Photo

Where they are used, purpose, what they are intended for and used, what metals and steels, types

Designed for manual arc welding of structures made of carbon steels in accordance with GOST 380-2005 (St0, St1, St2, St3 of all degrees of deoxidation - KP, PS, SP) and GOST 1050-88 (05kp, 08kp, 08ps, 08, 10kp, 10, 10ps, 15kp, 15ps, 15, 20ps, 20kp, 20).

Can be used for welding water pipes and low pressure gas pipelines.

They are used for welding butt, corner and overlap joints of conventional and critical metal structures with a metal thickness of 1.0 – 5.0 mm.

It is also possible to weld root seams of thick metal.

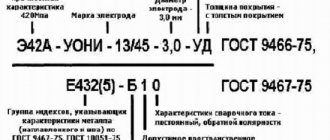

Marking, decoding

The electrodes were developed at the Welding Institute of the Academy of Sciences. Paton. ANO -21 marking means:

- A – Academy;

- N – Sciences;

- O – coated;

- 21 – development model.

The full designation E46-ANO-21-d-UD E 430(3)R 11 contains a detailed description of the product properties:

- E46 – product type according to GOST;

- ANO-21 – brand;

- d – product diameter;

- U – compound of carbon alloys;

- D – with thickened coating;

- 43 – tensile strength of the weld material 46 kgf/mm2;

- O – relative elongation up to 18%;

- 3 – impact strength of the alloy from 3.5 kgf m/cm2;

- R – rutile-based coating;

- 1 – works in any welding positions;

- 1 – uses direct or reverse polarity, or alternating current.

Comparison table

Electrode products, including ANO-21, are produced by several enterprises. The manufacturing technology is not followed at all, for this reason the properties of products from different manufacturers differ in ignition, maintaining arc stability and the appearance of pores.

We recommend reading Features and important nuances in the use of TsCh4 type electrodes

Masters conducted comparison tests with the participation of ANO-21, MR-3 and SSSI. The test results depending on the welding direction are shown in the table.

| Index | ANO-21 | MR-3 | SSSI |

| Metal consumption (1 kg) | 1,7 | 1,7 | 1,6 |

| Viscosity (J/cm²) | 80 | 80 | 200 |

| Elongation (%) | 18 | 18 | 26 |

| Capacity (kg/h) | 1,4 | 1,7 | 1,3 |

| Yield Strength (MPa) | 460 | 400 | 350 |

| Maximum current (A) | 220 | 260 | 200 |

| Minimum current (A) | 40 | 30 | 40 |

| Calcination (min.) | 60 | 60 | 60 |

The table will help in selecting the electrodes needed for the job.

Characteristics: coating, welding polarity and others

- The coating is rutile.

- The type of current used is direct and alternating (AC/DC).

- Polarity – forward or reverse.

- Diameter – 2.0, 2.5, 3.0, 3.25, 4.0, 5.0 mm.

- Wire grade – Sv-0.8; Sv-0.8A.

- Electrode consumption per 1 kg of deposited metal is 1.65.

- Metal yield is 63-68%.

- Deposition rate – 7.0-8.0 g/Ah.

- Spray coefficient – 2-4%.

Welding characteristics

Features of electrodes:

- product diameter – 1-5 mm;

- coating – rutile;

- metal spattering – does not exceed 4%;

- hourly consumption – 1.65 kg.

The arc remains smooth throughout the welding process.

The seam material can withstand:

- tensile strength – not less than 460 MPa;

- elongation – 18%;

- viscosity – 80 J/cm²;

- connection bend angle – 150°.

We recommend reading: What electrodes are used on stainless steel?

Other parameters are also important.

Chemical composition of the seam

Even for a person without work experience, the connection point between the parts is strong. Molten and solidified metal contains the elements presented in the table.

| Name | Quantity in % |

| Carbon (C) | 0,1 |

| Silicon (Si) | 0,3 |

| Magnesium (Mn) | 0,5-0,8 |

| Sulfur (S) | 0,04 |

| Phosphorus (P) | 0,045 |

The above list complies with state standards and must be observed in the production of electrodes at all factories. In practice, the composition of the seam is slightly different when welding with rods from different manufacturers.

Smooth weld seam.

Physical properties

Rutile coating consists of titanium dioxide and other substances: silica, calcium carbonate, ferromanganese. The mixture allows you to cook wet and corroded parts. You can make connections at non-rotating joints, which are often found on pipelines.

Products with a diameter of 2, 3, 4 and 2.5 mm are easy to ignite and burn evenly, the molten material hardly splashes.

The Sv-08 wire (the electrodes are made from) contains additives that can increase the surface tension in the weld pool. This allows vertical and ceiling seams to be made without leaking metal.

The maximum permissible moisture content in the coating is 0.9%. For larger values, the rods are calcined for 30-40 minutes. The temperature is 120°C. In the future, electrodes are used for welding non-ferrous and ferrous metals, incl. and aluminum.

When purchasing, you should choose dry products. You shouldn’t settle for cheap products; it’s better to buy more expensive products from popular manufacturers.

When welding with an ANO-21 electrode, there is almost no spatter.

Welding modes

These indicators depend on the thickness of the electrode. The parameters are indicated in the table indicating the spatial location of the seam.

| Diameter (mm) | Length(cm) | Quantity (1 kg) | Current (A) | ||

| Lower | Vertical | Ceiling | |||

| 2 | 30 | 95 | 60-100 | 70-80 | 80-100 |

| 2,5 | 30 | 58 | 70-120 | 70-100 | 90-110 |

| 3 | 35 | 40 | 100-150 | 90-110 | 110-140 |

| 4 | – | – | 160-190 | 150-170 | 150-180 |

| 5 | – | – | 170-220 | 150-190 | 120-160 |

It is not recommended to weld workpieces thicker than 5 mm and pipe joints with subsequent injection of pressure.

Packaging, how many pieces, weight and length of rods

Electrodes are produced in packs weighing 1 and 5 kg.

| Diameter, mm. | Length, mm. | Weight of one electrode, gr. | Quantity per 1 kg, pcs. |

| 1,6 | 250 | no data | no data |

| 2,0 | 250 | no data | no data |

| 2,5 | 300 | 17,0 | 58-59 |

| 3,0 | 300, 350 | 26,5 | 38 |

| 4,0 | 450 | 53,0 | 18-19 |

| 5,0 | 450 | 84,5 | 12 |

| 6,0 | 450 | 135,0 | 7 |

Technological features: calcination, how to cook correctly and more

In case of moistening or long-term storage, it is necessary to calcinate (dry) the electrodes at a temperature of 120ºC for 40 minutes. Repeated calcination is carried out for 60 minutes at a temperature of 120 degrees Celsius.

Store packaged electrodes in a dry, heated room at a temperature not lower than +15 degrees.

To work with fillet welds in a vertical position and from top to bottom the support method ; the electrode should be held in the plane of the angle bisector. The inclination to the welding direction is allowed within 40-70 degrees.

The welding currents recommended for each thickness and welding position must not be exceeded. This can lead to burn-through of the workpieces.

Consumption, consumption rates

Carrying out the work requires calculating the consumption of the number of electrodes. This is especially true for performers planning to carry out small-scale welding work. A competent approach to calculations ensures continuity of the process and eliminates unnecessary expenses. There are several calculation methods, the implementation of which may require different parameters.

Electrodes ANO-21 TM Tigarbo. Photo KOMZ-Export

In addition, we should not forget about the consumption rate - a static indicator that is part of the reference information presented in documents, in particular VSN 452-84. Other relevant information here.

General information

First, let's look at the technical characteristics of the ANO-21 brand. Produced according to GOST 9467-, type E46. The coating is rutile, which stabilizes the arc and reduces the pulverization of the metal.

So, when working with ANO-21, we have a stable arc and low spatter. The rutile coating prevents oxidation processes from starting by protecting the weld from interaction with oxygen.

It is possible even for a non-professional to obtain a quick and even seam with minimal likelihood of pores forming in it. About 1.5 kilograms of electrodes are needed per hour, which indicates the high productivity of the process.

Analogues of this type can be ANO 4, MR-3, OZS-6 or OZS-12. Usually they stop at the ANO 21 3mm and 4mm types. Reasonable prices for rods from manufacturers LEZ, ChZSM, which will cope with welding at home and for those trying their hand at this business.

Special properties

The electrodes have good welding and technological properties when performing work on professional and household equipment. They are characterized by:

- ease of arc ignition;

- stable and soft arc;

- small metal spattering;

- fine-scale formation of weld metal;

- easy and involuntary separation of the slag crust;

- not sensitive to the presence of rust, galvanic coatings and the quality of edge preparation;

- high resistance to the appearance of pores in seams when welding ordinary structures on wet, primed and oxidized surfaces;

- poor sensitivity to arc increase;

- low toxicity;

- strength, durability and seam tightness.

UONI or rutile (MP3, ANO-21, OK 46 ESAB, OZS) - what is the difference

All brands of the listed electrodes are the same in application - they are used for welding carbon and low-alloy steels, widely used in industry and everyday life. The difference between SSSI and their rutile counterparts is the manufacturability of the welding process and the technical parameters of the connection .

If there is a need to repair or install by welding the frames of homemade equipment (circular saw, pipe bender and other similar devices), the horizontal bar on which you are going to spin the “sun,” then it is better to use electrodes with a basic coating. Welding seams made with these consumables guarantee more reliable and safe operation of these devices than using technology with rutile consumables.

If you do not have the skill to work with consumables with a basic coating, there are many welding jobs using rutile electrodes. The ease of initial and re-ignition of the arc, the absence of the need to control its length, gives beginners the opportunity to experience belonging to a contingent of people who know welding. At the same time, unlike consumables with a basic coating, there is no need to clean the welded edges from rust, coating residues and other contaminants. In a private house, it is sometimes necessary to repair leaking pipelines - the presence of moisture is not an obstacle to repair welding work using rutile consumables. It is better for beginners to weld thin-walled workpieces such as, for example, profile pipes with rutile electrodes.