1 / 1

For welding metals, the welding torch plays an important role along with the machine itself. The quality of the final result, the safety of the process and the level of productivity directly depend on it.

A semi-automatic torch is usually supplied complete with a welding machine. A good manufacturer immediately selects the best option. But this is a consumable that periodically wears out and requires replacement. Choosing a new one is complicated by a large number of nuances, which can be difficult to understand.

Tools and materials

Before you start welding with acetylene and oxygen, it is worth considering what equipment should be used for this technology. It usually requires accessible and relatively inexpensive instruments.

But still, in order to avoid problems and errors during the welding process, it is worth first considering some nuances:

- Previously, generators were used to produce acetylene for welding. However, with the development of modern technologies, these elements were replaced with cylinders, which could greatly facilitate the welding process;

- The gas cylinder is always white. To support combustion, bottled oxygen is used. Cylinders are transported using special trolleys;

- Gas torches for welding with acetylene, as well as nozzles, are required. But they can come in different sizes;

- If strong heating of thick metal elements is required, then in these cases it is recommended to use the largest number with a large hole. It must supply a sufficient amount of gas mixture into the weld pool and ensure normal heating of the joint area;

- In addition, hoses with acetylene and gas are connected to the burner;

- The pressure of acetylene and oxygen during welding is regulated using gearboxes. They protect the cylinder from blowback;

- filler wire is required. Depending on the type of material being welded, it can be made of steel or metals with the addition of alloying additives.

If you prepare all of the above elements and materials, you will be able to obtain a strong and wear-resistant connection of metal parts. The main thing is to remember the important features and nuances of the process.

And do not forget that acetylene is used not only for welding, but also for cutting metals. However, experienced specialists who know the rules of technology must work with this gas. Still, this type of welding requires maximum precision and compliance with important safety precautions.

Welding gas torch: types, principle of operation

Content:

- Materials used in the production of gas burners.

- The essence of the work and the design of burners of different types.

- The essence of the operation of a gas burner equipped with an injector.

- The essence of the operation of a burner that does not have an injector.

- Requirements for gas torches for welding.

Types of gas burners.

One of the tools needed when carrying out most gas welding work is a gas welding torch. With its help, the metal product is heated and, in fact, the parts are welded.

A modern welding gas torch is a reliable tool that provides a stable flame, both in shape and strength, safety of welding work, and ease of use.

Materials used in the production of gas burners.

Durable and reliable materials are used in the production of gas burners. Thus, the burner itself is usually made of brass; manufacturers most often use copper for the mouthpiece.

Also, to lighten the overall weight of the burner (which ensures ease of use), aluminum alloys are often used.

Types of gas burners.

There are two main types of gas burners - injection and non-injector. They differ in the presence (absence) of an injector. Note that the presence of this element in the burner design determines the gas pressure permissible for use. Thus, injection burners are used for low and medium pressure, while non-injector burners are used for high pressure combustible gas.

The designs of these two types of burners are also different - non-injector ones have a simpler design.

In addition, in terms of application, torches can be either highly specialized, designed for a specific type of work, or universal, which allow welding, cutting, and heating of metal. Such universal burners are usually equipped with special tips.

Burners also differ depending on what combustible gas can be used with them: acetylene, liquid fuel, substitute gases.

The essence of the work and the design of burners of different types.

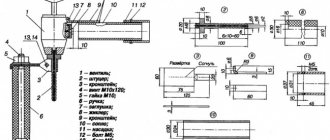

Figure 1. Injector gas burner.

Figure 2. Welding torch without injector.

The essence of the operation of a gas burner equipped with an injector.

In this burner, the formation of a mixture of gases is carried out by injecting flammable gas (which has low or medium pressure) and oxygen, which is supplied from a cylinder to the burner under a pressure of 0.5-4 kgf/cm 2. The process occurs as follows: oxygen, passing through the axial channel of the injector, is directed into the mixing chamber at a fairly high speed. As a result, a vacuum occurs in the channel through which flammable gas or liquid fuel vapor passes. This process forces fuel to also enter the mixing chamber, only it does not pass through the axial channel, but outside the injector. The mixture that forms in the chamber of the instrument is fed through the mouthpiece and ignites.

If desired, the proportions of gases in the combustible mixture can be slightly adjusted using the burner valves. Note that for injection burners, combustible gas must be supplied from a cylinder under a pressure of at least 0.01 kgf/cm2.

The essence of the operation of a burner that does not have an injector.

This burner operates on a simpler principle.

Both gases - oxygen and fuel - are supplied to the burner at almost the same pressure, which should be at least 0.5 kgf/cm2. The gases are mixed in the chamber and then directed to the burner tip.

Requirements for gas torches for welding.

Like any equipment intended for welding, gas torches must meet a number of requirements. Let's name the main ones:

- The burners should not be very large in size and relatively light in weight (otherwise they will be extremely inconvenient to use).

- Oxygen and flammable gas must be mixed in a certain ratio. For example, burners that are used with acetylene have the following requirements for the ratio - Vк/Va = 0.8-1.5.

- The torch must maintain a constant mixture composition during welding.

- A gas torch for welding must allow the welder to change the power of the flame.

- The speed at which the resulting mixture exits the burner must exceed the ignition speed of the mixture. Otherwise, a phenomenon called backfire may occur.

- The burner must be equipped with valves to adjust the composition of the mixture.

- Gas torches for welding work must meet all safety requirements.

Note that when using injection burners, you should remember that the composition of the mixture can be negatively affected by clogged mouthpieces, tip heating and other factors. Therefore, before using the torch, it is necessary to check it and, if necessary, clean the mouthpiece from welding spatter. During operation, ensure that the burner tip does not heat above the permissible temperature. Injectorless welding torches also require careful monitoring and maintenance.

The most popular methods

Criteria for choosing a chain for a chainsaw

Welding in the lower position.

Gas welding methods can be described and listed in several thick volumes.

Let's take the most common of them:

Left welding

The left-hand method of gas welding is the most common among craftsmen of any qualification. Used to join metals with thin edges and low melting points. Left and right welding are two sides of the same coin, it’s easy to remember.

Right welding

The right welding method is suitable for working with metals with a thickness of more than 3 mm and high thermal conductivity. It should be noted that the weld seam during right-hand welding is of higher quality due to better protection of the metal by the flame.

The use of flame heat with the right method is more economical, and the process speed is almost 20% higher. To the same piggy bank of advantages you can add savings in gas costs of about 10%.

The filler wire must be taken with a diameter that is exactly half the thickness of the metal workpiece. The wire cannot be thicker than 8 mm.

Welding using through bead

This gas welding technology involves the gradual, step by step, movement of the flame to melt the upper edge of the hole in the workpiece and apply a layer of molten metal to the lower edge of the same hole.

First, the metal sheets are fixed vertically, leaving a gap between them half the thickness of the workpiece itself. The seam is formed in the form of a roller, which connects the parts. It is dense, without any pores or slag residues.

Welding using baths

Here the name speaks for itself. The principle of the method is the formation of more and more new pools along the seam. As soon as one of them is formed, the end of the filler wire is inserted into it, melts there, and then moves to the reduction section of the burner fire.

This method is used to connect thin sheets when it is necessary to make butt or corner types of seams. This is a favorite type of welding for pipes made of low-alloy steel or low-carbon alloys.

Multilayer gas welding

It is used for very critical types of work, as it is characterized by rather low productivity, and welding gases are required here in large volumes - the method is not cheap. In it, the lower layers are annealed during surfacing of the upper and subsequent layers.

The result is excellent forging of each layer before the formation of the next seam. This method significantly improves the quality of the weld metal.

The process occurs in short sections

Pay special attention to cleaning the surface of the underlying layer before applying the next one.

Oxidizing flame and deoxidation welding

Cylinders for gas welding.

This technology was created for joining parts made of low-carbon steel alloys. The flame here has a sharply oxidizing character, as a result of which iron oxides are formed in the weld pool. If there is oxidation, so-called deoxidation is also necessary.

This is achieved using a special filler wire with high proportions of manganese and silicon. An excellent method with productivity 10% higher than other methods.

Necessary equipment for gas welding

Water seal

Types of brushes for grinders, selection criteria

This is a simple and effective protection of the pipe, acetylene generator and other elements from fire in the form of reverse draft from a gas burner. The water in this seal must be at a level that needs to be monitored. It is usually located between the burner and the acetylene pipe.

Gas cylinders

These cylinders are of different colors depending on the type of gas. A strict rule applies to all cylinders: never paint the top to avoid contact between paint and gas. Another technical nuance: copper valves cannot be installed on acetylene cylinders due to the high risk of explosion from the interaction of acetylene and copper.

Hoses for various purposes

Burner device.

Hoses are needed for many things: supplying gases and hot liquids. In addition, they must work under pressure, so these are not garden hoses for watering a vegetable garden, but serious devices with special technical characteristics.

Hoses come in three categories:

- with a red stripe for pressure up to 6 atmospheres;

- with a yellow stripe for flammable substances;

- with a blue stripe for pressure up to 20 atmospheres.

Gas-burners

Gases and vapors from flammable liquids are mixed in the burner mixer. They are produced in a huge variety, divided into injection and burners without it, of different powers and so on.

Gas post

This is a special work table for welding. The best option for a post is a tabletop with the ability to rotate and fix it. A good post is equipped with exhaust ventilation and a good storage system for welding tools.

https://www.youtube.com/watch?v=7_k6hZ0SyPo

Gas welding torch. Welding torch design

A gas welding torch is a device that allows you to properly mix flammable gas (or vapor of a flammable liquid) with oxygen and obtain a stable welding flame of the required power. Welding torches are part of gas welding equipment.

Classification of welding torches

Welding torches are classified according to several criteria:

a) according to the method of supplying oxygen and combustible gas for gas welding, injection and non-injector gas burners are distinguished;

b) according to the type of flammable substance, burners are divided into gas (in which flammable gas is supplied) and liquid (in which gasoline or kerosene is sprayed);

c) depending on their purpose, burners can be universal or specialized;

d) depending on the number of gas flame flows, heating pads are divided into single-flame and multi-flame;

e) according to the method of use, burners are divided into manual and machine;

e) in terms of power, burners are of low power (with an acetylene flow rate of 25-400 l/h), medium power (with an acetylene flow rate of 400-2800 l/h) and high power (with a gas flow rate of 2800-7000 l/h).

Classification and scope of application of torches for oxy-acetylene welding

According to GOST 1077, single-flame universal gas torches for oxy-acetylene welding are divided into four types: G1 (micro-power), G2 (low power), G3 (medium power), and G4 (high-power burners).

Low and medium power burners are most widely used. Low-power torches are used when welding thin metal, 0.2-07 mm thick. They come with four tips of different sizes.

Medium power torches are used for manual gas welding, for welding cast iron, welding non-ferrous metals and alloys, or for surfacing, soldering and preheating metals. The medium power burners come complete with a barrel and seven interchangeable nozzles of various sizes. The attachments are attached and fixed to the barrel using a union nut.

This configuration of the torches allows you to adjust the power of the welding flame over a wide range and weld metals with a thickness of 0.5-30 mm.

Design and principle of operation of injection and non-injector welding torches

The figure below shows the design of injection (top) and non-injector (bottom) welding torches.

Injection burners are most widely used in practice. The injector is a cylinder in which a small diameter channel for oxygen is made in the center, and radially located channels for combustible gas are made. Oxygen is supplied at a pressure exceeding the pressure of the combustible gas. Thus, with the help of an oxygen flow, combustible gas is sucked into the mixing chamber. This feeding principle is called injection.

Oxygen from the gas welding cylinder is supplied to the welding torch and passes through the connecting fitting (pos. 5) to the injector (pos. 7). The control valve (item 6) allows you to control the amount of oxygen supplied.

Passing through the central hole of the injector (pos. 7) under high pressure, oxygen creates a rarefied space in the mixing chamber (pos. 8) and sucks flammable gas into it, which is supplied through the radial channels of the injector. The combustible mixture formed in the mixing chamber is directed through the tip (item 2) to the mouthpiece (item 1). At the exit from the mouthpiece, the gas mixture burns, forming a welding flame. The tip is connected to the barrel of the welding torch using a union nut (item 3).

Injection welding torches come complete with replaceable tips. Replaceable tips differ in the diameter of the holes in the mouthpiece and injector, so you can change the power of the welding flame.

Injectorless burners do not have an injector. Oxygen and flammable gas are supplied to them at the same pressure (about 100 kPa). In such burners, instead of an injector, a conventional mixing nozzle is installed, which is screwed into the tip.

Information about the acetylene welding method

Types of grinding machines, criteria for selecting models

The main component in this type of welding is acetylene. It is obtained artificially by mixing water and calcium carbide. In the burner, a mixture of oxygen and oxygen is formed, the combustion of which allows one to create a high temperature.

As a result of the combustion of acetylene in an oxygen environment, a high temperature is created, which allows the edges of the parts to melt and firmly connect them to each other.

Difficulty of gas welding

The main difficulty in welding with acetylene and oxygen is to obtain C2H2. Previously, this was done in a special apparatus, then the gas was supplied through hoses to the burner.

Oxygen was supplied to it from a cylinder, they mixed, and a flame formed. Calcium carbide and water were poured into the generator manually. This labor-intensive process was performed before each weld. After completing the work, the water was drained and the remaining carbide was reused.

Now it is much easier to carry out acetylene welding. You no longer need to manually mix water with carbide: there are special acetylene cylinders, you just need to connect them to the burner.

Description of technology

To carry out welding, first open the acetylene supply to the torch. An unpleasant odor indicates that it is coming out. Then they ignite the gas and slowly begin to supply oxygen from the cylinder.

The flame should turn blue. Oxygen and acetylene tanks have gearboxes. For the first gas, the pressure is set to 2 atm, and for the second - 2-4 atm. Large values complicate the welding process.

During the gas welding process, under the influence of high temperature, the edges of the joined workpieces turn into a liquid state, and after they harden, a strong connection is obtained. Oxygen cylinders are painted blue, and acetylene cylinders are painted white.

Oxygen and acetylene cylinders.

Advantages of this method

When such a gas burns in an oxygen environment, a temperature is reached that exceeds the melting point of steel and other metals. A qualified welder using such equipment performs work efficiently and with high efficiency.

In addition, acetylene welding has such advantages as:

- high mobility (no electrical connection required);

- the ability to adjust the flame temperature (this allows you to prevent deformation of parts and joints, control the speed of work);

- convenient execution of a rotary seam when the distance to the wall is small (in other types of welding you have to make an operational joint);

- the ability to connect workpieces made of metals with different melting temperatures;

- the ability to weld thin-sheet products made of structural steel, copper, cast iron, brass (in such cases, other welding methods are ineffective);

- the use of different filler wires, which helps improve the quality of the weld.

Disadvantages of using acetylene

Among the disadvantages of this welding method, the following should be noted:

- Acetylene is highly explosive, but a lot depends on the person.

- During operation, a large area of the joined products is heated, which leads to a change in the properties of the material. This method is not used in mechanical engineering.

- If you need to connect parts with a thickness of more than 5 mm, then it is better to use electric welding.

- Acetylene is not suitable for high carbon steel.

- If you overlap, then large stresses are formed in the products and they become deformed.

- Materials and equipment costs increase, unlike electric arc welding.

- Only an experienced welder can carry out the work.

Only an experienced specialist can handle acetylene welding.

What metals is it suitable for?

This type of welding is suitable for most ferrous and non-ferrous metals. It is practically indispensable when connecting thin-walled pipes and similar parts, when working with copper, cast iron, and structural steel workpieces.

Acetylene torch working principle

§ 44. Welding torches

Burners are divided into injection and non-injector, single-flame and multi-flame, for gaseous fuels (acetylene, etc.) and liquid (kerosene vapor). The most widely used are injection burners operating on a mixture of acetylene and oxygen.

Diagram and principle of operation of an injection burner.

The burner consists of two main parts - the barrel and the tip (Fig. 64).

The barrel has oxygen 1

and acetylene

16

nipples with tubes

3

and

15

, a handle

2

, a body

4

with oxygen

5

and acetylene

14

valves.

On the right side of the burner (if you look in the direction of gas flow) there is an oxygen valve 5

, and on the left side there is an acetylene valve

14

.

The valves are used to start, regulate the flow and stop the gas supply when the flame is extinguished. The tip, consisting of an injector 13

, a mixing chamber

12

and a mouthpiece

7

, is attached to the burner barrel body with a union nut.

Rice.

64. Injection torch design: 1, 16 - oxygen and acetylene nipples, 2 - handle, 3, 15 - oxygen and acetylene tubes, 4 - body, 5, 14 - oxygen and acetylene valves, 6 - tip nipple, 7 - mouthpiece, 8 — mouthpiece for propane-butane-oxygen mixture, 9 — fitting, 10 — heater, 11 — combustible mixture tube, 12 — mixing chamber, 13 — injector; a, b - diameters of the outlet channel of the mixing chamber injector, c - size of the gap between the injector and the mixing chamber, d - side holes in fitting 9 for heating the mixture, e - diameter of the mouthpiece hole Injector 13

It is a cylindrical part with a central channel of small diameter for oxygen and peripheral, radially located channels for acetylene. The injector is screwed into the mixing chamber of the tip and is located in the assembled burner between the mixing chamber and the gas supply channels of the burner body. Its purpose is to create a rarefied state with an oxygen stream and suck in acetylene supplied under a pressure of at least 0.01 kgf/cm 2 . The vacuum behind the injector is achieved due to the high speed (about 300 m/s) of the oxygen jet. The pressure of oxygen entering through valve 5 ranges from 0.5 to 4 kgf/cm 2 .

The injection device is shown in Fig. 65.

Rice. 65. Section of the injection device: 1 - mixing chamber, 2 - injector, 3 - burner body

In the mixing chamber, oxygen is mixed with acetylene and the mixture enters the mouthpiece channel. The flammable mixture leaving the mouthpiece at a speed of 100 - 140 m/s burns when ignited, forming an acetylene-oxygen flame with a temperature of up to 3150 ° C.

The torch kit includes several tip numbers. For each tip number, the dimensions of the injector channels and the dimensions of the mouthpiece are established. In accordance with this, the consumption of oxygen and acetylene during welding changes.

The design of propane-butane-oxygen burners differs from acetylene-oxygen burners in that there is a device in front of the mouthpiece 10

(Fig. 64) for heating the propane-butane-oxygen mixture. Additional heating is necessary to increase the flame temperature. The regular mouthpiece is replaced by a modified mouthpiece design.

Technical characteristics of injection burners.

Currently, the industry produces welding torches of medium power - "Zvezda", GS-3 and low power - "Zvezdochka" and GS-2. The “Moskva” and “Malyutka” burners, produced before 1971, are also in operation.

Torches “Moscow”, “Zvezda” and GS-3 are designed for manual oxy-acetylene welding of steel with a thickness of 0.5 - 30 mm.

The medium-power torch kit includes a barrel and seven tips attached to the torch barrel with a union nut (Table 15). The required set includes tips No. 3, 4 and 6, most often necessary when performing welding work, the remaining tips are supplied at the request of the consumer. Burners “Zvezdochka”, GS-2 and “Malyutka” are supplied with tips No. 0, 1, 2, 3. In burners “Zvezda”, GS-3, “Zvezdochka” the mouthpieces are made of bronze Br.Kh 0.5, metal more more resistant than MZ copper, which was used for the manufacture of mouthpieces for “Moscow” and “Malyutka” burners. For this reason, the service life of the burners produced is increased compared to those produced previously.

15. Technical characteristics of low and medium power burners

Burners of the GS-3 type work with hoses with a diameter of 9 mm. Low-power torches “Malyutka”, “Zvezdochka” and GS-2 are designed for welding steels with a thickness of 0.2 - 4 mm. GS-2 burners work with rubber hoses with a diameter of 6 mm.

For the propane-butane-oxygen mixture, the industry produces burners of the GZU-2-62-I and GZU-2-62-II types; the first is intended for welding steel with a thickness of 0.5 to 7 mm, the second is for heating the metal. For flame cleaning of metal surfaces from rust, old paint, etc., an oxygen-acetylene torch GAO (acetylene burner, cleaning) is produced. The width of the surface processed by the burner in one pass is 100 mm.

For metal hardening, NAZ-58 tips are produced for the GS-3 burner barrel.

Welding and other types of metal processing with a propane-butane-oxygen flame can be performed with a GZM-2-62M torch with four tips.

Malfunction of the injection device leads to backfire and a decrease in the supply of acetylene in the combustible mixture. The acetylene reserve is an increase in its flow rate when the acetylene valve of the burner is fully open compared to the nominal flow rate for a given mouthpiece number. The causes of these problems may be clogging of the oxygen channel, excessive increase in its diameter due to wear of the acetylene channels, displacement of the injector relative to the mixing chamber, and external damage to the injector. For normal operation of the burner, the diameter of the outlet channel of the mouthpiece must be equal to the diameter of the channel of the mixing chamber, and the diameter of the injector channel must be 3 times smaller.

The injector seat is adjusted for the injectors included in the burner kit.

The Moscow burner injectors can be used in the Zvezda burner, and the Malyutka burner injectors can be used in the Zvezdochka burner.

The burner is checked for injection (vacuum) every time before starting work and when changing the tip. To do this, remove the acetylene sleeve from the nipple and open the oxygen valve. In the acetylene nipple of a working burner, a suction should be created, which can be detected by touching the nipple hole with a finger.

Maintaining the mouthpiece in proper condition ensures a normal flame in shape and size (see Chapter X). Mouthpieces operate at high temperatures, are subject to mechanical destruction from welding spatter and require maintenance (cleaning, cooling, etc.). Scores, scuffs, and carbon deposits on the walls of the outlet channel of the mouthpiece reduce the rate of exit of the combustible mixture and contribute to the formation of pops and backfires, distorting the shape of the flame. These shortcomings are eliminated by trimming the end of the mouthpiece by 0.5 - 1 mm, calibrating and polishing the outlet hole.

After each repair, burner parts must be degreased with B-70 gasoline.

Injectorless burners

operate under the same pressure of oxygen and acetylene, equal to 0.1 to 0.8 kgf/cm2. These burners provide a more constant composition of the combustible mixture during operation. Non-injector burners can be powered with acetylene, either from cylinders or from medium pressure generators.

Special burners.

For gas-flame processing of materials, it is sometimes advisable to use special burners. The industry produces burners for heating metal for the purpose of heat treatment, removing paint, rust, burners for soldering, welding thermoplastics; flame surfacing, etc. The fundamental design of special torches is in many ways similar to the torch used for welding metals. The difference lies in the shape and size of the mouthpieces, as well as in the heat output, shape and size of the flame. Special burners are produced for any flammable gas.

1. Why is acetylene mainly used for gas welding from flammable gases?

2. Tell us about the classification of acetylene generators.

3. What role does the injector play in the burner?

4. What effect does the injection device and mouthpiece design have on the operation of the burner?

5. What types of special burners are there?

Self-rescuer sleep 20m at a reduced price on our website.

Equipment used

In the recent past, it was difficult to ensure a high-quality connection using acetylene, which was explained by the imperfections of the technologies used. However, today high-quality equipment has appeared that makes it possible to obtain an output flame with even parameters, and the welder has the ability to easily adjust the intensity and temperature of the burner flame. Such acetylene welding equipment includes a corresponding generator, which is charged with carbide during operation and allows you to control the pressure level in the system. Modern installations for such acetylene welding are completely safe to use, they are reliable, and easy to use.

It is also possible to use a cylinder filled with acetylene instead of oxygen and a generator, which can significantly simplify welding work. This reduces labor costs and increases the productivity of such welding. However, it must be taken into account that the use of already filled acetylene cylinders leads to a slight increase in the cost of welding metal elements.

Gas welding of metal products with acetylene

One of the undoubted advantages of this welding technology is its simplicity. For such work you will need special burners for working with acetylene. Such burners are marked with indices from 0 to 5. Equipment with index 0 has the lowest productivity and is designed to work with light alloy metals. But installations marked 5 are characterized by maximum productivity, which allows them to be used for working with refractory metals.

The key to high-quality performance of such acetylene welding will be the correct choice of torch and its proper adjustment. It is also necessary to take into account that the number of electrodes used must correspond to the burner marking. In general, choosing electrodes is not difficult. In terms of parameters, they must correspond to the refractoriness indicators of metals and be close to it with their alloy.

The burner is purged with flammable gas from the generator and only after the characteristic smell of acetylene appears, you can ignite the burner and add a small amount of oxygen from the cylinder. By adjusting the valve on the oxygen cylinder, the welder can regulate the intensity of the flame, its temperature and saturation. The reducer pressure should be approximately 2 atmospheres for an oxygen cylinder and from 2 to 4 atmospheres for a generator. In each specific case, these indicators should be selected depending on the characteristics of the metal elements being welded.

The surfaces of metal elements for welding with acetylene must be cleaned of paint and other contaminants. They are adjusted as close to each other as possible. Next, the burner flame must be directed to the joint seam, and the filler material must move after the burner. This technology will ensure the elasticity and strength of the connection. You can also use welding technology, when the flame from the torch is directed away from the resulting seam. In this case, the filler material is introduced into the high-temperature weld pool, melts and flows into the resulting connecting seam. The disadvantage of this technology is the increase in the heating zone, which can lead to warping of metal elements and a change in the structure of the metal.

Operating principle of an injection burner

In injection burners, the supply of combustible gas to the mixing chamber is carried out due to its suction by a stream of oxygen flowing at high speed from the nozzle opening. This process of sucking gas of lower pressure with a stream of oxygen, which is supplied with more

Rice. 61. Injector burner design:

high pressure is called injection. Burners that use a similar operating principle are called injection burners.

For normal operation of injection burners, the acetylene pressure is required to be significantly lower than the oxygen pressure (0.001-0.12 MPa and 0.15-0.5 MPa, respectively).

In Fig. Figure 61 shows a diagram of the injection burner design.

The burner consists of two main parts - the barrel and the tip. The barrel has an oxygen nipple 1 and an acetylene nipple 16 with tubes 3 and 15, a handle 2, a body 4 with two valves - acetylene 14 and oxygen 5.

The valves are used to start and stop the gas supply when the flame is extinguished, as well as to regulate the flow.

The burner tip consists of a mixing chamber 12, an injector 13, a tube 11 with a tip nipple b and a mouthpiece 7. The entire tip assembly is connected to the burner barrel body with a special union nut.

Injector 13 (Fig. 62) is a cylindrical part with a central channel for oxygen and peripheral radial channels for acetylene. The central channel has a very small diameter.

Rice. 62. Diagram of the injection device

For normal injection you need the correct one* *

drilling the gap between the end of the injector and the mixture cone—the body chamber.

The vacuum behind the injector (suction of acetylene) is achieved due to the high speed of the oxygen jet (up to S00 m/sec). The pressure of oxygen, which enters through valve 5, ranges from 0.5 to 4 kgf/cm2.

In the mixing chamber, acetylene is mixed with oxygen and the mixture enters the mouthpiece channel. The mixture comes out of the mouthpiece at a speed of 50-170 m/sec.

Heating the burner tip reduces injection and reduces the vacuum in the injection chamber, which reduces the flow of acetylene into the burner. This, in turn, leads to an increase in the oxidizing effect of the welding flame. To restore the normal composition of the welding flame, the welder must increase the flow of acetylene as the tip heats up by opening the acetylene valve.

The torch kit includes several tips of different numbers. For each tip, the dimensions of the injector channels and the dimensions of the mouthpiece are established.

The design of propane-oxygen burners is distinguished by the presence of a device 10 in front of the mouthpiece for heating the propane-oxygen mixture. Additional heating is needed to increase the flame temperature.

Injectorless burners. In non-injector burners, combustible gas and oxygen are supplied at approximately the same pressure (0.05-0.01 MPa). The burner does not have an injector: instead there is a simple mixing nozzle, which is screwed into the burner tip tube (Fig. 63).

Oxygen flows through the hose through nipple 4, valve 3 and special metering channels into the burner mixer. Acetylene also enters the burner in the same way.

Rice. 63. Scheme of a non-injector burner

To form a normal welding flame, the combustible mixture must flow from the torch at a certain speed, namely the burning speed. If the flow rate is greater than the burning rate, the flame will break away from the mouthpiece and go out. If, on the contrary, the flow rate is less than the combustion rate, then the combustible mixture will ignite inside the tip.

In this regard, welding stations are additionally equipped with automatic regulators that ensure equal pressure of acetylene and oxygen.

A few words about consumables

What gas is used for welding is not an unimportant question that you need to understand in order to make the right choice. The types of gases used vary and the choice depends on several factors.

Oxygen

Oxygen, for example, is completely colorless and odorless. It has a special role; it acts as a catalyst for metal melting processes during welding. Oxygen is stored and transported in cylinders with constant pressure. This is not an easy task, but it is quite doable.

Gas burner flame.

In no case should there be a source of heat or direct sunlight in the rooms where cylinders are stored.

How to obtain welding oxygen: this is done quite simply - from atmospheric air using specialized equipment.

Oxygen is divided into three types based on purity:

- premium grade with a gas concentration of 99.5%;

- first grade with 99.2%;

- the second – with 98.5%.

Acetylene

This is the second most popular gas used in gas welding for both welding and cutting. It is also colorless and odorless. Acetylene may explode if pressurized or heated. It is made from calcium carbide and water.

Acetylene is not the cheapest gas, but its advantages make it very popular among welders. It's all about the combustion temperature - it is remarkably high for acetylene, especially in comparison with cheaper gases such as methane, propane or kerosene vapor.

Flux and filler wire

These are the main participants in the process of weld formation. The filler wire must be absolutely free from the slightest signs of dirt or corrosion. Sometimes, instead of wire, you can use a strip of the same metal as the workpiece for welding.

The only metal that can do without a flux mixture is carbon steel. Well, a special need for the presence of flux arises when welding copper, aluminum and their alloys.

Types of flame

One of the advantages of gas welding is the ability to use fire with different chemical properties: oxidizing, reducing, with a high acetylene content.

A “normal” flame is considered to be a reducing flame, in which the metal is oxidized at the same rate as it is reduced. It is used in most cases. To join parts made of bronze and other alloys containing tin, only reducing fire is used.

An oxidizing flame is formed when the amount of oxygen in the gas mixture increases. In some cases it is preferable and even necessary, such as when joining brass and brazing.

A special property of the oxidizing flame is the ability to increase the speed of gas welding. But in this case it is necessary to use a special additive containing deoxidizing agents - manganese and silicon.

If you use the same material as a filler wire with an oxidizing flame as in the parts being welded (with the exception of brass), the weld will come out brittle, with a large number of pores and cavities.

https://youtube.com/watch?v=rXRycorsAOo

A flame with an increased content of flammable gas is used for surfacing another part made of a harder alloy onto any part, as well as when welding parts made of cast iron and aluminum.

In-nozzle mixing

In devices with intra-nozzle mixing, the mixture is formed in slotted channels between the outer sleeve and the inner mouthpiece. The supply of cutting oxygen is carried out by a lever valve, and the heating and combustible gas is supplied by regulators installed on the handle.

This equipment is available in 3 versions: for working with acetylene, propane and natural gas. Since the gas is mixed not at the handle, as in injection devices, but at the head, such devices have an increased level of safety. At the same time, this principle of operation requires a more complex design, which leads to an increase in the cost of the device. Also, for stable operation, an increased pressure of combustible gas is required - from 20 kPa.

Devices with intra-nozzle mixing

Advantages and disadvantages

The most important advantage of this type of welding is its autonomy, so there is no need for a power source, which is especially acceptable when performing installation and construction work on sites where there is no electricity.

Advantages of acetylene welding:

- The ability to regulate the distance to the surface to be welded and operating modes, which eliminates defects in the form of burns, even in the case of joining thin metal sheets.

- Mobility of movement and transportation around the installation and construction site.

- Reliability and high quality of work performed.

- Monitoring the welding process.

- Possibility of making a non-rotating seam near obstacles, for example, a wall, without the need for an operational joint.

- Creation of permanent metal joints with different melting point temperatures.

- Adjusting the strength and size of the welding flame.

- Improving the quality of the weld using alloy steel wire.

- Elimination of the processes of occurrence of deformation shifts in the structure and joint by adjusting the heating temperature, thereby achieving the design mode of metal welding.

- Low cost of equipment and consumables for the device.

Disadvantages when using a mini acetylene torch:

- Work may only be performed by trained and certified workers.

- Low productivity of welding work.

- Changes in the chemical and structural properties of a material over a large heating area.

- The use of acetylene creates a high fire hazard in the environment;

- Large gas contamination in the welding area.

- Low-quality soldering of alloy steel components.

- Inability to perform overlap welding.

User manual

All operations with an acetylene torch can be performed by trained personnel certified in knowledge of the rules of PB 03.273/99 and other industry and regional regulations for work at facilities under the jurisdiction of the Gosgortekhnadzor of the Russian Federation.

When performing work using gas cylinders, welders are required to comply with strict fire safety measures: do not throw them away without supervision, do not place them near hot springs, with oxygen or other flammable gas mixtures.

Before starting welding work in the premises, it should be thoroughly ventilated before/during/after the welding process. Before carrying out work, all necessary permits and permits must be completed.

a brief description of

Acetylene welding is an ancient method of welding metal parts. Acetylene is obtained by combining calcium carbide and water. Previously, mixing was done manually using a special generator. Additionally, an oxygen cylinder, hoses, and a burner were used.

The main feature of acetylene as a chemical element is the structure of its molecule C2H2. It has two weak hydrogen bonds and a high-energy triple bond between carbon atoms. It is these properties that made it possible to use gas in welding technology. It produces high-quality and durable connections of structures made of different types of metal.

However, this technology had a big drawback - the use of a generator and manual mixing of acetylene. This measure was complex and had to be performed before each welding. But not everything is so bad, there were still positive aspects, the remaining gas was later drained, they were used again.

However, after some time, welding with acetylene and oxygen began to be carried out using special cylinders with the necessary gas. For this reason, it is no longer necessary to manually combine calcium carbide and water.