In order to supply technical or shielding gas to the torch during welding, a special part is required - a welding sleeve. It is a hose with a complex internal structure, which is protected on the outside by a rubber sheath. But to be useful, such a welding hose must be flexible, which makes it vulnerable to various deformations. More information about what a sleeve for a semi-automatic machine is and whether it can be replaced is further in the material.

Technical features

For proper semi-automatic welding, the device will require three components:

- A welding gun called a torch.

- A hose called a “welding sleeve”.

- A connector that allows you to connect the hose to the burner.

When using a torch, the hose fails more often than other parts, as it is abraded by wire from the inside and is subject to the influence of the external environment and mechanical deformations. It's all about its design, since it is a kind of multilayer hose, which has an inner layer that is in direct contact with the gas, as well as an outer protective rubber one. There can be any number of layers, depending on the production technology; they are separated by a special thread frame, which gives strength to the entire welding hose. The frame can be made of wire thread or fiberglass.

Bellows

Bellows tubes are most often recommended by gas equipment installation specialists. This option is the most reliable and most expensive. But given the very long service life (up to 30 years), its cost is justified. Price from 170 rubles for 60 cm of finished eyeliner.

The bellows hose is made of stainless steel, with a PVC coating on top. This ensures that it will last a long time: the average lifespan is 25–30 years. The metal braid reliably protects from mechanical influences, and the polyvinyl chloride coating provides electrical insulation and resistance to chemicals. Thanks to the corrugated surface, the product bends easily.

USEFUL INFORMATION: How much does it cost to connect a gas stove in an apartment officially?

Bellows gas hose has the following advantages:

- can be connected to any gas equipment: stoves, boilers, etc.;

- has connecting dimensions 1/2″, 3/4″, 1″;

- has excellent flexibility;

- withstands pressure up to 6 atmospheres;

- wide range of operating temperatures: from -50 to +250 degrees (installation outdoors is allowed; nothing will happen to it if it comes into contact with hot surfaces);

- able to withstand mechanical loads, aggressive environmental influences, and household chemicals;

- hoses comply with the requirements of GOST R 52209-2004, GOST12.2.063-81, GOST12.2.003-91;

- warranty service life - up to 15 years;

- service life – up to 30 years;

- is able to ensure the tightness of the system even under extreme loads, for example, during an earthquake.

The length of the bellows gas hose varies depending on the connection, it can increase in size by 2 times and has the following parameters (in meters):

- from 0.26 to 0.52;

- from 0.5 to 1.0;

- from 0.75 to 1.5;

- from 1.0 to 2.0.

And the hoses have a fixed length (in meters):

- 0,3;

- 0,4;

- 0,5;

- 0,6;

- 0,8;

- 1,0;

- 1,2;

- 1,5;

- 1,8;

- 2,0;

- 2,5;

- 3,0;

- 4,0;

- 5,0.

Dielectric insert, 1/2″, fitting-fitting >>>

Dielectric insert, 1/2″, fitting-nut >>>

Dielectric insert, 3/4″, fitting-fitting >>>

Eyeliner for size 1/2″

Flexible gas connection, bellows type, 1/2″, fitting-nut, 60 cm >>>

Flexible gas connection, bellows type, 1/2″, fitting-nut, 80 cm >>>

Flexible gas connection, bellows type, 1/2″, fitting-nut, 200 cm >>>

Flexible gas connection, bellows type, 1/2″, fitting-nut, 300 cm >>>

Flexible gas connection, bellows type, 1/2″, fitting-nut, 400 cm >>>

Flexible gas connection, bellows type, 1/2″, nut-nut, 60 cm >>>

Flexible gas connection, bellows type, 1/2″, nut-nut, 80 cm >>>

Flexible gas connection, bellows type, 1/2″, nut-nut, 100 cm >>>

Flexible gas connection, bellows type, 1/2″, nut-nut, 150 cm >>>

Flexible gas connection, bellows type, 1/2″, nut-nut, 200 cm >>>

Flexible gas connection, bellows type, 1/2″, nut-nut, 300 cm >>>

Flexible gas connection, bellows type, 1/2″, nut-nut, 400 cm >>>

Eyeliner for size 3/4″

Flexible gas connection, bellows type, 3/4″, fitting-nut, 100 cm >>>

Flexible gas connection, bellows type, 3/4″, nut-nut, 60 cm >>>

Flexible gas connection, bellows type, 3/4″, nut-nut, 80 cm >>>

Flexible gas connection, bellows type, 3/4″, nut-nut, 150 cm >>>

Flexible gas connection, bellows type, 3/4″, nut-nut, 200 cm >>>

Classification

It will be easier to choose a hose for gas welding if you know in advance what types exist. There are only three types, each corresponding to its own class:

- The first class is useful for working with propane, butane and acetylene; such a hose will withstand a pressure of no more than 0.63 MPa.

- A second class welding hose is useful for liquid fuels, such as kerosene or gasoline, and even white spirit solvent.

- The third class allows the semi-automatic device to work with only one gas - oxygen.

To make the hoses easy to distinguish from each other, they are painted in different colors. First class is always red, second is yellow, and third is blue. There is also a fourth, universal type, it is designated black or any other color other than the three basic ones.

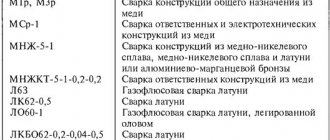

Types of hoses for gas welding according to GOST 9356-75

There are also limitations in operating conditions. Some gas welding hoses can be used at extreme ambient temperatures of +70 degrees, but it cannot fall below -35. If you plan to work in very cold climates, you can purchase a welding hose that can work at -55.

The temperature capabilities of welding hoses may vary depending on their manufacturer.

Construction of hoses for welding machines

A hose for argon welding, a gas torch or a cutter is a multilayer pipeline, the body of which is reinforced with a thread frame . That is, such a hose consists of an inner “pipe”, which is braided with threads of the load-bearing frame and covered with another, outer layer.

An elastic material with high resistance to pumped media (flammable gases, argon, helium and oxygen) is used as a structural material for the “inner” pipe and the outer layer. Typically, technical (black) rubber is chosen as such a material.

Moreover, the outer layer is made either of the same black rubber, or of vulcanized rubber with frost-resistant additives, to which a color is added that makes it easier to identify the hoses.

Thread or fiberglass is used as a reinforcing coating. Moreover, the coating is wound onto the “inner” black rubber pipe before applying the outer layer.

Welding Hose Classes

The classification of hoses is related to the characteristics of their operation. That is, the class of the hose is influenced by the type of welding machine to which such a “pipeline” is connected and the type of substance transported through it.

Based on these signs, there are:

- Oxygen hoses that can withstand high pressure (up to 20 atmospheres!). In the general classifier, oxygen hoses belong to the third class. Marking – blue color of the outer covering.

- Gas hoses that can withstand pressure up to six atmospheres. In the general catalog, such hoses belong to the first class. Moreover, this category should include hoses for gas welding or cutting, through which “fuels” are transported (acetylene, propane or butane), and hoses for argon-arc devices, through which inert gas is transported. Marking – black outer covering with a red stripe.

- Hoses for liquid fuel mixtures operating under pressure up to six atmospheres. This variety belongs to the second class, used in fuel lines supplying gasoline, kerosene and other flammable carbohydrates. Marking – black outer covering with a yellow stripe.

Moreover, the range of hoses is based on division by diameter and frost resistance class. Based on the first sign, hoses are divided into several varieties with diameters (internal) from 6 to 16 millimeters.

According to the second criterion, hoses are divided into two groups: the first is designed for operation in the range from – 30 to 70 degrees Celsius, the second – for operation in the range from – 55 to 70 degrees Celsius.

All varieties of the assortment go on sale in 100-meter bays. The price of welding hoses depends on their class, throughput diameter and is tied to the footage (length). Accordingly, the most expensive hose is oxygen (it is stronger), and “gasoline” and gas varieties are a little cheaper.

Marking

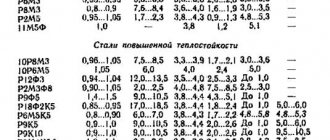

In order not to make a bad choice, in addition to the color, you need to pay attention to the markings that are applied to each gas welding hose. Usually it looks like this: III-9-2-HL GOST 9356-75. Here:

- III is a welding hose class, the third in this case. This can be understood by the blue coloring, but it is necessary to indicate the class on the labeling.

- 9 - diameter, in millimeters.

- 2 - design pressure, in MPa.

- HL is a designation confirming that the hose can be used in extremely cold climates.

Delivery of hoses for gas welding

Delivery cost in Moscow and the Moscow region: by courier - 500 rubles. (restrictions on courier delivery - no more than 50 kg and no further than 20 km from the Moscow Ring Road towards the region).

Delivery to other regions is carried out by transport companies. How to choose a transport company is described on our website in the Delivery in Russia section.

Contact number for receiving orders for delivery: +7 (495) 921-34-24 (accepted on weekdays from 9.00 to 17.00, on Saturdays from 10.00 to 14.00, and on the website - around the clock).

We do not divide orders into large and small; every customer is important to us. It's important that the next time you need something, you come back to our warehouse store.

How to choose when purchasing?

We've sorted out the colors and markers, all that remains is to understand what the basic rules for choosing a welding sleeve for a semi-automatic machine are. First of all, you need to try to buy a hose that matches the model of the device. But if this is not possible, the closest and highest quality analogue is selected.

First, pay attention to the color of the welding sleeve, which signals its class. Next, pay attention to the length. Here it is advised not to take a hose longer than 2-2.5 meters, as it will be more difficult to manage and is prone to twisting.

Also, when choosing, you need to know the diameter of the wire in the welding sleeve. Most often the size is standard - 0.6-1.6 mm, but sometimes other parameters are found, for example, 0.2-0.6 mm.

Welding conditions are also important. The marking always indicates whether the hose is suitable for use at very low temperatures.

And the last thing that attention is always paid to is external defects. There should be no damage or cracks, the welding sleeve should bend easily and return to its original state.

Choosing a complete hose for a torch or gun will require taking into account criteria such as:

- Convenience of form.

- Bending necks to allow access from different positions.

- Parameters of conductive mouthpieces.

- Presence of spring pins.

- Connectors. They should be suitable, although for the most part all are of the universal KZ-2 standard.

The burner is selected first of all, specifically for the materials that will be worked with most often. The sleeve is matched to the device.

Reasons for element failure

If a semi-automatic welding sleeve with a mechanical valve has failed or the device has received mechanical damage, the part requires repair or replacement. In order not to spend extra money, you first need to diagnose the node.

If the welding seam turns out to be of poor quality, then this directly depends on the condition of the sleeve. A bad weld can be caused by wire jamming inside the element or by insufficient gas. Both reasons are grounds for replacing the hose separately or together with the burner. The last option is rarely used. More often they buy one new element, or make a welding sleeve for a semi-automatic machine with their own hands.