Which protective helmet for welding should you choose – a chameleon or a regular one?

Progress has made its own adjustments even to such an issue as protective welding equipment, the modernization of which has made it possible to create more effective models of masks that have many advantages over the previously used simple helmets. A potential buyer must understand what he will have to overpay for and whether it is worth it at all.

So, an alternative to simple masks has become a specialized chameleon protective helmet, equipped with an automatic light filter (hereinafter referred to as ASF), the main purpose of which is still to protect the user from harmful UV and IR radiation, as well as from sparks and splashes generated during work molten metal, smoke and gases.

Among the main advantages of the new generation of protective equipment compared to an outdated mask:

- The presence of sensitive touch sensors that change the degree of darkness of the screen, which allows the master not to interrupt work by raising and lowering the helmet.

- Efficiency. The focus on ergonomics and improved visibility allows you to get more work done in the same period.

- Convenience. Using a chameleon allows you to keep both hands free, eliminating the need to use additional protective equipment when simultaneously performing plumbing work. In addition, as mentioned, the mask will not have to be constantly removed and put on in order to evaluate the front or the result of the work, since a good screen view eliminates such a need.

- Durability of ASF. Unlike ordinary masks, the chameleon does not require changing the filters.

As you can see, there are many advantages. As for the disadvantages, there is only one - the price, although the difference is not so great as to deprive yourself of comfort and put your health at greater risk.

How to choose a chameleon welding helmet for argon TIG welding?

The optical class of the welding helmet filter should be no worse than 1/1/1/2, and better - four units 1/1/1/1. The classification of light filters appeared relatively recently and perhaps not everyone still knows what these numbers mean. Let's figure it out. The first digit of the optical class shows the diopter of the filter - how much it distorts the outlines of objects. The second number is the light scattering indicator, determines the transparency of the filter and affects the clarity of visible objects; the higher the class, the clearer the picture. The difference between the first class of light scattering and the third is exactly the same as if you first look through clean glass and then through fogged glass. The third number is an indicator of the unevenness of darkening when viewing the filter at a right angle. And in fourth place is the angular dependence of the degree of darkness. Of all four indicators, the first two affect eye fatigue the most. Using a low-quality welding helmet with a low optical class is like reading through someone else’s glasses, and even with slightly foggy glasses. Not a very pleasant experience. The pupils constantly vibrate, trying to focus, but fail due to poor optics, which causes rapid eye fatigue and fatigue. For TIG welding there must be four optical sensors, at least not less than three. Many people think that four sensors are needed only for the case when the welder stuck his head into a hard-to-reach place and blocked the two lower sensors, then the other two will work. This is partly true, but when TIG welding four sensors are needed based on the characteristics of the arc itself. Optical sensors react to sudden changes in lighting and arc flicker. If the sensors simply responded to light, then the filter would always be in a dark state during the daytime. When TIG welding with constant DC current, especially at low currents, sometimes the arc is so stable that it practically does not flicker, and the sensors perceive this as background lighting and the light filter spontaneously opens during the welding process. However, unlike filters with two optical sensors, with four sensors the probability of accidental opening of the filter is reduced to zero, due to the high sensitivity of such a circuit to flicker, or, scientifically speaking, to the variable component of radiation. The sensors are located at different angles and better capture the difference in radiation.

The next thing to pay attention to is the shade range, you need to have two ranges 5-9/9-13DIN. Again, when TIG welding at low currents, especially simple steel structures, with a darkness level of 9DIN nothing is visible and you need to set it to 8DIN. Those with sharper eyesight can still see something, but older welders cannot do without the first range. Unlike welding helmets with traditional glass, where the darker the darker, the more protected the eyes, real welding chameleons do not have this dependence. Thanks to special protective layers, ultraviolet (UV) and infrared (IR) radiation are reflected and do not pass through the filter. Only visible light passes through. Therefore, eye protection is constant and does not depend on the degree of darkening, which makes it easy and simple to select a comfortable darkening based on the lighting conditions of the workplace, so that you don’t have to squint and strain your eyesight. Although the market is full of light filters, where protection is based on the principle, the darker it is, the more protected your eyes are. Therefore, I emphasized above, and I will repeat again: only in real chameleons there is no such dependence. Only high-quality welding chameleons from well-known global manufacturers have these properties. What else do you expect from a welding helmet with an automatic light filter that costs less than eyeglass frames?

Although there are masks that are not cheap at all, in the middle price category, with panoramic light filters, a huge window in the front and additional ones on the sides, a bunch of sensors, a lot of settings, but, alas, they are not suitable for TIG welding.

The color rendering of the light filter also plays an important role, because it is much better to see objects in their natural True Color.

Here's how one welder described the TECMEN True Color filter:

“Well, now, having put a real welding mask on my head, I saw that the colors can be different, that much more details can be distinguished, that before I had not seen everything that can be seen. And most importantly, my strong belief that there cannot be a better picture than ordinary glass gives is broken. It turns out it can. Today I discovered a new world - this is the world of professional welding filters, today I saw both the weld pool and the welding arc in a different way - I saw it all in super quality and in color.”

I have nothing to add, many thanks to the author for such a colorful description! I don’t know what kind of welder he is, but he’s certainly a writer.

To summarize, I will list point by point what should be in a chameleon for TIG welding:

- Optical class 1/1/1/1

- Dimming range 5-9/9-13

- Four independent optical sensors

- Adjusting sensitivity

- Adjusting the reset time

- TIG rating 2A

- True Color - true color rendition

I don’t specifically focus on the speed of operation of the light filter; now even budget masks work faster than required by the standard. Comfortable switching time from light to dark state lies in the range of 1/10,000 – 1/25,000 sec.

But, to distinguish themselves, some manufacturers give values of 1/30,000 -1/50,000 sec in their specifications. What is not true is simple deceit and substitution of concepts. This reaction speed, but from the moment the arc is detected by optical sensors until the dimming degree reaches 90% of the set one, takes time. Liquid crystals physically cannot unfold so quickly. Similar to a car, from the moment you press the brakes until you come to a complete stop, it takes much longer than the driver's reaction time. Therefore, this indicator is not so important, but for an inexperienced consumer, as they say, it’s just right.

Best Budget Welding Helmets

If you are looking for a good inexpensive chameleon welding helmet and are willing to sacrifice the size of the visor, but want the adjustments to be accessible from the outside, you should pay attention to the Patriot. Yes, the 92x42 mm visor is not so large, but it works clearly, and absolutely all controls are accessible without removing the mask. Under the left hand there is a dimming regulator (9-13 DIN) and a slider for disabling auto-dimming, under the right hand there is a sensitivity regulator and a three-position delay time selector.

The weight of the mask is just over half a kilogram, it is comfortable for long-term wearing. Of course, its headband is a bit rustic, but overall the mask is worth the money.

- Adjustments are fully accessible without removing the mask

- Good filter quality

- Small sliders are difficult to switch in leggings

In terms of price, the Wester is neck and neck with the Patriot, but only outperforms it in terms of weight (almost 20 percent less). But the visor itself is smaller here (90x35), and the shade range is limited from above not to 13 DIN, as usual, but only to 11 DIN. There is only one external regulator - it sets the degree of darkness and turns off the automation in the extreme position. Inside the panel there are smooth sensitivity and brightening delay controls.

As a result, we admit that the Wester welding helmet clearly cannot compete with the Patriot, since the quality of the light filter is the same, plus or minus, but the Patriot is more convenient to use.

- External dimming controller

- Limited dimming range

An inexpensive welding helmet with a minimum of adjustments: in general, there are none at all. Even the pause and sensitivity cannot be adjusted - and such adjustments, albeit stepwise, are now offered even by the most budget-friendly Corundums and others like them. So the mask works fully automatically, dimming from 4 DIN to 11 DIN if necessary. It is also impossible to disable the automation, so when trying to work with the angle grinder you will have to deal with the “blinking” of the visor. Although the visor itself is not bad in size for such a price - 98x35 mm.

But in any case, the mask of “Four Elements” was not the most successful, and it gets a corresponding place in the ranking of the best masks for welding.

- Light weight (less than 400 g)

- Low price

- Good visor sizes for this class

- No adjustments

- Primitive headband

This mask has many “doubles” from other Russian-Chinese brands. However, they differ only in name: even the wing-like colored prints on the sides of the mask are absolutely the same in “Resanta” and, for example, “Korunda”.

Features of choice

If you are thinking about installing such a thing as glass for a welding helmet with diopters, then you should choose a really suitable model that would be useful to use. First of all, the choice depends on the mask. Lens manufacturers produce standard products, but some masks may have other sizes, which does not happen very often, but given the huge variety of manufacturers on the market, sometimes similar options come across. The lenses are attached from the inside, not from the outside, so the difference in size with the viewing window of the mask does not matter much, since the coincidence with the mounting location is sufficient.

"Important!

To install glass, you need a standard mask that has fastenings for such glass, otherwise installation may be impossible.”

The next parameter, which is no less important, is the number of diopters in the lens. The above standards are the most basic and broadest, as some manufacturers may have a larger step between model ratings or will not represent the full range. Welding glasses with diopters are selected depending on the degree of vision impairment, or for a specific type of work, if they are required only for magnification. To make it easier to decide, you should take the same value as on the glasses, with a slight rounding up. When working with small objects, it all depends on what type of welding is being done.

Magnifying lenses for welding helmets

Principle of operation

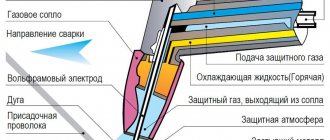

The chameleon mask for welding from different manufacturers has a similar design. More precisely: the case, the control board, the light filter and the power supply. The housing protects against metal splashes during operation. The board controls the change in light filter settings, so the screen is automatically darkened during welding. The power supply automatically switches the filter.

- The viewing glass of the mask is covered with a darkening film, protecting the human eyes from glare and burns. The light filter is located in the sight glass and includes several layers of liquid crystals. Some include 3 layers, others 4. In a quiet position, the filter crystals are in one position, but during an arc flash, the control board gives a signal about the restructuring of the crystals. And the sight glass darkens in ten-thousandths of a second. The intensity of the darkening depends on the brightness of the arc.

- After welding is completed, the crystals do not immediately return to their original quiet position, ensuring high safety.

In all chameleon welder masks there is a delay in the activation of crystals, and you can also set individual delay values. Also, many of them are equipped with steam vents that prevent the glass from fogging up.