Stable and coordinated functioning of steel entrance doors is impossible without special fittings. One of its most important types is canopies or hinges. Today the variety of these elements is quite large, although in practice teardrop-shaped hinges with bearings are used more actively than others.

The products gained such popularity due to their design features and a large list of advantages of this type of product. You will need to familiarize yourself with these characteristics in more detail so as not to make a mistake in choosing accessories.

Design features of hinged hinges

The cylindrical shape of hinges is already considered classic. It is both easy to manufacture and in demand. At least it was before the advent of a new generation of hinges. In this case, the structure consists of two cylindrical bases that fit one on top of the other. To make such manipulation possible, a special axis is made on the body of the main element in the form of a protrusion of a similar shape, but much smaller in diameter. In this case, a special element is made on the counter part in the form of a small protrusion with a similar shape. This groove serves as a connecting element in relation to the two parts.

A cylinder is installed between the cylinders of such a hinge, ensuring ease of movement of the sash and reliable functioning of the structure.

Despite its simplicity and seemingly distinguished by particularly positive characteristics, this form of hinges still has one significant drawback - the difficulty of welding in place. This led to the invention of teardrop-shaped loops.

Types of loops

It is important to choose the right fasteners, taking into account the weight of the door and its dimensions. For heavy metal doors, modern industry produces the following types of hinges:

- Cylindrical. The most popular because they make it possible to open the gate to the maximum angle. Disadvantages include difficulty in attaching to a flat surface.

- Teardrop-shaped. They are a type of cylindrical hinges.

- Hexagonal.

- Square. Used extremely rarely.

In this article you will learn how to properly weld hinges

Regardless of the cross-sectional shape, a door hinge is a part consisting of at least two elements. In the simplest hinges, the connection of these elements is made by a pin and a counter groove. Their main advantage is their low cost and ease of further maintenance (lubrication). At the same time, simple hinges fail faster.

In more complex designs, at the end of the pin there is a movably fixed ball (ball loops), the function of which is to replace sliding friction with rolling friction, which, as is known, is much less. This makes it easier to open and close the doors, and the hinges themselves will last longer.

There are also hinges equipped with ball bearings, but it is not recommended to use them for heavy doors, since the complex mechanism quickly becomes unusable. For massive gates and gate leaves, hinges are produced that are additionally reinforced with plates. Due to the plates, the weight of the door is more evenly distributed on them, which allows you to increase its service life.

Reinforced ball ones are considered the best option for heavy metal doors, garage doors and gates. They compare favorably with their cheaper counterparts in their long service life, ability to withstand significant weight loads and ease of installation.

In this video you will learn how to properly weld hinges:

For heavy metal doors, the welded method is recognized as the best. It allows you to fix the hinges as securely as possible, eliminating play and gradual loosening of connections.

Benefits of using teardrop hinges

In addition to the simplified installation scheme, this type of product is characterized by a number of other equally noticeable advantages. These include the following features:

- the presence of a special ball as part of the hinge structure, located at the end of the axis, and during the assembly process of the product rests against the bottom of the counter cylinder;

- the presence in the design of most drop-shaped hinges of a special mechanism that facilitates the process of lubrication of canopies. It is located at the top of the hinge and looks like a small hole that does not have any effect on the overall strength of the structure. A grease fitting is installed inside this recess, in the presence of which lubricant, poured in with a conventional syringe, is supplied to the moving parts of the product;

- Another important advantage of the design is the presence of a bearing. This addition, like the ball, is intended to reduce friction of mechanisms by reducing the area of surfaces in contact with each other. The bearing is easy to lubricate from the outside, so it does not cause discomfort in operation.

Taking into account all the above listed features and advantages, we can say that teardrop-shaped hinges are one of the most popular options for door canopies today.

How to properly weld hinges on a metal door at home

Installation work on installing fastening elements for metal doors requires a responsible approach. This is due to the weight of the structure and the inability to make adjustments by correcting errors made during the assembly process. The expression is relevant: “measure seven times, and cut once,” since “measure” is thick iron metal, and “cut” is a “grinder” or a welding machine. Installation errors are unacceptable due to the catastrophic consequences.

General view of metal doors

What is the marking process?

After the base is prepared, the gate or door leaves are raised to a vertical position and the parts are installed empty at the intended location for attaching the welded drop-shaped hinges.

Try not to forget that the doors should open outward. If they are unlocked inside, then during the winter season of heavy snowfalls this can play a cruel joke on the owners.

After the canvases are raised and fixed, mark out the locations for the future installation of hinges. Please note that on the gates they are placed at a distance of approximately 20-25 cm from the bottom and top of the door leaf.

When installing the hinges, make sure that they are welded strictly vertically, because even with a tiny misalignment during welding, problems may arise in further operation, and this will lead to sudden destruction of the support bearings.

To check the correctness of the design, use a plumb line or laser level.

Installation of welded hinges

Let's look at how to properly weld hinges. To do this, you need to go through three main stages:

- preparation of equipment and materials required for work;

- preparing a metal surface for welding;

- welding hinges on the door.

Tools and materials

Before properly welding hinges on a metal door, gate or gate, you need to prepare the materials necessary for the work:

- loops selected according to all the rules indicated above;

- metal plates (if welding of hinges is carried out with reinforcement of the structure with plates). The dimensions of the plates are selected based on the weight of the door leaf. The greater the mass of the door, the larger the plates required. For example, garage hinges for gates of standard sizes (approximately 2.5 * 2.5 m) are welded onto metal plates measuring 80 * 80 mm;

- electric welding machine;

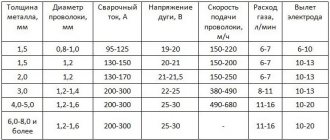

- dry electrodes. To carry out the work, it is enough to have electrodes with a diameter of 3-4 mm;

- a brush with metal bristles for preliminary cleaning of the work surface;

- personal protective equipment for the master.

When carrying out safety welding work, the welder’s face must be protected with a special mask that does not allow welding rays to pass through, and the body and hands must be protected with clothing and gloves made of non-flammable materials.

Special protective clothing and mask for welding work

Preparation

When answering the question of how to properly weld hinges on gates and other metal doors, it should be mentioned that the preparatory stage is in practice the most important.

At the preparatory stage it is required:

- mark areas for installing hinges. If two round hinges are installed, they should be located at a distance of 15-20 cm from the top and bottom of the door leaf. Additional hinges are located evenly along the entire height of the door;

- all areas in which hinges are supposed to be welded must be cleaned of dust, rust, and so on. To carry out cleaning, use a brush with metal bristles, dry rags and, if necessary, treat the surface with some kind of solvent;

Cleaning the metal surface before welding

- process the loops. The surface on which the weld will be located also needs to be cleaned. In addition, the inside of the hinge, where the ball bearing is located, must be thoroughly lubricated. For lubrication, you can use litol, solid oil, and so on;

Preparing the loop for installation

- if the hinges are installed using metal plates, then at the preparatory stage it is necessary to weld the inserts to the hinges. Welding of hinges and plates is carried out with an even seam;

Reinforcing hinges with metal plates before installation

- connecting the welding machine. When working with equipment, it is imperative to connect grounding;

Equipment elements and device regulation

- The device is adjusted using regulators located on the equipment body and by testing the production of a weld.

Achieving a high-quality weld by testing and adjusting the apparatus

All preliminary work is carried out with the utmost care. Any mistake or oversight may lead to the need to reinstall the hinges or replace the door leaf.

Hinge welding process

Before welding, the hinges are prepared, cleaned of rust and fat, and lubricated with grease or other similar lubricant. This will help avoid sintering of the hinges during welding of products to the base of the door leaf or gate.

Now it’s time to figure out how to weld the teardrop-shaped hinges to the base. It is worth saying that first the fittings are welded to the gate leaf, and then to the supporting pillars. This process must be accompanied by constant quality control of the seams, the condition of which determines the reliability of the further design.

After welding the hinges, treat the surface with a grinder, cleaning it.

The teardrop-shaped garage hinge is a modern version of the fittings used for mounting on garage doors, entrance doors, gates and gates. Anyone may be faced with the need to work with such a part, so it is worth studying at least the features of such products.

Which loops to choose

When choosing hinges, you must be guided by the parameters of the object on which they are going to be welded. Garage hinges, by definition, should be larger and stronger than hinges for a modest gate or door.

Typically, hinges with ball bearings are used for gates and metal doors. Moreover, such hinges and hinges in them can be of different shapes:

- cylindrical;

- square;

- hexagonal;

- drop-shaped.

Most often, cylindrical models have been used lately; square and hexagonal versions are found much less frequently in hardware stores.

And about the last drop-shaped loops (canopies) on the list, special mention should be made. Their use allows you to slightly simplify the installation process. There is no need to first attach ears to them - this is the main advantage of the teardrop shape.

Without any preparation, such loops can be welded to a support post. Moreover, only the top of the lower part of the canopy should be in contact with the post, and the top of the upper part should be attached to the gate leaf.

Drop-shaped products must be welded carefully - after welding they should still rotate easily and freely. And only if this is really the case, you can begin further work.

Welding without plates

If the weight of the gate is light, you can do without plates. The welding technology will be slightly changed:

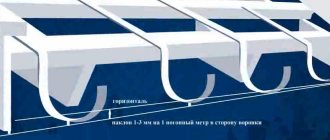

- The support and frame of the gate are laid horizontally so that their surfaces are in the same plane. A gap of 3-5 mm is left between them.

- 20 cm is measured from the top edge of the frame and a loop is placed in the gap. To raise it a little, you can use two matches, placing them perpendicular to the gap and installing a hinge on them.

- The hinge is fixed by spot welding: the lower element with the pin is welded to the support, the upper element with the groove is welded to the frame.

- To check how well the hinges work, it is not at all necessary to lift the sash: it is much easier to turn the support. If everything is normal, final welding is performed along the entire length of the fastener.

These methods are suitable for installing new gates, doors or gates. If it is necessary, for example, to replace old hinges on an already installed gate, experienced craftsmen suggest proceeding as follows:

- Secure the plaits to the loop.

- Laying the sash horizontally, weld the top part of the hinge.

- Place the sash in the opening and secure it.

- Insert the bottom of the loop into the top. Mark on the support the place where the bottom plate should be.

- Weld the lower part to the support.

After welding the door hinges, the seams are cleaned, primed and painted. Further care of the hinges comes down to regular lubrication, which will prevent rust and reduce friction.

Lubrication should be carried out only in the warm season, otherwise the hinges may freeze. Before applying lubricant, it is recommended to remove the door from the hinge, remove the remains of the previous composition, dirt, rust from the pin, and clean the groove.

Weld the hinge to the door

Did the hinge suddenly break and the front door sag? Have you noticed that the canvas cannot be closed? Do you want to repair it quickly, inexpensively and reliably? It is possible to weld hinges to a metal door, but it is wise to entrust welding work only to specialists. This is due to a number of factors, and in this article we will consider the main ones.

Do you need a welder to weld a hinge to a metal apartment door?

How to quickly and correctly weld hinges on an outdoor metal door? Few people think about this issue, since iron structures are purchased ready for installation. The installation itself is entrusted to specialists from the manufacturer. However, these elements are not eternal. They usually need to be replaced with new hinges over time. To do all the work correctly, you cannot do without the services of a welder. Only craftsmen will be able to weld the hinges correctly: be it teardrop-shaped or ordinary knots. Of course, consumables and tools will be useful to perform the services. Only in this case will the welding be performed efficiently and professionally.

If you order a technician to come to your apartment, you can be sure that he will select the correct fastening and will also arrive at the site with the necessary set of tools. These include a grinder, drill, hammer, welding machine and other related materials that may be needed during the work. The actual procedure for welding hinges to a metal door in an apartment is carried out in a vertical position of the sash. If you need to strengthen the existing weld, remove the structures from their hinges.

Replacing the entrance door hinge: we will weld a new one with a technician visiting Moscow and the region

Hinge failure is not uncommon today. Such damage occurs on gates and entrance doors. The welding itself must be carried out in strict accordance with safety rules and regulations. The work must be entrusted to a specialist with relevant experience and approvals. To weld a torn loop, the craftsman uses gas or manual arc welding technology. Here are just some of the services that our service technicians provide:

- Marking. Using a pencil and tape measure, you need to mark the places where the marks will be placed. This will prevent the front door from skewing.

- Lubricate the hinges with grease. The procedure is performed to avoid their caking, and you should also grab them in several places.

- Directly replacing and welding a new hinge on the front door.

- Checking the performance of the canvas in the apartment. If the door closes smoothly, then the hinges are already completely welded. Before putting the work into operation, the specialist sets the technological distance between the frame and the sashes.

The hinge on an iron door broke: repair with welding at home

is a Moscow service department that specializes in welding work at home. Our craftsmen will competently and inexpensively weld hinges on the entrance metal door, carry out repairs or other necessary work, visiting the apartment. Welder services are ordered from us because our specialists work:

- Comprehensively. If, during the welding of hinges, defects in the operation of the locks are discovered, our craftsmen will point out these defects to you and replace the door locks on the spot.

- Inexpensive. The prices for all our services are quite loyal and reasonable, which is why Moscow residents turn to us again and recommend us to their friends.

- Professionally. The welder’s departure is carried out as quickly as possible, and he arrives at the customer’s apartment with a set of necessary tools, locks, and materials.

Do you want to weld a new hinge instead of a broken one? Do you need guarantees for work performed? Then contacting our service is the right choice. By entrusting us with the replacement or welding of damaged elements, you will forget about broken hinges on a metal door for a long time!