What is plasma welding

The emergence of new types of metal alloys in modern technologies has forced specialists to develop new techniques and drawings of equipment for welding products made from them. Since many modern metals do not lend themselves well to traditional welding techniques. As a result, a new plasma method for welding metal samples has emerged, which is successfully used in various repair and installation processes.

The main differences between plasma welding technology

Plasma welding is somewhat reminiscent of argon welding, but there are characteristic differences. For example, it has an operating temperature that is much higher. The welding arc can have a temperature from 5 to 30 thousand degrees. Thanks to this quality, using plasma welding technology, it is possible to connect elements of building structures that cannot be welded with homemade and standard factory equipment, the arc temperature of which does not exceed 5 thousand degrees.

Operating principle of plasma welding

The essence of this welding: by exposing the metal surface to a flow of ionized gas conducting an electric current, the metal melts. When the arc is heated, the gas undergoes ionization, the level of which increases with increasing gas temperature. A plasma jet, which is characterized by ultra-high temperature and increased power, is formed from an ordinary arc after compression, injection into the arc formed by a plasma-forming gas, which is usually argon (hydrogen and helium are rarely used).

The kinetic energy of the chemical elements present in the gas during the ionization process significantly increases the thermal energy of the plasma arc. Moreover, the arc, when compared with a conventional one, has the ability to significantly increase the pressure on the metal surface due to a decrease in its own diameter.

Plasma welding - video on how to weld metal using plasma welding Multiplaz

Plasma welding will increase efficiency and also reduce the time required for metal cutting. Devices for this type of welding are gaining increasing popularity among equipment used for plasma welding. You can view it by following the link on our website.

Many companies around the world are developing this market segment, producing both the devices themselves and related accessories. It also released its devices in Russia, which in all respects are worthy competition to foreign ones. Welding is carried out by machines, some of which are capable of cutting.

plasma welding process

The operating technology of the device is as follows. Inside the plasmatron power supply, an electric arc is ignited by a nozzle, from which, at a temperature of ten thousand degrees, a jet bursts out at enormous speed, thanks to which cutting occurs. A powerful jet blows away the burr that was formed in this process, and the torch concentrates strong energy in the cutting zone. Plasma welding (video) is available for viewing on our website.

Cost and characteristics of a plasma welding machine

To satisfy consumer interest regarding the characteristics of devices, it is necessary to note several points: how exactly a plasma welding machine works, its price, and main technical features.

Plasma welding, which is very similar to argon welding, is carried out thanks to the flow of a plasma arc, which is formed by plasma or ionized gas.

The arc itself consists of neutral particles adjacent to charged ones. It has a sufficient supply of energy and high temperature. The generator usually consists of a plasma generator, power supply and control. The liquid is heated to a temperature at which ionization occurs.

In order for work to be carried out without interruption, you need power and water or a forty-five percent alcohol solution. A plasma welding machine weighs approximately five to six kilograms, and its price is around twelve thousand rubles. Preparing the unit for operation is not at all difficult.

How the device works

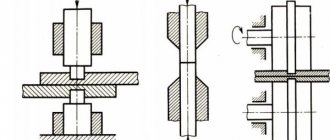

A burner or plasmatron can heat up to a temperature of thirty thousand degrees. When burning, the nozzle protects the area from outside air. In this case, the gas compresses the arc. Plasmatrons come with indirect (when the metal is melted by a plasma jet) and direct (where the arc occurs between the metal and electrodes) arc.

The power of the device is directly proportional to the combustion temperature. The influencing factors here are the speed of the gas and the torch, the distance between the part being welded and the nozzle, the strength and voltage of the current.

Recommendations for working with devices for beginners

A correctly selected apparatus and the mode required for welding will help to carry out work without cracks and the formation of cavities, even with a metal such as aluminum, which is quite capricious for carrying out this kind of work.

Plasma welding. . Inexperienced welders may experience excessive metal spatter during the welding process due to high steam pressure. It is better for novice welders to select equipment that has a large nozzle and the largest hole diameter for the job.

Thanks to this, the steam pressure will not be so high, and the torch will be able to simultaneously cover both edges of the parts, which will increase the likelihood of obtaining a high-quality seam.

Advantages of plasma welding machines

Plasma welding will reduce problems caused by metal spatter because:

- A gas cylinder is not required to carry out the work. All you need is water, alcohol and wire.

- You won't need a chameleon welding mask. Goggles for eye protection will be sufficient.

All this allows us to say that plasma welding is one of the most inexpensive types of welding, and by purchasing this device, it will be possible to carry out various work with a wide variety of types of metal.

Professionals highly value plasma welding, as it is the most advanced method of welding and cutting parts of various thicknesses. The highest productivity is combined with excellent work quality. However, during operation, you must follow all instructions when assembling the device, and during the preparatory process in general.

You also need to take care to provide working conditions where the plasmatron will be cooled after operation.

By applying all the recommendations, you can be sure that the work will be completed quickly, inexpensively and with high quality.

Share a link to this material with your friends on social networks (click on the icons):

Source: https://swarka-rezka.ru/svarka-plazmennaya-video-kak-varit/

Advantages of plasma technology

- Unlike gas welding, the cutting speed of metal 5-20 centimeters thick using the plasma method is three times higher.

- The high precision of the seams obtained as a result of melting and welding of metal, the quality of the work performed practically eliminates the need for subsequent processing of the edges of the products.

- Plasma cutting is used to process almost any type of metal. For example, you can cook samples from Zaporozhye steel, cast iron, copper, aluminum.

- When welding, the metal is not subject to deformation even when it is necessary to cut out complex shapes. The plasma welding technique makes it possible to cut on an unprepared metal surface, for example, rusty or coated with a layer of paint. In this case, the paint in the working area of the plasma arc does not ignite.

- There is no need for argon, acetylene, or oxygen. This significantly reduces financial costs.

- High degree of safety of work, since gas cylinders are not used. This indicator indicates the environmental friendliness of the process.

Advantages and disadvantages of units

To understand which plasma cutter is better, you need to know the advantages and disadvantages of the devices. Benefits include:

- in addition to ordinary metal, you can cut aluminum, stainless steel or cast iron;

- no surface preparation required. The presence of rust and paint is allowed;

- the cut is smooth without scale;

- even with a small thickness of the workpiece there is no thermal deformation of the surface;

- safety in operation;

- possibility of forming complex cuts.

However, with all the advantages, the plasma cutter also has disadvantages. These include:

- limitation on cut thickness. The maximum value is 100 mm;

- the workpiece must be positioned clearly perpendicular to the cut;

- You cannot work with two cutters connected to one machine.

Types of plasma welding

Depending on the tools used, plasma welding can be:

- on currents of any polarity;

- with penetrating/non-penetrating arc;

- point, pulse;

- automatic, semi-automatic, manual;

- with and without filler wire.

In the case of using low currents, the connection technique is called microplasma, which is the most popular. This scheme is in demand in the production of structures up to 1.50 mm thick - this is usually the connection of thin-walled pipes, containers, welding of small elements to heavy structures, the manufacture of jewelry, thermocouples, as well as welding of foil samples. Thin-walled metal products are also welded using electric rivets.

If the connection is made using filler wire, then solid wire (cored wire) is used.

Capabilities of plasma welders

The possibilities are shown below using the example of the Gorynych device:

- Welding and soldering of any non-ferrous metals, as well as stainless steels (the thickness of the welded metal depends on the device model).

- Cutting of non-ferrous and ferrous metals.

- Hardening of all types of steels.

- Creation of chemical compounds obtained under high temperature.

- Thermal shrinkage of all types of plastics and polymers, including LDPE, PP, HDPE and PVC.

- Cleaning surfaces from fungus, mold and other types of organic contaminants.

- Welding two or more metals, alloys or steels together.

- Soldering using soft solders.

- Melting metals in private forges.

- Initial heat treatment.

- Cutting glass and various organic elements (quartz, granite, graphite and much more).

- Initial bluing of compact parts.

- Powder coating on a small area.

- Making and cutting glass and glass products.

- Extinguishing initial fires with water vapor (without creating an electric arc between the cathode and anode).

For more information about the capabilities of the Gorynych device, see this material.

Features of microplasma connection

Plasma welding comes in three options, depending on the current used during operation:

- microplasma welding technology on currents - 0.1A-25A;

- connection with medium currents - 25A-150A;

- connection with high currents - 150A and above.

The first variation is more popular. In the process of connecting metal samples using a low-ampere current, a pilot arc is formed. It burns uninterruptedly between a water-cooling nozzle made of copper and a two-millimeter cross-section tungsten electrode.

The main arc is formed after bringing the plasmatron to the surface of the metal sample being processed. The gas that forms the plasma is supplied through a plasma nozzle, the diameter of which can be 0.5-1.5 millimeters.

The maximum diameter of the plasma arc is 2 millimeters. Thanks to this indicator, quite a large amount of thermal energy is generated on a relatively small element of the workpiece. This type of welding, like welding with electric rivets, is most effective for metal samples whose thickness is less than 1.5 millimeters.

Argon is used to form plasma, a protective gas environment, using this technology. Depending on what metal or alloy the sample is made of, additives can additionally be used to increase the efficiency of the “plasma”.

A plasma welding machine is capable of joining metal products in different modes. The range of welding uses is quite extensive:

- fastening membranes to large-scale structures;

- production of thin-walled pipes and containers;

- welding foil;

- jewelry manufacturing;

- many other connections.

DIY welding

This type of metal welding was not initially used at home, as it required a highly qualified welder. Today, thanks to the improvement of the methodology itself and the equipment used, there are welding units that can be used at home. The working method is very simple. To perform welding work, you need to purchase the appropriate equipment, filler wire, electrodes, and read the operating instructions for the device.

Tips for Beginners

- The electrode must first be sharpened to a cone-shaped shape, and the sharpening angle should be a maximum of 30 degrees.

- Important! Correct installation of the electrode. Its axis must coincide with the axis of the nozzles for gas formation.

- The welding joint is subjected to similar processing as when welding with argon.

- It is imperative to clean and then degrease the edges of the workpiece.

- It is necessary to ensure that there are no gaps larger than 1.5 millimeters.

- Additionally, the tack areas are cleaned; they must be of the same quality as the weld.

- You can start welding work.

- Do-it-yourself welding is carried out using direct current. Its value must be within the specified range.

- Before welding the samples, gas is supplied 10-15 seconds, which is turned off after 15 seconds after the arc breaks.

- During operation, the plasma torch should be located from the workpiece at a distance of less than one centimeter.

- It is recommended to hold the welding arc until the seam connection is completely completed.

- Do not overheat the metal during welding. After reaching the critical point, welding is suspended, the metal sample is cooled, after which welding work can be resumed.

- The gun (torch) must be moved evenly, then you can count on obtaining a high-quality welded joint.

Welding machine "Gorynych"

Multifunctional welding "Gorynych" is one of the most popular welding units of domestic production. This is a really high-quality tool that allows you to do welding work at home with your own hands. It should be noted that the Gorynych line of equipment includes devices of various capacities (8,10,12A).

For household work, an 8A device is perfect; a 10-amp device is characterized by price/performance, but more powerful 12A equipment is already considered professional. The welding unit of the Gorynych brand is quite popular both in Russia and in Ukraine (in particular, in Zaporozhye), and in Belarus.