A welding generator is an autonomous installation used for welding in the absence of a full source of electricity. This unit harmoniously combines two important functions: it organizes an independent power supply and generates welding current of certain parameters.

Its use makes it possible to carry out repair and installation work of any complexity where the electricity supply is intermittent or impossible at all due to the lack of appropriate lines. In addition, such a device is often indispensable in everyday life, for example, as an autonomous lighting system or for urgent welding.

Structurally, the welding installation consists of a current generator and a fuel drive engine, which are combined with a number of monitoring and control units and systems. These include: a rheostat for debugging the welding current, an armature, a fuel tank, a control panel, a manifold, a housing, a current collector, a hood with curtains and a roof.

It is worth noting that in general the principle of operation of a welding generator is similar to the operation of other similar installations. However, this device has one main difference - the presence of such a unit as an armature, rotated by a motor. Thanks to this, it produces electrical energy with constant characteristics, which allows for a stable and continuous welding arc.

The main operational advantages of welding generators:

- compactness, mobility;

- high reliability, functionality;

- low noise level;

- work in difficult conditions and under high loads;

- convenient, inexpensive and independent power source;

- long-term operation in autonomous mode;

- stable generation of electric current with certain parameters.

Types of Welding Generators

When purchasing such equipment, you should be aware that it is designed to produce a certain amount of electricity that is needed for welding. In this regard, all specific consumer requirements must coincide with the operational capabilities of the equipment. Otherwise, its effective operation is impossible. Depending on the technical and functional characteristics, the following types of welding generators are distinguished:

- Transformers are easy-to-use and compact units that produce alternating current and are affordable.

- Rectifiers are stations designed to produce direct current. This equipment is used to obtain high-quality welds and process stainless steel parts.

- Inverters are devices with the function of high-precision adjustment of operating parameters. Most often used for welding in automatic or argon arc mode.

Welding generators are also available for sale, classified according to the type of fuel used:

- Gasoline

These installations are characterized by low power and affordable price. They are not suitable for long-term work in difficult conditions, but are considered the best solution for occasional use in everyday life. They are distinguished by optimal dimensions and low weight, produce little noise during operation, and do not pollute the environment.

- Diesel

The main characteristics of such units are high operational reliability and a solid power range. Thanks to this, diesel plants have a significant operating life and the ability to operate at low temperatures, and, consequently, a higher market value. But their operation is much cheaper than gasoline-powered equipment.

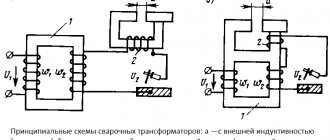

Valve type generator circuit

Gasoline generators of this type are made in the form of an inductor three-phase alternating current generator. It has a higher frequency, and the circuit has a built-in rectifier unit. A three-phase AC armature winding is installed on the stator. It is connected according to the “star” or “triangle” scheme. Between the two rotor packages, the excitation winding is also located on the stator.

The rotor itself is made in the form of two packages consisting of gear elements made of electrical steel. It has no windings and rotates around its axis. Each rotor package has eight teeth, offset from each other by 180 degrees.

When a direct current passes through the field winding, an alternating magnetic flux occurs in it. Its distribution is carried out in such a way that the first package creates only the north poles, and the second - the south. When the rotor and stator teeth are aligned, the maximum value of the magnetic flux is achieved, and the amount of resistance along the path of this flux will be minimal. The magnetic flux becomes minimum when the stator tooth coincides with the rotor slot.

Thus, it is clearly seen that the excitation winding is directly involved in the creation of a pulsating or alternating magnetic flux. Penetrating the three-phase stator winding, this flow causes the induction of an alternating emf with an increased frequency in it. In turn, the alternating EMF is converted into a constant voltage of the valve generator using a rectifier unit.

The name of the device is associated with the rectifier unit, which uses silicon valves assembled according to a three-phase circuit in the form of a bridge. The excitation winding is powered through a three-phase generator power circuit. For this, there is a special unit, which includes current and voltage transformers, as well as rectifiers. After starting, the generator is initially self-excited due to the residual magnetic flux.

Characteristics of welding generators

In addition to the above criteria, there are a number of important characteristics that directly affect the operation of welding generators. Firstly, it's power. This indicator is indicated by the manufacturer in the attached data sheet in kW or kVA. Experts recommend selecting a unit with a certain power reserve, since you never know what welding tasks will need to be performed in the future.

Secondly, protection from dust and humidity. Modern safety requirements strictly prohibit working with household and professional welding generators in heavy rain, since there is a high risk of getting an electric shock and damaging the equipment. That is why most stations have a protection class against “single drops and large particles of rain”; there are also installations with protection against “slanting rain”.

Thirdly, maintainability. Before you start a conversation with the seller about all the delights of a certain model, it is rational to find out where, by whom and under what conditions technical support is provided and warranty repairs are carried out. An important criterion is the equipment. If the equipment is intended to be carried by hand, it must be equipped with an appropriate case. It is also worth paying attention to the following indicators:

- type and starting current;

- operating and no-load voltage;

- electrode diameter;

- duration of switching on;

- working temperature;

- weight, size, transportability.

What is SAC: general information + features

When a person chooses a laser machine, he first of all pays attention to the output power, dimensions and other technical characteristics. Very rarely does a buyer think about the conditions under which he will use the welding unit in the future.

I mean thinking ahead, and not a momentary impulse to acquire 1-2 things.

SAK (Wheel Welding Machine) is a hybrid design that combines welding and a mobile power station. In addition to the classic abbreviation, this equipment is often also called SAG or welding power station.

Please note: when building in hard-to-reach places or in new areas, the problem of connecting to a power source is extremely acute. Recharging without obtaining the appropriate permits will result in penalties.

The key design feature of welding wheel units is the presence of an internal combustion engine. It is according to this that equipment is classified within our state. I will describe the detailed distribution by motor type for power supplies below in the table.

| Type | Subspecies | Description | |

| Petrol | Inverter portable | These are small generators with a power of up to 1 kW. Manufactured in a “suitcase” form factor. They are purchased for home use, because the intensity of the supplied electrical energy is not enough for industrial purposes. | |

| Inverter up to 6 kW. | Increased power also entails increased weight of the unit. Such models are supplied in the form factor of a chest on wheels. To prevent equipment parts from suffering mechanical damage, a frame of pipes is usually made around the engine. | ||

| Gasoline up to 10 kW | Designed for use at high intensity over long periods of time. Form factor like a barrel on wheels. | ||

| Diesel (DGS) | Design execution | Classical | Linear type rotation generator |

| Open | Used in buildings. | ||

| Soundproof | If a “quiet” operating mode is required. | ||

| Van | For difficult climates. | ||

| Mobile | In mobile structures. | ||

| Type of current | Low voltage | up to 1 kW. | |

| High voltage | from 1 kW to 10 kW. | ||

| Generator type | Parallel | Generation of current at standard frequency. | |

| Asynchronous | Generation of current of non-standard frequencies. | ||

| Welder | Constant | DC generation. | |

| Removable | AC current generation. | ||

Among gasoline power plants, container-type power plants can also be distinguished. For constant outdoor use, modification of the external casing is required (noise-absorbing casings are used) + fine adjustment to the form factor. Typically, such equipment is made to order. Peak power can be up to 200,000 watts.

Among diesel equipment, three concepts should not be confused - “power plant”, “unit” and “generator”. Each of the objects has its own design + differs in the scale of assembly.

Design features of SACs:

- Built-in cooling system that protects sensitive parts from overheating. With high-quality cooling, the operation of the welding unit will not be suspended at the most inopportune moment;

- the part of the equipment that is responsible for the welding operation itself is manufactured as an induction generator;

- The engine is usually covered with a special fireproof casing to prevent external negative influences of weather. The second function is to protect the welder from potential injury;

- the lower part of the frame is equipped with a chassis. The wheel size may vary and depends on the operating conditions of the equipment. For indoor use, these are small ones, but if we are talking about transporting the SAC over long distances (like a trailer), the diameter of the wheels increases significantly. All these points are discussed individually with the supplier of the units.

When referring to the technical characteristics of SACs, it is important to pay attention to the type of welding current and its peak power. Usually this is up to 120 A. The second, no less important selection rule is the ability to connect other electrical equipment to the unit. It is irrational to drag such a colossus behind you just for the sake of welding. It is necessary to select units that are capable of producing an output voltage suitable for most classic power tools. Such SACs can be useful during construction or installation work, and even in everyday life as a temporary power source for housing.

Welding generator operation

Multifunctionality of generating equipment, i.e. the ability to use it as an independent power plant and as a welding machine ensures comfort and mobility of the process, and also significantly reduces the time for its preparation. It is enough to fill such a unit with fuel, and it is ready for welding. While preparing conventional welding equipment for operation (laying cables, connecting, debugging) takes much longer, which is very inconvenient.

It is almost always more profitable to purchase a welding generator rather than an autonomous station and a separate welding installation. After all, it often happens that the fuel unit does not ensure the operation of the welding machine due to lack of power. But the welding generator is designed for a certain power and operation in a wide range of temperatures, which, if selected correctly, guarantees excellent quality of the created seams.

It is also important that such installations are designed for processing different metals in different, sometimes difficult, climatic conditions. In addition, it is in autonomous systems that various protective functions, microprocessor control and the ability to automatically debug voltage are provided. Thanks to this, such equipment is distinguished by versatility, high performance and safety.

Welding generator circuits

The modern industrial industry offers a wide range of models of these installations. Schemes of welding generators, which determine the principles of their operation and control, are made in various modifications and differ in external characteristics. Today, almost all well-known manufacturers use their own developments in this area.

This approach is very useful for end consumers, since it provides the opportunity to choose products not only taking into account the planned work, but also according to the budget. Currently, the greatest demand is for equipment operating according to the type of independent or self-excitation and the following schemes:

- universal;

- with a falling characteristic;

- with a rigid or gently falling characteristic.

Welding generator repair

Despite the fact that the welding generator has high technical characteristics and a degree of reliability, sometimes, like all electromechanical equipment, it breaks down. The reasons for device failure can be different: low-quality fuel, improper maintenance, incorrectly set operating mode, etc.

To avoid unexpected failure of the welding generator and subsequent stoppage of work at the site, it is necessary to carry out timely maintenance and, if possible, eliminate identified faults. As a rule, each device comes with instructions that describe in detail the most common problems and methods for solving them.

However, independent repair of a welding generator requires certain knowledge in the fields of electrical and mechanics. If these are not available, it is better to stick to standard preventative maintenance and leave the rest to the service center professionals. Such a distribution of responsibility will undoubtedly increase the service life of a welding generator from any manufacturer. Typical defect elimination work can be divided into two main groups:

- Engine repair

Usually involves periodic inspection and, if necessary, replacement of piston rings. The period of continuous operation of these elements of the welding generator is indicated in the instructions. Therefore, if, when disassembling the engine, wear of these spare parts is revealed, they should be replaced. Further suitability for service or the need to change engine lubricant and spark plugs is also determined by visual inspection;

- Electrical repair

Most often, such work consists of replacing worn-out current-collecting brushes and rewinding the windings in an interturn short circuit situation. Even if only one brush is worn out, be sure to replace both at once. It is for this purpose that a typical repair kit is equipped with a pair of spare ones. Another common defect is the shaft bearings breaking or spinning inside the housing. Such malfunctions of the welding generator are accompanied by noticeable noise and increased temperature.

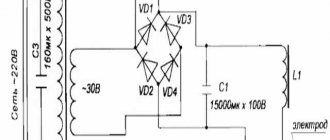

Collector generators

Design of collector generators

The main elements of a DC welding commutator generator are: a stator with a housing, four main magnetic poles and field windings; an armature with a core in the grooves of which the winding is laid; a collector made of insulated copper plates; four current collection brushes, as well as output clamps.

Rice. 1. Design diagram of a collector generator

The brush-collector device provides a constant EMF of the generator with a variable EMF of individual conductors, performing the function of mechanical rectification of the current.

Independent excitation generator with series demagnetizing winding

In Fig. Figure 1 shows a simplified circuit diagram of the generator. It has only one pair of brushes and one pair of poles. An independent NO winding is wound on one of the poles, receiving power from an external DC source. The demagnetizing winding PR is wound on the other pole, connected in series with the armature and load. Thus, the magnetic flux is created by the combined action of independent and series windings. This, as will be shown below, ensures the formation of a steeply falling external characteristic of the generator. Smooth control of the mode is performed using rheostat R1, rough control is performed by changing the number of turns of the series winding and turning on the ballast rheostat R2.

Rice. 2. Schematic diagram of a generator with independent excitation and series demagnetizing winding

The falling external characteristic of a generator with a series winding is obtained due to its demagnetizing effect.

The mode is regulated: smoothly by changing the current of the independent winding and roughly by sectioning the series winding and turning on the ballast rheostat.

Generator with self-excitation and series demagnetizing winding

Typically the generator has a stator with four main poles and a cylindrical armature with a commutator and four main and one additional brush. In Fig. Figure 3 shows a simplified two-pole design of the generator. In addition to the main brushes a and b, installed on the geometric neutral, the generator also has an additional brush c, used to power the magnetizing parallel winding NO.

The generator is designed in such a way that the voltage on the brushes a - c almost does not change with changes in the load, therefore the current of the magnetizing winding I is practically independent of the load current Id. This improves the welding properties of the generator and brings them closer to the properties of a generator with independent excitation. The flows of the parallel NO and serial PR windings are directed in the opposite direction, so the generator has a falling external characteristic. Regulating the mode, as with a generator with independent excitation, is performed: smoothly by changing the current in the magnetizing winding circuit and roughly by sectioning the series winding.

Rice. 3. Schematic diagram of a self-excited generator with a series demagnetizing winding

The technical and economic indicators of the collector generator are relatively low. The efficiency of the generator is 0.5 - 0.7, and taking into account the efficiency of the drive motor, it is even lower. Therefore, the energy consumption of converters is very high - 5 - 8 kWh per 1 kg of molten electrode metal. For units with a diesel engine, the corresponding characteristic is -1.5 - 3 kg of fuel per 1 kg of metal, with a gasoline engine - 3 - 5 kg of fuel.

If you find an error, please select a piece of text and press Ctrl+Enter.