Supply to the toilet.

A well-equipped bathroom in the house guarantees a comfortable stay for all residents. Before installing the toilet, you should choose the right model of plumbing fixtures and select the necessary tools to securely attach the toilet for safe use. The toilet liner is an important stage in the installation of plumbing, which needs to be given attention in order for the system to operate without failures or leaks. The plumbing connection consists of a tube connecting the toilet tank and the water supply system. The type of tube is selected taking into account the characteristics of the toilet model. A flexible hose can be connected to the drainage pipe at any angle and slight bend.

Features of toilet hoses

Toilet liner

The water supply to the toilet is selected based on the plumbing model. Manufacturers offer options for tanks that differ in size, installation methods and connection to the water supply.

Types of eyeliners

The type of toilet line depends on the size of the toilet, the distance of the water supply pipes, and the type of tank:

- Rigid - tube made of stainless steel, brass, copper. The service life reaches 20 years. The absence of adapters makes installation of the system simple. When purchasing, the type of thread is taken into account.

- Flexible - reinforced hose, bellows tube. Service life from 1 year. Convenient to install in any location of plumbing fixtures.

A rigid product is used infrequently. Mostly in old houses. In new buildings they are connected using flexible hoses.

Popular lines of flexible tubing are made from rubber. Bellows products are made of stainless steel. Resistance to temperature changes, flexibility, and wear resistance make them in demand in the plumbing market.

Parts manufactured using foreign technologies are durable. Products from the German brand Hydraflex are durable and functional. Products of the Italian company PARIGI have good technical qualities. Also, the Turkish plumbing company AYVAZ produces reliable pipes and fittings.

How to choose?

To choose a reliable, high-quality and suitable flexible eyeliner, a number of features should be taken into account. Experts give the following recommendations in this regard:

- It is necessary to select a braid taking into account the purpose of the room in which the pipeline will be used. Nylon tubes should not be installed near flame sources or heating devices, and metal products should not be installed in conditions of high humidity.

- The dimensions of the products must be such that they do not become strained when mated to the fittings. However, you should not purchase too long devices. If the length of the flexible hose is incorrectly selected, it will either not be securely fastened or become kinked, which will negatively affect its durability.

- The product should not emit any chemical or rubber odor. If the elastic liner smells, it should not be used to transport drinking liquids. Such tubes are applicable only for technical purposes.

- The device should not be too light. The small mass of the elastic eyeliner indicates that it is made of low quality material. The most reliable are brass and stainless steel products. There are hoses equipped with plastic fittings, but such products quickly become unusable.

- The product should bend perfectly. After straightening, no bends or cracks should appear on its surface.

As for manufacturers, experts especially highlight products of Spanish, Bulgarian and domestic production. The most popular and reliable Russian manufacturers are Gigant, Monolit and Akvatekhnika. At the same time, domestic flexible hoses have an affordable price and good quality.

Comparison of known models

Compact toilet with bottom connection

The range of reinforced pipes is distinguished by a variety of braids and hose materials. They have a fixed value. The reliability of the products depends on the compression density of the braid and the tube material.

Features of rubber products:

- low price;

- service life - 1 year.

Rubber products are characterized by:

- wear resistance;

- service period - 5 years.

Aluminum:

- withstands pressure of 5 atmospheres;

- warranty period - 5 years;

- is subject to corrosion in rooms with high humidity.

Nylon:

- withstands pressure of 20 atmospheres;

- operation - 15 years;

- high price.

Stainless steel:

- withstands pressure of 10 atmospheres;

- serves for 10 years;

- does not rust.

Parts made of brass will last longer than those made of plastic and silumin. The material from which the fitting and nuts are made is also of great importance.

The bellows flexible toilet hose is distinguished by a corrugated stainless steel surface. The product can change length if made by crimping.

Eyeliner characteristics:

- withstands pressure from 15 to 35 bar;

- service life up to 25 years;

- dampens vibration of the water supply system;

- not afraid of moisture.

The disadvantages are insufficient flexibility with a small bend radius and high price.

Manufacturers offer a wide range of supply products. The choice depends on cost, functional features, and installation method. Prices for flexible toilet hoses vary from 60 to 3,000 rubles.

Pipe fittings: advantages and disadvantages

The device is selected depending on the location of the sewer riser and the outlet pipe, while calculating how to connect the toilet with minimal financial and time costs. Otherwise, you will have to redo the sewer system, adjusting it to the features of the toilet exhaust system.

Various devices for connecting the toilet to the sewerage system provide flexibility in performing installation work yourself

If the connection of the toilet with the sewer is carried out using drain pipes, then it is possible to achieve visual visibility of the unity of the installed product with connecting elements made of the same material (sanitary ware, ceramics, porcelain, etc.).

The difficulty of installation lies in the need to accurately match the parts with the location of the socket of the sewer pipe, since there is no possibility of adjusting the connecting element by cutting it.

Eccentric cuffs, produced from polymers, are a structure of two bends, the axes of which are shifted relative to each other.

The cuffs are sold in various lengths, so you can easily select a suitable part for connecting the purchased toilet to a sewerage system that has different parameters for the outlet and socket of the sewer pipe.

Corrugated pipes or corrugations have a plastic shape, thanks to which parts can stretch or shrink, as well as bend at any angle.

All these qualities facilitate installation work, during which the master only monitors the slope of the corrugation, which ensures normal maneuverability.

A cast iron or plastic sewer pipe is connected to the toilet using a rubber cuff, which is turned inside out during installation, ensuring a 100% tight connection.

To enhance the reliability of the connection, be sure to use a sealant. The result is a fairly reliable connection that will last for many years.

Self-connection of the toilet is carried out according to the diagram, and the master must have the necessary tools:

- set of wrenches or at least one adjustable wrench;

- several screwdrivers;

- metal saw used when dismantling an old toilet;

- tape measure, hammer, knife;

- sandpaper;

- sealant, a little tow, cement;

- hammer drill with a set of pobedit drills;

- dowels

How to choose the right product

Flexible product

The criteria for choosing an eyeliner need to be determined before purchasing it. Necessary:

- measure the distance from the pipe to the plumbing, as well as the diameter of the hose;

- find out the connection method, which depends on the design of the tank;

- take into account the type of thread (external, internal);

- take into account the water pressure in the pipes;

- remember to match the outlet fittings to the threads of the equipment in order to do without adapters;

- give preference to such product materials as silumin, plastic;

- pay attention to the weight of the eyeliner - light weight indicates low quality.

The more information collected, the easier it is to make a choice.

Toilet cistern design

Today, the construction products market includes a wide variety of flush cisterns; their differences lie in the source material, the working arrangement of the parts, price and quality.

The principle of operation of all such structures is approximately the same, only the mechanism is different, which can be:

Toilet bull with one flush button

- with one flush button;

- with a pair of flush buttons;

- with a device that has two modes.

Relatively recently, a mechanism appeared on sale that included two buttons. This system can reduce water consumption. Using one button, all the liquid flows out from the drain tank; using another button, only a part will drain. The flushing procedure itself also looks different:

- Water enters the toilet directly from the flush cistern; here the water moves in one direction.

- During flushing, water constantly flows in different directions. This drain is more efficient, but it produces a lot of noise.

In order not to make a mistake in choosing such a device, and in the future to easily carry out assembly and repairs, it is worth knowing its design. The mechanism of operation of flush cisterns is simple: its work begins with collecting the required amount of water and discharging it into the sewer through the toilet.

To some extent, the design resembles a conventional water seal, which includes a seal, levers and a float. By independently pressing the lever or button on the lid, water flows out, while performing the most important tasks - eliminating waste into the sewer.

Toilet cistern design

There are visible structural elements, these are:

The invisible part of the structure includes:

- stub;

- float valve;

- drain fittings.

Installation, connection and fastening

Before installation, you must check the hose for cracks and scratches. The product should be connected, observing the rule of compatibility of elements (brass-brass, copper-brass). Do not overtighten the nuts and avoid tension on the hose.

Connecting the bathroom to the water supply

This installation option is carried out as follows:

- The cold water supply is turned off. A local water shut-off valve is installed.

- A flexible hose is connected with fittings to the tap on one side, and to the opening of the drain tank on the other.

- The quality of installation is checked. The water is turned on and the connections are inspected.

- The water is drained and filled into the tank 2-3 times.

If there are no leaks, the job is done correctly.

Connection methods

Side eyeliner

The holes are located on the side or bottom of the tank. The connection diagram is simple:

- Lateral water supply to the toilet cistern, when the tubes are attached to the right or left side. Pros: easy installation, repairable by replacing parts. Cons: the water is noisy when filling, the side hoses are visible.

- Bottom water supply to the toilet: the hole for connecting the water supply is located at the bottom of the tank. Pros: tubes are hidden, low noise level. Cons: difficult to install; during repairs, the system changes completely.

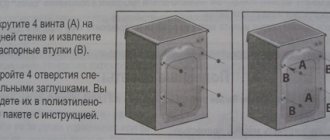

A number of container models have a universal connection type, when the excess hole is closed with a plug.

Types of fastenings

When connecting to a water pipeline, a fitting or union nut is used. The second end is connected to the tank. A plastic pipe is installed inside the container and secured with nuts. From the outside, the pipe is connected to the inlet hole of the sleeve with union nuts.

Brass fittings and nuts are durable, and rubber gaskets and sealant will make the connection more reliable.

A flexible toilet line, compared to a rigid one, has a number of advantages: it can be installed quickly, and can be installed in hard-to-reach places.

Types of water supply to the toilet

The drain containers contain holes for supplying water; the holes can be located in different places in the tank, so the following types are distinguished:

The liner is on the side of the tank. The water hole is on the side; this type of toilet is the most common. Installation work on the eyeliner can be carried out easily if there is room for access on the side. If the sink is installed closely, then difficulties may arise. In this case, it is better to choose a flexible hose method, when the hose can be slightly bent.- Eyeliner at the back of the tank. This type of liner is less common because access to the rear hole is not always convenient or possible. In this case, the toilet should be mounted at a distance from the wall to allow access to the pipes in case of emergency.

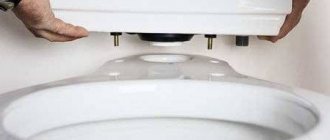

- Eyeliner from the bottom of the tank. This method is the most invisible to others, but has a number of difficulties during installation. First, the tank is connected to the plumbing system, and then secured to the toilet bowl.

Reviews

Vasily, Salekhard : “The bathroom was renovated. When the new tank was installed, all the hoses were replaced. We settled on a corrugated pipe. It was not difficult to let her down. We were attracted by the service life and material (stainless steel). 3 years have passed. It doesn't leak anywhere. I'm pleased."

Andrey, Krasnodar : “When 2 years ago the old pipe rusted and started leaking, we had to change it. There is not enough space for the toilet. Connecting communications is inconvenient. A reinforced flexible hose came to the rescue. Installing the side water supply to the toilet took 15 minutes. There was no leak. I took it in a metal braid, the fitting nut was made of brass.”