Technical specifications

ANO-21 welding electrodes are used for welding parts from 1 to 4 mm, pipelines and vessels under low pressure . Excellent for creating short seams.

Rutile coating based on titanium dioxide allows you to weld workpieces in a wet state and with traces of corrosion. The product is capable of working in all welding positions and directions, which is especially important for welding fixed pipeline joints.

The no-load voltage must be at least 50 volts; you can operate with direct and reverse polarity, as well as alternating current.

ANO-21 are produced with a diameter of 2; 2.5; 3 and 4 mm. Special mention should be made of such technical operational parameters as:

- facilitated arc ignition;

- combustion stability;

- reduced splashing.

The welding wire used for the production of ANO-21 contains additives that increase the surface tension coefficient of the melt .

This allows you to weld ceiling and vertical seams without fear of metal leaking out of the weld pool.

Features and Benefits

ANO-21 welding electrodes have a rutile coating (titanium dioxide). Thanks to the high resistance of TiO2, the weld pool is reliably protected from slag. As a result, for high-quality welding, a lower content of magnesium and silicon is required, which makes the gases and welding aerosols formed as a result of the reaction with “deoxidizers” less toxic.

In addition to the low toxicity of the material, the advantages include:

- ease of first, repeated, multiple ignitions even without contact of the rod and the surface of the part;

- resistance of the seam to the appearance of pores when changing the length of the arc;

- possibility of welding in any position without exception, including vertical from top to bottom;

- low splash rates;

- creating an even fine-scaled seam;

- Works with damp, primed surfaces and metals with traces of corrosion.

ANO-21 are electrodes whose characteristics allow them to be used for both industrial and household work. This is one of those brands that is equally suitable for professional welders and beginners. Work can be carried out with alternating current (using a transformer) or direct current of different polarity (using an inverter).

Advantages and disadvantages

Welding electrodes ANO-21 have the following advantages:

- availability;

- fast ignition of the electric arc;

- formation of a light and quickly removable slag layer on top of the weld material; layer;

- strength, durability and seam tightness.

The product also has a number of disadvantages:

- small range of workpiece thicknesses;

- the need for additional fluxes;

- unsuitable for welding joints in pipelines and high-pressure vessels.

These disadvantages are compensated by an affordable price and attentiveness to the rules of application. If you don’t try to use ANO to connect thick workpieces or high-pressure joints, they will not disappoint the buyer.

Technological features: calcination, how to cook correctly and more

In case of moistening or long-term storage, it is necessary to calcinate (dry) the electrodes at a temperature of 120ºC for 40 minutes. Repeated calcination is carried out for 60 minutes at a temperature of 120 degrees Celsius.

Store packaged electrodes in a dry, heated room at a temperature not lower than +15 degrees.

To work with fillet welds in a vertical position and from top to bottom the support method ; the electrode should be held in the plane of the angle bisector. The inclination to the welding direction is allowed within 40-70 degrees.

The welding currents recommended for each thickness and welding position must not be exceeded. This can lead to burn-through of the workpieces.

Areas of application

The product is used during manual electric arc welding (MMA) of workpieces made of carbon alloys. The most common areas of application are the following:

- installation and field repair of pipelines and vessels operating under low pressure;

- assembly of critical structures with butt, corner and overlap seams;

- welding root seams on thick workpieces.

ANO-21 is used at industrial enterprises in the field of shipbuilding, mechanical engineering, distribution networks in housing and communal services . Both repair shops and home craftsmen use electrodes with pleasure.

Features of application

The main area of use is the installation of gas and pipeline systems. In particular, these are utility network, ship and machine pipelines.

- The products are used in welding thin-walled structures with a thickness of no more than 5 mm, designed for low pressure working media (up to 12 atmospheres).

- Excellent welding of ordinary and butt joints.

- They have proven themselves when working with partially defective metal (oxidized surfaces of steel parts, oxide film on aluminum).

The humidity level of products of this brand should not exceed 0.5%. If storage conditions are not met, the rods must be calcined for 40–60 minutes at a temperature of 120–150°C.

Some of the best domestic examples of this brand are products of the Magnitogorsk Electrode Plant. These are, in particular, the electrodes of the Standard line, which meet all the requirements of state standards and have proven themselves to be excellent among both beginners and professionals. Electrodes are produced in the most popular and sought-after diameters - 2.5, 3.0, 4.0 mm. All products are certified.

Chemical composition

The chemical composition of ANO-21 is unchanged for all diameters and lengths of the range. It determines the physical, chemical and operational properties of the product. The normalized percentage of alloying additives and the maximum impurity content are indicated in the table:

| WITH | Si | Mn | S | P |

| 0,1 | 0,3 | 0,5–0,8 | 0,04 | 0,045 |

The chemical composition is regulated by the state standard and is mandatory for all electrode manufacturers. In practice, there is a certain difference in chemical composition between their products.

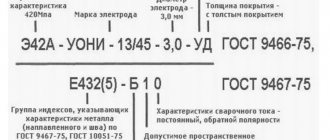

Decoding the marking of electrodes for welding

Like many other welding electrodes, ANO-21 (ANO-21 STANDARD) is a product developed by specialists from the Institute of Electric Welding named after. E.O. Paton, who belonged and now belongs to the Academy of Sciences of Ukraine. Hence the simple decoding of the abbreviation and number:

- AN – Academy of Sciences;

- O – general purpose;

- 21 – brand number.

The development of new welding electrodes in the 70s of the last century was caused by an important need. Before this, products with a basic coating were widely used - during the work, the coating released very toxic fluoride compounds, which limited the conditions for their use (welding - only in the open air or in a very well-ventilated area). Scientists have proposed a fundamentally new solution - welding electrodes with rutile coating.

Features of work

The main feature of ANO-21, like other products with rutile coating, is the ability to work in difficult conditions, on wet workpieces with traces of corrosion. However, the electrode itself must be almost completely dry. To do this, they are stored in sealed packaging, and if moistened, they must be calcined for 40 to 60 minutes at a temperature of 120°C.

Welding modes depend on the diameter of the product:

| Diameter, mm | Length, mm | Quantity per 1 kg, pcs. | Operating current, A | ||

| Lower | Vertical | Ceiling | |||

| 2 | 300 | 95 | 60-100 | 70-80 | 80-100 |

| 2,5 | 300 | 58 | 70-120 | 70-100 | 90-110 |

| 3 | 350 | 40 | 100-150 | 90-110 | 110-140 |

| 4 | — | — | 160-190 | 150-170 | 150-180 |

You should not try to weld workpieces thicker than 5 mm or pipe joints that must work under pressure with such electrodes. Such attempts will not lead to anything good. It performs the work for which ANO-21 was designed almost flawlessly

Dimensions and packaging

After release, the finished products are placed in moisture-proof film and a cardboard box. Packages of 1 or 5 kg are available for sale.

| Rod Diameter (mm) | Length(cm) | Weight 1 pc. (G) | Quantity per 1 kg |

| 1,6 | 25 | – | – |

| 2,0 | 25 | – | – |

| 2,5 | 30 | 17,0 | 58-59 |

| 3,0 | 30 or 35 | 26,5 | 38 |

| 4,0 | 45 | 53,0 | 18-19 |

| 5,0 | 45 | 84,5 | 12 |

| 6,0 | 45 | 135,0 | 7 |

We recommend reading Calculation of electrode consumption during welding

Small packages are convenient for home use.

Consumption rate

When connecting parts in small volumes, a competent calculation of the required number of electrodes and the diameter of the rod will ensure the continuous activity of the master and eliminate unjustified monetary costs.

This requires parameters that are inserted into tables developed by scientists from the Montazhspetsstroy Research Institute and other organizations. Detailed information about the types of welding is presented in document VSN 452-84.

In practice, the consumption is 1.65 kg for every hour of operation.

Labeling and manufacturers

The electrodes were developed at the Welding Institute of the Academy of Sciences. Paton. ANO -21 marking means:

- A: Academy

- N: Science

- O: coated;

- 21: development model

The full designation E46-ANO-21-d-UD E 430/3/-R 11 contains a detailed description of the product properties:

- E46: product type according to GOST;

- ANO-21: brand;

- d: product diameter;

- U: connection of carbon alloys;

- D: with thickened coating;

- 43: tensile strength of the seam material 46 kgf/mm2;

- A: relative elongation up to 18%;

- /3/: impact strength of alloy from 3.5 kgf m/cm2;

- R: rutile-based coating;

- 1: works in any welding positions;

- 1: Uses forward or reverse polarity, or alternating current.

ANO-21 electrodes are produced by the following manufacturers:

- Paton;

- MaxWeld;

- Granite;

- Tigarbo;

- LEZ;

- Monolith;

- KOMZ.

Experts admit that not all manufacturers strictly follow the manufacturing technology and chemical composition of the coating. Therefore, the quality and performance properties of their products differ from each other. The differences lie in ease of ignition, arc stability and bead porosity.

Comparison table

Electrode products, including ANO-21, are produced by several enterprises. The manufacturing technology is not followed at all, for this reason the properties of products from different manufacturers differ in ignition, maintaining arc stability and the appearance of pores.

We recommend reading Characteristics of LB 52U electrodes

Masters conducted comparison tests with the participation of ANO-21, MR-3 and SSSI. The test results depending on the welding direction are shown in the table.

| Index | ANO-21 | MR-3 | SSSI |

| Metal consumption (1 kg) | 1,7 | 1,7 | 1,6 |

| Viscosity (J/cm²) | 80 | 80 | 200 |

| Elongation (%) | 18 | 18 | 26 |

| Capacity (kg/h) | 1,4 | 1,7 | 1,3 |

| Yield Strength (MPa) | 460 | 400 | 350 |

| Maximum current (A) | 220 | 260 | 200 |

| Minimum current (A) | 40 | 30 | 40 |

| Calcination (min.) | 60 | 60 | 60 |

The table will help in selecting the electrodes needed for the job.

Advantages

This consumable material stands out from similar products due to its advantages, which determine the choice in their favor:

- during the welding process, the amount of smoke generated is significantly less compared to other types of electrodes;

- it is possible to connect metal structures by welding using these products in any position in space;

- an extended arc can be used for welding structures;

- welding using ANO-21 electrodes can be performed at low currents;

- welding work is characterized by the formation of a significant amount of metal spatter;

- welding using these products is characterized by independent separation of the resulting slag;

- The combustion process is quite gentle.

Electrodes for welding ANO-21 (ANO-21 STANDARD) - technical characteristics

- The metal composition of the rod is low-carbon steel (Sv-08 or Sv-08A).

- Temporary tensile strength – not less than 450 MPa.

- The proportion of splashed metal does not exceed 4%.

- The rod metal consumption coefficient per 1 kg of deposited metal is 1.65 kg.

- The typical value of the yield strength is 350 MPa.

- Relative elongation – no less than 18%.

- Electrode impact strength ≥80 J/cm².

- Productivity – 1.2 kg/h (for rod d 4 mm).

- Electrode length – from 250 to 450 mm.

Distinctive features of some brands

ANO – 3

The brand performs welding of non-critical joints. Rutile coating creates easier conditions for welding work. Installation of tacks, even if there are many of them, is performed with these electrodes without any problems. No cleaning of oxides, oils or other dirt is required. The slag crust is easily removed, right up to self-separation.

ANO – 4

The high welding characteristics of these electrodes at a relatively low price make them in demand by welders, from amateurs to professionals. They can be used when welding both ordinary and critical joints.

Even when welding wet, rusty and oily surfaces, the coating protection prevents the formation of pores and cracks in the weld. The quality of the seam is not hampered by the use of increased welding current values.

ANO – 4I

This brand is distinguished by its ilmenite-based coating. Allows you to combine the properties of both acidic and rutile coatings. Improved sanitary and hygienic parameters in comparison with purely acidic powder is the main advantage of this brand. Rutile powder allows you to work on all types of currents, regardless of polarity. As a consumable material, it is used for welding metals with a tensile strength of no more than 46 kgf/mm2.

ANO – 6; ANO – 6M

The coating of these electrodes can be rutile or rutile acid. Some manufacturers include the mineral ilmenite in the powder to reduce harmful emissions.

They are distinguished by the ability to obtain a high-quality seam when operating in modes with increased current strength. ANO-6M allow less spattering and create conditions for easier disposal of slag crust than ANO-6 electrodes.

ANO – 8

The characteristics of this brand are in many ways similar to the ANO-27 electrode. The difference lies in the mechanical characteristics of the metals being welded. ANO -8 is used for welding low-alloy and carbon steels with a tensile strength of up to 46 kgf/mm2, and the same indicator for ANO -27 is higher - up to 50 kgf/mm2.

ANO – 9

This type has a base coating, so it can be used to obtain plastic and high-impact joints. Before welding, cleaning of the edges of the weld is required . All types of currents can be involved in the work, only constant ones must be with reverse polarity.

ANO – 12

The grade, coated with rutile powder, is used in working conditions during installation work, where it is not possible to thoroughly clean the welded edges and it is necessary to carry out the process in different spatial positions . The porosity of the seams is not affected by the use of increased current to ensure high-quality penetration.

ANO – 13

The grade with rutile cellulose powder is distinguished by high-quality welding in any location of the seam in space. What especially distinguishes it from other brands of electrodes is the ability to apply sutures in a vertical plane from top to bottom. In this position, he can weld overlapped, butt and corner seams.

ANO – 17

The acid-rutile coating of the electrode with the addition of iron powder determines the specifics of its application. This composition increases the deposition coefficient, which increases the productivity of working with such electrodes.

Increased fluidity makes welding in the lower position of thick-walled workpieces with a long seam length most popular. Increased energy costs are required, so it is better to use this brand in a production environment.

ANO – 21

For small-sized structural elements, these electrodes have a high degree of applicability. It is not recommended to use them when welding thick-walled workpieces , since there are no guarantees about the quality of the seam.

They are available on the domestic market and outperform their competitors in price. Welding wire, due to additives that increase surface tension, makes it possible to weld joints in all positions.

The characteristics are characterized by free arc ignition (initial and repeated), easy slag separation, stable arc combustion.

ANO – 24

The use of the mineral ilmenite (Fe – TiO2) in the coating of this brand makes it possible to reduce the amount of harmful substances during welding. Widely used in many areas of industry and construction, both conventional and connections with increased requirements. Almost any welding machine can operate on any current with any polarity. Works on contaminated surfaces using various technologies depending on the length of the arc (it can be different).

ANO -27

The base coating provides a protective environment that is virtually free of hydrogen. The absence or minimally permissible presence of this gas allows us to obtain plastic seams with high impact strength . The electrode makes it possible to maintain the strength properties of the seam at low temperatures (down to -40°C). About this brand here.

ANO – 34

Rutile coating makes it possible to weld workpieces with the presence of oxides on the surface of the edges.

Important : the idle speed of the welding unit should be 50 V. At a higher value, the electrode quickly becomes red hot and begins to drain. There is no welding of the workpieces. During the process, smoke with an unpleasant odor is present. To learn more…

ANO – 36

This electrode is quite competitive in the welding materials market. A special rutile cellulose coating makes the characteristics of ANO-36 at least as good as the best analogues from other manufacturers. Very low toxicity is a significant argument to give preference to this electrode.

The stability of the chemical composition and uniformity of the seam reduces stress concentration in the weld zone and makes the structure more durable to external influences. Welding in a vertical “top-down” position is present in the arsenal of capabilities of this brand.

ANO – 37

The grade with rutile powder has properties that allow a beginner to obtain welds that are not inferior in quality to those made by a qualified welder . Simple ignition of the arc, and no problems arise when re-igniting it; formation of a seam does not require special skills - these are the main reasons to choose this brand of electrode for an inexperienced specialist.

The versatility of the ANO-37 electrode is determined by the ability to work on any equipment, welding with any seam location, with varying degrees of contamination of the welded edges. It is this quality that distinguishes this brand from a large number of similar ones.

ANO – T

Electrodes with a basic coating are used to produce critical welded joints of pipelines made of low-alloy and carbon steel.

At the same time, the possibility of welding for all seam locations, where even on the ceiling you can get a seam with a bead on the opposite side, creates conditions for using the electrode in the specific conditions of installation of the structure. The use of this electrode does not depend on climatic conditions.

ANO – TM

To obtain welds with high mechanical characteristics, this brand is used, where the protection is made using a base coating. This brand can be used to weld both root joints and fillers. You just need to change the polarity of the current.

ANO – TM/N

Here is the main type of coverage. It provides a minimum amount of sulfur and phosphorus impurities. This consumable material is used to produce critical connections, for example, joints of product pipelines in the oil and gas industries. Root seams, due to the formation of a reverse roller, can only be performed on one side. The surface of the edges must be cleaned to reduce the likelihood of pore formation.

ANO – TM60

These electrodes differ from the almost identical ANO - TM70 only in mechanical properties. The tensile strength of the weld is slightly lower - up to 588 MPa.

ANO – TM70

Low-alloy steels, where the strength of the weld must be quite high, are welded with this grade. Used for welding pipelines in the oil and gas complex. Cleaning of welded edges is mandatory . Root seams with this brand of electrodes are welded only on one side, since the welding bead is formed without welding on the other.