Features of a fence made of corrugated pipe

A do-it-yourself profile pipe fence is most often made from oval, rectangular and square products. This is explained by the fact that this configuration gives the profile high reliability with equal wall thickness, in contrast to rolled pipes with a round cross-section. The design of these fences is also very diverse.

Near the road

The range of metal fences made from profile pipes is quite extensive. For private construction the following are most often used:

- thin-walled professional pipes. This group contains metal profiled products with a cross section of 30x30 mm; the thickness of the walls in these pipes is around 1 mm. As a rule, these pipes are used to fill spans;

- professional pipes, which are of medium size. This category includes a profile pipe for a fence with a cross-section of up to 110x110 mm and a wall size of up to 5 mm. They are most often used to support fences.

Large-sized profile pipe, with a cross-section of more than 220x220 mm and a wall thickness of more than 7 mm, is, as a rule, not used for the manufacture of fences. Most often, these products are used to install the frame of prefabricated structures.

In addition, bases for large-sized machines are made from these pipes.

Office center

When making a fence from a profile pipe, you can use a different sectional structure, which is based on welded metal structures. These products can be framed, in which angles or other types of rolled metal are used as a frame, or they simply have supporting transverse connections.

All parts of the structures are firmly connected to each other by welding, creating a single structure. This makes it possible to withstand significant fracture loads, while the fence receives increased strength.

Section preparation

To install a fence from a profile pipe, steel with various additives that improve characteristics is most often used. In appearance, the pipes for fencing construction are similar to all-metal ones, but at the same time they have a hollow profile.

If you use a corrugated pipe for intake, its shape can be of different sections. Which pipe is suitable and which one is best to choose depends on individual circumstances.

The photo shows a fence made of corrugated pipe at the dacha.

private hedge

Construction stages

Like any construction, the construction of fencing is carried out in strict sequence.

Frame welding

The basis for the manufacture of the fence is a detailed design drawing. There are two types of fences made from metal profiles:

- all-welded structures;

- sectional structures.

To produce a fence from a profile pipe, you will need to prepare all the necessary structural components, that is, based on the working drawings, you need to cut the pipes.

Individual pipes that are used to create a fence are supplied with slight deviations in size. This is due to the peculiarities of rolled steel production. Therefore, before installing the pipes, they are processed using a grinding machine and grinding wheels, that is, all possible surface defects are removed.

After all the workpieces are prepared, begin welding the parts. Welding begins with securing the vertical guides, which in turn are attached to the support posts.

After this, they begin to install horizontal jumpers. Smaller pipes are used to fill the open space. Once the frame is ready to assemble, decorative elements are installed on it.

Expert opinion

Vladimir Ulyanov

I have been involved in fences for over 10 years, answering questions and helping people cope with the installation task on their own.

Ask a question to an expert

All places where welding was used are cleaned of slag and drops of molten metal.

After the welding of the profile pipe fence is completed, the resulting structure goes through anti-corrosion treatment. After the surface is cleaned of welding marks, a layer of anti-corrosion coating is applied to it.

Useful Which metal picket fence to choose for a fence at the dacha: dimensions, do-it-yourself installation

Sectional fences from profiled pipes are made in parts. The basis for production is working documentation. The sequence of operations is as follows. First of all, the section frame is made, then it is filled in guided by the drawings.

After the section is assembled, decorative elements are installed on it, for example, forged curls, etc.

Did you manage to weld the fence?

Yes No, I'll try again

Pouring the foundation and installing pillars

The type of foundation depends on the complexity of the fence design and weight; when installing a metal fence, the following types of foundations are made:

- tape;

- columnar.

Their arrangement does not differ from the technology for manufacturing similar structures during the construction of buildings.

Installation of sections

After the foundation is created and ready for further work, sections are installed on the installed supports. For installation, welding or mechanical connections are used.

Anti-corrosion coating

Protection of the product from corrosion is carried out at the finishing stage of the work; paint and varnish materials are applied to the surface of the fence, which protect the surface from the effects of precipitation and sunlight.

Advantages

Before welding a fence from a profile pipe, it is necessary to consider all the advantages and disadvantages of this fence.

The main advantages of barriers:

- Fences made from profile pipes are almost as reliable as all-metal products, this is due to their design feature.

- The corrugated pipe has an angular cross-section - this significantly increases strength, while the frame is light in weight and does not require additional material.

- The structure used is almost impossible to damage, since it is made of solid coils.

- Due to the fact that fences welded from corrugated pipe have a hollow structure, their production requires much less material, unlike solid fences. Taking this into account, the price of a fence or gate is much lower. This is especially true if a fence is required for a large summer cottage. In this case, even if the price is insignificant, the overall cost significantly increases installation costs.

- The section has a clear geometry. This gives the fence an attractive appearance. Due to this feature, a fence made of corrugated sheets can be installed on different objects.

Great option for a front garden

In addition, there are many more advantages if you install a welded fence. There are many types of welded fences, and these fences have a number of additional advantages, which in certain situations are the main selection criteria.

Advantages and disadvantages of fences made of profile pipes

The advantages of this type of fencing include:

- Low financial costs for materials.

- Possibility of building on your own.

- Quick installation.

- The strength of a welded profile fence is not inferior to brickwork.

- Durability. On a reliable foundation with regular maintenance, the fence will last 50 years.

- Creation, through combination with other materials, of an original design. Decorative forged elements will make even a simple welded fence unique.

The accessibility of viewing the site from the street is considered a disadvantage. However, places that are undesirable to be shown to strangers can be protected with wooden, plastic, and metal panels. The rest of the area will be well ventilated and illuminated.

Preparatory work

First of all, you need to prepare the gate, gate and the fence frame itself. To do this, the galvanized pipe is cut to the required dimensions. Step-by-step instruction:

- First you need to create a drawing and cut profile pipes for the vertical rails of the fence. In this case, all parts must be made exactly to size. When working with an angle grinder, you should follow safety precautions.

- The corrugated pipe for vertical supports should be sawed taking into account which fastening scheme is chosen for the installation of the underground part. For reliable fastening, the future frame is deepened into the ground by 1/3. So, to the required height of the corrugated board fencing you need to add the appropriate size.

- The pitch of the horizontal joists will depend on the distance of the installed supports.

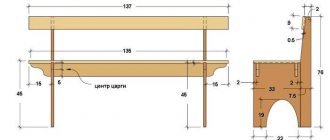

A drawing of the fence section is presented below.

Section drawing

The smaller the distance between the support pillars, the more reliable the fastening of pipes in spans will be.

How to install a fence

The technology for constructing a fence from profile pipes is quite simple, so absolutely anyone can do the construction if they have a number of necessary tools. Construction does not require any special knowledge or skills in the construction industry. The installation procedure consists of several main stages, each of which we will now examine in more detail.

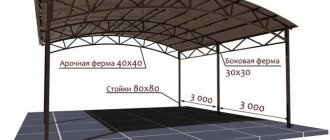

First you need to mark the area and pour the foundation. In most cases, a regular strip foundation or a separate foundation for each individual support is used as a base. If the fence is relatively small and light, and the soil is stable, then you can make a separate foundation for each support. To do this, markings are made and along the entire length of the perimeter the places where the support pillars will be installed are marked. For supports, profile pipes of rectangular or square cross-section with dimensions of 80 by 80 or 60 by 60 millimeters are used. The length of the supports should correspond to the height of the fence, and should also be buried approximately 1/3 of the entire length, depending on the depth of soil freezing in a particular region.

In the places where the supports are installed, holes of appropriate depth are dug. A special cushion of sand and crushed stone is made at the bottom, which is subsequently compacted tightly. Next, the pillar is installed evenly and the foundation is poured.

If the soil is dense and stable enough, then instead of a separate foundation, you can simply drive the supports into the ground. To do this, use a sledgehammer and a wooden block, which is installed on top so that the blows of the sledgehammer do not damage the support. Be sure to monitor the evenness and angle of inclination. The support should go straight into the ground without any deviation to one side.

Construction of a fairly large and high fence

If you plan to build a fairly large and high fence with massive brick supports on unstable ground, then it is recommended to make a strip foundation. To do this, dig a trench around the entire perimeter of the site. The depth of the foundation should be below the freezing depth of the soil in your region. If the support is made of brick, then its width should be between 30 and 40 centimeters, and its depth should be at least one meter. Pillars can also be made from pipes of the appropriate diameter. In this case, the depth can be within 65 centimeters.

After pouring the foundation, it is necessary to wait a certain time for the concrete to harden and become durable. The drying period will depend on weather conditions. In sunny, hot weather, the drying procedure will occur much faster than in cloudy and rainy weather. If you want to further strengthen the foundation, you can use special tape-type guy wires.

Further assembly technology will depend on the type of fence being built. If a welded structure is being built, then high-quality welding equipment is prepared and welding of the main elements is performed. When the main frame is welded, additional decorative elements can be welded for decoration.

If you are making a prefabricated fence, then you need to prepare all the main elements and fasteners. Assembly is carried out in accordance with the provided diagram. Fastening is done using bolts. Be sure to use a plumb line and a building level to ensure evenness.

Now we are attaching the lag. If the fence is of a continuous type, and it is also planned to be sheathed with profile sheets or other materials, then the lags are attached strictly along the edge of the support column. In this case, there is no need to take careful measurements in order to select the required distances for installing each subsequent log. We simply set the logs level and fasten them using ordinary self-tapping screws.

If you install the logs in the center of the support pillars, you will need to carefully measure the distance between the supports for fastening.

All metal parts of the fence are coated with anti-corrosion and protective agents to increase service life. At the final stage, all decorative elements of the decoration are attached.

Manufacturing of sections and installation

Installation of fences from profile pipes is usually made from products with a cross-section of 45x45 or 55x55 mm, while the thickness of their walls is approximately 4 mm.

You can also choose different modifications that are made to order. In this case, there may be pipes with forging elements, or they may have any other modification.

Diagram with dimensions

Profiled fence pipes are more reliable and economical in contrast to modular fencing. But there is one difficulty - welding the material.

If you have the skills to work with a welding machine, then you can start installing profiled pipes yourself:

- First you need to select and align the products. This procedure is mandatory, since the size of industrial rolled products may vary.

- Then the corrugated sheet is cut taking into account the installation pattern used.

- After this, they begin to assemble the gate and panel frame using welding.

- It is necessary to weld a thin profile and all decorative elements to the frame. To prevent all parts of the future panel from moving towards each other during welding, they are clamped together using clamps.

- Then, when the required size and number of panels are selected, installation begins.

Welding drawing

Installation of pillars

At the bottom of a well with a diameter of 200 mm to a depth of 1200 mm, drilled with a hole drill, a sand cushion 100–150 mm thick is poured. After this, 110x110 mm supports are inserted and secured with small crushed stone or broken brick. The most important thing is to clearly control the vertical level and size of the pipes’ depth. This is especially important when the profile pipe for the fence forms an opening for the gate.

For fence posts made of corrugated sheets, similar rolled products are used.

Then the concrete solution is prepared and poured into the well. It takes about one week for it to completely harden.

During the installation of pillars and their cementing in the marked areas, temporary vertical fastening is required strictly at level. For this purpose, supports are used. So the future fence is left until the concrete has completely hardened.

Pole installation diagram

Before the concrete mixture hardens, you can select the appropriate size of the profiled sheet and choose gates, which can be ordered from a forge, or they can be made by hand. After the concrete has hardened, facing material is hung on the spans. Fastening is performed in different ways, depending directly on the material.

This is how the outer part of the fence is mounted. The side parts are easier to attach. For this, as a rule, a metal mesh is used, which is stretched between the supports. In most cases, it is not necessary to build a foundation.

Fastening sections

Through holes are made in the horizontal joists of the fence; this is necessary for attaching the vertical posts. When the holes are prepared, veins are installed in them. To make everything as smooth as possible, use a square or tape measure.

Section installation

It is advisable to treat the intersection areas with spot welding, since this significantly increases the strength of the structure. Also, vertical beams are often installed using self-tapping screws, having first made holes in the required areas of the supports.

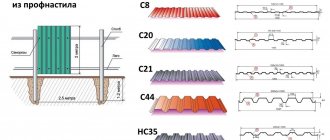

If you need a “solid” and light fence

Such a fence is usually built if the site is located at the edge of the block. The front fence is on one street, and the side fence is on the other. It can be done using a profiled sheet. Order corrugated sheets in the required size and color. Profile pipes for a fence made of corrugated sheets are welded from the outside to the supporting posts. Then the outer surface will have no breaks on the pillars.

Depending on the height of the fence, two or three logs are installed. After about 60-70 cm. If you make the distance large, then perhaps the profiled sheet will make noise. It also depends on the height of the wave. The sheets are attached to the joists using roofing screws. The technology for installing and manufacturing pillars is the same as described in the first case.

https://www.youtube.com/watch?v=hZ2FCG6dro8

Let's finish here. Good luck to everyone and good ideas in arrangement. Subscribe to our articles and ideas will definitely come. Share on social networks with your friends and acquaintances everything useful that you have learned from us, and they will be grateful to you for your attention and care.

Price

As for the price, in this case the most important thing is to take into account the material of the canvas. For example, the price of a fence made of corrugated pipes 2 m high per linear meter is about 4,500 rubles. This cost includes installation of poles, filling of spans and painting. The most common price ranges are:

- The cost of the simplest option is approximately 3,000 rubles. per 1 linear meter.

- Average level - about 4400 rubles. per 1 linear meter.

- Business class – 5800 rub. and above per 1 linear meter.

Span drawings

In any case, the price of the fence will depend on its components. Since sometimes the supports are made of concrete or brick, this significantly affects the final cost.

Sketches

As practice has shown, if you choose the right profile pipes and follow all installation technologies during installation, you can get an original and practical fence. And positive reviews and visual photos are a clear example of this.

Fence made from professional pipe. How to do it yourself

Construction of a house begins with the construction of a fence around the perimeter of your site. The fence prevents anyone from entering your property.

In the modern world there is a very large selection of building materials from which you can make a fence . It can be built from wood, metal, polymer materials, brick, concrete blocks, etc. The most optimal is to use metal . It has high strength characteristics, is durable, easy to install and maintain . But among metal fencing there are many options. You can build forged fences from metal , mesh fences from chain-link or welded mesh, fences from corrugated sheets or from ordinary sheet steel. For racks you can use profile or round pipes, channels or other types of rolled metal. The most optimal for constructing a frame for a fence is a profile pipe . Its price-quality ratio sets it apart from other types of rolled metal.

Profile pipes come in square or rectangular cross-sections, and a large selection of section sizes and thicknesses is the reason for its widespread use in construction. Not only frames and fence posts , but also other products. In private construction, it is in demand when installing frames of gazebos, canopies, pavilions, garages, small fences and other products.

The fence and corrugated pipes can be made completely or only the frame can be made, and then corrugated steel or any other material suitable for you can be strengthened on it.

In this material we will try to describe how you can create a fence yourself, what types of pipes can be used for this and what tools you may need for this.

What's good about welding?

Welding is considered one of the strongest connections. Neither screws nor nails can provide such reliability. Moreover, this type of fixation involves the assembly of metal parts, which also increases their resistance to negative external factors.

Therefore, welded fences have many advantages:

- You can assemble a fence from any available iron parts, including a bicycle wheel.

- Wire and reinforcement allow you to vary the shape of the future fence.

- Decorative elements are easy to use.

- There is no need to wait time for preliminary preparation.

- The installation process takes place quickly.

It is also worth understanding that iron does not burn, does not melt, and is able to remain safe and sound during sudden temperature changes, in heat and cold.

The service life of a metal fence is more than 50 years, and the existing gaps between the rods add beauty, visually increase the space of the site and are easy to maintain.