Life in the private sector in winter is full of problems and difficulties, and the owner of this house has to solve them. And often problems arise precisely with communications at home. For example, the water supply freezes.

This situation in itself is unpleasant. Therefore, everyone should know how to quickly warm up a metal-plastic pipe underground. We will tell you in this article what to do if the water in the pipe freezes.

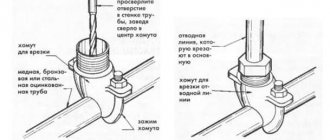

Figure 1. Metal-plastic

Of course, you can always call a specialist who will come and fix everything in a couple of minutes. But doing it yourself will be profitable and easy.

External pipe heating systems

Equipment for heating a pipeline from the outside is based on installing a heating element on top of the pipe, which is controlled remotely. The heating element in such systems is usually a film or wire.

The first type is a wire heater. It is mounted along the entire length of the pipe parallel to the movement of water, or in a spiral manner around the pipe. At the same time, when using the spiral winding method, you should know that this installation method will cost you significantly more than a parallel system, since the spiral will require more heating element.

A cheaper scheme does not guarantee complete protection of the pipe from icing, so in most cases they use a system that combines a spiral and parallel heating element installation scheme. In areas where the risk of icing is quite high, it is advisable to install a spiral "wire" pattern, while in areas less exposed to cold temperatures, a parallel system can be used.

The second type is a film heater. It is mounted along the pipe. The film does not have to cover the entire pipeline; a part of it will be enough. If the heating film completely covers the pipe, heating is carried out using two strips of heating film, which are mounted at the bottom and top of the pipeline. The width of each strip of film should be equal to half the circumference of the pipe.

Ultimately, the installation diagram for a film or cable heater looks like this:

- Initially, the pipe is coated with a primer and covered with a heat-conducting material, such as foil.

- A heating cable is installed on top of the foil, laying it in a spiral or parallel manner. The cable is fixed on the surface of the pipeline with a special tape. The film-type heater is mounted parallel to the pipe and attached to it using adhesive or the same tape.

- Then the entire pipeline is covered with a heat insulator that does not conduct electric current.

Of course, all this work should be carried out directly during the repair or installation of the pipeline. Heating elements must be turned on constantly during the winter period.

Defrosting pipes using a welding machine

This technology for heating pipes was invented by savvy owners of private houses. The method consists of applying electricity to the frozen area from a welding machine. Depending on the degree of freezing, the current can be adjusted down or up. The wires from the welding machine are connected to the ends of the frozen section and wrapped with wire. The equipment is then turned on for about half a minute. After a short break, this process is repeated. If during such exposure the pipe does not heat up, the current of the device is increased.

Industrial systems for defrosting pipelines operate on this principle. The terminals of this device are connected to the ends of the area that needs to be defrosted. The device is plugged into the network and a current is applied to the pipe. Using such a device, a pipe 25 meters long and 6 centimeters in diameter defrosts in about 1 hour, therefore, if the structure has a diameter larger than 6 centimeters, it is better to defrost it in separate parts, it will be faster.

Internal pipe heating systems

Heating of pipes from the inside is carried out by introducing a special heating element into the body of the pipe. It can also be the medium itself transported through the pipeline. In this case, an internal heating element is installed in the pipeline system, increasing the temperature of the flow, thereby ensuring its unhindered circulation. Before heating a pipe in this way, you need to warm up the contents of the pipeline and open all valves, taps and dampers so that the transported liquid has a continuous flow.

There is no doubt that such a technique leads to serious waste of energy spent on heating and the liquid itself transported through the pipeline. As an alternative to this method, when laying the pipe, a wire heating element is inserted into its inner part and positioned along its entire length.

In this case, the output and insertion of the heating element into the pipeline system is carried out using special tees, which is why it is possible to avoid installing the heating system in the area of the shut-off unit of the control valves.

In practice, the internal heater is installed like this. First, two tees are installed in the body of the pipeline. A heating element is inserted into the first of them, located along the flow direction, pushing it to the second tee. Then the heating element is removed from the second tee and the mounting elbows of both the second and first tees are sealed. If necessary, this operation is repeated on another section of the pipeline. Due to the design features, this method of installing a heating element for a pipeline is optimally used on long sections of pipelines that are not separated by components of the shut-off and control system.

How to prevent sewer freezing?

As a preventive measure, the system is periodically flushed with hot water. Large volumes of liquid need to be drained. If the temperature outside is low, the system is flushed regularly until the weather warms up. Along with heating the sewer pipes, other preventive measures should be taken:

- It is necessary to lay communications below the soil freezing level. The climate is different in different regions. Accordingly, the freezing limit of the soil may be different. If we take this factor into account when laying the pipeline, the system will continue to function even in severe frosts. In situations where the sewer system has already been installed, and the owner is faced with the problem of freezing in the first winter, in the spring it is recommended to dismantle it, deepen the trench along the entire length of the pipeline and install communications at the required level.

- To avoid freezing, pipes are insulated using special materials. In this case, non-hygroscopic coatings characterized by low thermal conductivity are used. This method will not help when laying communications too close to the soil surface. To avoid freezing of pipes, it is necessary to use heat-insulating materials of the required thickness.

- The communications used must be of sufficient diameter. During installation, it is necessary to control the slope of the sewer.

- Heated sewer pipes. In this case, a self-heating cable is used. When the air temperature drops significantly, it is regularly connected to the network.

How to heat a pipe yourself

The above pipe heating systems can only be installed during pipe installation or repair, so they have not yet been installed on most pipelines. Often, plumbers have to warm up frozen sections of utility and household pipelines. What to do if the pipeline is frozen? Almost all such work is carried out according to the same scheme, namely:

- First, the section of the pipeline where the ice plug has formed is determined. Often these places are external faucets, corner joints and columns. But this is not always the case; the problem can arise anywhere. To detect an ice blockage, you need to use a flexible probe made from plumbing rope and insert it into any free pipe in the pipeline system. As it passes through the pipe, the probe rests against the plug and along the length of the cable immersed in the pipe, it will be possible to find out the location of the plug by comparing this section with the body of the pipeline.

- After finding the location of the ice plug, you need to mechanically warm up the pipe body. This process is performed using various equipment. It is believed that the most effective way to heat a pipe is a special steam generator for heating pipes. It is used from the inside, so it can not only melt ice, but at the same time remove fat and lime deposits that have accumulated on the surface of the pipeline with water. A hair dryer is considered less effective equipment for heating a pipe, since it heats the pipe from the outside. The temperature of the air flow created by a hair dryer is 400-500 degrees. Homemade heaters based on gas burners are also used, but they are not very effective, since due to the high temperature of the fire jet, they can be used exclusively for heating metal systems. Steel and polymer pipes are quite successfully heated by a thin stream of boiling water.

When choosing the best way to heat the pipes, you must proceed from the type of structural material of the pipeline system.

After the pipes have completely warmed up and liquid circulation in the pipes has resumed, you need to check the system for leaks, because when water freezes, it increases in volume and often leads to pipe rupture. It is better to replace damaged areas in the shortest possible time.

Why does an underground pipe freeze?

Pipes in a private house are frozen, how to warm them up? How to warm up a pipe with water underground and why does it freeze there in the first place? How to warm up a plastic pipe? These questions come with particular regularity from our customers. Let's try to help!

As a rule, water freezes more often near the house, under the concrete blind area. Even if there is three layers of insulation.

It often happens that frosts are preceded by precipitation in the form of rain or sleet. And the insulation is saturated with moisture.

Wet insulation becomes a conductor of cold, and not a protector from it.

Plus, the snow area was thoroughly cleaned. Yes, the frost got worse at night.

There is a very high probability of freezing under the house if the house is on poles or screw piles. Here they often rely on covering the “foundation”. Doesn't save!!!

In general, the water supply coming out of the ground and entering the house is often a problem area.

And such places need to be insured with a heating cable. Believe me, this is not at all expensive compared to what you sometimes have to do when defrosting a pipe.

The cable you need is about 5 meters.

Those who have decided that global warming has already arrived in their yard, get ready.

January 2021. On the streets of Moscow and the Moscow region -25C.

The water in the pipes stands still at night and thereby makes things easier for the frost. And even a small area, 20-30 centimeters, will clog the water so that the pump will not push through. And, besides, the pump can burn out if the automation is in the house and the pump is in the well.

Often, in cases of freezing, people try to cope on their own. To help yourself, read below carefully.

How to heat a polypropylene or metal-plastic pipe indoors

If the pipeline is frozen inside the room or in the basement, the following methods can be used to warm it up:

- Warming by internal action on a plug of ice.

- Heating by external influence on the freezing area of the pipe.

- Replacing a frozen section of pipeline.

Heating from the outside is quite easy to do. To do this, a layer of material is wound around the outside of the frozen section of the pipe that absorbs water. It can be a sponge, a washcloth, rags, and the like. Hot water is then poured onto the material, which warms the pipe and turns the ice crust inside the pipe into water.

It is worth knowing that when heating water pipes made of metal-plastic, you need to disconnect the main branch from the frozen area. In this case, you need to leave a shut-off valve along the edge of the frozen branch and open it all the way. Melted ice will fly out of the pipeline at high speed, so you should be careful.

Internal heating is somewhat more complicated. First, the main branch of the pipeline system is disconnected from its frozen part. Then all the cold water is drained and hot water is poured in instead. If the ice has not flown out of the system, then the cold water is pumped out again and replaced with new hot water. When internally heating polypropylene pipes, you should be aware that water is heated only to 80 degrees Celsius; hotter liquid can damage the pipe, since polypropylene can withstand temperatures up to 90 degrees.

Replacing a frozen section by removing it involves installing a new section of pipeline and installing couplings. This method is optimal when it is possible to shut off the water to the part where the ice plug has formed. Otherwise, after dismantling the pipe, water will flow.

What causes freezing?

Common reasons:

- Insufficient slope of sewer pipes. In this case, the speed of movement of the wastewater is low, which is why the liquid freezes faster.

- Small diameter of sewer pipes from the inside. At the same time, the movement of water slows down.

- A leak has formed. In this area, the liquid freezes more intensely, and ice contributes to an increase in the area of deformation of communications.

- A small amount of water flows through the pipes. Due to the low rate of movement, the wastewater freezes.

- Lack of insulation, which is especially dangerous in areas with harsh climates.

- Violation of installation requirements. In this case, communications are not laid deep enough - above the freezing level of the soil.

- Formation of blockage.

If the liquid in the sewer pipes is frozen from the inside, different methods based on the use of heat sources are considered. This could be a soldering iron, hot water. An effective option is based on the use of wires to heat the pipe.

Causes of freezing of sewer pipes

It is always better to prevent any problem than to deal with its consequences. This part of the article will tell you about the reasons why sewer pipes may freeze. Having corrected the shortcomings in the system (if you are building or living in a private house), you will almost never have to think about the question of how and how to defrost a sewer pipe.

So, the biggest reason for this common problem is improper pipe installation. If you are just starting to build a house, be sure to check that all sewer pipes are laid below the level to which the soil on your site usually freezes in winter. In addition, it is additionally possible to wrap the pipes of the entire sewer system with special heat-insulating materials.

There are a number of other reasons:

- small pipe diameter;

- incorrect slopes;

- few drains in the pipe;

- formation of blockages.

Unfortunately, for most of us, knowledge of the reasons for freezing of pipes will not help in any way. Not all modern multi-storey and private houses have a well-built sewage system. It’s easier for residents of high-rise buildings - either the utility service or the company with which the service agreement was concluded is responsible for this system. As for residents of private houses, for the most part, they have to solve the problem of defrosting sewer pipes on their own.

Warming up the cold

To warm frozen pipelines, steam or hot water should be used, after first disconnecting the heated section from the operating system.

The use of open flames, blowtorches, welding torches and torches for this purpose is not allowed, as this often leads to accidents. It is prohibited to use blowtorches to warm frozen water pipes, sewer pipes and steam-water heating pipes in buildings with combustible structures or finishes.

87. The use of blowtorches to warm frozen water pipes, sewer pipes and steam-water heating pipes in buildings and structures of III, IV and V fire resistance degrees is strictly prohibited.

10.7. Methods for warming frozen valves, valves, pipelines and acetylene generators.

4.15. The use of blowtorches to warm frozen water pipes, sewer pipes and steam-water heating pipes in buildings with combustible structures or finishes is strictly prohibited.

87. The use of blowtorches to warm frozen water pipes, sewer pipes and steam-water heating pipes in buildings and structures of III, IV and V fire resistance degrees is STRICTLY PROHIBITED.

4.15. It is STRICTLY PROHIBITED to use blowtorches to warm frozen water pipes, sewer pipes and steam-water heating pipes in buildings with combustible structures or finishes.

In workshops, warehouses, laboratories, on farms and in other premises, to prevent fires from careless handling of fire, the following measures must be observed: designated smoking areas, posted signs prohibiting the use of torches and blowtorches to warm frozen pipes, in addition, should be appointed by order of those responsible for compliance with fire safety rules, etc. Intra-shop instructions should be specific, not repeat general industry rules and reflect only specific fire hazard conditions - for a given production operation, apparatus or installation (workplace), so that the shift foreman ( operator, operator or other worker) knew well what needed to be done to prevent a fire or explosion in the workplace. If there are no such instructions or they are poorly written, then the examiner should require their compilation or revision.

Careless handling of fire in everyday life, lighting fires near buildings, using open fire to warm frozen central heating pipes, sparks from electric and gas welding work, smoking in prohibited places, children playing pranks with fire, etc. Fires associated with the use of household chemicals and aerosol preparations , as well as incorrect ex-

Objective sources of ignition include the effects of atmospheric electricity, which are random in nature. Subjective ignition sources include violation of basic fire safety rules by maintenance personnel, namely smoking in the warehouse or the use of open fire to illuminate or warm frozen elements of process equipment, etc. The appearance of this group of ignition sources becomes possible as a result of low labor discipline of maintenance personnel , dulling the senses of the potential danger of flammable liquids and flammable liquids. Yes, it is indeed possible that in 1000 cases, failure to comply with basic fire safety requirements did not lead to serious consequences, but in the 1001st time a disaster can occur, as at the Volkhov oil depot. As a result of the negligence of the maintenance personnel, gasoline overflowed over the edge of the tank when draining it from railway tanks. Warm, windless weather at night contributed to the gas pollution in the area. The driver's smoking served as a source of ignition for gasoline vapors in the gas-polluted area. Railway tanks exploded, and the roofs of tanks in which diesel fuel was stored were torn off by an explosion. At the dispensing station, two fuel tankers were in the fire zone. Another example is typical. On a cold January morning, one of the workers at the Tashkent Electrical Machine-Building Plant decided to heat a 40-liter flask with an oil emulsion solution in the crucible furnace of the foundry. The liquid ignited, and a torch of flame shot up and reached the combustible coating. By the time fire brigades arrived, the fire had engulfed the ceiling and covering of the foundry and adjacent mechanical area over an area of 800 m2.

* warm up frozen pipes of various systems with blowtorches and any other method using an open flame;

careless handling of fire: using gasoline or kerosene for kindling, heating frozen water pipes with an open fire, smoking in prohibited places.

Warming frozen drainage pipelines of devices with the valve open is prohibited.

862. Warming of frozen or frozen pipelines can only be done with steam or hot water.

1477. Warming of frozen pipelines can only be done with steam or hot water. The heated area must be disconnected from the operating system. The use of open fire in these cases is not allowed.

24. Warming frozen water and sewer pipes with open fire is prohibited. Pipelines should be heated with steam, hot water or hot sand.

3.5.1.34. The ice plug in the pipeline must be heated with steam or hot water, starting from the end of the frozen section. It is prohibited to warm frozen descents (drains) of pipelines and apparatus with an open valve, or with open fire.

3.6. Warming of frozen heating pipelines, water and sewer pipes, as well as frozen fittings (gates, valves) is permitted only with hot water, steam and other fireproof means.

carry out cleaning of premises and washing clothes using gasoline, kerosene and other flammable liquids and flammable liquids, as well as warming frozen pipes with blowtorches and other methods using open fire;

Warming frozen drainage pipelines of devices with the valve open is prohibited.

862. Warming of frozen or frozen pipelines can only be done with steam or hot water.

1477. Warming of frozen pipelines can only be done with steam or hot water. The heated area must be disconnected from the operating system. The use of open fire in these cases is not allowed.