A fence made of welded mesh is used to mark the boundaries of a suburban area, pasture or garden. It has a number of features of use. The fence is classified according to several criteria. Each type has its own distinctive features. When choosing, you need to pay attention to some nuances. Installation of a welded mesh fence is carried out using various methods depending on the type of coating.

Polymer coating for fencing

Preparation of materials

How to choose a mesh

To weave a chain-link, wire is used: galvanized wire is used to make an expensive mesh, beautiful and durable, while black wire is used to make a cheaper one, suitable for temporary fences. The thickness of the wire ranges from 1mm to 4.5mm, the cell sizes also vary. The smaller the cells and the thicker the material, the higher the cost of the chain-link. The standard mesh length per roll is 10 meters, but sometimes they produce more. A 1.5 m wide mesh is considered the most popular; it is suitable for demarcating a site, fencing a utility yard, and internal fences. There is a chain link meter wide, as well as 1.2 and 1.8 m. The design of the machine for weaving netting allows you to make a mesh of almost any width.

The purpose of the grid will help you quickly decide on its choice. It is best to install a temporary fence from the cheapest steel mesh - it will last for three or four years. Permanent fencing requires a high-quality and durable chain-link that can last 15 years. Nowadays, manufacturers coat galvanizing with special polymers, so the mesh is not afraid of weather conditions, lasts longer and looks elegant.

Galvanized mesh

Racks for chain-link mesh

Any fence requires support, and a mesh fence is no exception. Due to the light weight of the chain-link mesh, installation is carried out on small poles, mostly metal.

In general, you can use any supports:

- wooden stakes;

- thin logs;

- iron pipes;

- metallic profile;

- asbestos pipes;

- concrete pillars.

Wood is used less frequently, as it is susceptible to rotting, and is more suitable for temporary fencing. If wooden supports are used, they must be properly treated. First, remove the bark, chop off the protruding parts, and carefully sand them. The surface should become clean and smooth, without rotten or rotten places. Next, the pillars are primed with an antiseptic, and the lower part is coated with bitumen.

Metal pipes with a diameter of 60mm, steel profiles 60x40mm, and channels 100mm wide are ideal for fence posts. Such pillars also need treatment, but last much longer. Before installation, they are cleaned with a wire brush, be sure to be degreased, and primed with an anti-corrosion compound. Often, small hooks are welded to attach the mesh to the posts; the welding areas are ground and coated with a primer. After this, the racks can be painted and installed.

Important! When using hollow columns, they are filled with concrete mortar and covered with a special cap on top. This will prevent water from penetrating inside and destroying the base when it freezes.

Concrete and asbestos supports also go well with chain-link. They do not need to be prepared, periodically tinted or repaired. These supports last longer than iron ones, have an attractive, neat appearance, and hold the mesh well.

Installation Tools

To securely install the chain-link mesh, you will need the following tools:

- small drill;

- scrap;

- level;

- roulette.

Conventional knitting wire is used as fasteners. You can dig holes for the posts with a shovel, but with a drill it will be much more effective and easier. A tape measure, as well as a level, must be used; inaccuracies and deviations are unacceptable here, because then the fence will look skewed. In order for the grid to stand level, all spans must be the same, and the pillars must be strictly vertical.

Chain link installation diagram

Section structure

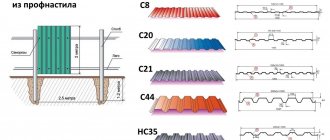

The classic type of section has the form of a frame made of a strip, corner or profile, to which a mesh is welded.

If the welded mesh for the fence was made “individually”, then the diameters of the horizontal and vertical elements may be different. In order not to make the supporting frame of the section, the horizontal rod is installed with a larger diameter than the vertical one.

As another option for strengthening fence sections made of welded mesh, a “volumetric” mesh structure is used. It can be of two types:

- In the form of a triangular “wave”, which performs decorative functions and serves as a stiffening rib for the span structure. Such fences are called 3D.

- In the form of double horizontal rows. And if in a conventional welded mesh the rods are oriented in two planes, then in this one they are oriented in three – horizontal/vertical/horizontal.

Wave-like mesh structure Source archiexpo.com

Decorating the fence

Mesh fencing does not shine with attractiveness and design. But the problem can be solved. With the help of some tricks, you can decorate the fence so that it becomes much prettier than a fence made of corrugated board. Several ways to make a chain-link fence beautiful:

- Openwork weaving. Various patterns are created using wire. You can choose easy or complex options, but this will significantly decorate the hedge.

- Landscaping. Climbing plants are planted along the perimeter of the site, which will intertwine between the cells and thereby reduce the visibility of the yard from the street. The hedge is also decorated with pots of flowers. This method is chosen by many summer residents.

- Wire flowers. This will require a lot of wire. Petals and other parts of the flower are bent from pieces of wire. Then the elements are secured using welding. The finished structure is welded to the chain-link.

- Coloring. Even simple painting will improve the appearance of a chain-link fence. As a rule, thin wire is more difficult to paint than, for example, a sheet of metal. Therefore, you need to be patient.

Advantages

- You can install a fence made from this material easily and quickly. At the same time, you don’t have to be a specialist - you just need patience, and you can build a fence with your own hands;

- A wire fence is reliable and fairly inexpensive;

- Unlike closed fences, this one allows the sun's rays to pass through the area and the green spaces receive natural warmth.

Net

Installation of a chain-link fence is not possible from any type, of which there are dozens, if not hundreds, in production and sale. “Black” chain-link made of structural steel without coating (item 1 in the figure) is a plastering and reinforcing mesh, not intended for external use: it rusts quickly, does not hold paint well, is quite fragile and begins to tear from the winds even sooner than it rusts.

Types of mesh

Fences are most often used with galvanized chain-link made of wire of increased ductility (item 2), the so-called. gray It costs approx. 7-12% more expensive than black. A cheerful fence can be made from plasticized chain-link (coated with colored PVC, item 3), but only sectional. The solid fabric of their colored chain-link frays in the wind, the plastic at the joints wears out over the winter, and the mesh rusts. Very quickly, because in this case, the metal is eaten by capillary moisture. Plasticized chain-link costs about 1.5 times more than sulfur.

Mesh and wire

Fences are usually made from vertical chain-link with a mesh of 50-60 mm, from wire with a diameter of 1.6-2.2 mm, pos. 5. To fence a household yard with birds, you need a more expensive mesh with a mesh no larger than 30 mm, otherwise the chicks and ducklings will scatter, and it will not be difficult for ferrets and weasels to get into the house. In this case, the lower gap of the fence (see below) is covered with boards or slate.

A high-strength mesh made of wire up to 4-5 mm thick (item 6) is needed to fence a paddock or pasture for cattle. It is difficult to work with it, especially to splice panels (see below), because reinforced chain-link is heavy and rigid.

A very strong and elastic type of chain-link with a small, up to 20 mm, highly flattened mesh, the so-called. armored mesh (item 7, remember the old beds?). But it is much more expensive than a regular fence chain-link, and it is even more difficult to work with. And finally, horizontal chain-link, pos. 8: it is impossible to make the joint of its panels in the fence invisible.

Splicing and tensioning

Chain-link mesh is available in widths starting from 1.1 m in rolls of 10 m. For fences, 10-meter rolls with a width of 1.5-3 m are usually purchased. It is impossible to turn large rolls without lifting mechanisms. That is, the fence will need several rolls, the panels of which (if the fence is not sectional) need to be spliced into one sheet.

There is no need to splice the chain-link panels into a fabric with wire (item 1 in the figure) - it is ugly and fragile. To splice chain-link webs, one spiral is carefully unscrewed from the edge of one of them (one layer) and, screwed into the 2 outer layers of the fabrics, they are spliced, pos. 2.

Splicing and tensioning mesh

Also, when installing a chain-link fence, the mesh must be tensioned. Especially - if the fence is tensioned along a string, then the mesh should be stretched tightly. In the methods for this, it is recommended to use a screw lanyard (pos. 3) or hoists, but with improvised means and with 2 assistants you can do it easier, pos. 4:

- Sections of reinforcing bars with a diameter of 10 mm or more are tucked into the outer layers, and bridles made of textile or synthetic cable with a thickness of 12 mm or more are knitted to their ends.

- On one side, the bridle is carried along the hollow on the support 4a, thrown onto a firmly driven “boy” stake with a support between it and the outermost post, and a cable collar 4b is made, without tightening it tightly yet.

- On the other hand, a stake (waga) 4c is placed in the hole with an emphasis with another bridle thrown over it.

- One worker holds the collar vertically, holding the bridle on it so that it does not slip, and the other wraps the collar as tightly as possible.

- The worker on the gate holds it, and the worker on the gate pulls it towards himself. The mesh will be tensioned with a force of approx. equal to the force of hoists made of 4 blocks.

- Workers hold the mesh taut, and the foreman secures it.

Mesh attachment

The mesh is attached to the outer pillars by inserting the same reinforcement into the layers closest to the pillars from the inside. Then the rods are pulled to the posts in 4-5 places with clamps and, if necessary, the rods (not the mesh!) are additionally secured to the posts by welding. The mesh is attached to the intermediate posts in the same way and is thus tightly stretched. Depending on the type of fence, the method of attaching the mesh may be different, see below.

Design Features

Barbed wire is a metal thread or a narrow strip with barbs attached to it. The wire is available in several configurations. The material is used both for the construction of a full-fledged fence, and for an additional obstacle on an already installed fence of any type.

The thorn is used both for fencing private houses and for protecting industrial facilities.

Initially, the design was invented to protect the territory against animals, and was often used in cattle breeding.

Such a wire fence does not allow painless passage into the fenced area, since the thorns cling on contact, which leads to large scratches and wounds to the body. Later, the technology began to be used for fencing against people. The advantages of the design are its low cost, practicality and the ability to install the fence yourself.

Advantages of a fence

It is advisable to install a chain-link fence to mark the boundaries of your own plot immediately after purchasing it. To build such a fence, you do not have to hire construction equipment or hire craftsmen for the work. It is quite possible for one person to build such a simple fence.

On a Sportsground

Many homeowners make chain-link fences for their dachas. A country private country house is a place visited periodically. Therefore, installing a concrete fence around the territory is not an economically feasible measure, since the price of such a fence will significantly exceed even the cost of the property inside the building.

There are many advantages to such a mesh structure:

- Affordable price. Components for fencing construction are sold at a low price. Thanks to this, it is possible to create a simple fencing of an area surrounding several acres of land without any special financial costs - this is an economical option.

- Simple mesh installation. You can secure such a fence even where there is no electricity. No complicated tools are needed for installation. The usual tools that are always at hand in the home workshop will suffice.

- Speed of fencing installation. Even without special practical skills, it is possible to build a beautiful fence from chain-link, if not in a day, then not much longer.

- Such a fence does not prevent the penetration of sunlight into the area. Thanks to this, it is convenient to plant plants right near the border of the front garden.

- Visual lightness of the grid. The transparent wire fencing does not become a visual barrier at all and does not interfere with admiring the surrounding nature. Because of this, the homeowner feels a sense of unity with the outside world, and there is no pressure from a confined space.

- Wire fencing combines successfully and effectively with flower beds and berry bushes.

- The mesh fencing is easy to maintain, replace or repair. Wire that has become unusable can be transported to a scrap metal collection site without any problems.

Country fence between neighbors

The durability of the fence is affected by the quality of the material used. Therefore, you should think through all the nuances in advance.

Bruno spiral

In addition to farmers, this invention was also appreciated by representatives of the general staffs of many European armies. The seemingly harmless wire changed the tactics of warfare, minimizing the possibility of active offensive actions. The war took on a trench character. During the First World War, tens of kilometers of the front line were surrounded by barbed wire fences; in some areas the depth reached several hundred meters. The use of deadly wire was facilitated by the so-called Bruno spiral - a barbed fence that can be quickly installed in several rows, despite enemy fire. Made in advance from barbed wire in the form of a compressed spring, it instantly stretched on the battlefield.

Attaching chain-link mesh to metal posts

Fastening the chain-link mesh to the corrugated pipe is carried out using self-tapping screws and a hook or with a welding machine. In any case, fence supports must be secured carefully. Since they play the role of a frame that allows you to connect all the component nodes with each other.

Drawing for installing a fence

Methods for manufacturing sections

A roll of mesh for the fence is laid out on the ground, measured approximately 2 meters and carefully cut with a grinder, taking into account the selected size. Next, reinforcement rods are installed in the outer rows of links

The metal rods do not need to be connected to each other.

You can also make a frame from a 40x40 mm corner and attach a chain-link to it. Welding will be required to make the frame. This method of fastening will be more expensive.

The photo shows a fence made of profile pipes at the dacha.

Metal fencing made of corrugated pipe

How to attach sections to corrugated pipe posts

The chain-link is laid out on the frame and welding is used to attach the upper part of the reinforcement to the inside of the corner. Then carefully straighten the mesh from below and weld the lower rods. Next, the side parts are installed.

Sketch for installation

The prepared structure is installed vertically to a column made of corrugated pipe and secured to steel plates or corners. You can also attach the fragment with screws by making a hole of the required size.

When installing the next element to the corrugated pipe, you need to make sure that the extreme sections of adjacent frames are in the same plane. Even a difference of a centimeter is noticeable; it will give the fence an untidy appearance. Finally, the mesh is primed and painted. In this way, interconnected sections can be easily installed to any length.

The photo below shows a fence at the dacha.

Sectional fence option

Fastening the chain-link to the pipe using the tension method

To ensure the rigidity of the mesh fence during attachment to the corrugated pipe, a cable with a cross-section of 5–7 mm is stretched from above. This is necessary to resist wind and prevent the chain-link from sagging. This structure can be attached to metal posts and tensioned in any way, but it is better to use special tensioners.

Fastening examples

When installing a fence made of chain-link and corrugated pipe and fastening it with guy wires, the distance between the supports can be made larger, up to 3 m. But it must be taken into account that during the tension process, the load on the metal posts, which are located at the edges, increases. It is necessary to increase their strength in contrast to posts with a regular fence.

You can fasten the chain-link mesh to a metal post by stitching the corrugated pipe through the width. But this is labor-intensive, and with increasing wire cross-section, the complexity of fastening increases.

How to attach a canvas using a tension method without welding

That is, in practice, the strings are first secured to a metal corrugated pipe, after which the mesh is installed and secured in the manner described above. Next, at intervals of 20–30 cm, the chain-link is tied to the guy wires with wire with a diameter of 1.3–1.75 mm.

Fastening diagram with clamps and cable

The video provides instructions for installing the canvas using the tension method.

Hook mounting and hanging features

This method of fastening the mesh is used in dachas if a fence made of corrugated pipe is installed to delimit the area from neighbors. The hooks must be welded onto the supports so that the top of the chain-link is clearly horizontal. That is, the upper parts of the fasteners must be placed level.

Scheme of fastening to a metal corner and to wooden veins

To make the correct installation of the chain-link mesh, you need to fasten one hook on top on the corner supports made of metal corrugated pipe, measuring the height, and stretch the rope.

But it is necessary to observe the nuances:

- This installation takes more time, especially if you use metal rods and staples to fasten the chain-link mesh.

- Fastening using this method requires the presence of free space, since the roll needs to be unwound to a greater length.

- You cannot attach a chain-link fence to a corrugated pipe using this method alone.

In the picture below you can see the types of hooks for attaching the chain-link to the corrugated pipe.

Sketch of hooks on the corner

Types of barbed wire

Barbed wire is made by cold drawing and then twisting sharp parts - spikes. More often, the cross-sectional shape of the spine is round. Diameter and hardness vary. There is a soft wire that is easy to install.

Another option is a stiffer material that is more difficult to work with, but more reliable. Production is carried out on special machinery. Steel is used for manufacturing.

The most common design option is a single or two-strand thread, onto which short pieces of wire with pointed ends are wound. The wire is made galvanized or uncoated.

The ribbon thorn is knocked out in the form of a long metal strip with protruding spikes in the shape of a pyramid. This tape is wound onto solid bases. By itself it is quite soft, it can be cut with metal scissors. Even when used on hard substrates, it can be removed, which reduces the reliability of the fence. Therefore, most often the tape is used on a durable basis - a steel core. A simple option is regular wrapping.

The disadvantage is that the barb can be separated from the steel core. A more reliable option is to crimp the tape around the core. In this case, the structure is very difficult to disconnect, and the steel core does not allow cutting the barbed wire fence.

The last option is known as “Egoza”. The 0.6 mm thick tape is made of steel with a small amount of carbon in its composition. It has a zinc coating. The protrusions on it are very sharp and tenacious. The core is a spring carbon steel wire with a diameter of 2.5 mm. Has high strength. Also has a zinc coating.

Methods for installing chain-link

Having determined where the fence will stand, it is necessary to schematically depict the future structure and draw up a cost estimate.

We recommend using metal pipes as pillars, after applying an anti-corrosion agent to them.

The building site is cleared of debris and vegetation. Marking is carried out using pegs and a stretched rope.

Further creation of the fence depends on the selected type of mesh fastener. Let's look at each of them in more detail.

Tensioner

It is easy to install and low cost. One edge of the chain-link is fixed to the post, the other is pulled tightly. The recommended distance between supports is no more than 2.5 m.

To achieve good tension of the mesh, you can use the following intermediate fasteners:

- clamps;

- cable;

- lanyard;

- hook with long thread.

The disadvantage of this method of fixation is that the chain-link will begin to sag, so it is better to use it to create small temporary fences.

Sectional

A good fence option for areas that are on a slope, on sandy, moving soils.

It is recommended to install the posts at a depth below the freezing point of the soil. The supports are fastened using any method other than concreting.

It is better to choose metal as a material for racks. For brick supports, you will have to install the mortgages in advance.

Photo: sectional fence made of metal corner and chain-link

An alternative is to buy sections in a store.

The work order is as follows:

- Steel plates 5 mm thick, 5 cm wide, 15–30 cm long are welded to the pillars. They are fastened at a distance of 20 cm from the top and bottom of the supports.

- The frame is made from a metal corner measuring 30*40, 40*50 mm. A corresponding piece of mesh fabric is welded inside the frame. Reinforcement rods are inserted along the edges and fixed with spot welding.

- An alternative solution is to weld long hooks 3 mm thick, bend them inward and attach a chain-link to them. After tensioning the mesh, it is better to weld the ends of the hooks so that the mesh does not slip off over time.

The finished frames are cleaned, coated with an anti-corrosion agent and painted in a suitable color.

With guide

A type of tension. It is mounted using the same method, but 2-3 metal ones are welded between the pillars or wooden logs are fixed.

On heaving soils, pillars should not be concreted; it is better to install them below the freezing point of the soil and backfill them.

With metal rod

This is a tension-type fence, which is strengthened by pulling strong wire through the mesh. They fasten it along the top and bottom rows of the chain-link so that the fabric does not begin to sag over time.

The simplest way is to make a loop out of wire, throw it over a post, tighten it, thread it through the cells to the next post and repeat the procedure.

You can weld plates with hooks to the supports and attach a metal rod to them. There is an option to buy special tensioners for wire, but they will not be cheap, and when installing a budget structure made from chain-link, it is not profitable.

It is convenient to use mesh fabric as a sectional material for fencing in summer cottages, when, in conditions of limited finances, it is necessary to delineate the boundaries of the estate without shading the plants growing nearby. For other purposes, it is worth using chain link to create a temporary fence.

Installation

A net, two meters wide, is stretched between the pillars. But first you need to plan the site. We drive pegs in each corner and pull the rope. Then you need to dig holes for the pipes, one and a half meters deep, and the distance between the supports is two meters. We lay sand and crushed stone in layers at the bottom of the pit, after which we install iron supports and fill it with cement mortar, as shown in the video.

It is worth noting that the pipes must be coated with a special anti-corrosion compound before filling. It is also necessary to close the pipes at the top with plugs. Otherwise, dirt and moisture will accumulate inside it over time, contributing to the destruction of the support.

After the solution has completely hardened, we begin installing the wire fence. It is necessary to weld hooks onto the metal pipes on which the mesh will cling, as shown in the photo. This procedure will continue until the last support. The final stage of work will be treating the product with an anti-rust substance.

To prevent the chain-link from sagging, sometimes they use this option: an iron rod is stretched along the upper edge of the mesh, which is attached to all the posts, as shown in the photo.

Let's sum it up

Barbed wire fence. The emaciated faces of prisoners, guard towers with machine gunners. The evil grin of the shepherd dogs. Agree, these are the associations that the mention of barbed wire evokes in most of us. An innumerable number of troubles and misfortunes were brought to this earth by an invention that was originally intended to serve completely humane purposes.