Scope of use of the device

The table press can operate on automatic or manual traction. The popularity of such a device is also explained by its particularly small size. Which is very important given the high rental price for production purposes. This equipment can be called truly durable, as it is made of hardened steel. Such equipment can operate for about 10 years without replacing component mechanisms, as well as without making additional repairs. Its operation does not require consumables, and the maintenance of such a machine can be entrusted to even the most unskilled and inattentive employee in the enterprise.

Using a hand press you can process the following materials:

- Cardboard.

- Skin.

- Foam rubber.

- Plastics and polymers.

- Various types of materials.

- Rubber.

Mechanical presses are actively used in all areas of production activity for pressing plastic containers, paper, various non-ferrous metal waste, aluminum, metal shavings, as well as other waste after production. This type of press is commonly used in printing houses, restaurants and hotels. The press will significantly reduce the costs of waste disposal.

Scope of application

rack type press

The table press can operate on manual or automatic traction. The popularity of the device is also explained by its small size. Which is very important given the high cost of renting for industrial purposes. This is reliable equipment with a long service life, which is made from durable types of hardened steel. The device can operate for decades without replacing components or repairs. No consumables are required; machine maintenance can be entrusted to the most unskilled worker.

Using a hand press the following is processed:

- various metals;

- plastics and polymers;

- cardboard;

- skin;

- rubber;

- foam rubber

A mechanical press is used in metalworking for pressing out bushings or bearings, cutting out small products, stamping, pressing and riveting. With its help, time is saved on the manufacture of parts, and their quality remains high. At the same time, even a beginner can handle the job. Another advantage is the ability to work even at sub-zero temperatures.

Design and operating features

All processes can be divided according to the shape of the rod into the following:

- Screw.

- Rack and pinion.

The design of desktop equipment that operates using manual traction is quite simple:

- Rack type rod.

- The bed is column-shaped, which is combined with a stand for placing a workpiece or a turntable.

- Specialized shaft.

- A gear train that is driven by a screw or lever.

The principle of operation of such a mechanism is that with the help of manual traction, the general rotational movement of the eccentric is launched. At the same time, it is attached to a piston, which efficiently presses the raw material through a special matrix. With all this, the force of counterpressure should be regulated by the very shape of the matrix , which can be easily replaced with a new one. There are a large number of matrices for different types of raw materials. In addition to this machine, there are special dies for the production of flat components from sheet metal.

When creating a structure, you can use various matrix schemes:

- Spinning.

- Hexagonal replaceable.

- Point replaceable.

Device characteristics

The main characteristic that will mainly determine the application of the press: maximum reinforcement in the area of the rod. In this case, the indicator can vary between 450-5 thousand kilograms. To create an auto repair shop, a pressure of 2 tons is enough, for use in a personal plot - 500 kilograms.

In addition to all this, the very size of the working area and the reach of the rod itself are considered important - it is on them that the dimensions of the manufactured parts will depend. The more powerful the machine, the more it will weigh and the more difficult it will be to lift. So, with the process of increasing the force by one ton, the weight of the device begins to multiply by two. The higher the power rating, the larger the mechanism itself and with the greater number of components it can function.

- Effort (varies from 500 to 5 thousand kilograms).

- The total cross-sectional area of the rod (the larger the area, the larger the product itself can be made).

- The height of the total workpiece (from 10 to 25 centimeters and depends on the range of the rod extension).

The desktop type of product is considered more stable, durable and reliable, and it will also be much easier to work with such equipment. Changing parts in it is quite simple, the parts at this time will come out quite accurate. Accuracy in performing the work will be ensured by the overall rigidity of the structure, as well as the monolithic body.

What is the structure of a hydraulic press and how to make it

A hydraulic press is absolutely indispensable in rural areas. And it was invented back in 1975. The principle of its operation is to use communicating cylinders with pistons of different diameters. Moreover, the less pressure, i.e. the hydraulic pump and the more receiving hydraulic cylinder, the stronger the pressure will be created with less force. In essence, this can be compared to the movement of a car in a low gear.

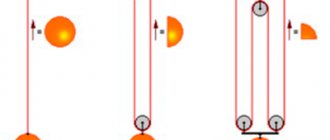

The operating principle of hydraulics is much clearer this way

The most common form of hydraulic press, as already mentioned, has become a rectangular frame. And the main task in its manufacture is accurate calculations. The first step is, of course, to draw up a diagram of the future press, because Without it, it will be difficult to figure out all the connections. Both the quality and speed of assembly of the unit depend on how detailed it is.

All structural elements must be made of steel, with a thickness of at least 15 mm. This is done so that the frame does not move during operation, because significant force will be applied. The main thing that needs to be considered is the design itself. It is necessary to remember that hydraulic jacks are designed specifically for working in a vertical position and cannot be placed on their side, nor can they be installed with the rod down.

Mechanical work with a hydraulic press becomes much easier

Ideally, you should get the following design. A rectangular, elongated upward frame is fixed to the frame. Inside the frame, vertically along the edges, there are 2 guides along which a horizontal crossbar runs up and down. A hydraulic jack is fixed on top of it, and the transverse beam itself is suspended from the upper part of the frame by springs, which ensure that the transverse beam is pressed back when the jack is loosened.

An ideal example of a homemade hydraulic press

The hydraulic press produced in this way will press down when the jack is “pumped up” and rise up when it is loosened using springs. A large nut can be welded to the bottom of the beam, into which various tips needed for a particular job will subsequently be screwed.

If you have a separate hydraulic cylinder and hydraulic pump at hand, then you can make a more convenient unit. Indeed, in this case, it becomes possible to install a pedal, and during work both hands remain free, which is sometimes extremely necessary.

In general, how to make a hydraulic press is everyone’s business. And the answer to this question is limited only by the imagination and wishes of the master. A little ingenuity and now an exclusive device is ready that meets all the requirements of convenience.

Drawing diagram of a hydraulic press - everything is clear and clear

The importance of drawing up drawings of a self-made hydraulic press

The main task in such work is accuracy and attentiveness. And if the dimensions, for example, of the vertical posts do not match, the unit may press slightly to the side, which in some cases can be critical. That’s why drawing up drawings of a manual hydraulic press with your own hands is very important. Moreover, all dimensions on them must be written down and calculated down to the millimeter. And during manufacturing, deviations from the drawing are unacceptable.

A hydraulic press drawing of which is drawn up correctly and will function perfectly. For a typical garage installation, the ideal size would be a supporting frame 50 cm wide and up to 1 m high.

Do-it-yourself hydraulic press - how long will such work take and which connections are better

It is best to assemble the frame for a hydraulic press with your own hands using welding joints. In this case, the seams must be of high quality. Of course, if a 3-ton jack is installed, no extra forces will be applied to the frame, but it’s still better to play it safe.

But what will happen if the weak seams do not hold up and the structure “leads”? Let's look at this with an example. It is necessary to replace the failed electric motor bearing. It is pressed into a duralumin cover, and therefore you need to work with a homemade hydraulic press to remove it. And if, during its extrusion, the structure frame is driven, the force on the bearing is applied unevenly in a circle. As a result, the duralumin engine cover breaks. We've arrived. Now, in addition to the bearing, it is necessary to purchase a cover for an asynchronous motor (or a generator, the meaning does not change).

This type of jack is also suitable for a mechanical press, but it must be used with caution

That is why, before making a press with your own hands, you should think about the connections. If you are not confident in your ability to make high-quality welds, then it is better to either turn to a professional or stick to bolted connections. But you also need to be careful with this type of installation. You should not spend 2-3 small diameter bolts on one connection, this will not make it stronger. The best thing that can be for a garage hydraulic press is a connection with one, but thick bolt.

Ideal bolted frame connections

Related article:

Special devices will help you create a pipe bender for a profile pipe with your own hands . For such products you do not need to purchase expensive materials and equipment. Read more in our material.

Types of hand presses

To use the press in different industries, the following types of manual presses are created:

- Hydraulic. The required force occurs using a hydraulic cylinder rod. The hydraulic cylinder itself contains a certain working fluid, which begins to actively compress under pressure to create connections, compression, and deformation of the shape of objects. It is considered more powerful and of higher quality than a manual mechanism: it is capable of creating tens of tons of force with the slightest effort on the part of the employee.

The main component of the design is a pair of hydraulic cylinders in various sizes, which are filled with technical oil. They operate between themselves using a working fluid. The operating principle of such a device will be very similar to a mechanical one, only in this case a special technical oil is used in place of the lever. The power of the equipment will be directly proportional to the ratio of the diameters of the cylinder and piston.

- Hole punching. A special type of press for stamping holes in sheets of various types of materials, including metal no larger than 4 mm. The total diameter in the punched surfaces will vary from 10 to 40 mm.

- Manual mechanical press. It is used mainly for crimping cables and tubular sleeves. Crimping is the most reliable method of connecting electrical cables; it increases the overall current conductivity, which reduces resistance and prevents overheating in the cable, reduces the possibility of accidents during the production process, as well as burning of individual connections. It is most effective to perform crimping using a mechanical hand press.

This mechanism is presented in the form of a lever, equipped with ratchets or ratchets; they prevent the development of reverse motion and create a fairly strong force so that high-quality adhesion occurs in the wires. The design allows you to easily change the total length of the arms. The pressure that occurs in the equipment can be compared with that provided by a hydraulic analogue , but the second one has a significantly higher cost. To achieve high-quality compression in the wires, you should press the handle several times, and then change the included nozzles.

A mechanical press can work with electrical wires of absolutely any cross-section up to 240 sq. mm. When choosing equipment, it is worth clarifying its operating range. The larger the device, the thicker the cable it can crimp.

- Press jaws. Used for putting lugs and sleeves on special cables and electrical wires. In this case, such a device creates a special press-type profile. Capable of working with a maximum cable cross-section of about 35 square meters. mm. The total weight of the instrument at this time will be three kilograms.

- Tablet press. This is a special device that is designed to create tablets in the laboratory. There are a large number of modifications of tablet devices, including tabletop ones, which perform their work using manual traction. The total productivity in such a device varies from 200 to 1 thousand tablets per hour.

The diameter of the tablets is created by a certain shape in the range from 0.4 to 1 centimeter, the thickness is no more than half a centimeter. The maximum gain will reach 700 kilograms. Laboratory tablet devices can be of the hydraulic type, and also perform work from an electric motor. Such devices will be more powerful , the productivity per hour will be about 6 thousand tablets.

Types of hydraulic presses for service stations

- Manual. It has a simple design and low weight, works on the force of lever traction. The unit is easy to transport from one place to another.

- Auto. This is a stationary device that allows you to obtain high pressure. The hydraulic press is controlled using a switch, lever or button. The purpose of the unit is extrusion and installation of bearings, crimping wires, stamping of various parts. An electric drive is used to supply fluid to the hydraulic cylinders.

Press selection criteria

- Power indicator. The clamping force in a manual type mechanism will directly depend on the effort on the part of the person. A hydraulic device is considered more complex and powerful, and therefore does not require a person to apply any increased effort; a hydraulic press is considered more powerful and complex in structure, and does not require too much effort; the effect at this time is achieved due to a special design.

- Size indicator. The size of the device is considered a fairly important indicator; it will be especially important for small production points. At the same time, the smaller the device, the fewer parts it will be able to perform work with. A small desktop device can cover the needs of workshops or households. If you are going to do work with large parts, then you should choose a larger unit. In most cases, these perform their work hydraulically.

- Purposes of use. Presses are mainly used only in production or during installation. There are special models for the production of food products, for example, juice. Such drugs are in most cases used in home production.

Functions of the business press

The first step is to take a closer look at the functions of the business press. Among the main ones are the following:

- increasing the business circle of the review, disseminating accumulated experience in the business sphere, which is one of the main purposes of journalism (in any field);

- prompt provision of commercial information to a specialized audience (for example, exchange rates, quotes, reports);

- motivating consumers to purchase goods and services;

- providing consumers with specialized information that relates to certain properties of a product, service, production process, or their use;

- providing the audience with regulatory documentation, including government regulations and legislative acts;

- creating a positive entrepreneurial image in the mass consciousness of the consumer;

- formation of business ideology;

- influencing government and management bodies in order to make decisions that will help develop entrepreneurship.

Finished works on a similar topic

- Course work Typological features of business publications 400 rub.

- Abstract Typological features of business publications 270 rub.

- Test work Typological features of business publications 190 rub.

Receive completed work or specialist advice on your educational project Find out the cost

All business information is divided into blocks, each of which performs its own functions:

- The first block is presented with texts with analysis, as well as forecasts for the development of various sectors of the economy and finance. This block is in demand due to the importance of the information provided.

- The second block includes reports from exchanges, quotes, commodity prices, etc. This is valuable information, which is indispensable in making operational decisions in the field of finance, the stock exchange, and when conducting transactions with real estate and other commodity objects.

- The third block is intended for trading services. This includes small wholesale, retail, wholesale trade, as well as the insurance, entertainment, and transport sectors.

- The fourth block consists of messages with facts from the business environment. Facts are often necessary for making important decisions, for analysis, forecasting and planning. All these actions are integral in a business environment. Therefore, specific facts are of interest and are valuable, useful information.

Looking for ideas for study work on this subject? Ask a question to the teacher and get an answer in 15 minutes! Ask a Question

Note 1

Quite often in the business press there are custom-made advertisements on behalf of an organization, published in order to convey information to a specialized circle of people.

Based on how facts and events are reflected, as well as the type of channel, all business information is divided into mass and specialized.

As business relations grow and develop, the involvement of the mass audience also grows, and interest in certain sections of business information increases. And here we are talking about mass media.

Specialized information is intended for a specific audience of readers.