- home

- Blog

- GOST UZK (ultrasonic testing) of welds

To cover the topic more fully, let’s first understand what GOSTs are.

As follows from the official definition, GOST is a state standard that reflects the requirements for the quality of products, services or work. GOSTs reflect modern technology achievements and practical experience. To competently and correctly perform non-destructive examination using ultrasonic flaw detection of welds, there are GOSTs and special regulatory documents that regulate the basic requirements and rules for performing work.

Flaw detection by ultrasonic inspection, although a simple procedure to perform, however, it requires care and certain knowledge to obtain the most reliable results, which is why it is so important to comply with all the requirements of regulatory documentation.

It is important that this type of research must be carried out by a certified specialist in this service.

At the moment, in Russia there is a regulatory document introduced in 2015: GOST R 55724-2013 Non-destructive testing. Welded connections. Ultrasonic methods. This document is a revised version of GOST, introduced in 1988.

In addition to GOSTs for welding work, during ultrasonic examination they are guided by GOSTs for the operation of thickness gauges, testing methods and means, general technical requirements, etc.

The 2015 standard regulates corner, butt, T-joints, and overlap joints. And connections made by various types of welding: electroslag, arc, gas, gas press, electron beam, laser, etc.

Ultrasonic testing of welded joints is carried out in accordance with GOST for pipelines for various purposes (transportation of gas and oil products, water and other substances), tanks, building structures, products for industrial and household purposes, various vehicles for general use and agriculture - the list is very wide.

GOST standards for ultrasonic testing

In total, there are about 30 regulatory documents that determine the procedure for conducting tests or examinations, the equipment used, etc.

We list some currently valid GOST standards for ultrasonic testing:

- GOST R 55724-2013 - Non-destructive testing. Welded connections. Ultrasonic methods.

- GOST 8.502-84 - Coating thickness gauges. Methods and means of verification.

- GOST R 55725-2013 - Non-destructive testing. Ultrasonic piezoelectric transducers. General technical requirements.

- GOST 28702-90 - Non-destructive testing. Ultrasonic thickness gauges. General technical requirements.

- GOST R 55809-2013 - Non-destructive testing. Ultrasonic flaw detectors. Methods for measuring basic parameters.

- GOST 27750-88 - Non-destructive testing. Restorative coatings. Methods for controlling the thickness of coatings.

- GOST 23858-79 — Welded butt and tee connections for reinforced concrete structures. Ultrasonic quality control methods. Acceptance rules.

- GOST 17624-87 - Concrete. Ultrasonic method for determining strength.

- GOST 24983-81 — Reinforced concrete pressure pipes. Ultrasonic method for monitoring and assessing crack resistance.

- GOST 26266-90 - Non-destructive testing. Ultrasonic transducers. General technical requirements.

- GOST 12.1.001-89 - Interstate standard. System of occupational safety standards. Ultrasound. General safety requirements.

- GOST R ISO 10332-99 — Seamless and welded steel pressure pipes (except for pipes manufactured by submerged arc welding). Ultrasonic method for monitoring continuity.

- GOST 24507-80 - Non-destructive testing. Forgings from ferrous and non-ferrous metals. Ultrasonic flaw detection methods.

- GOST ISO 4386-1-94 — Multilayer metal plain bearings. Non-destructive ultrasonic testing of the connection between the bearing metal layer and the base.

- GOST 21397-81 - Non-destructive testing. A set of standard samples for ultrasonic testing of semi-finished products and products made of aluminum alloys. Technical conditions.

Carrying out ultrasonic flaw detection according to GOST

Carrying out ultrasonic (pulse-echo, mirror-shadow or echo-shadow) testing is described in Chapter 9 of the National Standard of the Russian Federation “Non-destructive testing. Welded connections."

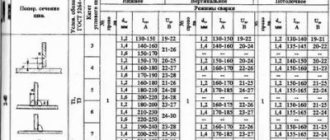

This chapter describes ultrasonic methods of non-destructive testing of welded joints in accordance with GOST. Standards for sensitivity levels (search, reference, rejection, etc.) are given. The maximum speed of scanning areas is determined to be 150 mm/s. The standards for sounding products with different shapes and diameters are given. There is also a point that reminds you that each equipment should be used in accordance with its operating characteristics and rules, which are described in the manual for this device.

If we talk about the sequence of performing sound flaw detection of welds, the process looks like this:

- First of all, old coatings (paint, varnish, primer, etc.) and rust are removed from the connection.

- Further, in order for sound waves to easily penetrate the metal, its surface is treated with special conductive solutions and substances (some oils, glycerin).

- After this, the device is configured according to the specified initial examination parameters.

- After adjustment, the device is applied to the surface and begins to move along and across the connection, viewing the inner surface.

- When defects are detected, they are recorded in a special act; if possible, their dimensions and specific location are determined and recorded.

According to GOST, ultrasonic flaw detection of one connection should be carried out in several approaches.

Theory of ultrasonic flaw detection of welds

The ultrasonic testing method is based on the ability of high-frequency vibrations (from 0.8 to 2.5 MHz) to penetrate the weld metal and be reflected from the surface of defects located in the welds.

Ultrasonic non-destructive testing requires the use of narrowly directed beams of ultrasonic vibrations. They are produced using piezoelectric plates made of barium titanium or quartz. Crystals placed in an electric field have an inverse piezoelectric effect - they convert electrical vibrations into mechanical ones. What creates a source of ultrasonic vibrations that penetrate metal.

The reflected vibrations are received by the probe (finder), after which they are again converted into electrical vibrations. Electrical impulses are transmitted to an oscilloscope. Discontinuities are determined by the nature of the deviations observed on the oscilloscope screen. The size of the formation is determined by the operator based on the amplitude of the reflected pulse, the distance to which depends on the propagation time of the acoustic wave.

Interesting: How to cook cast iron

On the screen on the left is a seam without defects, on the right is with defects

Inspection methods, sounding patterns and methods of scanning welded joints

Control methods

According to GOST, ultrasound can be performed using various methods, such as: mirror-shadow, echo-shadow, echo-pulse, diffraction, echo-mirror or delta method.

Carrying out an examination by any of the mentioned methods cannot be done without converters that are connected to a combined or separate circuit.

Pulse echo

Mirror-shadow

Echo-shadow direct beam (a) and inclined beams (b) probe

Echo-mirror

Diffraction

Variations of the delta method

Scanning methods

According to GOST, ultrasonic testing has two main scanning methods: longitudinal and transverse. In practice, both of these methods are combined to obtain the most accurate and extensive data on the presence of damage in the welded joint.

Transverse-longitudinal scanning options

The least popular scanning method is a swing beam, but it is also allowed by the state standard.

Swing beam method

Sounding schemes

The sound patterns for each type of weld are different. For example, according to GOST for ultrasonic testing of welds, butt joints are examined with a direct, single-reflected or double-reflected beam.

Sounding a butt seam with a doubly reflected beam

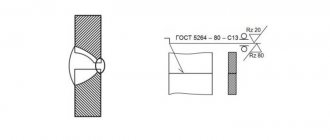

According to GOST for ultrasonic testing of welded joints, the study can be carried out with straight and inclined transducers, a direct or single-reflected beam scheme.

Scheme of sounding a fillet weld using combined inclined and direct transducers

It is worth noting that the standards allow the use of various sounding patterns in any type of welded joints that are included in the regulatory documents for control.

Pulse echo testing of intersecting welds is carried out using inclined transducers using a sounding circuit, which is shown in the figure:

Ultrasonic testing accurately detects transverse cracks. This procedure is carried out by inclined transducers with sound circuits, which are presented below:

Examination of butt welded joints for the presence of transverse cracks: a) - with the weld bead removed; b) – in the presence of a seam bead

How to correctly apply the ultrasonic testing technique

Ultrasonic inspection technology for joint control depends on the size of the weld and the requirements for its quality. Main stages:

- visual inspection;

- choosing a verification method;

- determination of the type of finder and the limits of its movement;

- preparing the surface of the object;

- checking and setting up equipment;

- sounding the metal of the connection;

- registration of inspection results;

- Quality control.

The reliability of the ultrasonic testing results is also influenced by the qualifications of the operator, his concentration when performing the work and the degree of compliance of the control parameters with the standards provided for in the instructions.

For pipeline welds

The ultrasonic inspection method for pipeline connections is given in the document OST 36-75-83 “Non-destructive testing. Welded connections of pipelines. Ultrasound method". The standard covers butt ring welded connections of process pipelines formed by all types of fusion welding, made of low-alloy and low-carbon steel.

The need for ultrasonic inspection of pipe welds, volume, and quality requirements are specified in the pipeline documentation.

Using this method, lack of penetration, cracks, slag inclusions, pores, and lack of fusion are detected in the seams and the surrounding area. The nature of the defects is not explained. The number of discontinuities, conventional dimensions and coordinates are indicated.

Important points:

- Ambient air temperature is in the range of 5-40°C. When the test object is heated to the standard temperature, testing is allowed at air temperatures down to -10°C. At low temperatures, flaw detectors are used that maintain (according to the passport data) operability under such conditions.

- The location of the pipeline welded joint in space is any.

Requirements for flaw detectors:

- It is recommended to use devices that meet the requirements of standard 14782-76.

- For research in hard-to-reach places, use small-sized, lightweight devices.

Preparation for control:

- The basis is a written request from the customer.

- A connection that meets the requirements of GOST 16037-80 is accepted in accordance with the results of an external inspection.

- The surface in both directions from the seam must be clean from paint, dirt, scale, metal splashes, and rust. The cleaned area should be free of nicks, irregularities, and dents. And the corroded surface is pre-mechanically processed until a smooth and even area is achieved.

- It is prohibited to inspect the seams of pipelines filled with liquid.

- The workplace is prepared in advance.

- The sounding method, type of finder, contact fluid, and control circuit are selected.

- Depending on the thickness of the connected pipeline elements (GOST 16037-80), the sounding method is determined.

Interesting: Description of direct and reverse polarity when welding

Parameters of ultrasonic inspection of pipeline welds

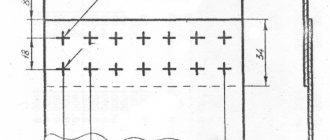

The treated ring joint is marked around the circumference into 12 equal sections and numbered clockwise in order to unambiguously determine the location of the defect along its entire length. The direction of movement of the product in the pipeline is indicated.

Marking and numbering of the circular welded joint of the pipeline

Conducting control:

- The flaw detector is configured and prepared for operation in accordance with the operating instructions.

- A check is carried out: the weld metal and the heat-affected zone are sounded, and the measured parameters of the detected flaws are determined.

The results are recorded in a table.

For the quality of welded joints

The quality assessment of ultrasonic testing connections is carried out on the basis of the measured characteristics of defects, in accordance with the standards and requirements of the technical documentation for the product under study. The main measured characteristics of identified discontinuities include:

- The amplitude of the echo signal from the flaw with the measured distance to it.

- The number of discontinuities in a section of a certain length.

- Coordinates of defects, their nominal sizes and conventional distance between them.

Additional characteristics are the orientation and configuration of the discontinuity, the need for assessment of which is specified in the technical documentation.

Quality is assessed according to the “Pass” or “Fail” principle, depending on the control results. The term “Pass” is assigned to seams without defects or with discontinuities, the measured parameters of which do not exceed acceptable standards. “Unfit” - if the characteristics of the defects exceed the norms.

Safety requirements

A mandatory clause in any regulatory literature is the safety clause. It is also present in GOST for non-destructive ultrasonic testing of welded joints. It reflects the rules for the technical operation of consumer electrical installations and safety rules when working with these devices.

It also contains restrictions on the noise level created at the workplace of a flaw detection specialist. Fire safety standards are regulated.

The documents mentioned in this section apply not only to ultrasonic inspection, they are widely applicable to other types of work and inspections, respectively.

Work performed in accordance with approved standards is of higher quality, which means there is no doubt about its reliability. GOST standards for ultrasonic testing of welds help regulate the quality of products, conduct inspections correctly, thereby protecting people from low-quality products that can harm their life and health.

Application area

Ultrasonic flaw detection of welds is in demand in the following industries:

- construction;

- mechanical engineering;

- thermal and nuclear energy;

- oil and gas and chemical industry.

Interesting: Features of aluminum welding

The technique is used to determine internal macroscopic welding defects, check the quality of welded joints made of low-alloy and low-carbon steels, blast furnace bodies, bridges, boilers, hydraulic press frames, pipes, ship hulls.