What is a grease trap, its structure and principle of operation

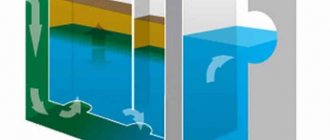

These are special tanks used to remove fats contained in wastewater. A simplified drawing of such a device is shown below.

Grease trap design

Designations:

- A – pipe installed at the inlet;

- B – partition, plays the role of a flow damper;

- C – first separation partition;

- D – separation chamber;

- E - second separation partition;

- F – settling compartment;

- G – output distribution compartment;

- H – pipe for discharging treated waste;

- I – seal that ensures the tightness of the structure;

- J – tank cover.

The most common method of fat separation is mechanical. Separator partitions are installed in the tank, which help slow down the movement of wastewater and cool it. As a result of this, the fatty formations contained in them, due to the transition to a non-emulsified state, accumulate on the surface of the water. When a certain amount of fat accumulates, cleaning is carried out. A visual diagram of the device’s operation is shown below.

Grease trap operation diagram

Designations:

- A – supply of wastewater to the tank;

- B – sediment from heavy pollution;

- C – fat accumulated on the surface of the water;

- D – separation partitions;

- E – water level line;

- F – discharge to the sewer.

The main technical characteristics of separators are determined by their size, productivity, peak discharge volume and installation method.

Design and principle of operation of the grease trap

Every household must have an effective device for cleaning the drainage system, but if such a device has to be used regularly, it is easier to prevent sewer clogging. To do this, household grease traps are installed under the sink and sink.

The design of these devices is very elementary. The device consists of a housing with a partition that divides it into compartments, a flow damper and a gas outlet pipe with ventilation. Depending on the purpose and amount of wastewater, equipment can have various parameters and vary in design.

The operating principle is based on the difference in density between water and fat. When the liquid cools, the fat also cools, rising to the surface in the form of lumps. The liquid medium enters the next compartment, and then into the sewer and drain. The fat remains in the first compartment thanks to the partition. When the tank is full, the grease traps must be cleared of the mass of fat, then the device is reconnected to the system for subsequent operation.

The cleaning procedure depends on the type and volume of the model. Household separators are easy to clean with your own hands, but dirt from large containers must be pumped out using pumps.

Main types

Devices of this type are classified according to the principle of cleaning; it can be performed in three ways:

- Mechanical. This most common option was described above, its main disadvantages are:

- during operation, it is necessary to regularly clean the device from the accumulation of fats;

- low efficiency and level of purification; some impurities still remain in the wastewater.

- Gravitational. The design of such separators and the operating principle are similar to the previous type (see Fig. 3), the only difference is in the cleaning process. The effluent is given time to settle (about a day), which allows almost all impurities to collect near the surface. Often, these devices use special chemical reagents that bind fatty impurities, forming heavy conglomerates from them that precipitate.

The principle of operation of the Evo Stok gravity grease trap.

Such devices have a much higher cleaning percentage, approximately 98%, but they also have characteristic disadvantages:

- manual cleaning and subsequent disposal of fat is required;

- In the precipitated organic matter, the process of decay may begin, which manifests itself in the form of an unpleasant odor.

- Biological. Such separators are called biological destructors. The difference from previous types also lies in the cleaning technology. It is produced by adding biological products (special cultures of microorganisms), which, feeding on fat, convert it into a neutral sediment.

Tablets for the Custom GT grease trap

The advantages of this method are obvious: after the grease decomposes, there is no unpleasant odor and the cleaning process is less difficult.

Concluding the topic about the types of grease traps, we should mention devices for ventilation systems, for example, a kitchen hood, which also has special devices for separating fats.

Grease traps in kitchen hoods: a – grille filters; b – labyrinth type

Passing through the filters, fat vapors settle on them, which reduces contamination of duct ventilation systems.

Selecting material for a grease trap

To make your own device that removes fat from water, you first need to find a suitable container. The container for the grease trap can be made of food-grade plastic, fiberglass, stainless steel or polypropylene.

The selected container must be in the shape of a rectangle. A tight lid for such a container is a very important element. It is located near the plastic box in which toys are stored, so it can be safely used as a grease trap body.

Even a spacious toy box can be used as a box for a grease trap.

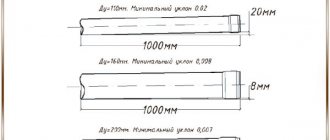

There are no special requirements for pipes. In order for the box made of harmless material to have holes that allow water to enter and exit, you can use a sewer elbow.

The diameter of the elements directing liquid along a certain route must correspond to the parameters of the sewer system pipes. Most often, the drainage communication line has a diameter of 5 cm. But sometimes a product with a diameter of 11 cm is used as an outlet pipe.

The sewer elbow, as an element of the grease trap, delivers water for further cleaning and direction to the sewer system

In addition to a spacious box and elbow, to assemble a grease trap you will need:

- 2 pipes with a diameter of 10 cm, the length of which is 2/3 of the height of the box, or 2 plastic sheets of the same height (future partitions);

- a piece of pipe with a length similar to the above-mentioned elements, but with a smaller diameter (5 cm), a mounting extension and a rubber cuff on the edge.

To simplify the task of choosing suitable materials, a pre-drawn diagram showing the sewer system to which the grease trap is planned to be connected will help.

Judging by the diagram, not many parts are required to remove fat from water

Selection criteria and main manufacturers

To select the necessary device, you must first consider its purpose. The operating parameters of separators depend on this. For example, for domestic purposes, productivity will be sufficient within the range of 0.1-2 liters per second. But these characteristics are completely unsuitable for cleaning wastewater entering the sewer from a canteen, cafe or restaurant; this task will require industrial models with the appropriate technical characteristics.

It is worth noting that many industrial models (for example, for workshops where the production of dairy products is established) are equipped with additional equipment that increases the efficiency of service. These could be automatic pumps for pumping out wastewater, fill sensors, etc.

An important factor is the material from which the tank body is made; it can be plastic, fiberglass or stainless steel. In industrial devices, the well is often made of concrete.

Household cleaners, as a rule, are made of plastic, which is explained by the low cost of the material, as well as its following useful properties:

- light weight, which greatly simplifies installation and maintenance;

- long service life (at least 30 years);

- harmless to humans.

Grease traps made of Termit polypropylene

Such devices are designed for domestic use or installation in small catering establishments.

Fiberglass separators. A distinctive feature of such cases is high mechanical strength and resistance to aggressive chemicals. Such characteristics are excellent for industrial models, especially taking into account the fact that outdoor installation is allowed.

Fiberglass grease traps Flotenk

Fiberglass housings are resistant to any weather conditions, are lightweight and easy to clean.

Stainless steel housings are typically used for industrial separators. Characteristics:

- long service life;

- high hygienic properties;

- presentable appearance.

The listed characteristics perfectly meet the requirements of public catering establishments.

Stainless steel separator produced by ACO Group

The only drawback limiting the use of such a case is the high price.

When choosing a manufacturer, we recommend giving preference to well-known brands, for example: Ecoline, Alta, Fifth Element, Termite, etc. We also note that domestic products are not inferior in quality to foreign ones, but are significantly cheaper. As for unknown manufacturers from the Middle Kingdom, here, as always, the quality must be checked on site.

How to calculate productivity?

When choosing a grease trap for installation under a kitchen sink or making the unit yourself, you need to decide on the desired technical parameters. The main characteristic is the peak discharge, i.e. the volume of liquid that the device can pass at one time.

For an ordinary apartment or small private house, a device with this figure of 30-40 l/s is suitable. If we are talking about installing an industrial structure, then it is better to entrust the calculation of technical parameters to professionals.

If you plan to purchase a household device, you can use a simple formula for calculation:

Р=nхPs , where:

P – required device performance in l/s; n is the number of sinks from which wastewater will flow into the grease trap; Ps is the speed at which water will be supplied to the container (it is equal to the speed of water flow in the water supply system and is usually about 0.1 l/s).

Let's look at an example of how to calculate the performance of a fat separator. If one sink is connected, then P=1×0.1=0.1 l/s , i.e. For the kitchen, a household model with minimal performance is sufficient.

Based on the data obtained, you can find out the required container volume. Calculation formula:

V=60xPxt , where

V – required volume in liters; P – productivity; t is the time required for fat to settle, in minutes (most often this period is 6 minutes).

An example of calculating the required volume if the productivity is 0.1 l/s: V=60×0.1×6=36 l.

Having determined the required volume, you can select a finished product or calculate the dimensions of a home-made unit. The best option for a grease trap for washing with a capacity of 0.1 l/s and a volume of 36 l is a capacity of 0.3x0.3x0.4 m.

When choosing a tank, it does not matter whether the height will be 0.3 or 0.4 m. Based on the data obtained, you can develop a sketch, diagram and drawing.

Installation

When choosing a separator model, it is necessary to take into account its installation location. There are models designed for installation indoors and/or outdoors. There are three installation options in the house:

- under the sink or sink;

- in the basement;

- in a room designated for this purpose.

In everyday life, as a rule, the first option is used. Let us briefly describe the sequence of actions when installing a household separator:

- We choose where the device will be located. Any surface with a smooth and hard surface is suitable for this. Since the grease trap requires regular cleaning during operation, it is necessary to ensure easy access to it. The best option is a place under or next to the sink.

- Install the separator at the selected location.

- We connect the sink drain hose to the inlet pipe. To ensure sealing of the joint, we use rubber gaskets (usually supplied with the device); as an additional safety measure, you can use silicone sealant.

- We connect the drain pipe to the sewer drain (it is best to use a corrugated hose of the appropriate diameter for this purpose), not forgetting about the rubber seals.

- We fill the structure with water to check the tightness. If a leak is detected, we fix it.

- Close the top cover, after which the device is ready for use.

An external vertical or conventional grease trap is installed in the ground according to the same principle as a septic tank; a description of this process can be found on our website.

Prices for installation (installation) and connection of grease traps

| Service | Volume | Price |

| Turnkey installation of grease traps for sinks | 25-150 l | from 5000 rub/unit |

| Turnkey installation of workshop grease traps | 200-400 l | from 10,000 rub/unit |

| Turnkey installation of industrial grease traps | from 500 l | by agreement |

The exact cost of grease trap installation services is calculated separately for each facility by specialists. The calculation is provided to the client at the time of submitting a commercial proposal for the supply of the device.

Installation and subsequent diagnostics of devices should be trusted only to professionals in order to exclude any installation inaccuracies, breakdown or failure of equipment, and any other problems during its use.

Installation of a grease trap to protect the sewerage system of country houses and cottages

In addition to organizations, our grease traps are used by private owners - owners of country houses and summer cottages - to protect sewers from fatty deposits in pipes and possible blockages.

A clogged sewer system is a fairly common problem. Residents in country houses that have an autonomous sewer system often encounter it. Blockages occur for various reasons: discharge of insoluble substances into the sewer, large discharges of wastewater with fatty particles, incorrect slope of pipes and other installation errors. The best option to solve this problem is to install a grease trap.

To contents

How to clean a grease trap?

Household appliances installed inside the house are cleaned manually. For this purpose, the separators are equipped with a special blade. This process is quite simple, does not take much time, but is somewhat unpleasant. The algorithm of actions is as follows:

- Open the top cover.

- We collect the accumulated fat with a spatula. It should be noted that waste fats when unloading grease traps are subject to mandatory disposal, but these standards do not yet apply to household devices.

- We check the pipes and, if necessary, remove large particles that have accumulated from them.

- Remove accumulated sediment from the bottom. Can be cleaned using any detergent.

- Flushing the system with hot water will remove particles of fat and oil from the pipes that can lead to clogging.

- Close the lid and continue further operation of the separator.

To pump out accumulated fat from a street separator, you will need to use special equipment.

Cleaning must be carried out regularly, otherwise there is a high probability of system clogging.