Home / Electrodes

Back

Reading time: 2 min

0

904

Every novice welder asks the same question - which welding electrode is better? There are hundreds of models on the market from different companies, both national and foreign.

Experts will advise you on a couple of options. If you are just learning the art of welding, then OZS-12 may be recommended to you. It is affordable and multifunctional.

The article talks about the OZS-12 brand. You will learn about the technical parameters of the rods and important details. Once you become familiar with this, you will be able to quickly complete the work and get the desired result.

- general information

- Peculiarities

- Usage

- Summarize

Explanation of symbols

The production of electrical conductors with the least toxic – rutile – coating began in the 70s of the last century. The products were developed by specialists from the laboratory of the Institute of Electric Welding of the Academy of Sciences of Ukraine, headed by I.K. Pokhodnya (they are also credited with developing consumables of the ANO and UONII brands). Explanation of the abbreviation:

- OZ – pilot plant;

- C – construction;

- 12 – model number.

In the mid-70s, standards for OZS-12 were adopted and still remain unchanged - GOST 9466-75 and 9467-75.

Technical characteristics of OZS electrodes

When assessing technical capabilities, OZS groups use indicators that are traditional for all welding technologies. First of all, these are the type and range of welding current, permissible spatial orientation, physical characteristics of the weld metal, productivity, consumption, etc. The features of the group also include the high hygroscopicity of the rutile coating, which requires mandatory calcination before starting the welding process. The table below shows the technical parameters of several popular electrodes in this group.

| Specifications / Brand | OZS-3 | OZS-4 | OZS-12 |

| Spatial position | Lower | Everything except vert. top down | All |

| Type of voltage | AC/DC+ | AC/DC+ | AC/DC+ |

| Type according to GOST | E46 | E46 | E46 |

| Current (for Ø 3 mm) (A) | 150÷210 | 70÷120 | 70÷130 |

| Diameters (mm) | 3,0; 4,0; 5,0 | 3,0; 4,0; 5,0 | 2,0; 2,5; 3,0; 4,0; 5,0 |

| Quantity per 1 kg (for Ø 3 mm) (pcs.) | 20 | 38 | 36 |

| Deposition Capacity (kg/h) | 3.3 | 1.4 | 1.2 |

| Consumption per 1 kg of surfacing (kg) | 1.3 | 1.6 | 1.7 |

| Coating | rutile | rutile | rutile |

| Calcination temperature and time (º/hour) | 150÷170/1,0 | 120÷160/1,0 | 150÷180/0,5 |

| Technological features | Short and ultra-short arc welding | Poss. long arc welding. | Poss. long arc welding. |

It should be noted that one of the leading manufacturers of these products, Spetselektrod, directly indicates that the newer and better in terms of characteristics analogue of OZS-4 brand electrodes is OZS-12.

Description of OZS-12 electrodes

The rods are manufactured in accordance with GOST 2246-70 from cold-drawn wire Sv-08 or Sv-08A (low-carbon steel). The products have a thick coating of mineral substance – rutile concentrate, 95% of which is titanium dioxide (TiO2).

By releasing slag during the welding process, Ti dioxide protects the weld pool and weld metal from the effects of nitrogen and oxygen. Mn and Si deoxidizers also perform the same function, but since their content in the composition is insignificant, the volume of toxic compounds they form with oxygen is extremely small. That is why rutile-coated electrodes are considered the least toxic and safe for health when welding.

Titanium dioxide is a good electrical conductor. This ensures easy re-ignition without contact of the rod with the surface of the part being welded.

OZS electrode markings

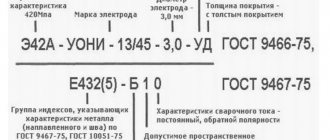

The coding procedure for individual brands of electrodes for manual arc welding is regulated by GOST 9467–75, and OZS electrodes in this case are no exception. The code marking consists of two lines arranged in the form of a fraction. At the top indicate the type designation for the physical qualities of the welded joint, brand, dimensional characteristics and purpose. And at the bottom there are various welding, technical and technological parameters. For example, the designation of electrodes of the OZS-4 brand looks like this:

Figure 2 - Designation of electrodes of the OZS-4 brand. Here E46 means that the weld or surfacing metal has a tensile strength of about 460 MPa. Other normalized physical characteristics follow:

- OZS-4 - name of the product brand;

- Ø - diameter is marked separately (this position may also have a value in mm);

- U - intended for welding low-carbon and low-alloy steels;

- D - coating thickness code, expressed as a quotient of the coating diameter divided by the rod diameter (four ranges of values); type D is a thick coating with a value of this ratio of 1.45÷1.8.

Figure 3 — Packaging of OZS-4 electrodes

The second line contains the following encodings:

- E (Latin) - international code for coated consumable electrodes;

- 430(3) - index for determining the limiting characteristics of weld metal according to GOST tables;

- P - type of coating (in this case, rutile);

- 2 - code of permitted welding orientation, this figure means “everything except vertical from top to bottom”;

- 5 - use on direct current of straight polarity.

This designation system applies only to electrodes that are used for steels. Models used in welding non-ferrous metals and their alloys have a different marking procedure.

Recommended current values

| Electrode diameter, mm | Current strength, A | Electrode length, mm |

| 2 | 30… 90 | 300 |

| 2,5 | 50… 110 | 350 |

| 3 | 70… 130 | 350 |

| 4 | 110… 180 | 450 |

| 5 | 130… 220 | 450 |

Advantages and disadvantages

When using OZS electrodes in accordance with their purpose (i.e. for welding low-carbon and low-alloy steels) and in compliance with the technical requirements, they demonstrate a number of advantages over products with other types of coatings:

Figure 4 - Welding OZS

- almost complete absence of porosity of the weld metal (regardless of the arc length);

- the likelihood of hot cracking is lower than that of acid-coated grades;

- a small amount of slag crust and its easy separation;

- minimal metal spattering;

- the coating contains almost no harmful substances that affect the welder.

OZS electrodes do an excellent job of removing rust, primer and even paint residues. In addition, it is possible to carry out welding work on wet surfaces. At the same time, the welding arc has reliable ignition, stability and easy renewability.

The limited scope of application of OZS cannot be attributed to their shortcomings, because they were originally created only to work with certain types of steels. But the real disadvantages of this group of electrodes include the hygroscopicity of the shell material and the dependence of their properties on humidity. Mandatory calcination before use limits the scope of their application, since it is not always possible to do. This is an additional technological operation, and quite a long one.

Features and Benefits

The characteristics of the coating provide many advantages for electrical conductors of this brand. Welding can be performed either with a transformer (alternating current) or with an inverter (constant reverse polarity). Among other advantages:

- easy first and re-ignition, stable arc burning;

- when re-igniting, direct contact of the electrode with the surface of the base metal is not required;

- the amount of metal splashed during work is very small;

- due to the composition of the coating, a minimum of toxic substances are released during welding;

- welding can be performed at all arc lengths - short, medium, long;

- the surface of the parts being connected may have traces of oxides, be wet or dirty - OZS-12, like other electrodes with rutile coating, are insensitive to such barrier factors;

- the result of the work is a high-quality weld with a smooth and precise pattern.

Welding work can be performed in any spatial position. It is allowed to use a household network with a voltage of 220 Volts.

Electrodes give excellent results, including when setting tacks, as well as when connecting fixed joints in pipelines. In addition, OZS-12 welding electrodes are one of the best brands when working with T-joints: they allow you to obtain an even concave seam.

Before welding, the products must be calcined for half an hour at a temperature of 150–180°C.

general information

OZS 12 electrodes are one of the most popular on the market. Rods of this brand are produced by a wide variety of manufacturers. Among the most worthy representatives, we highlight LEZ and ESAB. At the same time, LEZ electrodes or ESAB OZS 12 electrodes do not differ much in quality, so you can purchase packaging from one of these manufacturers.

Technical characteristics are similar to analogues, such as MP-3 or ANO-21. The base used is filler steel wire, which has a thick rutile coating. Rutile coating ensures arc stability and improves the quality of the welded joint. The electrodes themselves are manufactured in accordance with GOSTs No. 9466-75 and No. 9467-75. Check the packaging for this information.

By default, the humidity level of the electrodes should not exceed 0.7%. Of course, you won't be able to verify this yourself, so just don't buy rods from a basement store. We also recommend calcining the electrodes in an oven before welding. For the OZS-12 brand, the optimal calcination temperature is 150-180 degrees. Calcination time is about half an hour.

OZS 12 electrodes are designed for welding various types of steels. Both low-alloy and carbon. The average consumption of electrodes per 1 kilogram of metal is about 1.6 kg. This indicator can be considered optimal. It is very convenient to use OZS 12 rods; they are strong and durable. But only if the storage conditions are met.

Areas of use

Welding electrodes OZS-12 allow you to weld both ordinary parts used in everyday life and critical industrial structures. This:

- lifting and transport special equipment;

- mining equipment;

- pipes and pipe fittings in the chemical and petrochemical industries;

- equipment at metallurgical enterprises;

- pipelines in the gas industry;

- boiler equipment.

This material is also used to weld units, installations, and lifts used in explosive industries.

Application

To get a quality connection, you must follow some rules. First of all, we recommend that you calcinate the electrodes before welding in any case. Even if you are sure they were stored correctly. An extra half hour of calcination will significantly improve the quality of the finished joint. We also note that it is not necessary to cook on a short arc, as is the case with other brands. You can use an extended arc. This is a big advantage for beginners. After all, a long arc allows you to openly observe the welding process. The OZS-12 brand is universal in many ways. With the help of such electrodes it is possible to achieve excellent weld quality when welding a wide variety of metals. You should not experience any problems when welding non-ferrous metals or when welding steels. If something goes wrong, check that the welding mode is set correctly. We recommend welding with reverse polarity. Both direct and alternating current can be used. There are no restrictions here.

We wrote above that you can cook with OZS-12 electrodes by connecting the device to a household power supply. This is true, but make sure that the diameter of the electrodes is not too large. Also, beginners can safely cook at a low current value, since the OZS-12 brand allows this.

Application area

In addition to welding various structures from profile and sheet metal made of carbon and low-alloy steels, OZS electrodes are used in the repair of various pipelines, especially when it is impossible to dry their inner surface. Another widely used function of these electrodes is welding ceiling seams. In addition, as already mentioned, they are indispensable when working on corroded and contaminated surfaces.

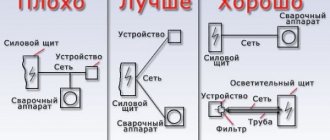

OZS-12 electrodes with a thickness of 2÷2.5 mm have a fairly low operating current (up to 30–50 A) and therefore can be used with welding machines powered from a household electrical network. The only problem in this case is related to their calcination (or at least drying). If anyone has an answer to this question, please share it in the comments to this article.

Characteristics

OZS electrodes have excellent technical characteristics. First of all, there is a rutile coating that covers the filler metal rod or wire. Rutile electrodes are recognized as one of the best for welding work. When using electrodes with rutile coatings, the weld seam is strong and has good impact resistance.

Rutile coating prevents the formation of pores in the weld even if welding is performed on oxidized surfaces. It is possible to weld metal with traces of rust. Also, this type of coating prevents slag formations from entering the metal of the joint being formed.

Another advantage of rutile coating is safety, since it contains no hazardous substances. Rutile makes up almost half of the composition of the coating, and the remaining elements include magnesite, feldspar, and ferromanganese. Rutile is titanium dioxide. Other additives have a deoxidizing and stabilizing effect. They also perform a connecting function. This coating allows you to work with direct and alternating current. Rutile electrodes are demanding regarding storage conditions, so calcination is necessary before starting work.

The tensile strength of the electrode material over time is in the range from 420 to 520 MPa/m2. The characteristics may vary slightly depending on the brand of electrodes. What they have in common is the type according to GOST - “E46”, rutile coating, and also the fact that the welding voltage can be constant or variable.

As for such an important characteristic as spatial position, OZS-3 electrodes can be used mainly in the lower position. In a more advantageous situation, OZS-12 electrodes turn out to be, with which you can weld in all positions.

The performance indicators of surfacing, measured in kg/h, are different. For example, OZS-6 electrodes with a diameter of 4 millimeters have this value equal to 1.8. And the technical characteristics of OZS-4 electrodes indicate that this indicator for the same diameter is 1.4. Technological features such as arc length are different for each model.