Magnetic and electromagnetic welding control methods

7.4.1 Physical basis and classification of methods.

Electromagnetic testing methods are based on recording characteristic changes in electromagnetic fields in areas of various product defects.

For these purposes, both constant and alternating magnetic electric fields are used. Magnetic and electromagnetic (eddy current) testing methods are used in industry. The latter are suitable for both ferromagnetic and non-ferromagnetic electrically conductive materials.

For magnetic and electromagnetic control, pulsed, constant, alternating and combined magnetic and electric fields are used. Control can be carried out using both the residual magnetic field formed after magnetization and during the magnetization process.

Based on the methods of recording magnetic field inhomogeneities caused by defects, testing methods are divided into magnetic particle, magnetographic, magnetic flux probe, and induction.

Electromagnetic methods are distinguished mainly by the methods of producing an electromagnetic field in a controlled product, depending on the type of electromagnetic inductor used (covering or overhead).

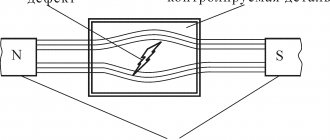

The reason for the occurrence of magnetic field inhomogeneities in the area of the defect is the secondary magnetic field, which is induced in the defect cavity, since the magnetic permeability of the cavity environment differs significantly from the magnetic permeability of the controlled metal.

The amplitude value of the defect field components depends on the size of the defect, its orientation relative to the external field, and the ratio of the magnetic permeabilities of the defect medium and the base material. To obtain maximum perturbation of the magnetic field, it is necessary that the vector of the external field strength be directed perpendicular to the plane of the defect.

The direction of magnetization must coincide with the seam along its length. In this case, the weld bead does not have a significant effect on the uniformity of the magnetic field and the field disturbance above the defect is easily detected. When a bead with a large height and small radius is transversely magnetized, the magnetic field strength above it decreases and disturbance above the defect is difficult to detect.

The nonlinearity of the magnetic properties of the material affects the structure of the magnetic field and makes it difficult to obtain information about defects. Therefore, in practice, they use the method of comparing the magnetic field of a controlled product with the reference field of a specially prepared sample.

7.4.2 Magnetic testing methods.

Depending on the method of recording information about the presence of a defect, magnetic methods can be magnetic particle, magnetographic, fluxgate, induction and others.

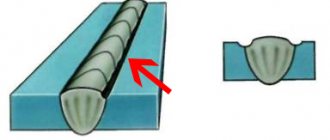

The magnetic powder method involves applying ferromagnetic powder in the form of a suspension with kerosene or oil to the surface of a magnetized product. Above the defects, where an inhomogeneity of the magnetic field is formed, the powder accumulates in the form of rollers, repeating the outlines of the defects. The powder is finely ground ferric oxide (Fe3O4) with a particle size of 5...10 microns. For better indication, the powders are colored or treated with a phosphor. In the latter case, accumulations of such powder on defects are clearly visible in ultraviolet rays due to their glow.

Products are magnetized in various ways, but most often attached electromagnets are used.

For magnetic particle testing, stationary and portable flaw detectors are used, which are equipped with magnetizing and demagnetizing devices of various types. Magnetic particle testing methods are good at identifying surface and subsurface defects such as cracks, lack of fusion, lack of fusion, hairlines, inclusions with an opening of 0.01 mm and a height of more than 0.05 mm. Round pores are less easily identified. Large defects can be detected at a depth of up to 6 mm from the surface of the product.

The essence of the magnetographic method is to magnetize a controlled welded joint, record the resulting magnetic field on a magnetic film, and then read the magnetogram from the film using special magnetographic flaw detector devices. The tangential component of the magnetic field is recorded on the magnetic tape, which contains information about the welding defect. This method of magnetic control has become most widespread. Magnetographic control is carried out in the following sequence: clean the welding seam, apply a previously demagnetized tape to it and press it with a rubber belt, using a magnetizing device (for example, a U-shaped electromagnet), magnetize the welding zone with a transverse magnetic field (for extended seams, magnetizing devices moving along the seam are used device), then the tape is removed and the magnetic recording obtained on it is reproduced on a flaw detector.

Magnetographic flaw detectors consist of a reading device, an electrical signal amplifier, a scan generator and a cathode ray tube (or television tube) with the necessary electronic units. On a cathode ray tube, information about the magnetic recording is reproduced in the form of beam pulses on a time base. On a television tube - in the form of a black-and-white image of a weld with defects.

The magnetographic testing method is good at identifying cracks, lack of penetration, chains of pores and slag inclusions, but much worse at identifying single slag inclusions and round-shaped gas pores. This method can detect cracks and lack of penetration with a sensitivity of 3–8%, rounded pores and slag inclusions with a sensitivity not exceeding 20%. As the depth of the defects increases, the sensitivity decreases.

The essence of the fluxgate testing method is to detect the magnetic fields of defects using fluxgate sensors. In magnetic flaw detection, fluxgates of small sizes are usually used. Such a fluxgate consists of a ring-shaped magnetic drive having a cross-section, and two coils - a generator and a measuring one - in the section of the magnetic drive located opposite the cut. The presence of a cut with a small gap ensures the concentration of the magnetic field in the gap, which makes it possible to record changes in magnetic fields in small areas of the magnetized product.

To record electrical signals received from fluxgates, fluxgate flaw detectors are used, which are highly sensitive. This method can detect surface microcracks and internal defects at a depth of up to 8 mm, but this method requires high purity of processing of the controlled product.

Non-destructive testing methods

According to GOST 18353-73, non-destructive testing methods are divided into the following types: - Acoustic testing (ultrasonic NDT method); — Magnetic testing (magnetic particle flaw detection); — Control by penetrating substances; — Radio wave control; — Radiation monitoring (X-ray NDT method); — Optical control; — Thermal control; — Electrical control; — Electromagnetic (eddy current) control. — Hardness testing (hardness measurement). Non-destructive testing (NDT) methods are based on observation, recording and analysis of the results of the interaction of physical fields (radiations) or substances with the test object, and the nature of this interaction depends on the chemical composition, structure, state of the structure of the controlled object, etc. All non-destructive testing methods are indirect methods. Setting and calibration should be carried out using control samples that simulate the physical parameter being measured. There is no universal non-destructive testing method capable of detecting defects of a wide variety of nature. Each individual NDT method solves a limited range of problems. A non-destructive testing system usually consists of a device, a transducer and a control sample. An important characteristic of any non-destructive testing method is its sensitivity. Sensitivity - detection of the smallest defect; depends on the features of the non-destructive testing method, testing conditions, and product material. Satisfactory sensitivity for detecting some defects may be completely unsuitable for detecting defects of another nature. The sensitivity of non-destructive testing methods to detect the same type of defect is different. When determining the maximum permissible error of the selected non-destructive testing method, it is necessary to take into account additional errors arising from influencing factors: - the minimum radius of curvature of concave and convex surfaces; — roughness of the controlled surface; — material structure; — geometric dimensions of the control zone; — other influencing factors specified in the instructions for specific devices. Currently, various physical methods and means of non-destructive testing of metals and metal products are widely used, making it possible to check the quality of products without compromising their suitability for intended use. All defects, as is known, cause changes in the physical characteristics of metals and alloys - density, electrical conductivity, magnetic permeability, elastic properties, etc. The study of changes in the characteristics of metals and the detection of defects that cause these changes forms the physical basis of non-destructive testing methods. These methods are based on the use of penetrating radiation of x-rays and gamma rays, ultrasonic and sound vibrations, magnetic and electromagnetic fields, optical spectra, capillarity phenomena, etc. Advantages of non-destructive testing (NDT) methods: - relatively high speed of testing, - high reliability (reliability) of control, - the possibility of mechanization and automation of control processes, - the possibility of using MNC in the operational control of products of complex shape, - the possibility of using MNC in operating conditions without disassembling machines and structures and dismantling their units, - comparative cheapness of control, etc. At the core Non-destructive testing methods are based on physical phenomena (parameters). Acoustic method This method of non-destructive testing is based on recording the parameters of elastic vibrations excited and (or) arising in the controlled object (the controlled object means materials, semi-finished products and finished products). In the acoustic method of non-destructive testing, sound and ultrasonic frequencies are most often used, i.e. A frequency range of approximately 0.5 kHz to 30 MHz is used. In the case when frequencies above 20 kHz are used during testing, the term “ultrasonic” is used instead of “acoustic”. Acoustic NDT methods are used to detect surface and internal defects (discontinuity, structural inhomogeneity, intergranular corrosion, defects in gluing, soldering, welding, etc.) in workpieces and products made from various materials. They allow you to measure geometric parameters with one-sided access to the product, as well as the physical and mechanical properties of metals and metal products without their destruction. Acoustic methods include methods of sound (impedance, free vibrations, etc.) and ultrasonic (echo-pulse, resonant, shadow, emission, velocimetric, etc.) ranges. Based on the nature of the interaction of elastic vibrations with the controlled material, acoustic methods are divided into the following main methods: - transmitted radiation (shadow, mirror-shadow); — reflected radiation (echo-pulse); — resonant; — impedance; — free vibrations; — acoustic emission. According to the nature of registration of the primary informative parameter, acoustic methods are divided into amplitude, frequency, and spectral. Application of acoustic methods of non-destructive testing: - the transmitted radiation method reveals deep-seated defects such as discontinuity, delamination, leaks, failures; — the reflected radiation method detects defects such as discontinuity, determines their coordinates, dimensions, orientation by sounding the product and receiving the echo signal reflected from the defect; — the resonance method is used mainly to measure the thickness of a product (sometimes used to detect zones of corrosion damage, missing solders, delaminations in thin places made of metals); — the acoustic emission method detects and records only developing cracks or those capable of developing under the influence of mechanical load (qualifies defects not by size, but by the degree of their danger during operation). The method has a high sensitivity to the growth of defects - it detects an increase in cracks by (1...10) microns, and measurements, as a rule, take place under operating conditions in the presence of mechanical and electrical noise; — the impedance method is intended for monitoring adhesive, welded and soldered joints that have thin skin glued or soldered to the stiffeners. Defects in adhesive and solder joints are detected only from the side where elastic vibrations are introduced; — the free vibration method is used to detect deep defects. Magnetic method of non-destructive testing This is a type of non-destructive testing based on the analysis of the interaction of the magnetic field with the controlled object. In this case, magnetic stray fields over defects or magnetic properties of the controlled object are recorded. Magnetic non-destructive testing methods are used to detect surface and subsurface defects in parts and semi-finished products of various shapes made from ferromagnetic materials. The magnetic type of non-destructive testing includes methods: magnetic particle, fluxgate, magnetographic and others. The magnetic particle method is based on recording stray magnetic fields over defects using ferromagnetic powder or suspension as an indicator. The fluxgate testing method is based on measuring the magnetic field strength, including magnetic and stray fields arising in the defect zone, using fluxgates. The magnetographic method of non-destructive testing consists in magnetizing the zone of the controlled metal or weld together with an elastic magnetic carrier (magnetic tape) pressed to its surface. Recording stray fields arising in places of defects on a magnetic carrier and subsequently reproducing the resulting recording. Reading of magnetic fingerprints of defect fields from magnetic tape is carried out in flaw detectors. Using magnetic methods of non-destructive testing, the following problems are solved: - The magnetic particle method is used to identify surface and subsurface (at a depth of 1.5 ... 2 mm) defects such as violation of the continuity of the product material: cracks, hairlines, delaminations, flakes, lack of penetration of butt welded joints , sunsets, etc. It is used to control products of any overall dimensions and shapes, if the magnetic properties of the product material (relative maximum magnetic permeability of at least 40) allow it to be magnetized to a degree sufficient to create a defect scattering field capable of attracting particles of ferromagnetic powder. The magnetic particle method has found wide application in industrial plants, repair facilities and operating departments. — The fluxgate testing method is used to identify surface and subsurface (up to 10 mm deep) defects such as a violation of the continuity of the material: hairlines, cracks, cavities, sunsets, caps, etc., as well as to identify defects such as a violation of the continuity of welded joints and for quality control of the structure and geometric dimensions of products, used to determine the degree of demagnetization of products after magnetic testing. This method can be applied to products of any size and shape if the ratio of their length to the largest dimension in the transverse direction and their magnetic properties allow magnetization to a degree sufficient to create a magnetic stray field of the defect detected by the transducer. — The magnetographic testing method is used to identify defects such as a violation of the continuity of the material of products, mainly for monitoring welded butt joints made of ferromagnetic materials with a thickness of 1 to 18 mm. The optical method of non-destructive testing is based on the interaction of light radiation with the controlled object. They are designed to detect various surface defects in the material of parts, hidden defects in units, control of closed structures, hard-to-reach places in machines and power plants (if there are channels for optical instruments to access the controlled objects). Registration of surface defects is carried out using optical devices that create a complete image of the inspected area. The advantages of these methods are ease of control, simple equipment and relatively low labor intensity. Therefore, they are used at various stages of manufacturing parts and structural elements, during routine maintenance and inspections carried out during the operation of equipment, as well as during its repair. Since control using optical instruments has low sensitivity and reliability, it is used to search for fairly large surface cracks, corrosion and erosion damage, nicks, open cavities, pores, to detect leaks, contamination, the presence of foreign objects, etc. Inspection penetrating substances. This method of non-destructive testing includes capillary methods and leak detection methods. Capillary methods are based on the capillary penetration of indicator liquids into the cavities of surface defects and registration of the indicator pattern. When testing by these methods, a penetrating liquid is applied to the cleaned surface of the part, which fills the cavities of surface defects. The liquid is then removed, and the portion remaining in the defect cavities is detected by applying a developer, which adsorbs the liquid, forming an indicator pattern. These methods are used in workshop, laboratory and field conditions, at positive and negative temperatures. They make it possible to detect defects of production, technological and operational origin: grinding cracks, thermal cracks, fatigue cracks, hairline cracks, sunsets, etc. Capillary methods can be used to detect defects in metal and non-metal parts of simple and complex shapes. Due to their high sensitivity, ease of control and clarity of results, these methods are used not only to detect, but also to confirm defects identified by other flaw detection methods - ultrasonic, magnetic, eddy current, etc. The most common capillary methods are color, fluorescent, fluorescent-colored, filtered particles, radioactive liquids, etc. Leak detection methods are based on recording indicator liquids and gases penetrating through defects of the controlled object. They are used to monitor the tightness of welded vessels, cylinders, pipelines operating under pressure in hydraulic, fuel, oil systems of power plants, etc. Leak detection methods include hydraulic testing, ammonia indicator method, freon, mass spectrometric, bubble, using helium and halogen leak detectors, etc. Carrying out leak detection using radioactive substances has significantly increased the sensitivity of the method. Radiation method (radiography) Based on the interaction of penetrating radiation with a controlled object. Radiation methods of non-destructive testing are used to control the quality of welded and soldered seams, castings, the quality of assembly work, the state of closed cavities of units, etc. Penetrating radiation (X-ray, neutron flux, γ- and β-rays), passing through the thickness of the material of the part and interacting with its atoms, they carry various information about the internal structure of the substance and the presence of hidden defects inside the controlled objects. The most common radiation methods are radiography, fluoroscopy and gamma control, which are used in metallurgy and mechanical engineering enterprises. X-ray machines, betatrons, linear accelerators and microtrons, gamma flaw detectors, etc. are used as sources of penetrating radiation. The radio wave method is based on recording changes in the parameters of electromagnetic oscillations interacting with the controlled object. They are used to control the quality and geometric dimensions of products made of dielectric materials (fiberglass and plastics, rubber, thermal protective and thermal insulating materials, fiber), vibrations, thickness of metal sheets, etc. Magnetrons, klystrons, backward wave lamps, etc. serve as energy sources. frequency converters, solid-state generators, Gunn diodes, etc. These methods have not yet found proper application in industry, although they are very promising. Thus, with their help it is possible to detect non-gluing, delamination (with an area of 10 mm2 or more), air inclusions, cracks (from 10 microns or more), inhomogeneities in density, stress, measure geometric dimensions, etc. Thermal method Based on recording thermal fields, temperature or thermal contrast of the controlled object. The thermal method of non-destructive testing is used to measure temperatures, obtain information about the thermal conditions of an object, determine and analyze temperature fields, defects such as discontinuity (delamination, cracks, etc.), identify defects in soldering of multilayer connections made of metals and non-metals, gluing metal - metal, metal - non-metal, etc. Control is carried out using thermometers, temperature indicators, pyrometers, infrared microscopes and radiometers, etc. These methods are also still used to a limited extent, mainly in instrument making for monitoring electronic equipment. In film conductors and resistors, microcracks, thinning, poor adhesion, and poor contact are detected; in microcircuits - poor contact, thermal contact disturbances, short circuits, overheating; in film capacitors - leakage currents; in microdiodes and microtransistors - overheating, poor contacts. Electrical method Based on the registration of electrostatic fields and electrical parameters of the controlled object. Electrical NDT methods are used to detect cavities and other defects in castings, delaminations in metal sheets, various defects in welded and soldered seams, cracks in metal products, cracking in enamel coatings and organic glass, etc. In addition, these methods are used to sorting parts, measuring the thickness of film coatings, checking the chemical composition and determining the degree of heat treatment of metal products. The most common of these methods are measuring electrical resistance, triboelectric, thermoelectric, etc. It should be noted that non-destructive testing methods are not universal. Each of them can be used most effectively to detect specific defects. For example, using radiation methods it is possible to detect internal defects in the form of voids and pores in parts made of various materials, but it is impossible to detect very dangerous thin fatigue cracks. For this purpose, it is necessary to use another method that is sensitive to surface cracks, for example capillary, magnetic or eddy current. Therefore, two or more different methods are used to control parts of responsible purpose. The use of complex control of products in the conditions of production and operation will improve the quality and reliability of equipment. Systematic conduct of NK at various stages of the technological process and statistical processing of the results of these tests will establish and eliminate the causes of marriage. At the same time, control becomes an active method of adjusting the process. The vortex method of the NK (electromagnetic) this type of non -destructive control is based on the analysis of the interaction of an external electromagnetic field with an electromagnetic field of vortex currents, which are brought into the object of control by this field. This method is used to control parts made of electrical conductive materials. The method allows you to identify violations of the continuity, mainly cracks, on the details of different configurations, including coatings. Based on the vortex current method, devices were developed for measuring the thickness of sheets and coatings, the diameter of wire and rods. Apply in factories and repair enterprises. Under the operating conditions, it is used for the preventive control of the turbines of gas turbines, welded and cast units of structural elements, etc. Features inherent in vortex methods: multi -parameter, contactless control, insensitivity to changes in humidity, pressure and pollution of the gas medium and the surface of the control objects with non -conductive substances. Vortimonal methods have two main restrictions: 1. They are used only to control electrically conductive products; 2. They have a small depth of control associated with the features of the penetration of electromagnetic waves into the control object. Control and measuring tasks solved using vortex methods:-detection of cracks, shells, non-metallic inclusions and other types of continuity disorders (flaw detector); - measurement of the thickness of the rods, the walls of the pipes (with one -way access), the diameter of the wires, as well as the thickness of the paint, enamel, ceramic, galvanic and other coatings applied to the electrical conductive base (thickness); - control of the chemical composition, mechanical properties, residual stresses (structuraloscopy).

GOST standards for non-destructive testing:

- GOST R 56542-2015 Non-destructive testing. Classification of types and methods - GOST 18353-79. Non-destructive testing. Classification of types and methods

MAGNETIC CONTROL

MAGNETIC CONTROL (magnetic flaw detection), a non-destructive testing method used to identify and record defects in products made of ferromagnetic materials that can significantly change their magnetic characteristics under the influence of an external (magnetizing) magnetic field. MK is based on the study of distortions of the magnetic flux (scattering field) at the location of a defect in a product and obtaining its magnetic characteristics, the shape and amplitude of which carry information about the size, depth of the defect, its structure, and chemical properties. composition, properties, etc.

The choice of method, method and means of M. to. depends on the nature of the defect, the reasons for its origin. When determining discontinuities, identifying the presence of cracks, lack of penetration in the surface and subsurface layers of welds, methods are used based on magnetization of the product by passing current through it using the influence of electromagnets, solenoids, etc. Magnetic powder based on iron oxide (or its suspension in oil with a particle dispersion of 5–10 μm), which is applied to the surface of the product. When a product is magnetized, the powder settles at the locations of defects (magnetic particle method). Magnetic tape, which is applied to the area of the magnetized product under study (magnetographic method), can serve as an indicator of the scattering field and registration of a defect. To indicate a defect, a passive induction transducer can be used, through which the product is moved during the processing process (for example, metal strip, railway rail during rolling). Deep defects up to 10 mm in length are determined by a fluxgate - a small-sized sensor (active transducer) with a core made of soft magnetic material (permalloy) and an excitation coil, the field of which interacts with the field of the defect. When moving across the product at the defect site, the sensor indicates a change in the current pulse (fluxgate method). To indicate the field of a defect, converters that operate on the basis of the Hall effect and magnetoresistive converters, which use the effect of electrical changes, are also used. conductor resistance under the influence of a magnetic field. M. to. also finds application in the study of the structure and thermal regimes. processing, mechanical properties of the material (magnetic structurometry), thickness (magnetic thickness measurement). The condition and quality of the material is assessed using magnetic characteristics, for which special equipment is used. instruments (e.g. ferritometers, coercimeters, magnetic analyzers). When measuring the thickness of products and ferromagnetic coatings (up to hundreds of microns with an error not exceeding 1–10 microns), instruments are used based on ponderomotive action, which consists in measuring the force of attraction (separation) of a permanent magnet or electromagnet to the surface to which it is pressed, or on measuring (using Hall sensors, fluxgates) the magnetic field strength in a magnetic circuit installed on the controlled surface. After completing the inspection, the products are subjected to demagnetization. The sensitivity of magnetic testing methods depends on the magnetic characteristics of the materials, the indicators used, the magnetization modes of products, and the cleanliness of the surface being tested.