For many owners, the main difficulty when installing a corrugated fence with your own hands is the need to use welding. Carrying out welding work can become a real obstacle for those who want to get a fence made of corrugated sheets quickly and cheaply, because:

- You need to buy or rent a welding machine

- Sufficient qualifications will be required, because handicraft welding of a profile pipe can lead to errors that will then be impossible to correct

- Welding pipes can greatly slow down the fence installation process

- You will have to provide the place where the fence is being erected with electricity, which is not always possible.

Of course, you can invite a welder to connect the pillars and longitudinal joists, but, again, you will have to pay for his services. But, fortunately for everyone who wants to install a corrugated fence with their own hands on a minimal budget, there is an excellent alternative to welding, and you will find out which one by reading our article.

Types of corrugated sheets

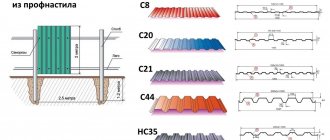

Profiled sheet is rolled steel that has undergone special treatment (painting, corrosion protection). This is a durable, wear-resistant material from which you can install a fence without welding. For these purposes, price corrugated sheeting, designated by the letter “C,” is used. The most common types of material are:

- S-8 (S8) is the most affordable. The trapezoid wave is low and wide, which allows reducing consumption to a minimum. The working width is 115 cm, the total width is 120 cm. Disadvantages include the difficulty of installation, the need to use a lot of screws, and low resistance to wind.

- S-20 (С20) is the best option in terms of price and quality ratio. The wave height is optimal, which ensures good rigidity of the entire structure. The working width is 110 cm, the total width is 115 cm. It is convenient to work with the material, and a fence made from such corrugated sheets without welding is wind-resistant.

- S-21 (C21) - sheets with a working width of 100 cm, a total width of 105 cm. The wave height is the largest, which provides better strength. However, the cost of such products is higher than all others.

C20 corrugated sheeting is ideal for creating a fence

Is it possible to attach cross pipes to posts without welding?

Carrying out welding work is undesirable for various reasons. For example, the desire to save money on welder’s servants in the absence of your own welding machine and the skills to carry out such work. In addition, there may simply not be electricity supplied to the site.

For such cases, alternative methods of attaching lags to pillars are suitable:

- pipes with welded fasteners (“ears”),

- x-shaped brackets,

- welded holders,

- clamps.

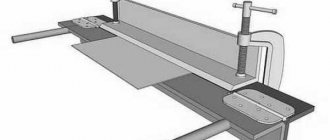

To secure the logs in this way, it is enough to use a screwdriver and self-tapping screws and bolts. It is only important to accurately measure the height of the bracket so that it is the same for each pillar.

X-shaped brackets are stamped from a single sheet of steel, which is then galvanized. They have the shape of a cross, the wide side of which is fixed to a support, and the narrow side is positioned horizontally, with logs screwed to it.

Metal holders consist of two curved parts welded together: one is attached to the post, the other is used to fix the veins. Metal holders are coated with primer and powder paint. Clamps differ from brackets in that they wrap around the support pipe.

What tools and materials will be needed

To make a prefabricated fence from corrugated sheets without welding, you will need certain materials and tools. The list of what you need will help you quickly prepare for work:

- corrugated sheeting;

- profile (section 40*50 mm, wall thickness 2 mm);

- fastening elements (discussed in more detail below);

- screwdriver with a set of special bits;

- shovel;

- hole drill;

- crushed stone;

- sand;

- gravel;

- cement;

- concrete mixer;

- building level;

- roulette;

- wooden boards and timber for formwork;

- metal logs;

- paint and brush;

- pegs;

- fishing line or rope.

How to calculate the amount of material

The required amount of corrugated sheeting is calculated based on the parameters of the land plot (length of the first and second sides, width) and the fence itself (interval between supports, dimensions of the gate, gate). The calculation rules are as follows:

- Determine the exact span width (spacing between supports).

- Find out the length of the fence without welding. Divide this figure by the width of the span, then you can understand how many supports will be needed.

- Calculate the length of the supporting elements as the sum of the upper and underground parts. The fence is usually made with a height of 180 to 300 cm. In this case, the depth of the hole is from 70 to 100 cm (more for sandy soil, less for clay soil).

When carrying out calculations, it is necessary to take into account the features of the terrain. For example, if the site has descents and ascents, higher supports are installed in these places with your own hands. Therefore, you first need to take several measurements on the ground and outline a clear perimeter of the future structure.

What fasteners to use

When assembling a corrugated sheet structure with your own hands without welding, special attention should be paid to the fasteners for the fence. To do this, choose self-tapping screws with special anti-vandal heads. They practically make it impossible to remove fasteners without using a special tool.

To ensure reliable fastening without welding, you should use special screws for corrugated sheets

Bolts can also be used. Determine the number of attachment points. For example, the plate is mounted to each post with your own hands using two self-tapping screws. Two plates are placed on each pillar, and logs are mounted to them. It turns out that in the standard version, each post will require 12 fasteners. It is recommended to take them with a margin of 10-15% of the calculated quantity.

Advice! Two washers should be installed under the screw head - rubber and metal.

This will ensure maximum tight fastening of the corrugated sheet to the fence and will allow you to make a reliable structure even without welding. Additionally, you can use plastic plugs.

Fastening the corrugated sheet

The sheets are fastened with bolts or roofing screws. If the latter option is used, the screwing procedure can be simplified with a low-speed screwdriver.

Installation of corrugated sheeting is carried out from the corner support. It is very important to install the first sheet evenly, because the rest are aligned with it.

In order for the profiled sheet to be positioned strictly vertically, you need to use a building level.

The sheet is attached in 4 places, 15-20 cm from the edge. How to make a brick from plastic? The next profiled sheet is attached with an overlap of 1 wave.

When the corrugated sheet is hung completely, additional fastening is required. It involves inserting screws through 2 waves along the entire length of the crossbar.

More sparse fastenings can cause the entire structure to become loose, since the corrugated sheets can bend under strong gusts of wind.

To make it easier for you to hit the crossbars with self-tapping screws, it is worth stretching the string on the outside of the fence at their level.

How to make and install a metal fence without welding

Building a fence from corrugated sheets without welding with your own hands consists of several stages. First you need to prepare the place, put up pillars, make a concrete foundation and formwork. Then the logs are fixed to the supports, and sheets of corrugated sheets are attached to them.

Removing the old fence and preparing the site

First of all, you need to determine the location. As a rule, a new fence is installed in the place of the old fence, less often - in a different area. The place should be well prepared. To do this, remove the turf around the perimeter with a shovel and completely uproot the roots, since over time they can give rise to new layers. If the terrain is uneven, it needs to be leveled and embankments made.

Next, install wooden pegs with your own hands and pull the fishing line or rope strictly in a straight line. At the same stage, you should mark the locations for the fence supports. Usually they are placed at intervals of 2.5 meters.

The perimeter of the structure is marked with a rope

Digging trenches and holes

The next stage of installing a fence without welding from a corrugated sheet with your own hands is digging a trench 30-40 cm deep. This is done to lay a foundation that will give the structure reliability and durability. Then, in pre-designated places, they dig holes with a depth of 70-80 cm with a shovel - they will serve as the basis for supports. Sometimes a drill is used for work, but since the fence is light and great depth is not needed, you can get by with improvised tools.

Trench and pits for future corrugated fence

Installation of pillars and filling of trenches

At this stage of building a fence without welding, you need to prepare concrete with your own hands, put up pillars with a cross-section of 50*50 mm and fill the holes with the mixture, and then the trench. First, small stones are placed in the pits for supports, and sand is placed on top of them (the total height of the layers is at least 20 cm). The evenness of the installation at each stage is controlled by the building level.

It will take at least two days for the concrete to completely harden.

Attention! First, the main pillars are installed - the first, corner and last. Then other supports are placed at intervals of 2.5-2.6 m. They are also filled with concrete.

Installation of formwork

A fence made of corrugated sheets without welding must stand level and stable, so poles alone will not be enough. It is necessary to make formwork from long boards. To ensure that they are positioned strictly parallel, many inserts are made from timber and inserted between the boards. The width parameters selected are 60 mm, 70 mm and 180 mm.

Inserts are installed near each pillar

Then pour concrete to the level of the fishing line and wait a few more days until the solution dries completely. That is why the stretched rope cannot be removed until this stage of work.

Installation of logs and sheathing with corrugated sheets

Now you can proceed directly to the installation of a fence made of corrugated sheets without welding. First, you need to mark the places on the poles for attaching the logs and make holes. If you use self-tapping screws with a drill, you can do without drilling. The fastening technology is shown in the video.

Then, with your own hands, you attach sheets of corrugated sheets to the logs without welding. For this, the same fasteners are used - self-tapping screws.

The corrugated sheet fastening diagram will help you carry out the work correctly

Important! After installing the logs, they must be covered with a protective layer of paint. This is necessary not only for aesthetics, but also to prevent corrosion due to precipitation.

Painted logs are allowed to stand for 1-2 days until completely dry.

Final works

To ensure that a self-installed fence made from corrugated sheets has a finished look, a U-shaped strip is placed on the upper edge of the sheets. With it, the fence will be safer and prettier. Forged products installed on top of the fence increase its attractiveness and prevent intruders from climbing over the fence.

Plastic plugs are driven into the ends of the supports with light blows. To protect the pillars from moisture getting inside, decorative covers of various shapes and colors are also used. They are easy to choose in accordance with the design of the site.

A self-made metal fence will reliably protect the area from stray animals and uninvited guests. With the right color, it will fit perfectly into any landscape design, complementing or highlighting the decoration of the house. Manufacturers have mastered the production of profiled sheets with imitation of valuable wood species. You can do all the work yourself without involving specialists. All you need is desire and time.

Advantages and disadvantages of a fence made of corrugated sheets

Installation of a corrugated fence will take several days. This is mainly due to the installation of supports and casting of the foundation. As can be seen from the description, the technology is simple - it has several advantages:

- quick and easy installation;

- you can act independently, using available materials and tools (without a welding machine);

- corrugated sheeting – high-quality and durable;

- fasteners are affordable;

- The terrain can be anything, including drops (cascades).

But it is worth considering the disadvantages:

- since the fastening is done without welding, special attention must be paid to both the selection of parts and installation;

- there is a need for additional anti-vandal protection - the screw heads should be ground or fasteners with a non-standard design should be used.

Briefly about the main thing

It is advisable to solve the problem of how to close the bottom of the fence from dogs even before its installation, but it is not too late to do this at any other time. The most reliable and durable option is a permanent base in the form of a strip foundation made of concrete, stone, or brick. If you need a simpler and cheaper method, cover the gap above the ground with mesh, slate, corrugated sheets or strips of any other sheet material. It is attached to a pre-welded frame or installed deep into the ground and fixed to the lower load-bearing crossbar of the fence.

Ratings 0