Installing a toilet with your own hands is not that difficult. To do this, you do not need to be a trained plumber with extensive experience. It is enough to have the desire and be informed about the difficulties of doing this work.

One of the problems that everyone may encounter is the displacement of the sewer hole to one side. This problem is solved by a toilet cuff, which has its own connection details. We will talk about how to work with the cuff in this article.

Types of cuffs

A piece called a toilet cuff or coupling is needed to connect the toilet outlet to the sewer pipe. Depending on the form it is:

- corrugated;

- eccentric (it is called a toilet eccentric);

- conical;

- smooth straight line;

- smooth corner.

Models differ in diameter, length and material of manufacture. The diameter of one end must correspond to the size of the sewer pipe (most often 110 mm), and the second - to the toilet outlet channel. With a direct connection, you can choose a conical toilet cuff, the end of which gradually tapers.

The advantages of corrugation are that it can be used in difficult situations when the holes are strongly offset relative to each other. The corrugation can be rotated at the desired angle and stretched a little. However, its walls are quite thin, so many people prefer to use an eccentric or a straight smooth adapter.

The eccentric consists of two cylindrical surfaces with offset axes. This shape allows you to hermetically connect holes that are unevenly opposite each other.

Sometimes the parts are combined, ensuring the tightness of the connection, since it plays a very important role in the drain.

Toilet cuffs are made of plastic or rubber, white, gray or black. It is clear that white is more preferable for aesthetic reasons. Rubber couplings are used primarily for cast iron pipes; in other cases, plastic is used.

Types and purpose of cuffs

Cuff white

Initially, it is important to know what this element is, what materials it is created from, and also in what main varieties it is presented. The cuff is two cylindrical surfaces that are reliably and firmly connected to each other, as a result of which their longitudinal axes are located in a certain plane to each other.

This element is usually created from polyethylene or polypropylene, since these materials make it possible to create truly sealed devices that can easily cope with the tasks, which primarily include the formation of sealed connections. Also, from these materials you can easily obtain cuffs that will have an unusual and unique shape, so for a specific non-standard toilet you can always choose the appropriate element.

There are two main types of toilet cuffs:

- The eccentric is called a straight cuff, and at the same time it has a standard shape and configuration, due to which it is most often used for standard toilets that do not differ in any specific parameters.

The main function of such an element is considered to be the process of connecting the toilet outlet to the sewerage system, and in this case ideal tightness and reliability will be achieved. Eccentric cuff - The corrugated cuff usually has a specific shape, but its installation can be done independently. Typically, this option is chosen if the plumbing fixture itself has exquisite and unusual shapes, making it impossible to use a conventional straight cuff. The fact is that the corrugation has excellent flexibility and elasticity, so you can install it at different angles and in the most difficult situations, so you can install the toilet anywhere in the room where it will be most convenient to use it.

Selecting the right model

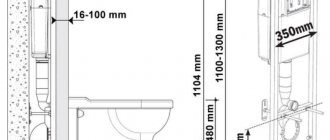

If the toilet outlet is vertical, then you can use the simplest straight cuff. Corrugated or eccentric models are not needed here, since the toilet is placed on top directly at the outlet of the sewer pipe. But vertical outlets are rarely found in apartments and private houses.

For horizontal release, you can take a straight short cuff or a corrugated one in the middle.

Note! If the inlet and outlet are shifted relative to each other in height, then you need to take an eccentric model.

There is also an oblique type of release. It can be connected to the sewer using different samples. The specific type of connecting part is chosen depending on the location of the toilet.

Practical advice

Finally, take on board some useful tips from professionals that will help you avoid possible problems when installing the cuff or preparing for it. First, try to minimize the distance between the sewer pipe and the socket. If this is technically impossible or impractical, try to strengthen the corrugation as best as possible. This can be done using special supports.

If you use a fairly short cuff, you should not stretch it before installing it in the system, since you can accidentally stretch it and it will simply sag during installation.

Advice. If we are talking about using a cuff in the sewer system of a private building, pay attention to the presence of tailed “guests”. If any are present, it is better to use the standard option - a cast iron elbow.

This concludes our acquaintance with the existing types of toilet cuffs. Enjoy the shopping!

How to replace a part

The cuff needs to be changed if it cracks, as well as when replacing an old toilet with a new one. If water begins to leak during descent, repairs should be made.

To properly connect the drain pipe to the toilet, you need to put the plumbing fixture in place and check the connection. You can attach the cuff and make sure that it fits perfectly in size.

Important! The sewer pipe outlet must be cleaned. All surfaces to be joined must be dry.

First, a connection to the sewer is made. Sometimes a seal is additionally placed in front of the cuff. To ensure that the joints are waterproof and tight, adhesive sealant is applied to the joining surfaces. But some specialists do without it.

Then connect the toilet output. Place it on the floor and mark it (at the same stage you can check the drain by flushing the water). After which they are temporarily removed to drill holes for fastening. And they are finally installing it.

It is convenient to use an eccentric with a corrugated insert for installation. If the installation is not done very accurately, then the corrugation can be stretched a little and it will take the desired position. Experts do not advise stretching a corrugated pipe to the maximum, because it becomes inelastic and quickly becomes unusable. The corrugation should not sag, otherwise its functions will be disrupted and blockages will form. At the end of the installation, it is necessary to carry out a control drain of water to make sure that everything is connected correctly.

Installation or replacement of the eccentric

Sequence of actions when installing an eccentric

Installing the cuff is one of the required steps. The element will need to be replaced when leaks appear - a signal that the old part is worn out. The stages of work in both cases are identical.

When replacing, the first step will be to clean the connecting surfaces: the sewer pipe pipe and the drain outlet of the bowl. After this, all elements are thoroughly dried - this will ensure the tightness of the connection of the parts.

Then proceed directly to installing the eccentric. A marker on the floor marks the location of the toilet. Afterwards, it is moved to the side for ease of installation of the cuff. The part with the seal inside is fixed to the sewer pipe.

The next step is to return the toilet to the place marked with a marker and connect the other end of the cuff to the sewer pipe. If the size is chosen correctly, there will be no problems with installation. The structure will lock in place without much effort. When working with a non-standard drain shape, the corrugated part of the cuff is carefully rotated to the desired position, trying not to damage the integrity of the surface.

The application of sealant in order to increase the strength of the fastening is carried out immediately before attaching one and then the other end of the cuff. However, some craftsmen do not consider it necessary to use silicone sealant, arguing that the quality of modern eccentric cuffs does not require increasing their moisture resistance.

After the composition has dried, at least half an hour should pass. To make sure the structure is tight, several buckets of water are poured into the bowl, and paper is placed under the connecting seams. If after checking no leaks are found, the plumbing fixture is secured to the floor with screws.

Cuff for cistern

In some toilet models (non-compact), another cuff is used - between the flush cistern and the bowl. It serves as a seal, preventing leakage. To install a separate tank, you must first pull the cuff onto the toilet extension shelf and secure it with a clamp. Then pull the other end of the cuff onto the tank drain pipe, also tighten it with a clamp or wire and screw on the shelf.

If the cuff begins to leak, then you need to inspect it; often these parts crack and break. In this case, they must be replaced with new ones. If there is no visible damage to the part between the tank and the toilet, then you can tighten the bolts to strengthen the fit. Rubber and plastic cuffs are cheap and are always on sale, so there will be no problems with repairs.

Toilet cuffs in St. Petersburg

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

“One-click ordering” is available on the seller’s website. To go to the site, click “Go to store”

Related article: How to clean a stone in a toilet

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

“One-click ordering” is available on the seller’s website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

“One-click ordering” is available on the seller’s website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

“One-click ordering” is available on the seller’s website. To go to the site, click “Go to store”

An “Online Consultant” is available on the seller’s website. To go to the site, click “Go to store”

An “Online Consultant” is available on the seller’s website. To go to the site, click “Go to store”

An “Online Consultant” is available on the seller’s website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

An “Online Consultant” is available on the seller’s website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

“One-click ordering” is available on the seller’s website. To go to the site, click “Go to store”

Toilet cuff: varieties, how to choose an adapter and step-by-step installation instructions

A rubber cuff for a toilet solves the problem of inconsistency between the central guide of its outlet and the expansion of the sewer drain pipe. A variety of adapter models allows you to choose the appropriate option for any type of device.

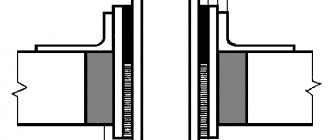

On the left is a straight cuff, on the right is an angled smooth cuff for the toilet.

Classification of toilet cuffs

The seal is a mandatory element of the connecting circuit of plumbing products. With its help, the necessary tightness of pipe fixation is achieved.

Depending on the design features, there are several types of cuffs:

- straight smooth;

- corner smooth;

- eccentrics;

- corrugated;

- conical;

- combined type.

The adapter is selected taking into account the diameters of the drain inlet and the toilet pipe.

When installing a plumbing fixture on a cast iron sewer pipe, a rubber coupling is used. A plastic analogue is used to connect to a polymer structure. The color of the material does not affect the quality of the product. Among the popular models there are samples of white, gray and black colors.

In some plumbing items, both the drain tank and the bowl need to be sealed with a seal that prevents leakage. In order to fix a free-standing tank, the adapter is pulled onto the attached toilet shelf and secured with a clamp. The second end of the product is put on the drain pipe and tightened with a clamp or wire, after which it remains to screw the shelf.

On the left is a straight corrugated cuff, on the right is a conical toilet cuff.

Criterias of choice

Rubber product

The upcoming installation of a toilet in a bathroom or repair work to eliminate drain leaks requires the selection of high-quality parts. To do this, it is recommended to decide on:

- material;

- length;

- appearance.

Polypropylene eccentrics are a reliable option. The material is durable and moisture resistant. With proper operation, leaks will not form within 3-5 years. Rubber parts are less preferable. This material stretches over time. Its density is disrupted, as a result of which the tightness decreases. However, rubber seals at the ends of the cuff are the main element contributing to high moisture resistance.

Size is the main thing to pay attention to. If the diameters of the inlet and outlet rings meet the standards, then the length is selected depending on the location of the toilet in relation to the sewer pipe. For a non-standard method of placing a plumbing fixture, a stepped option is used. This guarantees a perfect “fit” of the part. A corrugated cuff will also work. Moreover, the corrugation should not be short: if it is tightened, it loses its elasticity. It is recommended that a product that is greatly stretched due to an incorrectly selected length be strengthened in a straightened form with additional fasteners. A corrugation that is too long will sag and the water will not drain completely.

External characteristics - the white color of the material, in harmony with the bowl, the smooth surface of the cylinder without burrs and scratches - are no less important. The overall impression of the aesthetics of the toilet room directly depends on the appearance of the elements.

Selecting an Outlet-Oriented Adapter

There are 3 types of toilet bowls:

Vertical release

The design involves installing the device on a drain hole located in the floor. In this case, a cuff made of direct type polymer is used, which is matched to the color of the plumbing fixtures. Drain pipes are sewn into the ceiling or placed under the floor lining.

Horizontal release

Toilet with oblique outlet.

Toilets with a horizontal outlet type are more in demand among residents of Moscow and the regions, since they correspond to the standard arrangement of sewerage components. It uses a small plastic coupling or seal, consisting of a corrugated center and 2 cylinders at the edges.

If the plumbing inlet/outlet guides deviate in height or there is a large gap to the wall, a smooth eccentric for an offset toilet or its version with a corrugated pipe will be useful. The cuff consists of 2 welded cylindrical surfaces, the axes of which are offset relative to each other.

To fasten structures of different diameters, a short plastic cone-type coupling is used. It can be attached to the sewer hole with a 110-100 mm pipe, and to the toilet outlet with an 80 mm pipe.

Oblique release

If the outlet is located at an angle of 45°, the device is installed slightly above the sewer drain. For fixation, short cylindrical parts or long couplings with corrugation are used.

Cuff to cuff is different

Polyethylene or polypropylene parts are made in complex shapes. The cuff represents two cylindrical surfaces connected together, but their longitudinal axes are shifted in relation to one another. Such eccentricity is necessary in the case when, when connecting, the toilet outlet and the inlet pipe of the sewer pipe do not coincide with each other. For different installation options, a long cuff and a short one are available.

Straight cuff and eccentric - very easy to distinguish visually

For information: the toilet eccentric performs the function of connecting the outlet of the plumbing fixture to the sewer inlet.

The versatility of the corrugated version lies in the fact that it is applicable in extremely complex installation and connection options for the toilet. With corrugation, you can always maneuver around the bathroom area, mounting it at any angle, moving the sink to a convenient place.

Important: the use of a corrugated cuff is only advisable when performing the required slope.

Installation instructions for various types of cuffs

The principle of using various adapters is the same, but the process of their installation has a number of features due to the characteristics of the products.

Installing the rubber seal

The rubber element is placed in the socket of a metal pipe, thereby sealing the joint between the drain and the toilet. In addition, the part protects the plumbing product from damage during replacement and installation.

To create a tight connection between the device and the pipe with a rubber cuff, a sealant is applied along the entire joint, forming a waterproof sealed ring after curing.

Rules for using the eccentric

When there is a slight displacement of the axes of the toilet and wastewater drain, curved couplings are used - eccentrics. A height difference of more than 5 cm will require a change in the location of the pipes. If communications are installed at floor level or close to it, it is better to choose devices with an oblique type of outlet.

Related article: Toilet with built-in bidet

The drain hole must be free of dirt and rust.

Work algorithm:

- Preparing the drain hole, which is cleaned of old deposits.

- Installation of the adapter. It must be inserted with the wide end onto the sewer outlet pipe and the joint must be secured with sealant. If the product parameters are selected correctly, the drain outlet can be lubricated only with soap.

- Connecting a sealing part to the outlet of a sanitary product, which is also performed using a sealing agent.

- Check the water tightness of the connection by draining the water.

- Fastening the device with bolts.

Since the eccentric coupling can be selected incorrectly, it is recommended to purchase a part with a flexible corrugated center. If necessary, it needs to be moved or pulled out a little, while maintaining the functional characteristics of the product. The eccentric is equipped with a threaded connection, which allows the use of several seals.

Installing a corrugated cuff

The versatility of corrugated adapters is explained by the ability to change shape and length. Such products can be mounted at any angle, moving the sink to a suitable location. The most popular models include products with a diameter of fixing ends of 110/90 mm and 110/80 mm. The disadvantage of the devices is the thin material of the walls, which can be damaged if used carelessly.

The corrugated model is used for temporary connection of plumbing fixtures during repairs, in the presence of a large displacement of the axis of the input and output of system elements, as well as during work on installing the product at a distance of up to 1.5 m from the riser.

The principle of connecting the adapter is similar to the fixation scheme for other types of couplings. It is not recommended to stretch the sleeve to its maximum length, as it will quickly lose flexibility and fail. As an option, you can use a combined cuff, the design of which includes rigid parts.

Cuff installation

Installing or replacing a part

Now it’s time to figure out how to install the cuff on the toilet. This is very important to know even if the construction work during the renovation of your house was carried out by hired workers.

The easiest way is to entrust the installation of the cuff to specialists...

The fact is that sometimes this part leaks, which makes it impossible to use the toilet. Therefore, you will need to replace the cuff urgently. The price of such a service is quite high, so you can save a significant amount of money by performing the replacement yourself.

... but it’s cheaper to do everything yourself

There is nothing complicated about this; it is enough to strictly adhere to the sequence of actions outlined below:

- It is necessary to thoroughly clean the toilet outlet pipe from the remains of the old cuff, sealant, debris, dust and dirt . At the same time, it is recommended to perform similar actions with the inlet of the sewer network.

Thoroughly clean the toilet pipe and sewer pipe inlet

Note! Cleaning must be done as thoroughly as possible. Debris and dust can cause leaks in the future, forcing you to start from scratch.

- To obtain the tightest possible connection, the pipe and the sewer inlet must be thoroughly dried . Remaining moisture will not allow sealant to be applied, which, again, can lead to leaks.

- Upon completion of the preparatory operations, silicone plumbing sealant should be applied to the previously purchased cuff . Although some experts say that you can do without additional sealing, you should not neglect the use of silicone. The connection obtained in this way will be as reliable as possible.

- First you need to coat the part that fits onto the toilet with sealant . Then the cuff is mounted on the pipe of the plumbing fixture and left alone until the silicone has completely hardened.

- After this, the procedure is repeated, but with a hole in the sewer network . If the dimensions are adjusted correctly, all operations are performed without significant physical effort and any difficulties.

Advice! After installing the cuff, it is advisable not to use the toilet for several hours so that the silicone sealant sets well and ensures the most airtight joint.

Once installation is complete, do not use the toilet to allow the silicone to harden.

Emergency temporary leak repair

There are cases when a leak appears suddenly and there is no time to purchase and install a cuff.

In this case, you can deal with the problem in two ways:

- Use an elastic rubber bandage, which is sold in pharmacies. To do this, you need to take a rubber band and wrap it around the toilet pipe on which the cuff is placed.

It is better to carry out this operation together, since you are unlikely to be able to provide the required degree of tension yourself.

- Seal the leak with a plastic bag tied with twine. In this case, you need to take cellophane, wrap it around the leak and secure it tightly with a thick thread. You can make several such layers to ensure maximum tightness.

Cellophane or a rubber bandage will help temporarily fix the leak.

Note! The methods described above are a temporary solution to the problem. As soon as you have the opportunity, you should replace the damaged cuff with a new one.

Tips for attaching adapters

Difficulties in installing the toilet are explained by the fact that the length of the cuff is shorter than necessary. This means that before choosing a seal, you need to calculate the distance between the plumbing outlet and the sewer drain.

When purchasing a corrugated product, you can follow this rule - the length of the sleeve should be greater than the diameter of the coupling by a third of its length. The use of seals of this type will require the installation of additional fasteners, which will maintain the straight appearance of the structure. If this is not done, large bends and sharp corners may lead to blockages in the system.

In addition to the configuration and length, the effectiveness of the functioning of devices is affected by the thickness of their walls - the thicker it is, the longer the service life will be. If the coupling begins to leak, the part must be replaced; if there is no visible damage, you can tighten the fasteners and strengthen the fit of the sink to the riser.

Selection by issue

In addition to the cuff parameters, you need to take into account the specific dimensions of the device and the release form. It comes in three types:

The vertical solution is rarely used in bathrooms in the Russian Federation, due to the fact that the presence of coalition lines above the floor interferes with such a device. A vertical outlet assumes that the drain is equipped in the same plane as the floor tiles, and the pipes themselves are located in the ceiling or under the floor.

If the installation of a model with a vertical inlet is realistic, then it makes sense to use a straight short cuff made of plastic (in the shape of a cylinder). Complex additions or eccentrics will not be needed due to the location of the toilet with a vertical outlet - it is located above the sewer drain.

The cuff is needed to seal the joints and disguise them. If the connection is located in plain sight, then it is better to choose a model that matches the color of the toilet; if it is inside the plumbing, the exterior appearance does not play a special role.

Replacing the toilet cuff

A toilet in an apartment or private house is no longer a luxury. And the main plumbing fixture of this room is the toilet. This seemingly simple device works without problems for many years, but sometimes it lacks repair work, for example, when a leak appears at the junction of the toilet outlet with the sewer. In this case, you have to replace a special part - the cuff. Everyone can do this. And in more detail how to replace the toilet cuff will be discussed in this article.

Artist selection

If you have decided that replacing the toilet seat cuff should be carried out by a specialized service, all you have to do is make the right choice of contractor. Pay attention to:

- Experience of the company and its employees;

- Availability of recommendations and positive reviews about the performer;

- The cost of performing the work - naturally, too high a price may scare you away, but too low a cost should raise questions (whether the contractor is skimping on the quality of materials or the qualifications of workers);

- The company is currently holding promotions and discounts for work;

Contacting the “Plumbers Service” by phone When contacting the previously listed advantages, the following will be added:

- Efficiency of visiting the work site and speed of its execution;

- Warranty for work performed;

- Many years of experience of our employees;

- Optimal ratio of price and quality of work performed;

- Independent purchase of all necessary materials.

is ready to save you from the agony of choosing spare parts, studying replacement technology and will put professionals at your disposal at your disposal.

Little about design and predestination

The cuff is a product made of polypropylene or polyethylene. The use of these materials in production is determined by their good properties. Firstly, it is possible to produce parts of virtually any configuration from polypropylene and polyethylene. In particular, products such as toilet cuffs have a complex shape. Secondly, polymer materials are quite plastic, which provides a reliable and tight connection.

The design of such a part may be different, but in any case it has the same elements. Along with this, the longitudinal axes of each of the rings can be moved relative to each other or lie on the same line. The first option is used in the case when the toilet outlet and the sewer pipe do not coincide with each other.

Depending on the need, it is possible to use both a short and a long version of the toilet cuff. The choice will depend on the distance between the plumbing unit and the sewer system.

Advice! The most popular cuff option is corrugated. Thanks to the corrugated pipe, it is possible to make a connection of virtually any complexity. This allows you to install the toilet in the location you choose, regardless of the distance to the sewer pipe.

The principle of using a toilet cuff is quite simple. One of its rings is pulled over the toilet outlet. The second end is inserted into the sewer pipe. At the same time, a sufficient level of tightness is ensured. Neither liquids nor unpleasant odors will pass through such a connection.

Article on the topic: The water in the toilet does not drain well, what to do?

Why change the cuff and how is it done?

There are cases of water leaking from the water seal through the cuff or from under it. This can be detected when draining water from the cistern. Perhaps there was a displacement due to the tank being skewed, or perhaps a crack appeared in the part itself. If it is not possible to eliminate the malfunction using improvised means, you should act radically: replace the cracked component.

Installing a toilet using an eccentric is the optimal solution when working with old communications and new generation toilets

Standard replacement procedure

- Both the toilet outlet and the inlet sewer pipe are cleaned until dust, cement residues, etc. completely disappear. The treated surfaces must also be dry.

- The entire perimeter of the cuff is lubricated with a special silicone sealant.

- One end of the cuff with a waterproofing seal is effortlessly placed over the toilet flush outlet. This is facilitated by preliminary waterproof treatment, which protects the contact area from leaks. For better adhesion, you should let the sealant harden and then continue work.

- The other end of the connector is inserted directly into the sewer drain.

By the way: not all specialists use sealant for sealing. It is believed that the cuffs fit so perfectly that they themselves fit very tightly onto the toilet outlet.

Toilet with horizontal outlet

- When the sewer pipe and toilet bowl outlet are located on the same axis, you can use a straight cuff for connection. If the levels of the two inputs do not match, an eccentric toilet cuff is used.

Important! In this case, the distance between the socket and the outlet should not be more than 5 cm.

- A cuff is placed on the nozzle of the shelf of the inverted tank from the end of the smaller diameter to a third of its length: the neck of the toilet bowl and the distance between the ends are “packed” into the remaining 2/3 of the space. The work should be carried out by first disconnecting the float valve of the tank with a rigid liner, removing the screws from the shelf and the tank lid.

- This remaining part is turned inside out, and then tightly placed on the bell until its end is marked. The cuff should fit tightly onto the toilet outlet neck.

Using an eccentric will allow you to place the toilet as compactly as possible. If you use corrugation in this case, the loss of space will be significant

What if the tank is low?

- A rubber cuff for the toilet is placed on the end of the extension shelf and immediately fixed to it with a wire.

- The rubber part comes out.

- An extension shelf is bolted onto the toilet.

- A cuff is pulled over the outlet pipe of the sink.

- The pipe with a rubber sealed connection is clamped with wire.

If the connection of the plumbing fixture to the sewer is done correctly, this guarantees the uninterrupted operation of the entire system without breakdowns or blockages.

How to install a new cuff

If, when draining, you notice a leak at the place where the cuff is installed, then it’s time to think about how to change the cuff. It goes without saying that you can try to fit the product onto the toilet outlet better. If the cause of the leak is a displacement of the cuff, then such actions will help.

But, in most cases, rarely does anyone do anything behind the toilet, so it is unlikely that the cuff will be moved out of place. Based on this, much more often the cause of a leak is the appearance of a crack. Some home craftsmen suggest sealing the gap that appears using silicone sealant or using other improvised means (for example, wrapping a rubber strip). But, based on the cheapness of the toilet cuff, it would be more rational to replace it. In this case, you will have a 100% guarantee that the leak will not appear again in the near future.

The work itself of changing the cuff on the toilet will not cause enormous difficulties, especially for beginners. There is no need for special skills and abilities. Besides this, you do not need to prepare any tools. All that is needed for the job is the cuff itself and a knife or chisel.

All actions occur according to the following algorithm:

- First of all, remove the old cuff. To do this, just pull it out of the sewerage system pipe and pull it off the toilet outlet.

- After this, proceed to prepare all surfaces. Carefully clean the toilet outlet and sewer pipe from deposits, rust and mortar residues (if any). If this work is not done, the new cuff will not fit correctly. And this will lead to the reappearance of the leak.

- In order for the cuff to sit securely in its place, you need to carefully dry all surfaces. If there is also slight moisture, there may not be a completely reliable and airtight connection.

- Then it is possible to coat the entire perimeter of the cuff with plumbing silicone sealant. This is done both with the inner surface of the end, which will be put on the outlet, and with the outer side of the ring, which will be inserted into the pipe. Some experts do not use sealant. According to their point of view, the cuffs themselves are quite reliable, so using additional sealing materials is a waste of money. Everything here will depend on your personal opinion.

- Now put one end (the one with the larger diameter ring) onto the toilet outlet. This must be done with little effort, but do not overdo it. The cuff must sit well in place.

- The other end of the cuff is inserted into the sewer pipe.

If desired, it is possible to additionally treat the joints with silicone sealant.

This method of replacing the cuff is suitable if the distance between the socket and the outlet is no more than 5 cm. Moreover, if they are located on the same axis, then a straight cuff is used. When shifting the axes, an eccentric is used. In this design, the axes of the cuff ring are shifted by the required distance.

If the distance between the sewer pipe and the toilet outlet is enormous or the displacement of their axes does not allow the use of an eccentric, then it is better to use a corrugation. Thanks to the flexible corrugated pipe, connecting the toilet will be easy, regardless of where it is installed.

Why does it become necessary to replace the cuff, and how to do this work?

Replacing the toilet cuff is required quite often, and such a need arises most often as a result of the fact that the old product simply ceases to cope with its main tasks, as a result of which water begins to seep in at the location of the toilet outlet, since the old cuff no longer provides an ideal tightness of the connection. In this case, it is important to choose the new element correctly, as well as install it in accordance with certain rules in order to avoid any mistakes, since then the new element will last a very long time and will also have all the necessary parameters.

If you have an old toilet, then a regular straight cuff is best suited, and it’s easy to do all the installation work yourself. The whole process can be divided into several successive stages:

Rubber corrugated cuff

- Thorough cleaning of the toilet outlet so that as a result it becomes clean and free of unnecessary parts, elements and contaminants. During this work, it is best to immediately clean the outlet pipe of the sewer system, as a result of which there will be no contamination, deposits or dust in it.

- All treated surfaces must be thoroughly dried, since subsequent installation work must be carried out exclusively on a dry base, since moisture will not allow sealed connections to be obtained.

- The new cuff itself is being prepared, which must be purchased in advance, and at the same time must be suitable for high-quality installation. The preparation consists in the fact that all surfaces of this element must be completely and carefully treated with silicone sealant, since it will significantly increase its already good tightness.

- One part of the cuff, on which there is a seal with excellent waterproofing parameters, is placed over the toilet flush, and this should not create any effort.

After this, you need to wait some time necessary for the sealant to thoroughly and reliably harden, ensuring perfect tightness of the resulting connection. Cuff fastening type - The other part of the cuff must be inserted into the drain of the sewer system, and here experts also advise using a sealant, but it must be sealing. With the correct choice of the element itself, it is possible to ensure that the cuff takes the desired position without any effort on the part of the person.

The above instructions are quite simple, and if you follow all the steps exactly, installing the cuff will not take much time and can also be done very easily. This will create a connection that will be airtight, so while using the toilet you don’t have to worry about unnecessary leaks occurring at the point where it connects to the sewer.

Changing the location of the cistern

Some toilet designs require the cistern to be installed quite low. In this case, it is quite difficult to install the cuff using the method described above. Based on this, it is better to use another option for performing installation work.

Here's what you need to do:

- You need to find a special add-on shelf. One end of the cuff is put on it and secured with a special clamp. Some craftsmen use simple wire instead of a clamp.

- Then the attached shelf is fixed on the toilet (at the same time, the other end of the cuff is put on the drain pipe). To do this, use bolts of suitable size. You should not be too zealous when tightening - you risk the toilet becoming cracked or chipped.

- To secure the cuff, you can also use a suitable size clamp or wire.

In order to increase the tightness, the joints are treated with silicone sealant. This way it is possible to install a cuff on a toilet with a low flush cistern.

What to do in a situation where the tank is located at a low height?

Another common situation is when the design of the device is such that its main element, namely the tank, is located very low. In this case, the process of using the cuff is a little more complicated, but it will still be quite easy to implement. The connection can be made as follows:

- Initially, the cuff is placed on the end of a special extension shelf.

- It must be well and carefully secured, and standard wire is usually used for this.

- The cuff must be carefully and correctly turned out.

- The attached shelf is fixed to the toilet using suitable bolts.

- The cuff is pulled onto the outlet pipe of the sewer system, which is then clamped with a wire so that a high tightness of the connection is achieved.

Thus, using a toilet cuff is considered a fairly simple job, and at the same time this element is important and necessary for any plumbing fixture. Repair of a leaking element can be carried out without inviting a plumber, and in this case it is only important to choose the right cuff itself, which should be suitable both for the toilet itself and for the drainage of the sewer system.

Since it is created from flexible materials, and sealants are used during operation, you can expect that all connections that are formed during operation will be sealed, which will allow you to use the plumbing fixture with comfort and safety, without fear that during the draining process it may any leakage occurs.