We will learn how to control welded joints on a pipeline in this article. To get an idea of the real state of the metal at the joints, so-called non-destructive testing of pipeline welded joints is used. Safety along with the reliability of the structure is often determined by the quality of the seams.

Standards in legislation create strict guidelines for the process. It is carried out only by professionals with the appropriate skills.

Quality control of welded joints and the need for it

When welding work is carried out on pipelines, the occurrence of defects cannot be avoided. In turn, these shortcomings have a negative impact on the appearance of welded joints, their technical characteristics, and reliability. In total, there are two types of damage: weld formation and metallurgical type defects.

The formation of a structural seam leads to the appearance of metallurgical flaws. They usually appear while the material is cooling or heating. The second group of damages is caused by non-compliance with standards during work.

It is necessary to identify the following types of deficiencies in advance. They all negatively affect the quality of the entire pipeline in the end.

- Disturbances in the metal microstructure. This leads to an increase in the oxide content and the appearance of coarse grains and grains with oxidized edges.

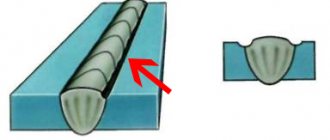

- Presence of gas inclusions or pores. They can be grouped or individual, sometimes they look like bridges. Or they come to the surface. Then they are called fistulas.

- Impurities with slag inside the seams. Because of them, the product loses its original strength.

- The occurrence of cracks of various types is typical for areas with seams and heat-affected areas. The differences lie in size.

- Group of incomplete preparations. This is the name given to local areas of a seam where there is no adhesion to the base material.

- Burns or holes in welds that appear when melt flows out during welding.

- Undercuts. The name for grooves in the longitudinal plane at the boundaries with seams, the surface of the base metal.

- Irregularities in the shapes and sizes of seams.

Only if each of the defects is identified can the reliability of the pipeline be guaranteed at the maximum level.

A thorough assessment of how such flaws affect the design must be carried out. Otherwise, it is impossible to correct the situation before the pipeline begins operation.

Steel pipelines - section SNiP water supply and sewerage

Section SNiP water supply and sewerage

STEEL PIPELINES

3.18. Welding methods, as well as types, structural elements and dimensions of welded joints of steel pipelines must comply with the requirements of GOST 16037-80

.

3.19. Before assembling and welding pipes, you should clean them of dirt, check the geometric dimensions of the edges, clean the edges and the adjacent inner and outer surfaces of the pipes to a metallic shine to a width of at least 10 mm.

3.20.

Upon completion of welding work, the external insulation of pipes at the welded joints must be restored in accordance with the design.

3.21. When assembling pipe joints without a backing ring, the displacement of the edges should not exceed 20% of the wall thickness, but not more than 3 mm. For butt joints assembled and welded on the remaining cylindrical ring, the displacement of the edges from the inside of the pipe should not exceed 1 mm.

3.22. The assembly of pipes with a diameter of over 100 mm, made with a longitudinal or spiral weld, should be carried out with an offset of the seams of adjacent pipes by at least 100 mm. When assembling a joint of pipes in which the factory longitudinal or spiral seam is welded on both sides, the displacement of these seams need not be made.

3.23. Transverse welded joints must be located at a distance of no less than:

0.2 m from the edge of the pipeline support structure;

0.3 m from the outer and inner surfaces of the chamber or the surface of the enclosing structure through which the pipeline passes, as well as from the edge of the case.

3.24. The connection of the ends of joined pipes and sections of pipelines with a gap between them greater than the permissible value should be made by inserting a “coil” with a length of at least 200 mm.

3.25. The distance between the circumferential weld seam of the pipeline and the seam of the nozzles welded to the pipeline must be at least 100 mm.

3.26. The assembly of pipes for welding must be carried out using centralizers; It is allowed to straighten smooth dents at the ends of pipes with a depth of up to 3.5% of the pipe diameter and adjust the edges using jacks, roller bearings and other means. Sections of pipes with dents exceeding 3.5% of the pipe diameter or having tears should be cut out. The ends of pipes with nicks or chamfers with a depth of more than 5 mm should be cut off.

When applying a root weld, the tacks must be completely digested. The electrodes or welding wire used for tack welding must be of the same grade as that used for welding the main seam.

3.27. Welders are allowed to weld joints of steel pipelines if they have documents authorizing them to carry out welding work in accordance with the Rules for Certification of Welders approved by the USSR State Mining and Technical Supervision.

3.28. Before being allowed to work on welding pipeline joints, each welder must weld an approved joint in production conditions (at the construction site) in the following cases:

if he started welding pipelines for the first time or had a break in work for more than 6 months;

if pipe welding is carried out from new grades of steel, using new grades of welding materials (electrodes, welding wire, fluxes) or using new types of welding equipment.

On pipes with a diameter of 529 mm or more, it is allowed to weld half of the permissible joint. The permissible joint is subjected to:

external inspection, during which the weld must meet the requirements of this section and GOST 16037-80

;

radiographic control in accordance with the requirements of GOST 7512-82

;

mechanical tensile and bending tests in accordance with GOST 6996-66

.

In case of unsatisfactory results of checking a permissible joint, welding and re-inspection of two other permissible joints are performed. If, during repeated inspection, unsatisfactory results are obtained at at least one of the joints, the welder is recognized as having failed the tests and can be allowed to weld the pipeline only after additional training and repeated tests.

3.29. Each welder must have a mark assigned to him. The welder is obliged to knock out or fuse the mark at a distance of 30 - 50 mm from the joint on the side accessible for inspection.

3.30. Welding and tack welding of butt joints of pipes can be carried out at outdoor temperatures down to minus 50 °C. In this case, welding work without heating the welded joints is allowed to be performed:

at outside air temperatures down to minus 20 °C - when using pipes made of carbon steel with a carbon content of no more than 0.24% (regardless of the thickness of the pipe walls), as well as pipes made of low-alloy steel with a wall thickness of no more than 10 mm;

at outside air temperatures down to minus 10 °C - when using pipes made of carbon steel with a carbon content of over 0.24%, as well as pipes made of low-alloy steel with a wall thickness of over 10 mm. When the outside air temperature is below the above limits, welding work should be carried out with heating in special cabins, in which the air temperature should be maintained not lower than the above, or the ends of the welded pipes for a length of at least 200 mm should be heated in the open air to a temperature of at least 200 ° C.

After welding is completed, it is necessary to ensure a gradual decrease in the temperature of the joints and adjacent pipe areas by covering them after welding with an asbestos towel or other method.

3.31. When multilayer welding, each layer of the seam must be cleared of slag and metal spatter before applying the next seam. Areas of weld metal with pores, pits and cracks must be cut down to the base metal, and the weld craters must be welded.

3.32. When manual electric arc welding, individual layers of the seam must be applied so that their closing sections in adjacent layers do not coincide with one another.

3.33. When performing welding work outdoors during precipitation, the welding sites must be protected from moisture and wind.

3.34. When monitoring the quality of welded joints of steel pipelines, the following should be done:

operational control during pipeline assembly and welding in accordance with the requirements of SNiP 3.01.01-85

*;

checking the continuity of welded joints with the identification of internal defects using one of the non-destructive (physical) control methods - radiographic (x-ray or gammagraphic) according to GOST 7512-82

or ultrasonic according to

GOST 14782-86

.

The use of the ultrasonic method is allowed only in combination with the radiographic method, which must test at least 10% of the total number of joints subject to inspection.

3.35. During operational quality control of welded joints

steel pipelines should be checked for compliance with the standards of structural elements and dimensions of welded joints, welding method, quality of welding materials, edge preparation, size of gaps, number of tacks, as well as serviceability of welding equipment.

3.36. All welded joints are subject to external inspection. On pipelines with a diameter of 1020 mm or more, welded joints welded without a backing ring are subject to external inspection and measurement of dimensions from the outside and inside of the pipe, in other cases - only from the outside. Before inspection, the weld seam and adjacent pipe surfaces to a width of at least 20 mm (on both sides of the seam) must be cleaned of slag, splashes of molten metal, scale and other contaminants.

The quality of the weld according to the results of the external inspection is considered satisfactory if the following is not found:

cracks in the seam and adjacent area;

deviations from the permissible dimensions and shape of the seam;

undercuts, recesses between rollers, sagging, burns, unwelded craters and pores coming to the surface, lack of penetration or sagging at the root of the seam (when inspecting the joint from inside the pipe);

displacements of pipe edges exceeding the permissible dimensions.

Joints that do not meet the listed requirements are subject to correction or removal and re-control of their quality.

3.37. Water supply and sewerage pipelines with a design pressure of up to 1 MPa (10 kgf/cm2) in a volume of at least 2% (but not less than one joint for each welder) are subject to quality control of welded seams using physical control methods; 1 - 2 MPa (10-20 kgf/cm2) - in a volume of at least 5% (but not less than two joints for each welder); over 2 MPa (20 kgf/cm2) - in a volume of at least 10% (but not less than three joints for each welder).

3.38. Welded joints for inspection by physical methods are selected in the presence of a customer representative, who records in the work log information about the joints selected for inspection (location, welder's mark, etc.).

3.39. Physical control methods should be applied to 100% of welded joints of pipelines laid in sections of transitions under and above railway and tram tracks, through water barriers, under highways, in city sewers for communications when combined with other utilities. The length of controlled sections of pipelines at transition sections should be no less than the following dimensions:

for railways - the distance between the axes of the outer tracks and 40 m from them in each direction;

for highways - the width of the embankment at the bottom or the excavation at the top and 25 m from them in each direction;

for water barriers - within the boundaries of the underwater crossing determined by section. 6 SNiP 2.05.06-85

;

for other utilities - the width of the structure being crossed, including its drainage devices, plus at least 4 m in each direction from the extreme boundaries of the structure being crossed.

3.40. Welds should be rejected if, upon inspection by physical control methods, cracks, unwelded craters, burns, fistulas, and also lack of penetration at the root of the weld made on the backing ring are detected.

When checking welds using the radiographic method, the following are considered acceptable defects:

pores and inclusions, the sizes of which do not exceed the maximum permissible according to GOST 23055-78

for class 7 welded joints;

lack of penetration, concavity and excess penetration at the root of a weld made by electric arc welding without a backing ring, the height (depth) of which does not exceed 10% of the nominal wall thickness, and the total length is 1/3 of the internal perimeter of the joint.

3.41. If unacceptable defects in welds are identified by physical control methods, these defects should be eliminated and the quality of a double number of welds should be re-controlled compared to that specified in clause 3.37

. If unacceptable defects are detected during re-inspection, all joints made by this welder must be inspected.

3.42. Areas of the weld with unacceptable defects are subject to correction by local sampling and subsequent welding (as a rule, without overwelding the entire welded joint), if the total length of sampling after removal of defective areas does not exceed the total length specified in GOST 23055-78

for 7th grade.

Correction of defects in joints should be done by arc welding.

Undercuts should be corrected by surfacing thread beads no more than 2 - 3 mm high. Cracks less than 50 mm long are drilled at the ends, cut out, thoroughly cleaned and welded in several layers.

3.43. The results of checking the quality of welded joints of steel pipelines using physical control methods should be documented in a report (protocol).

Related Posts

- Privacy Policy

What are the principles of non-destructive quality control?

In total, there are two methods on the basis of which quality control of welded joints of pipelines is carried out.

- When the integrity of the connection is not violated.

- With violations.

To assess the condition of all welds, a non-destructive quality control method is used. Such control must be carried out both during welding work and after its completion.

This is necessary in order to secure the structure even before direct operation begins. In turn, there are methods for conducting non-destructive quality assessment.

- By permeability.

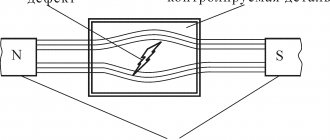

- Magnetic, radiographic control.

- Method using ultrasound.

- Capillary, radiation flaw detection.

- Measurements and external inspection.

As for destructive methods, they are carried out on product samples that have already been cut out from their original position.

Quality control of steel pipe welding

Quality control of welds is carried out by the construction organization during the entire period of welding work. The following are subject to verification: the quality of the materials used, the technical condition of welding equipment and tools, as well as the qualifications of welders; quality of work on operations during assembly, tack welding and position of seams; welds (external inspection). Control also includes checking the continuity of seams by physical methods, mechanical testing of samples cut from control joints, and pneumatic or hydraulic tests of a completed heat pipeline while ensuring the safety of work.

Welding materials are checked by comparing the characteristics specified in the certificates with the requirements of the relevant GOSTs and technical specifications, as well as a thorough external inspection. The technical condition of welding equipment and tools is checked before the start of work, as well as against documents and, if necessary, against a test joint. Operational control is carried out during the assembly and welding of pipeline joints. At the same time, they check the correct alignment of the pipes, the coincidence of the edges, the size of the gap, the bevel of the edges, the blunting and cleaning of the edges, the location and quality of the tacks. They also check the welding technology and mode, the order of application of individual seam layers, the shape of the seam layers, the removal of slag, the absence of undercuts, pores, cracks and other external defects of the seam. Establish compliance with technological instructions. When conducting an external inspection of all joints, the following requirements are imposed on them: the surface of the deposited metal along the entire perimeter must be slightly convex with a smooth transition of the deposited metal to the base metal without undercuts, there should be no unwelded craters on the seam; the height of the seam reinforcement must be even; The width of the weld must be uniform, preventing the presence of cracks of any size, pores, sagging, craters and rough flaking in the seam. Joints that do not satisfy the requirements stated above in appearance are rejected and immediately corrected.

The following welded joints are subject to continuity testing using non-destructive testing methods: pipelines that are subject to the requirements of the Rules of Gosgortekhnadzor of Russia, with an outer diameter of up to 465 mm - in the volume provided for by these Rules, with a diameter over 465 to 900 mm - in a volume of at least 10% (but not less than four joints), with a diameter of over 900 mm - in a volume of at least 15% (but not less than four joints) of the total number of similar joints made by each welder. In the case of checking the continuity of welded joints using magnetic testing, 10% of the total number of joints subjected to control must also be checked using the radiographic method.

When laying heat pipelines under railway and tram tracks, highways, city passages and when constructing underwater and underground passages through these obstacles, when laying in collectors and technical corridors, 100% of welded joints in a given area are subject to physical control methods.

Welded joints of heat pipelines are rejected if, when tested by non-destructive testing methods, cracks, unwelded craters, burns, and also lack of penetration at the root of the seam made on the backing ring are detected.

When non-destructive testing methods are used to identify unacceptable defects in the welds of pipelines that are subject to the requirements of the Rules of the Gosgortekhnadzor of Russia, the quality of the seams established by these Rules is repeated, and in the welds of pipelines that are not subject to the requirements of the Rules - with a double number of joints compared with the above.

If unacceptable defects are detected during re-inspection, all joints made by this welder are checked.

Tensile and bending tests of welded joints are carried out mechanically on samples cut from control joints. Control joints are welded under conditions identical to those for welding working pipelines, using the same base and filler materials and in the same position in which the production joints were welded. The worst ones accepted in appearance are selected as control joints. For mechanical testing, 0.5% of control joints are selected from the total number of joints welded by each welder, but not less than one joint per month. Still have questions?

Rules for external and technical inspection

Any pipeline quality check begins with an external inspection. It is not only purely visual, but also involves the use of measuring and other types of technical instruments. This will allow us to identify problems in external factors, compliance of the current state with standards and legal requirements.

Video

Section II Lesson No. 5. Carrying out control.

Detecting even small cracks in welded joints will not be difficult if you clean a small area on the seam and then treat it with alcohol or a weak acid solution.

Geometric dimensions cannot be determined without a ruler and caliper. Good lighting will make inspections more efficient. As does using a magnifying glass that supports 8-10x magnification.

Capillary methods for testing welded joints: the essence

This quality control of pipeline welded joints involves the use of contrast liquids that seep into the metal through the smallest damage if found on the surface. So-called penetrants are used most often.

When such substances are used, the defects are simply painted a certain color.

Penetrants can consist of different bases:

- Transformer oil.

- Benzene.

- Turpentine.

- Kerosene.

In addition, the compositions themselves are divided into several varieties.

- With dyes that are observed in daytime color. The most commonly used color is bright red.

- With luminescent components. Disadvantages appear if ultraviolet rays are used.

The method has a sensitivity of 0.1-0.5 microns. It can reach 500 µm if the upper limit is maintained.

Video

Installation of automatic ultrasonic testing of circumferential welded joints (UMKa model)

Checking a welded pipeline joint using kerosene is considered one of the simplest methods. It is important that the composition has high penetration properties. Such tests have their own separate order. An aqueous mixture with kaolin or chalk is applied to the connecting areas. After which everything is dried until a white film forms.

Kerosene should generously moisten the back side of the seam for at least half an hour. Even if there are only microscopic cracks, kerosene will pass through the surface. After which it becomes noticeable from the reverse side. Visually identifying defects is not difficult.

Physical control of welds

Among the many methods for quality control of welds, physical ones occupy a special place, including:

- Radiation control method. It includes X-ray and gamma-graphic methods, based on the ability of X-rays to pass through opaque objects. In this case, the defects, which are most often voids, appear as spots or stripes on an x-ray. Gamma radiation operates according to the same system, but has a lower sensitivity. The product is rejected if the following defects are detected: single and chain slag inclusions, as well as pores.

- Ultrasonic method. Based on the ability of ultrasound to penetrate into a structure and be reflected from defects.

- Magnetic flaw detection method. The seam being tested is lubricated with a composition of oil and a special magnetized powder; the product itself is also magnetized using a current that is passed through the winding. Under the influence of a magnetic field, iron powder particles spread more around defects.

- Hydraulic tests. The vessel is filled with water and increased pressure is created. This method is used when testing steam and water boilers.

- Pneumatic tests – tests with compressed air.

Interesting: Description and types of welded joints

All details of the test processes depend on the technical conditions for each test object.

X-ray inspection

How is permeability checked?

When containers, pipelines, and so on are welded, it becomes necessary to assess what the tightness is. Such quality control is also carried out using various methods and tools:

- Hydraulics and pneumatics tests.

- Bubble method.

- Leakage.

And so on. Pneumatic testing is when large quantities of water or gas are released into a pipeline. The foaming composition is applied to the surface from the outside. If foam bubbles appear, it means the seal has been broken.

Video

ERW-pipe welding machine for field application - Equipment for welding and non-destructive testing.

How to choose the right method for non-destructive testing of pipeline connections?

Choosing the best way to check pipeline connections is not difficult. You just need to consider the following factors.

- Indicators of economy and technical properties.

- Features of manufacturing a welded structure.

- The state in which the surface is found.

- Welded joint by thickness and type.

- The metal itself with a definition of physical properties.

Video

Story about the use of Non-Destructive Control Methods

The main thing is to remember that when using non-destructive methods, defects are detected only indirectly.

Non-destructive testing of welded joints using ultrasound

The method is based on acoustic changes that occur when ultra-high-frequency sound vibrations are passed through the compound under study. The degree of attenuation of the return signal and the speed of propagation become the most important properties of sound for this study.

Ultrasonic flaw detection is carried out based on the following principles.

- An ultrasound source generates sound waves. They definitely pass through the zone that requires diagnostics. Then they are reflected from those places where defects are most likely to appear.

- The sound wave must be reflected from something, otherwise identifying flaws will be impossible. The angular search head is a special device that ensures the desired effect.

- The sound wave not only reflects from the area with the flaw, it contributes to a change in the angle of refraction. The size of internal defects is judged by how large such changes turned out to be.

Result: elimination of defects

Any defects that do not meet the initial specifications require elimination. If this is not possible, then the product is simply considered defective.

Video

Welding technologies and control of welded joints

Plasma-arc cutting in normal situations helps to cope with problems. For this purpose, an inspection is carried out, followed by processing using abrasive wheels.

After tempering the welded products, defects that allow heat treatment are corrected. The main thing is to follow certain rules.

- Areas with defects should remain smaller in length compared to the areas being removed, on each side.

- Cutting also requires special sampling. The double width of the stitches before the procedure should remain approximately the same as after.

- It is imperative to maintain the reliability of the welds.

- The presence of smooth outlines without breaks is mandatory for the surface for each sample. The presence of sharp burrs along with indentations is also unacceptable.

The area must be completely cleared after the renovation work is completed. Transitions to the base metal from defective areas should be smooth.

Video

laboratory of non-destructive testing of welded joints Simferopol

It is permissible to use only the mechanical method when it comes to aluminum and titanium alloys. Grinding requires abrasives.

To eliminate the shortcomings, they use the same materials and technologies that were used to apply the main seam. After this, re-inspection becomes mandatory.