When to wear

It is advisable to use protective glasses in cases where the use of a welding helmet is impossible due to limited space at the welding site. Sometimes welding glasses are used to reduce the intensity of the load on the cervical spine during work.

The goggles are much smaller than the welding helmet, and their weight is also significantly different from its weight. These are, perhaps, the only advantages of glasses, since their protective properties are limited only to protecting the retina of the eyes and the skin around them from the influence of ultraviolet and infrared radiation, as well as from the mechanical effects of particles of molten metal, dust and smoke.

Nevertheless, very often the working environment requires the welder to use just this type of protection.

Welder glasses for gas welding and semi-automatic welding

Safety glasses – safety first

One of the most vulnerable places of a person is his eyes.

It is very important to provide reliable protection for the organs of vision not only in production and construction sites, but also during household work involving the presence of fragments, wood or metal shavings, dust and other mechanical influences. In this section you can familiarize yourself with our range of welding glasses and select everything you need.

You need to select suitable safety glasses in accordance with the specific tasks that will be assigned to the worker.

Products are classified into the following types:

- welding glasses – for electric and gas welding;

- construction safety glasses;

- safety transparent glasses with direct or indirect ventilation;

- for metalwork;

- optics with ASF and other light filters.

Manufacturers do not stand still, developing new and improving old models. The range of welding glasses is very wide. Modern models combine not only reliable protection, but also convenience and ease of use.

Today, such optics have excellent high characteristics:

- panoramic glass: scratch-resistant, provide good visibility and a wide viewing angle;

- darkened glasses (for welding work): protect the eyes from sparks and debris, protect the cornea and crystal from increased light radiation;

- direct and indirect ventilation prevents the glass from fogging up;

- eye protection from infrared and ultraviolet radiation;

- reliable fasteners and fasteners guarantee the safety of the retina and provide additional comfort (since the glasses do not need to be adjusted or held);

- Can be combined with prescription glasses.

Another advantage of modern welder protection is an increased level of comfort. Most models are made from high-quality materials that do not cause allergic reactions, are pleasant to the skin and have high ergonomic characteristics.

The section contains not only welding glasses, but also a transparent protective mask, which is designed to protect not only the eyes, but also the face. It protects against sparks, splashes, dust, abrasive particles, and splinters.

The safety helmet provided in this section is a necessary means of protecting the head during construction work from impacts, electrical discharges, metal splashes and all kinds of liquids.

If you have any questions or cannot decide on a choice, call us by phone or +7 (495) 77-55-830! We will answer any question you may have!

Device

The simplest glasses for welding work consist of two static, that is, light transmittance, filters that do not change light transmission. They are installed in a housing that fits tightly to the skin of the welder’s face, protecting it from the mechanical effects of welding products.

Filters are installed in two ways:

- still;

- with the ability to open them to inspect the welding site and visually assess the quality of the seam outside the arc burning time.

The second option is preferable due to the fact that you do not need to periodically remove glasses to monitor welding. If the filters open, the glasses must have transparent lenses to protect the eyes from dust.

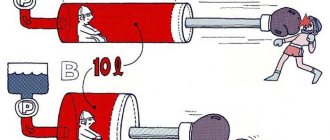

The case, which is usually made of non-flammable and refractory plastic, has holes for ventilation of the space inside the glasses. The holes are made in the form of louvered grilles, closed on the welding side and open on the opposite side.

The goggles are attached to the welder's head using elastic straps. The use of glasses must be complemented by the use of a protective construction helmet .

Welding goggles can be used for both manual welding and semi-automatic welding. When using electric arc and gas welding, glasses must have different characteristics. Light filters should have different degrees of darkness.

Kinds

Each specialist has his own requirements for protective equipment. Everyone chooses what they consider necessary, and with glasses for gas welding.

The most budget-friendly and simplest model are glasses with permanently darkened filters. Externally, they look like two eyepieces, fastened together with a strap, or framed by a lightweight body. This design provides a wide view even from the side, and is fixed on the head with a special elastic band.

It is convenient to work in such glasses, except that when assessing the quality of the seam you will have to take them off. Storing glasses of this type is very simple, just roll them up and put them in your ammunition pocket.

The second type is glasses in a hard case with a folding frame. This model is a little more expensive, but it makes it possible to evaluate the quality of the seam without removing the device. Under the darkened filters there is a frame with transparent but durable glass. The hinged lid allows you to change your view with one movement of your hand.

The third, most expensive type are auto-darkening glasses, the so-called “chameleons”. The price for this model is quite high, but the demand is not small. They are worth considering in more detail.

In appearance, chameleon glasses resemble a diving mask. The body is made of durable, refractory plastic; there are holes around the perimeter for ventilation, thanks to which the eyes do not water and fogging does not occur from the inside.

Glasses of this type have both built-in durable transparent lenses and a folding frame with automatically darkening liquid crystal filters.

In the inactive state, the light transmittance is similar to sunglasses, but when there is a sudden change in light, which is what happens with a welding flash, the crystals are ordered, providing optimal darkness for a particular type of welding.

These super glasses are powered by “solar” batteries that accumulate energy from bright lighting. Some models have a built-in control unit that allows you to change the level and speed of dimming.

With automatic filters

Recently, chameleon welding glasses have been widely used. When they are used, protection from ultraviolet and infrared radiation is carried out as a result of automatic changes in light transmittance by light filters. As a result, the darkening of the glass changes in accordance with the fury and intensity of the welding arc.

Chameleon filters are a multilayer structure consisting of layers of liquid crystals located in layers of polarized polymer material.

When external voltage is applied, the liquid crystals are arranged in a certain order and provide darkening of the filter. The dimming intensity can be changed by supplying current with different characteristics.

Externally, automatic light filters look like rectangular plates measuring approximately 90x140 millimeters and up to 10 millimeters thick.

Current parameters are calculated by electronic control units based on data received from light sensors. There may be several of them on welding glasses. Each of them blocks a certain sector of the view in order for the control unit to obtain more reliable information.

Control units and light filters receive energy for operation from portable power sources or from photocells that convert light into electricity.

Such photocells are also called “solar batteries”. Very often combined power supply circuits are used, when the functionality of the light filters when the arc is turned off is ensured by batteries.

When the arc is excited, the photocell begins to work, providing energy to the control unit and light filter, as well as recharging the batteries.

Features of some models

Some glasses models have controls on the body that change the filter settings. With their help, you can control the intensity of dimming and the response time to turning on the arc (response time).

Automatic light filters, depending on the design of the glasses in which they are used, can rise to reveal simple transparent lenses.

In this state, it can be convenient to use glasses when carrying out preparatory work - cutting metal with special tools, fitting and processing the edges of parts with abrasive tools. Glass protects the organs of vision from mechanical damage from metal particles and abrasives that fly apart during operation.

Automatic filters are quite expensive, so many models have a protective hard polymer coating on the outside to prevent damage to the outer polarized layer when using electric welding manually or using semi-automatic welding.

Many glasses allow replacement of automatic filters in case of damage or exhaustion of their resource

Peculiarities

Before buying welding glasses, you should pay attention to some characteristics:

- the body of the glasses should fit snugly against the skin;

- glass must be durable, at least 3 mm thick, which guarantees the preservation of the organs of vision from damage by metal particles;

- good visibility during operation;

- the frame with a “chameleon” does not jam and folds out easily;

- light weight of the device.

Considering these features, buying glasses will not turn into torture. Be sure to remember that the dimming rate is much slower when working in cold conditions. Do not weld at temperatures below -10°C degrees.

Welding glasses are comfortable and attractive in many ways. Reviews from owners of this device are mostly positive. But buying a mask or glasses is a personal choice of the master. When working for a long time, glasses will only protect the eyes themselves, but the face itself will remain defenseless. If you still decide to purchase glasses, then purchase them in a specialized store to reduce the risk of purchasing a low-quality device.

Security measures

Since welding glasses only protect a limited area of the welder's face, it is necessary to take into account the rules that allow you to carry out work safely.

When the seam is located at a high altitude, splashes of metal and scale may fall on the unprotected head and neck of the welder, so glasses can only be used when welding lower and horizontal seams located no higher than chest level .

If the seam is located higher, the use of scaffolding equipment is allowed. It should be remembered that welding at a height of more than half a meter should be carried out using safety belts.

For welding work, this is also relevant because the welder’s visibility during work is significantly limited. The use of protective equipment when performing welding work will ensure safety and improve its quality.

Application

As you know from the name, miracle glasses have found their application in the welding field. They are convenient to use when carrying out arc welding or semi-automatic welding. To do this, when buying glasses, you should pay attention to the degree of darkening; medium is enough (level 3 or 4). Please note that each type of welding has its own standards for shading welding glasses.

The main situations with the use of protective welding glasses are when it is necessary to apply a small (short) seam, and it is not possible to get close to it with a mask.

There is one strict rule: wearing glasses it is allowed to work with seams located no higher than the level of the chest.

This is due to the fact that with any welding method you can get injured from splashes and small particles of hot metal. When working with seams below chest level, the likelihood of injury is reduced, and it is almost impossible to get a facial burn.

It should be emphasized that it is recommended to use welding glasses when working with gas welding or when plasma cutting metal. It is not recommended to use them for electric welding. The reason is particularly strong radiation and a large area of scattering of splashes of metal particles.