Hello, friends! Sewer lines may run in hard-to-reach places where there is not enough free space to carry out work. If you lay ordinary pipes, for example plastic or cast iron, you will have to add more joints and buy additional fittings, as a result of which not only the cost of the system increases significantly, but also the risk of leaks.

Corrugated sewer pipe is more flexible and easy to use; with its help you can quickly install a sewer system anywhere.

Device

A corrugated pipe is a hollow, elongated product with a circular cross-section, the outer surface of which consists of ridges and grooves alternating at equal distances, and the inner surface is smooth. The distance between the ridges and their size may vary between different manufacturing companies; the degree of rigidity is adjusted by changing the thickness of the rings.

Characteristics

Corrugated pipes are made from a special polymer, the features of which also affect the technical characteristics of such products:

- Nominal diameter DN – from 110 to 1200 mm.

- The color of the outer surface is black or orange-brown.

- Ring stiffness indicator - for pipes with DN less than 500 mm: SN4; SN8 or SN16; for products with DN more than 500 mm: SN2; SN4; SN8 or SN16.

- Impact strength - TIR≤10%.

- Ring flexibility at 30% deformation - no cracks, wall delaminations, kinks or warping.

- Installation temperature - up to -20ºС.

- Change in length and appearance after overheating - from 2 to 5%.

- The Vicat softening point is not less than 76ºС.

- Depth of occurrence (depending on the parameter of ring rigidity) - from 1 to 15 m.

- The warranty period is at least 50 years.

Application area

Corrugated sewer pipes are designed for long-term operation and, depending on their degree of resistance to physical stress, are used for laying communications:

- Lightweight corrugated pipes with low mechanical stability - for the installation of external sewer systems. In addition, lightweight flexible corrugation is used as protective boxes for low- and high-voltage cables of power and communication lines.

- Heavy corrugated pipes that have an average level of mechanical strength are used for underground installation of drainage lines for domestic and industrial wastewater, rainwater, drainage systems, and storm sewers.

- Extra-heavy corrugated pipes, which have high mechanical resistance, are used in places where sewer lines pass under roads or railway tracks.

Classification and types

Corrugated sewer pipes are divided into several types, depending on the type of plastic used for their manufacture and the structural features of the wall.

According to the wall structure, corrugated pipes are divided into:

- Single-layer - products of increased flexibility, the wall is structured on the outside and inside. They have insufficient strength and are prone to clogging due to the uneven inner surface, so their scope of use is limited to protective casing for electrical wiring and drain hose of household appliances, for example, a washing machine or dishwasher.

- Two-layer - have a more complex wall structure: the inner layer is smooth, and the outer wall is corrugated. Double-layer pipes are more durable, resistant to any type of mechanical stress, and can withstand the pressure of soil or concrete mass.

- Reinforced - with a steel layer, which increases the ring rigidity of plastic corrugated pipes many times. The metal insert is located under a layer of plastic, so the product is no less resistant to corrosion than other types of polymer pipes.

- Perforated - with a two-layer wall structure and evenly distributed holes over the surface of the entire product. They are used to organize drainage systems in construction and agriculture.

For the production of sewer corrugated pipes the following is used:

- Polyvinyl chloride (PVC).

- Low-density polyethylene (HDPE).

Both types of rolled pipes are included in the group of polymer materials, but differ in their structure and a number of performance properties.

Products made of polyvinyl chloride

Corrugated pipes made of PVC and unplasticized polyvinyl chloride (UPVC) can withstand heavy loads and can be used both for the installation of external sewer networks and for their underground installation and passage through reinforced concrete structures. They are inert to chemical influences, do not corrode in a humid environment, are durable, and can withstand working environment temperatures in the range from -40ºС to +50ºС for a long time, and up to +90ºС for a short time. The disadvantages of PVC pipes include low frost resistance; when the ambient temperature drops below the permissible limit, they become fragile. When heated to too high temperatures, polyvinyl chloride releases toxic elements.

Polyethylene products

An alternative to PVC products is corrugation made of low-density polyethylene, the outer layer of which is made of structured HDPE, and the inner layer of smooth LDPE. Such products bend well, do not stretch, withstand compressive and tensile loads, are resistant to water hammer, have anti-corrosion properties, biological and chemical resistance. Their operating temperature range is from -50 to +120 degrees. When liquid freezes in pipelines, HDPE corrugated pipes will not burst, since the material has the ability to expand by 5-7%. After defrosting, the pipes regain their original shape and size. HDPE corrugation is used for the installation of pressure sewers, storm sewer lines, for drainage and in filtration fields. The only disadvantage of such products is their higher cost compared to polyvinyl chloride corrugation.

Types of corrugated pipes for sewerage

For sewerage, smooth-walled, corrugated, double-layer pipes are used, the outer shell of which is painted in different colors to protect the inner surface from solar radiation. A single-layer corrugated pipe, due to its uneven ribbed inner surface, is not used for drainage of sewage; in exceptional cases, in order to save money, they make a drainage pipeline with holes in the walls from it themselves or buy a ready-made similar product from one of the many manufacturers.

A distinctive feature of all corrugated pipes is the indication in their technical characteristics of the ring stiffness parameter, expressed in conventional units SN, corresponding to a load of one kiloNewton per square meter (kN/m2). The ring stiffness class indicates the load on the area (in square meters) of the pipe in the radial direction, at which its deformation does not exceed 4%; depending on its value, all pipes are conditionally divided into the following categories:

- Lungs . Sewage pipes have ring stiffness SN 2 - 4 - 6 classes, are designed for laying in the ground to a depth of no more than 6 m, and are made of two-layer polyethylene HDPE and LDPE. This category includes two-layer flexible corrugated products made of polyethylene, the main purpose of which is the laying of electrical cable lines (outer shell red), telecommunications (blue shell), as well as storm, waste and drainage sewers (outer shell green or black).

- Heavy. The ring stiffness of products of this class is 8 - 10 - 12 SN, the pipes are made of polyethylene or polypropylene, are laid in the ground to a depth of 15 m, and are widely used for laying most types of utility and industrial sewer networks.

- Super heavy. High-strength pipes with a ring stiffness of 16 - 24 SN are made of polypropylene; they are designed for laying sewer networks under soil areas experiencing high loads: roads, railways, airfield runways.

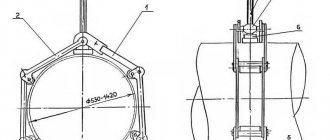

In the Korsis product line, the super-heavy ones include the ARM series, with an outer diameter from 800 to 2400 mm, the products have a yellow inner shell, are made of two-layer polyethylene, inside of which steel inserts in the form of rings are placed in a corrugation to increase strength. This pipe is capable of withstanding axial loads of 24 SN when manufactured to order; pipe sections are usually connected to each other using heat-shrinkable couplings and a polyethylene rod, which is extruded by a manual extruder and firmly joined to the coupling when its surface is heated with a gas torch.

Characteristics and requirements for Corsys products

Advantages and disadvantages

Corrugated pipe products, regardless of the material of manufacture, have the following advantages:

- Light weight, facilitating the process of transporting, storing and laying such products.

- High flexibility. The corrugation is capable of bending in any direction, so when laid, it can bend around obstacles in areas with complex terrain with a small number of connecting elements.

- Corrosion resistance. Corrugated pipes of all types are resistant to corrosion in a humid environment.

- They are simply laid without the use of lifting equipment or additional equipment.

- High ring rigidity and mechanical strength, thanks to which they can be used for underground installation and concreted in building structures.

- High throughput. Rolled pipes with a smooth inner surface transport the working substance with minimal friction, so the walls of pipelines made of corrugated pipes are not subject to biofouling and significant deposits that narrow the flow area.

- Low cost of products, reliability and economical operation.

- Durability. Communications assembled from corrugated pipes will last at least 50-70 years.

Despite the large number of advantages, plastic corrugation also has disadvantages:

- Low frost resistance.

- Increased noise level.

What can experts advise?

Despite the truly low degree of complexity, the process of connecting plumbing fixtures to a toilet using a corrugated pipe has its own characteristics that absolutely must be taken into account. And then some tips will be given that will make this process as quick and easy as possible.

Mikhail M. – master plumber with 20 years of experience: If the choice was made in favor of a very rigid corrugated pipe, then the best option should be considered purchasing a siphon separately. In the case of increased rigidity corrugation, it will either not be possible to organize an S-shaped water seal siphon at all, or such a siphon will not be able to provide the required degree of sealing.

Sergey: Don’t get carried away with stretching the corrugation too much along its length. Sometimes, in order to save money, people buy pipes that are too short so that they can be stretched later. But in this case, the pipe loses its stiffening ribs - that is, folds. Which, of course, does not have the best effect on its strength. There is no need to place any objects on corrugated pipes. This will cause the pipe to deform over time and burst.

Product Standards

Requirements for the technical characteristics and dimensions of corrugated pipes made of polymeric materials are established by GOST R 54475-2011 and TU 2248-001-96467180-2008.

Dimensions

Corrugated pipes are sold in lengths of 6 or 12 m and have the following cross-sectional dimensions (Table 1):

Table 1

| Outer diameter, mm | Inner diameter, mm | Wall thickness, mm | Corrugation protrusion width, mm |

| 110 | 91 | 1,0 | 8,6 |

| 125 | 107 | 1,1 | 8,6 |

| 160 | 138 | 1,2 | 9 |

| 200 | 176 | 1,4 | 12 |

| 250 | 216 | 1,7 | 23 |

| 315 | 271 | 1,9 | 27 |

| 400 | 343 | 2,3 | 30 |

| 500 | 427 | 2,8 | 38 |

| 630 | 535 | 3,3 | 47 |

| 800 | 678 | 4,1 | 56 |

| 1000 | 851 | 5,0 | 60 |

| 1200 | 1030 | 5,0 | 80 |

Tips for choosing

The sewer system will function uninterruptedly only if the work on its assembly and installation is carried out correctly, as well as the correct selection of all components. As for pipes, they must be selected according to the following parameters:

- Nominal diameter and wall thickness.

- Length of sections.

- The type of system is pressure and non-pressure.

- Estimated load on the system.

It is better to purchase such products in specialized stores, where the quality of the product is confirmed by an appropriate certificate describing the technical characteristics and a quality certificate. You should also check the integrity of the packaging and the presence of markings on each section of pipe, consisting of:

- Name or trademark of the manufacturer.

- Symbol.

- Dates of manufacture.

approximate cost

The cost of plastic corrugated pipes for sewerage depends on the size of the product, stiffness class, material of manufacture and manufacturer.

Average prices for the most popular two-layer corrugated HDPE pipe with a welded socket are shown in Table 2.

Table 2.

| No. | Outer/inner diameter, mm | Hardness class | Price 1 linear meter, rub. VAT included |

| 1 | 110/94 | SN 8 - SN 9 | 210 |

| 2 | 160/136 | 360 | |

| 3 | 250/216 | 758 | |

| 4 | 230/200 | SN 6 - SN 7 | 512 |

| 5 | 250/216 | 622 |

The best domestic and foreign manufacturing companies

The most famous manufacturers of plastic corrugation for sewerage are the following companies:

- Wawin (Holland).

- PIPELIFE International GmbH (Austria) - Pragma pipes.

- Polieco (Italy) - Corsis PRO sewer corrugation.

- Russian companies - FD-plast, Poliplastik, Politek.

Types of drainage devices under the sink

The modern market offers an enviable variety of designs and materials for the manufacture of drains. Among the most popular materials are plastic and metal. Structural forms are made in the following main options:

- pipe;

- corrugated (usually a plastic hose);

- bottle;

- "dry".

Let us dwell in more detail on the differences in the structure and functioning of the listed types of drains.

Pipe siphon

A pipe siphon is a curved pipe. Most often, such a structure is made of metal. This is a traditional old style drain called an "elbow". In its modern design, its design has acquired a decent appearance: a shiny stainless steel surface of bronze or brass, convenient connectors for disassembly and assembly, light weight (unlike the old-style cast iron elbows). The pipe bend can be made in a “U” shape or in an “S” shape. The curved part is the lowest point of the structure; this ensures that dirt, waste, and foreign particles settle in it.

Photo: pipe siphon

If it is necessary to organize drainage from two holes (for example, two bowls of a kitchen sink), the pipe elbow is placed as low as possible, close to the sewer pipe. Above the elbow, a structure is assembled from connecting pipes and adapters, collecting two drain streams into one before bending the pipe siphon.

Corrugated siphon

A corrugated siphon is a type of curved pipe. The difference is that the bending part is not made in the form of a solid pipe, but in the form of a movable corrugated hose. It is the corrugation that ensures its mobility and the possibility of simplified installation to the drain pipe. These structures are made of plastic. The curved position of the corrugation is supported by a clamp. If necessary, the connecting clamp can be moved to make the bend more pronounced or less curved.

Photo: corrugated siphon

Corrugated folds have not only advantages, but also disadvantages. Dirt and food deposits quickly accumulate in their depressions (if it is a kitchen sink). They are difficult to clean. In addition, the corrugated material becomes brittle over time and leaks. The characteristics of the plastic used do not allow pouring boiling water into such a sink.

Bottle siphon

The bottle siphon represents the most popular drain design for the kitchen sink. Its external shape resembles a bottle. Inside the siphon of the device, water moves down and up along a curved path, which is formed by the double wall of the device. The waste moves down the middle of the inner pipe and sinks to the bottom of the siphon. Then they rise along the gap between the inner and outer walls of the drainage device. Then they are drained into the sewer through the side opening of the siphon.

Photo: bottle siphon

If it is necessary to connect several drains to one siphon, a transition element is installed in front of it. The main drain drains into such an adapter from above (from the bowl), and an emergency drain (overflow) from the same sink or a drain from another plumbing fixture (washing machine, dishwasher) can flow into the side.

Bottle structures are made of both plastic (more affordable price solutions) and metal (more expensive, prestigious and durable siphons).

"Dry" siphon

“Dry” siphons are one of the modern inventions of plumbing. The name “dry” is due to the fact that there is no constant standing water in them. The role of the water seal is performed by rubber gaskets, which are located inside the siphon and block the passage of sewer odors. When draining the wastewater, the rubber opens under water pressure and allows the flow to pass, after which it again closes the free lumen of the pipe. The rubber element is called a “dry” water seal.

Photo: dry siphon for sink

The absence of water in the check valve makes it possible to install such structures in country or country houses, where heating does not operate constantly. In winter frost conditions, the water seal will freeze and deform the siphon pipe. Therefore, the optimal type of drainage would be a “dry” check valve.

The “dry” design has more compact dimensions; it does not have a curved part, so its installation saves space under the sink.

Dry drain siphons are installed in the following cases:

- there is no room for a curved siphon;

- cold room, periodically not heated;

- hot room where the water seal often dries out;

- air conditioner drain (outdoor location);

- objects where there is shaking and vibration (for example, RVs).

The direction of installation of a “dry” drain can be either vertical or horizontal. If installed horizontally, a corner adapter is installed between the drain and the sink.

Features of installation and dismantling

The installation of a gravity sewer system is carried out in accordance with the requirements of current SNiP. The laying of a corrugated pipeline is carried out in several stages.

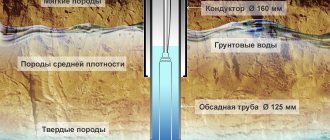

Trench excerpt

A straight trench is dug from the point of exit from the house to the septic tank or central highway with a slope of 7 mm/m. for pipelines with a diameter of 150 mm and 8 mm - for a diameter of 200 mm, turns are allowed only in wells. The width of the ditch must be at least 40 cm greater than the outer diameter of the pipe (20 cm on each side). The depth of its occurrence is calculated based on the thickness of the freezing layer of soil in the region. The bottom of the trench is leveled and compacted.

Sand cushion device

The bottom of the prepared ditch should be filled with sand, a layer thickness of 15-20 cm. The sand cushion will increase the pipe’s resistance to crushing in the event of uneven subsidence of the soil base.

Methods for connecting corrugated pipes

After completing the excavation of the trench and preparing the base, the pipes are connected to each other and laid.

Corrugated pipes can be connected to each other in several ways:

- Coupled - using a coupling and an o-ring. The surfaces to be joined are cleaned of dirt and lubricated with silicone sealant with water-repellent properties. Then a sealant is inserted into the corrugation wave of one of the pipes. For products with a diameter of less than 200 mm, the installation location of the ring is the second wave, for pipes with a larger diameter - the first wave. The ring ensures complete fit of the fitting and guarantees the tightness of the connection.

- Bell-shaped - used for pipes with a diameter of more than 250 mm. The socket is manufactured separately and welded to the end of the pipes at the corrugation production stage. The mounting end of one of the connected sections is inserted into the socket of the subsequent part using silicone grease, and then fixed with an O-ring.

- Butt welding - used for small diameter products. The two ends of the pipes are placed into a special welding machine, in which the ends are melted and connected to each other through the mutual penetration of polymer molecules of both parts into each other.

Backfilling the trench

The sewer pipeline is first filled with sand to a depth of 30 cm with layer-by-layer pouring of water. After this, the ditch is completely filled with soil.

Well installation

Inspection wells are installed every 35 meters in straight sections and rotary wells in places where there is a need to change the direction of the pipeline. To monitor the condition of the sewer network, an inspection or cleaning is installed every 15 m of a straight line.

Direct connection of the corrugation to the sewer

As a rule, corrugated pipe is used to install a toilet. So this process will be described further. However, in the case of a sink and other plumbing fixtures, everything will look approximately the same.

So, at the first stage it will be necessary to prepare the plumbing equipment itself. If it's just from the store, you won't have to do anything. However, if it has been dismantled, then before connecting it is necessary to thoroughly clean the dismantled toilet from the old sealant. You can even additionally sand the edges of the outlet to remove any remaining sealant, cement, etc. After all, even the slightest roughness at the joints will lead to the seal being broken in this particular place.

Now you will need to apply a small amount of sealant to the outlet from the outside. The end of the corrugation where the membrane is located is put on the outlet. In this case, you also need to ensure that the outlet covers the edges of the outlet by approximately 50 - 60 millimeters. You must also carefully ensure that there are no distortions. The corrugation should be put on as evenly as possible.

Corrugated pipe is used for installing toilets, sinks, sinks and other plumbing fixtures.

Once the sealant has dried, you can install the toilet in place. And it will be possible to remove the corrugation to the sewer. To do this, the edge of the pipe with an external seal is inserted into the previously cleaned hole until it stops. In principle, sealing is not necessary here, but you can play it safe.

Now you can do a test run of water. Just turn on the water supply and perform several intensive flushes, or pour a bucket of water into the toilet a couple of times. If there are no leaks, then everything is in perfect order. The connection procedure can be considered complete.

Tips for Sewer Pipe Maintenance

To ensure the normal operation of the sewer communication, it is necessary to regularly perform its maintenance. Maintenance means carrying out a set of activities (routine and major repairs, as well as maintenance), during which it is possible to identify all problems in the operation of the system and eliminate them. It consists of performing the following actions:

- Visual inspection of pipelines and wells.

- Regular cleaning and flushing of pipes and septic tank chambers.

- Current or major repairs, during which worn-out sections of pipelines and manholes of inspection wells are replaced. If necessary, well necks are restored, pumping equipment and valves are repaired.

- System leak testing.

Timely implementation of such measures will prevent the occurrence of serious damage to these communications.

Features of the arrangement of an external sewerage system

In-house or intra-apartment sewerage requires the use of fittings. Another case is the external system. It is laid in the local area. A prerequisite is the installation of wells. Such structures allow you to clean the sewer without difficulty. Having learned how sewer pipes are connected, it becomes obvious that the external system involves the use of larger diameter pipes.

Helpful advice! Be sure to take into account the fact that when inserting a sewer pipe into an external one, it is necessary to increase the size of the latter. It is better to take a model with a “reserve” so that when the need arises to connect new plumbing, you do not have to change the entire system.

After completing the preparatory work, you can get down to business. Types of sewer pipes and connections provide two options for performing the work: detachable and permanent connections.

For external sewerage, it will be necessary to install inspection wells