Types of welding defects

A correct welding seam implies homogeneity of the composition of the base and filler material, the formation of its desired shape, the absence of cracks, lack of penetration, overflow, and the presence of foreign substances. The following types of defects in welded joints are distinguished:

What are external defects?

External defects in welds and joints are detected visually. Violations of the welding regime, failure to maintain the accuracy of the direction and movement of the electrode due to haste or irresponsibility of the welder, fluctuations in electrical voltage during welding work lead to the formation of a seam of the wrong size and shape.

Characteristic signs of the external appearance of defects are: the difference in the width of longitudinal welds and corner legs, the sharpness of the transition from the base steel to the deposited one.

With the manual welding method, violations occur due to errors in edge preparation, neglect of the welding mode and speed, and lack of timely control measurements. Defects in welds and the reasons for their formation when carrying out automatic or semi-automatic welding methods lie in excessive surges in electrical voltage and operating errors. The following external types of weld defects are distinguished:

Cracks in seams can be hot or cold, longitudinal, transverse or radial. The first of them occur when high temperatures from 1100 to 1300°C are used, affecting the properties of the metal in terms of reducing ductility and the appearance of tensile deformations. This type of weld defects is accompanied by an increase in undesirable chemical elements in the steel composition. Cold cracks can appear at temperatures up to 120°C during cooling, and later under the influence of loads during operation. The reason for this type of defect may be a decrease in the strength of the steel due to welding stresses or the presence of dissolved hydrogen atoms.

An undercut is characterized by the presence of a depression between the alloyed and base steel. This type of weld defect is more common than others. An increase in arc voltage during fast welding leads to a thinning of the steel thickness and a decrease in strength. Deeper penetration of one of the edges causes liquid steel to flow onto the other surface, which is why the welding groove does not have time to fill. In this case, welding defects and methods for eliminating them are determined visually. Defects in work are eliminated by stripping, followed by overcooking.

Sagging occurs when the fused metal flows onto the surface of the base steel without forming a homogeneous mass with it. This type of defect is characterized by the formation of a seam outline without gaining sufficient strength, which affects the overall endurance of the metal. The reason for the defect is the use of low arc voltage, the presence of scale on the edges of parts, and the leakage of fused steel when welding horizontal seams when the surface of the structures being welded is vertical. Excessively slow welding also leads to the formation of sagging, due to the appearance of excess molten metal.

Craters appear due to a sharp separation of the arc. They have the form of depressions where lack of penetration and looseness of the material with shrinkage properties can form, leading to the appearance of cracks. Craters occur due to welder errors. Since the crater is usually the cause of cracks, which is why it is not allowed, if it is found, it should be cleaned out, then re-welded.

Fistulas look like funnels with a depression on the body of the suture. They are formed from shells or pores of sufficiently large sizes, with insufficient preparation of the surface of the welding elements and filler wire. This type of defect can also be seen during visual inspection and must be corrected immediately.

Internal weld defects

Internal welding defects cannot be visually detected. Usually appear due to a violation of the welding process and inadequate quality of the material. With internal defects, cracks may also appear, but they are not visible or small, but may open over time. Hidden cracks are dangerous because they are difficult to detect, and stress can increase gradually, and can lead to rapid destruction of the structure, and therefore are extremely dangerous. The cause of defects can be enormous stresses and rapid cooling when using carbon and alloy steels. The most common types of this type of defect are as follows:

Lack of penetration occurs when there is insufficient fusion of the welded parts of the seam in place. The reason lies in improper edge preparation due to rust, scale, lack of clearance and dull edges. In addition, haste and fast welding speed, low current strength or displacement of the electrode from the axis of the seam can also lead to lack of weld penetration. Due to the reduction in the cross-section of the weld, a stress concentration appears, which is reflected in a decrease in the strength of the joints, which under vibration loads is up to 40%, and large areas of lack of penetration - up to 70%. If the permissible values are exceeded, the seam must be cleaned and rewelded.

Pores are free spaces in the weld filled with gas, mainly hydrogen. The reason for this type of defect is the presence of foreign impurities in the materials being welded, dampness, and insufficient protection of the weld pool. If the permissible pore concentrations are exceeded, the weld is subject to overcooking.

In addition, one can note slag, tungsten, and oxide inclusions, which also arise when the welding process technology is violated.

Through defects

This type of defect implies the presence of pores passing through the entire thickness of the weld and is also detected visually. Mostly occur during through welding. With this type of defect, burns and cracks may appear.

Burn-through occurs from the use of high current and slow welding. The reason is excessive openness of the gap at the edges, loose fit of the pads, resulting in leakage of the weld pool. Checking the seam for defects is carried out visually; if it exceeds the permissible norm, the weld must be cleaned and re-welded.

Defects in welding seams and the reasons for their formation

All deviations from technological parameters caused by negligence in work, violation of operating conditions and external causes, often beyond the control of the welder, can lead to defects in the weld seam and the weld zone falling into the thermally affected area. Defects can also be caused by violation of technological methods of both the welding process itself, and poor-quality preparation, equipment malfunction, deviations from the quality standards of welding materials, the influence of weather conditions, and low qualifications of the welder.

The occurrence of defects is often associated with metallurgical and thermal phenomena that occur during the formation of the weld pool and its crystallization (hot and cold cracks, pores, slag inclusions, etc.; These defects reduce the strength and reliability of the welded joint, its tightness and corrosion resistance. All this can have a significant impact on the operational capabilities of the entire structure and even cause its destruction.

Defects in welding seams can be external or internal.

External defects of welding seams

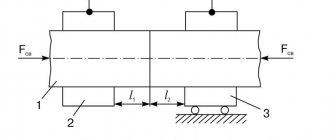

External defects in welds (Fig. 1) include violations of the size and shape of the seam, undercuts and other deviations that can be detected during an external inspection of the welded joint.

Violation of the shape and size of the weld is most often caused by voltage fluctuations in the electrical network, negligence in work or low qualifications of the welder, manifested in the wrong choice of modes, inaccurate direction of the electrode and the method of its movement. Defects manifest themselves in unequal width of the weld along its length, uneven leg of fillet welds, excessive convexity and sharp transitions from the base metal to the deposited one. Deviations from the size and shape of the welded joint, which appear in fillet welds, are associated with improper preparation of the edges, uneven welding speed, as well as untimely control measurements of the seam. In automatic and semi-automatic welding, these defects are most often associated with voltage fluctuations, wire slipping in the feed rollers, and violations of welding conditions.

Lack of penetration is a local lack of fusion between the elements being welded, between the base and deposited metal or individual layers of the weld in multilayer welding. The reasons for lack of penetration are poor preparation of the welded edges (scale, rust, small gap, excessive dullness, etc.), high welding speed, displacement of the electrode from the axis of the joint, insufficient current. As a result of lack of penetration, the cross-section of the weld is reduced and local stress concentration occurs, which ultimately reduces the strength of the welded joint. Under vibration loads, even small lack of fusion can reduce the strength of the connection by up to 40%. Large lack of root penetration can reduce the strength by up to 70%. Therefore, if the lack of penetration exceeds the permissible value, the seam section must be removed followed by overwelding.

Undercut is the most common defect found in welding. It is expressed as a depression along the line of fusion of the weld with the base metal. As a result of undercutting, a local decrease in the thickness of the base metal occurs, which leads to a decrease in strength. Undercutting is especially dangerous in cases where it is located perpendicular to the operating stresses. Undercut usually occurs at increased arc voltage with increased welding speed, when one of the edges is melted deeper, liquid metal flows onto the horizontal plane and is not enough to fill the groove. When welding fillet welds, undercuts occur mainly due to the displacement of the electrode towards the vertical wall, which causes significant heating, melting and flow of the metal onto the horizontal shelf. In butt welds, undercuts are formed when welding at high currents and when the filler material is incorrectly positioned. Increased cutting angles can lead to undercutting. This defect is detected visually and in case of deviations above the established norm, it must be overcooked with preliminary cleaning. Short cuts that weaken the seam section by no more than 5% in structures operating under static loads can be considered acceptable. In endurance structures, undercuts are not allowed.

Sagging - manifests itself in the form of leakage of weld metal onto the surface of the base metal without fusion with it. Sagging sharply changes the outline of the seams and thereby reduces the endurance of the structure. The cause of this defect may be reduced arc voltage, the presence of scale on the edges being welded, or slow welding when excess molten filler metal appears. Most often, sagging occurs when welding horizontal seams on a vertical plane. When welding circular rotary joints, sagging can occur if the electrode is incorrectly positioned relative to the axis of the seam. Long surges are unacceptable.

Burn-through - penetration usually occurs due to high current at low welding speed. It appears in the form of a through hole in the weld, which occurs as a result of leakage of the weld pool. In multilayer welding, burn-through occurs during the first pass of the seam. The causes of burn-through can be an excessive gap between the welded edges, insufficient thickness of the lining or its loose fit to the base metal, which creates the precondition for leakage of the weld pool. Burn-through can occur when the supply of shielding gas suddenly stops. When welding rotary annular joints, burns are caused by incorrect positioning of the electrode relative to the zenith. The defect is detected visually and is digested after preliminary cleaning. Burns are caused by liquid metal entering areas outside the weld.

An unwelded crater is a weld defect that forms in the form of depressions in places where the arc is abruptly torn off at the end of welding. Shrinkage looseness may appear in the recesses of the crater, often turning into cracks. Craters are usually caused by improper welding practices. During automatic welding, a crater may appear in the areas of the lead strips where the weld seam breaks. Craters are often the cause of crack development and are therefore unacceptable. They are cleaned and brewed.

Surface oxidation is scale or a film of oxides on the surface of a welded joint. Surface oxidation depends on poor protection of the weld pool, the quality of preparation of the welded edges, improper adjustment of the supply of shielding gas, its composition, and large electrode overhang.

A fistula is a funnel-shaped depression in a weld seam, developing from a shell or large pore. The reason for the development of a fistula is most often poor preparation of the surface and filler wire for welding. The defect is detected visually and must be overcooked.

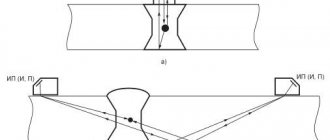

| Rice. 1 External defects of welds, revealed by external inspection: A - undercut; B - influx; B - burn; G - unsealed crater; D—fistula. | Rice. 2. Cracks in the weld and heat-affected zone: A - longitudinal hot crack; B - cold crack in the heat-affected zone. |

Internal weld defects

Cracks can be cold or hot (Fig. 2). Cracks can be both external and internal. These are the most dangerous defects in a welded joint, often leading to its destruction. They appear in the form of a gap in the weld or in areas adjacent to it. At first, cracks form with a very small opening, but under the influence of stress their propagation can be commensurate with the speed of sound, resulting in the destruction of the structure. The reasons for the formation of cracks are high stresses arising during welding. Most often, cracks appear when welding high-carbon and alloy steels as a result of rapid cooling of the weld pool. The likelihood of cracks increasing when the parts being welded are rigidly fastened.

Hot cracks - appear during the crystallization of metal at temperatures of 1100-1300°C due to a sharp decrease in plastic properties and the development of tensile deformations. Hot cracks appear at the grain boundaries of the crystal lattice. The appearance of hot cracks is promoted by an increased content of carbon, silicon, hydrogen, nickel, sulfur and phosphorus in the weld metal. Hot cracks can occur both in the weld mass and in the heat-affected zone. Hot cracks can propagate both along and across the seam. They can be internal or come to the surface.

Cold cracks - occur at temperatures below 120°C, that is, immediately after the weld has cooled. In addition, cold cracks can occur after a long period of time. The reason for the appearance of cold cracks is welding stresses arising during phase transformations, leading to a decrease in the strength properties of the metal. The cause of cold cracks may be dissolved atomic hydrogen that did not have time to be released during welding. The reasons for the ingress of hydrogen may be undried seams or welding materials, or violations of the weld pool protection.

Pores are cavities inside the seam, filled with gas that has not yet escaped (primarily hydrogen). They can be round or elongated, and their sizes depend on the size of the bubbles of the formed gases. Pores can be single or develop in a chain along the weld seam. The main reasons for the appearance of pores are: the presence of harmful impurities in the base or filler metals, rust or other contaminants that are not removed from the welded edges before welding. Increased carbon content also contributes to the appearance of pores. Pores can appear when the protection of the weld pool is violated or the welding speed is increased. The main reason for the appearance of pores when welding with a consumable electrode is a damp coating. Single pores are not dangerous, but their chain affects the strength of the welded joint. The area of the weld seam in which pores are present must be rewelded by preliminary mechanical cleaning.

Slag inclusions are weld defects, expressed in the presence of cavities filled with slag that has not had time to float. The formation of slag inclusions occurs due to poor preparation of welded edges and filler material, excessive welding speed or poor protection of the weld pool. When welding in shielding gases, slag inclusions are rare. Slag inclusions can be up to several tens of millimeters in size and are therefore very dangerous. The section of the seam where slag inclusions exceed the permissible standards is subject to cutting and rewelding.

Tungsten inclusions - occur when the protection of the weld pool is violated when welding with a non-consumable tungsten electrode. In addition, tungsten inclusions occur during short circuits or excessive current density. Tungsten inclusions are especially common when welding aluminum and its alloys, in which tungsten is insoluble.

Oxide inclusions are formed as a result of the formation of poorly soluble refractory films. Most often they occur due to significant surface contamination or violations of the weld pool protection. Being an interlayer in the weld mass, oxide inclusions sharply reduce the strength of the welded joint and can lead to its destruction under the load applied during operation.

build.novosibdom.ru

Methods for detecting, monitoring and eliminating defects

To detect weld defects, the following methods are used:

- visual inspection - carried out using magnifying devices;

- color flaw detection - based on a change in the color of a special material upon contact with a fluid material, for example, kerosene;

- magnetic method - measuring the distortion of magnetic waves;

- ultrasonic method - the use of ultrasonic flaw detectors that measure the reflection of sound waves;

- radiation method - X-raying welds and obtaining an image with all the details of the defect.

Read also: How to properly set up a torque wrench

To ensure the quality of the weld, marking and branding are carried out. Each welder puts his mark on his welding area.

If a defect is detected, it is necessary to eliminate welding defects. For this, the following types of work are used:

- welding - used to eliminate large cracks, having previously prepared the crack by drilling and cleaning with a chisel or an abrasive tool;

- internal small cracks, lack of fusion and inclusions must be completely cleaned or cut out with re-welding;

- incomplete seams and weld undercuts are eliminated by surfacing or welding in thin layers;

- Sagging is removed mechanically using an abrasive tool;

- Overheating of the metal is eliminated by heat treatment.

Welding is one of the main processes in most engineering industries. In addition, welding is often used in everyday life to connect metal structures, since it has advantages over other methods.

The advantages of the method include:

- Provides better tightness when connecting pipelines than threaded connections.

- Reduces material costs for the purchase of hardware for the manufacture of fences, stairs and other metal structures.

- It looks natural as part of prefabricated metal products, since a high-quality weld is always neat. Due to this, welding is widely used in the production of highly artistic metal structures, including for connecting elements made using artistic forging.

But welds are not always made with high quality. This becomes especially noticeable if a master with extensive production experience and a novice took part in welding one product together. A professionally made seam will never raise any questions upon visual inspection, unlike hanging beads or uncooked areas of a seam made by a novice. But this is only an external picture. It is also important what condition the metal inside is in. The strength of the welded joint and other characteristics greatly depend on this.

Let's consider defects that can occur in welds, the reasons for their occurrence, ways to prevent their occurrence, as well as options for elimination.

How are defects formed?

Let's try to figure out what undercutting a weld seam is and how it affects the physical nature of the metal structure. The undercut itself is a structural recess inside the base metal, located along the edges of the finished weld. Most often, such a defect occurs due to the appearance of an excessive welding current during the work process of welding or soldering metal. Also, the reasons for undercutting the weld are caused by the uncontrolled length of the electric arc. In this case, the length of the weld will unnaturally increase, and the edges of the finished edges will be heavily melted.

Appearance of weld undercut

In the photos presented, the undercut of the weld can be seen if the electrode is displaced towards the most visible and closest part of the horizontal wall. In this case, the vertical wall itself melts as quickly as possible than the horizontal one. The molten metal in this case instantly flows down the horizontal part. In this case, there is a tolerance for undercutting the weld on the vertical part, and sagging is formed in the horizontal plane.

Causes of defects

There are two types of factors affecting the quality of welding work:

- Objective - related to the properties of the materials being welded, the behavior of metals under conditions dictated by the technological process. It is not without reason that one of the important characteristics of any alloy is weldability. Sometimes it becomes necessary to weld materials with poor weldability. Such tasks are sometimes posed in small-scale or single-piece production. Even with full compliance with the requirements of the technological process, a certain percentage of defects may remain, which has to be officially considered acceptable.

- Subjective - depending on the performers. Moreover, the performers should include not only the workers performing welding, but also the technologists who are responsible for the correctness of the technological process parameters, the correct choice of equipment and welding modes.

The main subjective reasons for the occurrence of welding seam defects are:

- errors in preparing welded surfaces;

- use of a tool different from that specified by the technologist;

- welding tool malfunction;

- little work experience and low qualifications of the welder;

- deviation from the required welding conditions.

Types of weld defects

Defects in welded joints are usually divided into two groups:

- External, the presence of which becomes obvious when examining the seam with the naked eye.

- Internal, the identification of which requires the use of special monitoring devices.

In some sources, through defects are classified as a separate group, but from a scientific point of view they are classified as external, since they are detected during inspection.

External disadvantages

Since external defects are visible, they are associated with a violation of the geometry of the seam and adjacent areas of the material. In manual welding, in the vast majority of cases, defects are associated with low qualifications of the welder or negligence in performing the work. Errors in electrode direction and movement can often be observed. In automatic welding, defects can be caused by working on faulty welding equipment.

The most common types of external defects are:

- Deviation in width and height. The main reasons for the occurrence are usually poor preparation of the welded edges and their unsatisfactory fit, uneven movement of the electrode, deviation from the required conditions. This defect not only spoils the appearance of the product, but also reduces the mechanical characteristics, because the deposited metal cools unevenly, which can lead to internal stress and even plastic deformation.

- Surges. They are the main problem of many beginners who have recently mastered the welding profession. They arise in the process of excessive leakage of the electrode metal onto the joining surfaces without fusion. The occurrence of sagging is facilitated by the presence of scale on the elements being welded, which indicates poor surface preparation. If the speed of movement of the electrode is insufficient, excess molten metal is formed, which solidifies without connecting to the base material. Low arc voltage, long arc, high current can also cause flashing. Even displacement of the electrode relative to the axis of the weld being performed can lead to this common defect. It is worth noting that sagging does not always affect the mechanical properties and tightness of the connection. Therefore, in some cases, the use of welded joints with beads is allowed if the appearance of the product is not particularly important.

- An undercut is a defect that can be considered the opposite of an overflow. It is a groove on both sides of the weld. As a result, a local decrease in thickness occurs, which negatively affects the strength characteristics of the product. Undercutting can occur when the welding speed is too high or the voltage is high. If, when making a fillet weld between horizontal and vertical surfaces, the electrode is moved above the axis of the weld, the molten metal will rapidly flow down, and an undercut will appear above the axis.

- Lack of penetration is another common type of defect, most often caused by an inexperienced welder. Lack of penetration is the absence of fusion between the joined elements or between the deposited metal and the base material. When multilayer welding, lack of penetration may occur between the individual layers. The main reasons for the appearance of this defect are poor surface preparation, the presence of rust or scale, reduced gap between the joining surfaces, excessive welding speed, displacement of the electrode relative to the seam being performed, and reduced current strength. Lack of penetration sharply reduces the strength of the welded joint, and is often critical for tightness.

- Unfilled recesses. They are called craters. They are depressions that usually form in places where the arc is abruptly torn off. May be accompanied by shrinkage looseness, which causes cracks to form.

- External cracks. They can be located both longitudinally and transversely. They are formed not only in the deposited metal, but also in the base metal. In the latter case, they are located in the heat-affected zone of welding, that is, close to the seam. The reason for the formation of cracks can be stresses arising from uneven heating and cooling. The presence of pores and lack of penetration can cause cracks.

- Burn-through is a through penetration, accompanied by the flow of liquid metal from the seamy side of the seam being made. Burn-throughs usually occur due to high current values, an increased gap between the joining edges or their poor fit, and low speed of electrode movement.

Read also: Why do you need a gas burner?

Internal defects

The presence of internal defects in a weld is not always obvious. Hidden defects are especially dangerous, so all welded joints must be carefully monitored.

Let's consider the main types of internal defects:

- Pores. They appear when the molten metal absorbs hydrogen, carbon monoxide and other gases that did not have time to be released onto the surface of the metal during its solidification. Pores are bubbles filled with gas. They usually occur when electrodes are incorrectly selected or stored in a humid environment, or when there is rust or scale at the junction.

- Oxides and slag inclusions. Formed by an excessively long arc. Significantly reduce the strength characteristics of the seam. In critical structures, only single inclusions are allowed.

- Lack of penetration of the root or edge of the seam. In essence, it is similar to external lack of fusion, but is visually invisible, since it is located in the thickness of the metal.

- Internal cracks. The mechanism of appearance is similar to the appearance of external cracks.

- Overheat. The essence of the defect is the coarse-grained structure. Large grains have a smaller adhesion surface to each other, as a result of which strength and ductility are reduced. Sometimes this defect can be corrected by heat treatment.

- Overburning is the appearance of oxidized grains, the adhesion of which to each other is significantly weakened, which sharply increases fragility. Overburning, unlike overheating, is an irreparable defect.

Eight Tips to Reduce the Chance of Weld Undercuts

Below are recommendations that will help reduce the likelihood of undercuts when welding products made from pipes, sheets, channels, angles, etc.

Correct heat input

One of the most important reasons for the formation of undercuts in welds is the large amount of heating when welding near the free edges of the part, resulting in deeper penetration of one of the edges, which leads to the formation of a groove that remains after the metal of the weld pool has solidified. This can cause overheating and melting of nearby base metal or previously applied weld metal. To prevent it, it is necessary to monitor the heat input while reducing the welding current when approaching thinner areas of the part or the free edge of the product.

Correct electrode angle

As you know, the angle of the electrode plays a very important role in preventing the formation of defects during welding. If you weld at an incorrect angle, which will direct more heat to the free edges of the product, the likelihood of undercutting increases several times. Therefore, it is necessary to use the correct angle to direct more heat to the thicker part of the part.

Correct welding speed

Welding at high speeds is another cause of undercut welds. At high speed, some of the base metal passes into the molten metal of the weld and, as a result of rapid crystallization, depressions (grooves) remain along the edges. Therefore, it is recommended to weld at a moderate pace because too low a welding speed does not give satisfactory results. Thus, specific welding conditions correspond to a certain speed range within which it is possible to obtain seams without undercuts.

Choosing the right gas protection

When welding with semi-automatic welding, the wrong choice of shielding gases is also one of the main reasons for undercuts during welding. The welder must be sure that he is using the correct welding mixture that is suitable for welding that metal. The use of mixtures of carbon dioxide with inert gases provides high-quality results when welding carbon steels.

Correct Welding Technique

The reason for the formation of undercuts during welding is also the attempt of the welder to perform welding with excessive transverse vibrations of the electrode. It is recommended to perform welding with minimal transverse vibrations - the so-called “thread seam”. The size of the vibrations should not exceed the permissible values, because this significantly increases the likelihood of undercutting in the weld. To prevent the formation of this weld defect, it is necessary either to reduce the width of the transverse vibrations of the electrode, or to perform a multi-layer weld instead of a single-layer one.

When manual arc welding with coated electrodes, the recommended range of transverse vibrations should be no more than 2-3 electrode diameters.

Correct spatial position when welding

Welding in a horizontal or vertical position, in turn, increases the likelihood of seam undercutting. In this case, the groove is formed due to insufficient filling along the weld fusion zone. If possible, welding should be performed in the lower position.

Use multi-layer welding

This is the best option for preventing undercuts during welding. The technique of applying a multilayer seam implies the implementation of all the above recommendations and helps to achieve high-quality welded joints with guaranteed mechanical properties.

Using preheat

Preheating reduces the rate of crystallization of the metal and improves wettability due to the smaller temperature difference between the highly heated metal of the weld pool and the weakly heated base metal.

Control methods

To prevent the occurrence of defects, systematic monitoring must be carried out at all stages of production: before, during the welding process, and after completion.

- Before welding, the preparation of the joining surfaces and their geometry are checked.

- During the process, compliance with all parameters of the technological process, including welding modes, is carefully monitored.

- After welding, the finished product is inspected.

The main methods for identifying weld defects:

- Visual inspection and geometry check. It is suggested that a magnifying glass be used to detect small surface cracks and pores. The metal area is cleaned with sandpaper and etched with a solution of nitric acid. A matte surface is formed, on which cracks are more noticeable. After inspection, the remaining acid is removed.

- Mechanical properties testing. Together with the product, samples are welded and sent to the laboratory to determine tensile strength, relative elongation, and impact strength.

- Macrostructure control. It is carried out on samples that have undergone grinding and etching.

- Microstructure control. Conducted on samples using a microscope. This research method makes it possible to detect burnout, grain boundary oxides, changes in metal structure, and microcracks.

- Hydraulic and pneumatic tests. Used for monitoring vessels and pipelines.

- X-ray control. X-ray scanning makes it possible to identify pores, lack of penetration, cracks, and slag inclusions.

- Ultrasonic testing. Produced using an ultrasonic flaw detector. High-frequency vibrations penetrate the metal and are reflected from cracks, pores and other defects.

- Monitoring for the presence of intergranular corrosion. Carry out only for products exposed to aggressive environments.

Defect detection methods

Detection of defects in welded joints is carried out in the following ways:

- visual inspection and measurement of joining seams;

- testing joints for tightness;

- determination of weld joint defects using special devices;

- testing samples for strength in laboratory conditions.

Inspection of the welding seam is carried out only after cleaning it from slag, eliminating frozen metal splashes and other types of contaminants. The dimensions and correctness of the shape of the connections, the presence or absence of burns, craters, cracks, fistulas and other errors are subject to verification.

Impermeability testing allows you to identify defects in welded joints of pipelines, for example, pores, cracks, and through lack of penetration. Designs are checked in several ways:

- blowing or filling the seams with air;

- watering with a stream of water or filling the compartments with water under pressure;

- lubricating the seams with kerosene.

If a defect is found during inspection, the part is returned for additional processing.

Methods for eliminating defects

Often, identified defects in welding seams cannot be eliminated and lead to product rejection. Of course, no one will throw away a section of fence with ripples, but for critical parts strict control is always necessary.

Some defects can be easily eliminated:

- Sagging is removed mechanically using an abrasive tool.

- Large cracks must be welded. The place where the crack appears is drilled and cleaned with abrasive.

- Small cracks and lack of penetration are more difficult to eliminate. Usually it requires complete destruction of the completed weld, a new thorough cleaning and re-welding.

- Undercuts are eliminated by welding on thin layers of metal.

- Overheating can be eliminated under certain heat treatment conditions.

After all defects have been eliminated, the part is subject to repeated, even more thorough inspection, which will make sure that there are no defects. If deficiencies are re-discovered, additional corrections may be made. However, such procedures can be repeated no more than three times, otherwise there is a high probability of a sharp decrease in the mechanical properties of the material.

It is often difficult to complete a weld without any defects. However, constant practice and strict adherence to technology will reduce their number to a minimum . And knowledge of the theoretical basis will help to properly organize the technological process in order to obtain high-quality products.

| Below are the basic definitions of weld defects in fusion welding. |

Lack of penetration

- this is a section of a welded joint where there is no fusion between the parts being welded, for example, at the root of the weld, between the base and deposited metal (along the edge) or between adjacent layers of deposited metal. Lack of penetration reduces the working cross-section of the weld, which can lead to a decrease in the performance of the welded joint. Being stress concentrators, lack of fusion can cause cracks, reduce the corrosion resistance of the welded joint, and lead to corrosion cracking. Lack of penetration is a very dangerous welding defect.

a, b, c – at the root of a one-sided and two-sided butt weld; d – along the edge between the base and deposited metal; Fig.1. Lack of penetration

Reason for lack of penetration: 1) Low welding current; 2) High speed of electrode movement; 3) The arc length is too long; 4) Small bevel angle of edges or large amount of bluntness; 5) Displacement and distortions of welded edges; 6) Small gap between the edges; 7) Inappropriately large electrode diameter; Slag flowing into the gaps between the welded edges; 9) Incorrect choice of polarity for a given brand of electrodes Lack of penetration is a very dangerous welding defect.

2) High speed of electrode movement; 3) The arc length is too long; 4) Small bevel angle of edges or large amount of bluntness; 5) Displacement and distortions of welded edges; 6) Small gap between the edges; 7) Inappropriately large electrode diameter; Slag flowing into the gaps between the welded edges; 9) Incorrect choice of polarity for a given brand of electrodes Lack of penetration is a very dangerous welding defect.

Porosity

– gas bubbles in the metal. They usually have a spherical or similar shape. In carbon steel welds, the pores are often tubular in shape. Initially, having arisen in the liquid metal of the weld due to intense gas formation, not all gas bubbles have time to rise to the surface and escape into the atmosphere. Some of them remain in the weld metal. The sizes of such pores range from microscopic to 2...3 mm in diameter, and can grow due to the diffusion of gases. In addition to single pores caused by the action of random factors, pores may appear in welds, evenly distributed over the entire cross-section of the seam, located in the form of chains or individual clusters.

Read also: Electromagnetic starter 220V reversible

a – extending to the surface of the seam; b – not extending to the surface of the seam; c – group arrangement of pores; d – location of pores during electroslag welding; Fig.2. Pores

Reasons for porosity: 1) The presence of gases in the metal that do not have time to completely release during the crystallization of the metal; 2) The interaction of ferric oxide with carbon, resulting in the release of carbon monoxide and carbon dioxide; 3) The presence of moisture in the coating or in the flux (during automatic welding); 4) Presence of rust on welded edges or wire.

Cracks

– weld defects, which are macroscopic and macroscopic intercrystalline fractures, forming cavities with a very small initial opening. Under the influence of residual and operating stresses, cracks can propagate at high speeds. Therefore, the brittle fractures they cause occur almost instantly and are very dangerous.

Fig.3. Longitudinal hot crack.

a – longitudinal crack along the seam; b – transverse crack along the seam; c – longitudinal and transverse cracks; Fig.4. Cold cracks.

Causes of cracks: 1) Shrinkage stresses exceeding the tensile strength of the metal; 2) Rigid fastening of the welded elements; 3) Structural stresses, for example, the formation of martensite; 4) Increased content of carbon, sulfur and phosphorus in the metal; 5) Welding at low temperature; 6) Weld defects (pores, slag inclusions, etc.), causing local stress concentration in the weld metal; 7) Concentration of several seams on a small area of the product, causing increased local stresses (stress concentration).

Slag inclusions

- these are cavities in the weld metal, filled with slag that does not have time to float to the surface of the weld. Slag inclusions are formed at high welding speeds, with heavy contamination of the edges and during multi-layer welding in cases of poor cleaning of slag from the surface of the seams between layers. The shape of slag inclusions can be very diverse, as a result of which they are more dangerous defects than round pores.

a – at the root of a one-sided seam; b – at the root of a double-sided seam. Fig.5. Slag inclusions

Reasons for slag inclusions: 1) Refractoriness and increased viscosity of electrode coating slags; 2) High specific gravity of slag; 3) Insufficient deoxidation of the weld metal; 4) High surface tension of the slag; 5) Poor cleaning of the surface of the rollers from slag during multi-layer welding; 6) Flow of slag into the gaps between the welded edges and in the place of undercuts; 7) Uneven melting of the electrode coating.

Burnout

– oxidation along grain boundaries. Causes of burnout: 1) Slow movement of heating sources; 2) High amperage (large torch tip number).

Burn-through

– a welding defect, consisting in the leakage of the metal of the weld pool through the hole in the seam with the formation of a cavity in it. Causes of burn-through: 1) Excessive current; 2) The heating source moves too slowly; 3) Small metal thickness; 4) Large gap between the welded edges; 5) Small amount of edge dulling.

Undercut

– weld joint defects, which are local decreases in the thickness of the base metal in the form of grooves located along the boundaries of the weld. Undercuts are one of the most common external defects, usually formed when welding fillet welds with an excessively high arc voltage and in case of inaccurate electrode guidance. One of the edges is melted more deeply, the metal flows down onto the horizontally located part and there is not enough of it to fill the groove. In butt welds, undercuts are formed less frequently. Typically, with increased arc voltage and high welding speed, double-sided undercuts are formed. The same undercuts are formed if the cutting angle is increased during automatic welding.

Fig.7. Undercuts

Reasons for undercutting: 1) High current strength; 2) Incorrect electrode position and arc direction.

Non-fusion

– Lack of fusion between the base metal and the metal of the weld pool along the perimeter of the seam. The defect is formed at increased speeds and current strengths of more than 1500A. To prevent the occurrence of non-fusion, they resort to reducing the time gap between the formation and filling of the groove, as well as obtaining a favorable form of penetration and reducing the welding speed. The welding area must be thoroughly cleaned of dirt and oils.

Fig.8. Non-fusion.

For spot welding

Lack of penetration – absence or small diameter of the cast core.

Reasons: 1) Voltage drop in the network; 2) Introducing large magnetic masses into the machine circuit; 3) Shunting current through adjacent points or random contacts; 4) Large electrode contact diameter; 5) High pressure; 6) Increasing the thickness of the parts being welded; 7) Reduced welding time. A splash of metal.

Reasons: 1) Poor cleaning of parts or electrodes;

2) Low pressure; 3) High current; 4) Long welding time. Burnout.

Reasons: 1) Significant surface contamination;

2) Contamination of the surface of the electrodes; 3) Reduced pressure. Cracks.

Reasons: 1) Hard welding mode;

2) Non-free deformation of parts in the device; 3) Low forging pressure. Shells and porosity.

Reasons: 1) Low pressure;

2) Contamination of the metal surface; 3) Splash when the core overheats. Dents more than 10-20% of the sheet thickness.

Reasons: 1) Insufficient diameters of the electrode contact surface; 2) Overheating of the point; 3) Significant splash of metal; 4) Poor cooling of the electrodes.

For roller welding

Seam leakage is caused by the same reasons as in case of lack of penetration by spot welding. Melting. The reason is poor cleaning of parts and rollers. Burnout. Reasons: 1) Poor cleaning of parts and contamination of rollers; 2) Large gaps between parts; 3) Reduced pressure.

For butt welding

Displacement of welded parts. Lack of penetration. Overheating and burnout. Burnt surfaces of parts in clamps. Excessively large amount of extruded metal. Cracks. Residues in the weld of cast metal, slag, oxides.

Acceptable and unacceptable defects

In fusion welding, defects are usually corrected by welding the defective area. Before welding, the defective area must be cut so that welding can be carried out conveniently. It is usually not allowed to repair the same place by welding more than twice in order to avoid overheating or burning of the metal. When spot welding, defects are corrected by setting a new point. In some cases, for example, in the case of a burn through, rivets are placed in the defective area. The nature and number of defects allowed without correction must be indicated in the technical specifications for the weld or assembly.

Discuss the article on the forum

Repair of undercut welds

Depending on the requirements of regulatory documents, in some cases it is possible to correct small undercuts by stripping without subsequent welding. If repairs are required followed by welding, the repair process consists of the following steps:

- Mechanical cleaning until the defect is completely removed

- Visual inspection of the cleaning site. If the part is critical, it is necessary to conduct penetrant testing of this area to ensure that the defect has been completely removed.

- Re-welding of this section of the welded joint. It is advisable, when correcting, to use argon welding because it allows you to perform the process of applying a weld seam more accurately.

- Visual and measuring control of the place where the undercut weld was repaired. It is necessary to recheck the width and height of the weld to ensure that they comply with the requirements of the drawing and regulatory documents.