Various electrodes are used to weld metal parts. The most common are SSSIs. The reason for this popularity is their versatility, as well as the fact that they are used for welding low-alloy steels. But most metal products are made from steel with a low degree of alloying.

What is a welding electrode in general? It consists of a metal rod, which is actually the material for filling the seam between the parts being welded. A special coating made of flux with the addition of certain elements is applied to it. For example, in an SSSI these elements are nickel and molybdenum.

Why is coating needed?

During combustion, the core metal takes oxygen and other substances from the atmosphere, which, when mixed, adversely affect the quality of the weld. It is necessary to remove them to the slag, preventing them from getting into the metal. This is why coating is needed. Here are specially selected materials that, when mixed with substances harmful to steel, combine with them.

This connection is lighter and when the seam hardens, it is brought to the surface into a slag crust. Thanks to this crust, the porosity of the seam is eliminated, which increases the strength and reliability of the connection. And this is considered the main point when welding metal parts.

Why SSSI electrodes are most in demand

A distinctive feature of electrodes of this brand is that they can be used at low temperatures. The main problems arise when the seam cools, and when it cools quickly, cracks, shrinkage cavities and other defects may appear. Subsequently, they will lead to the fact that the welded parts will simply separate from each other.

High quality, as well as the absence of defects during hardening, is due to the fact that the chemical composition of the resulting seam assumes sufficiently high ductility and impact strength. This will extend the life of this connection in the future, especially if the welded parts are intended to be used in harsh and frosty climates.

It is precisely on the basis of these useful properties and qualities that SSNI electrodes have gained such high popularity among users.

It is worth noting that this connecting material is considered more professional than, for example, ANO. Therefore, it will be quite difficult for an ordinary person to work using this brand.

How do UONI electrodes differ from MP-3?

Below you will be presented with the main differences between UONI electrodes and MP-3:

Coating type : MP-3 electrodes have a rutile coating. Rutile is a good conductor of electric current, so all rutile electrodes have easy arc ignition. They ignite well and re-ignite, which cannot be said about electrodes with a basic coating.

In turn, SSSI electrodes have exactly the basic type of coating. Therefore, the first difference between UONI electrodes and MP-3 electrodes is the type of coating.

Welding current : both alternating current and direct current are suitable for welding with MP-3 electrodes. In addition, you can cook with rutile electrodes in any polarity. The same cannot be said about the SSSI electrodes. They can only be cooked using direct current of reverse polarity .

Many novice welders are faced with the main problem when welding with UONI electrodes; they do not know what current and what polarity is needed.

Working conditions : MP-3 electrodes can weld rusty and dirty metal, that is, poorly prepared for welding. Rutile electrodes ignite well, which cannot be said about the main electrodes. Just as mentioned above, MP-3 electrodes are less sensitive to moisture than UONI electrodes.

Technical characteristics of SSSI

Among the many parameters that relate to the properties of electrodes, the most important are:

- coating – basic;

- surfacing productivity – 1.4 kg/h;

- the cost of surfacing one kilogram is 1.7 kg;

- current – constant;

- polarity is reversed.

It is worth noting that this type of electrodes has an internal additional classification. There are 4 groups in total:

- SSSI 13-45. Most often used to connect parts that were made by casting or forging. The seams are plastic and also have a fairly high viscosity.

- SSSI 13-55. This type of electrode is also intended for welding parts made of low-alloy steels, but with a high carbon content. A distinctive feature is that this brand cannot be used when welding a seam from top to bottom. A composite material consisting of sulfur, manganese, silicon and phosphorus is used as coating. The use of such electrodes contributes to the production of a high-strength weld with high resistance to the formation of cracks and fractures.

- SSSI 13-65. They can be used for particularly critical work, as well as on those metal structures for which increased quality requirements are put forward. According to GOST, these electrodes are produced with diameters of 2 mm, 3 mm, 4 mm and 5 mm. Regardless of whether it will be the manufacturer ESAB, LEZ or some other. Different manufacturers may offer their products at different prices, and this will be the difference. It is worth noting that an increase in thickness inevitably entails an increase in current strength. Therefore, those using an inverter may be a little limited as weaker models may not be able to produce the required amount of current.

- SSSI 13-85. Allows you to work with metal structures of increased strength, including those made of alloy steel. Like model 13-65, they can be used when welding parts in all spatial directions.

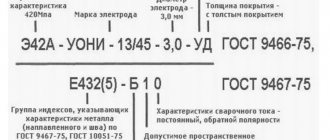

SSSI marking and explanation of the main parameters

To distinguish electrodes of even the same brand from each other, they came up with additional markings that determine their purpose. For example, what could the marking e50a or simply e55 mean? Having a special table at hand, you can easily determine what is what and how these names differ.

So, the letter “e” means that this is an electrode designed for manual arc welding. The number 50 is the limit of strength of the connection obtained when used correctly. The letter "A" is used to represent a seam. She says that the seam will be plastic and can easily withstand high impact loads.

This is followed by the name of the SSNI electrodes themselves, after which additional markings are placed, for example, 13-55 or 13-85. After this, the diameter of the steel core is indicated. It is worth noting that it is indicated with an accuracy of tenths of a millimeter. That is, if it’s a 5, then it’s 5.0, if it’s a 4, it’s 4.0, and so on.

At the very end there is a letter “U”, which indicates that this type of electrode is used for welding carbon steels.

Additional markings

In addition, other designations may be used:

- T – welding can be performed with thermally resistant metals;

- B – welding of high-alloy steels is possible;

- N - this letter means that these electrodes can be used for surfacing the surface of the part (in case of restoration of its geometry or design dimensions);

- L - such electrodes can be used when welding alloy steels.

It turns out that an experienced welder, looking at a pack with markings, descriptions or a product certificate, can immediately understand what these electrodes are intended for. In addition, it will be clear how effective their use is in a particular job. It is recommended not to violate the technology in any way, then the welded elements will last for a long time without the need for repair or replacement.

Storage conditions and manufacturers

In order for products to retain their basic properties , they must be stored in appropriate premises.

The relative humidity in the warehouse should always be at 50%, and the temperature should not exceed 14 degrees, which is achieved by using air conditioners. If the conditions are met, then the shelf life has no limitation. The production of welding devices is carried out by such companies as LEZ, Spetselektrod, SZSM, Monolit. When purchasing, you must have a certificate of compliance with their standards. They are issued by the relevant authority.

Pros and cons of SSSI

The useful properties of these electrodes were described in detail in the previous paragraphs, so we will specifically focus on the disadvantages. In fact, there are almost none except that some types of SSSI cannot be used in top-down welding. Troubles can also arise due to moisture that is absorbed into the coating.

But, despite the fact that this is a very significant drawback that prevents the arc from burning correctly and the seam from laying evenly, it is very easy to deal with. This can be corrected by calcination. This is the process of heating the rods and coating in an oven at a certain temperature.

Advantages of welding electrodes UONI-13/55

- Fluorides and carbonates of the coating ensure easy ignition of the arc and its stable combustion.

- Thanks to these elements, the weld pool is reliably protected from nitrogen and oxygen. The electrodes are excellent for working in open space and field conditions.

- Metal losses due to spattering or burning out are partially compensated by iron powder, which is also present in the coating. Hence – lower (up to 15%) consumption of rods in comparison with many analogues.

- The metal of the resulting weld, as already mentioned, has excellent impact strength and ductility, and contains a minimum of hydrogen.

Features of SSSI calcination

- It is important to heat the oven to 250-280 degrees, and also to ensure uniform calcination of the electrodes. This is achieved using special containers.

- It is forbidden to keep the electrodes in the oven for more than 4 hours, or to calcinate them more than three times.

- After calcination, the electrodes should be used within 8 hours. After this time, the event should be repeated.

If everything is done correctly and clearly, without violating technology, the quality of the seams will be at the highest level. The welder will receive a stable arc without the electrode sticking to the surface of the parts being welded.

Storage

A high level of quality of seams depends not only on the electrodes themselves and the experience of the master in welding metal. The ability to store rods also plays an important role.

To store electrodes, it is necessary to equip a separate room in which the instrument can be kept for a long time. An important condition for such a room is dry air.

The temperature must be kept at a stable level. A more acceptable value is 15 degrees. For such conditions, an air conditioning system is usually used.

If you plan to store in a basement or garage, take care of waterproofing. Excess moisture can damage the electrodes. Such conditions can be difficult to create at home. How can you save on storage?

Reviews

Egor. While working at a metallurgical plant, I managed to stock up on many SSSI electrodes for various purposes, including MR ones. As they say, there is everything for all occasions. I don’t use it very often, but no matter how much time has passed, they still work and work without problems. Quality is QUALITY in Africa too!

Anatoly. I welded with electrodes at a SSSI in the north, worked in Magadan, even in severe frost you light an arc and everything burns normally. And the seam is plastic and even with rapid cooling it does not warp or break. In 10 years it will be a solid monolith, no cracks or chips, I guarantee it. Now I have an inverter welder, if I need to weld something, I use only SSSI.

Vladislav. It’s convenient that a pack of electrodes is 5 kg, so you don’t need to constantly print it out if you’re working. In short, don't get distracted. I got an internship as a welder and am now learning the skills. I practice, improve, learn to select the brand that is best suited. I have already mastered the bulk of electrodes - now I am studying with SSSI. True, at school they said that they were the hardest to cope with.