02

The updated version of this SNiP, set out in SP 30.13330.2016, suggests that the minimum slope value for non-calculated sections of the pipeline should be considered equal to 1/d, where d is the outer diameter of the pipe in mm.

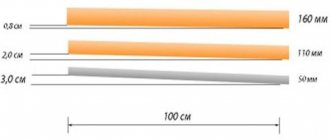

Recommendations from specialists for laying a collector from an individual country house to a septic tank:

- A medium-sized house with two bathrooms - 110 mm pipe with a slope of 0.02

- House with three or more bathrooms - 160 mm pipe with a slope of 0.08

Compliance with the proposed parameters preserves the transporting capacity of the liquid flow in the pipeline.

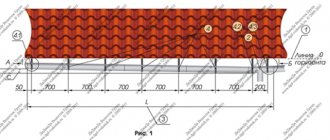

Slope check

The best device for checking the angle of inclination is a level. The device measures the depth of the trench under the pipeline at control points, and the difference is compared with the required value. If there is a deviation from the calculated value, the trench depth is adjusted.

To check the slope without a level, use a simple method using available tools. Two pins are inserted into the bottom of the trench at both ends. The cable is pulled between the pins and the horizontal position is checked using a building level. If necessary, leveling is done.

Then, near both pins, measure the height from the bottom to the cable. After determining the magnitude of the difference, proceed in the same way as in the situation with a level.

In the figure below, the initial depth of the trench is 0.5 m. Based on the recommended slope of 0.02 for a 110 mm pipe, we obtain:

We add the calculated depth difference of 0.6 m to the initial depth of 0.5 m and obtain a trench depth at the end point of the pipeline of 1.1 m.

Solving the problem of a steep slope

If in the direction of laying communications the steepness of the slope exceeds the standard slope, then at some point the more gently located pipeline will come to the surface. The problem can be solved in two ways.

The first option is to make vertical decreasing sections in the pipeline as it approaches the surface. In the second option, a large vertical depression is immediately made, which is enough for the entire length of the collector.

Downgrade scheme according to the first and second options

Prices for materials and installation

The length of communications and their cost will be reduced by the compact location of objects (houses, septic tank - if the sewerage system is autonomous, the connection point to the city sewer - if the drainage system is centralized). When choosing bends, they are guided by their price, costs of delivery, installation, drainage during work.

The cost of construction per unit length of the sewer system is affected by diameter, material, laying depth, and hydrogeological conditions. The volume of excavation work will decrease if the average slope of the terrain and the actual pipeline coincide.

How to choose sewer pipes in a private house, details here.

Everything about connecting to the city water supply network in a private house: documentation, work, prices, sample documents.

The total cost of installing a street sewer system without connecting to a collector in a small suburban area varies from 40, 50 thousand rubles. up to 100. The figures are approximate, reflecting the “order” of prices, since the factors for each individual object vary too much.

The main expense items that form the final amount:

- installation of septic tank or filter pit rings, engineering work (one ring with work - ~ 5,000 rubles);

- digging wells (~ 20,000 for 2 glasses, with lowering rings);

- treatment of rings with bitumen mastic (~ 2000 rub.);

- removal of earth when constructing wells (RUB 2,000–4,000);

- hatch with a lid (depending on the material and load withstand (plastic - 3000–4000 rubles);

- bottom of wells (RUR 3,000–3,500, including work);

- pipeline laying (~ 1000 rubles per cubic meter of excavation work, with laying - ~ 1500 rubles).

If there are problems with the delivery and installation of concrete rings, a brick well may be advantageous.